| Citation: |

Dongyi Wang, Lili Wang, Guozhen Shen. Nanofiber/nanowires-based flexible and stretchable sensors[J]. Journal of Semiconductors, 2020, 41(4): 041605. doi: 10.1088/1674-4926/41/4/041605

****

D Y Wang, L L Wang, G Z Shen, Nanofiber/nanowires-based flexible and stretchable sensors[J]. J. Semicond., 2020, 41(4): 041605. doi: 10.1088/1674-4926/41/4/041605.

|

Nanofiber/nanowires-based flexible and stretchable sensors

DOI: 10.1088/1674-4926/41/4/041605

More Information

-

Abstract

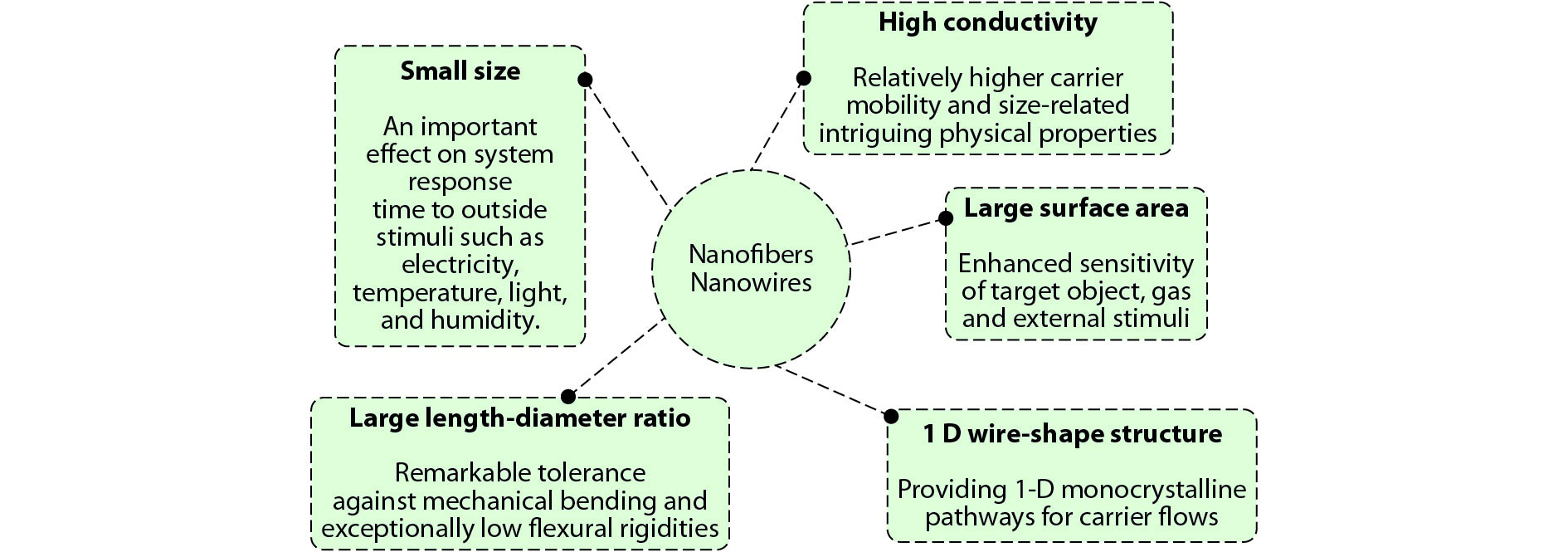

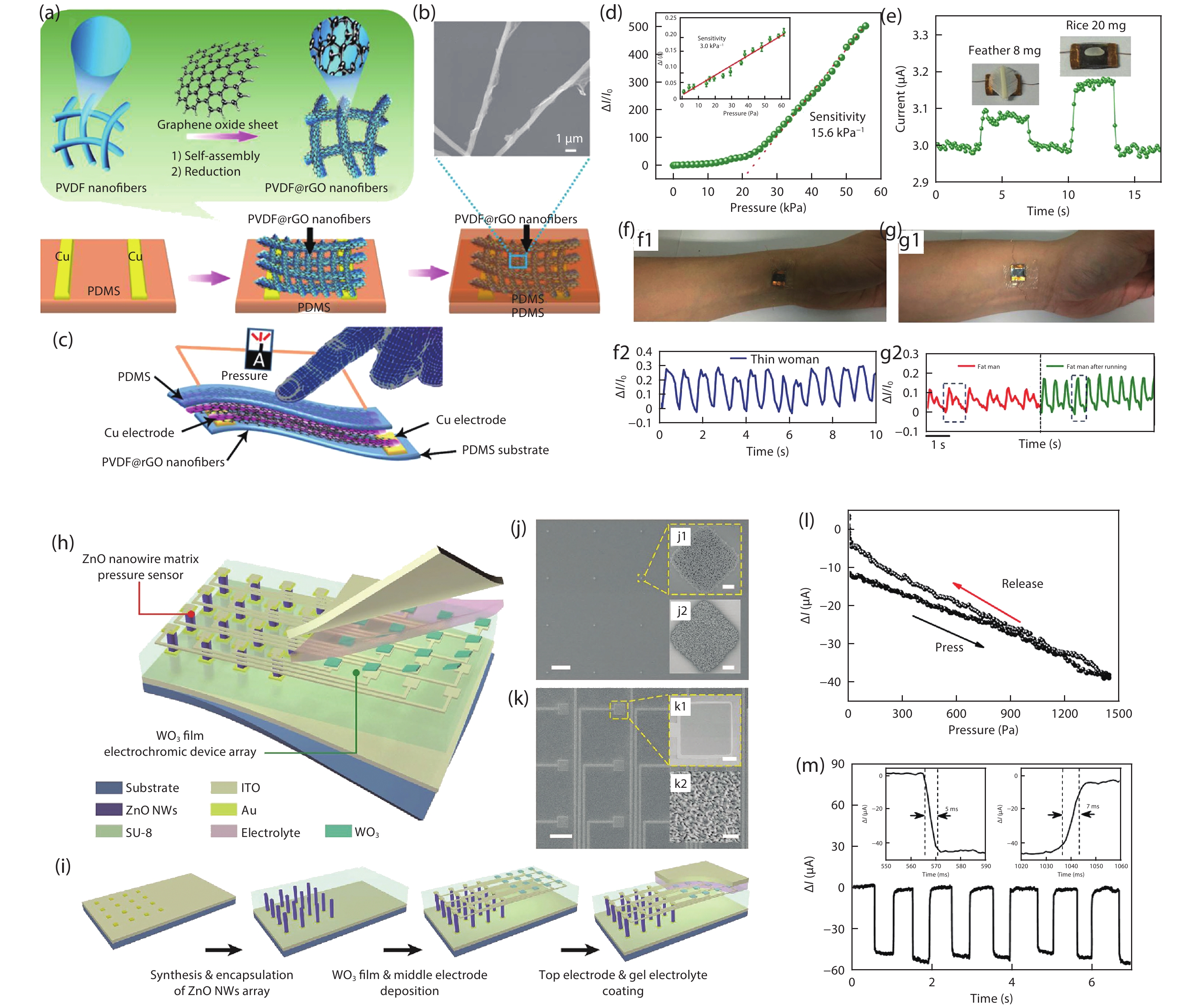

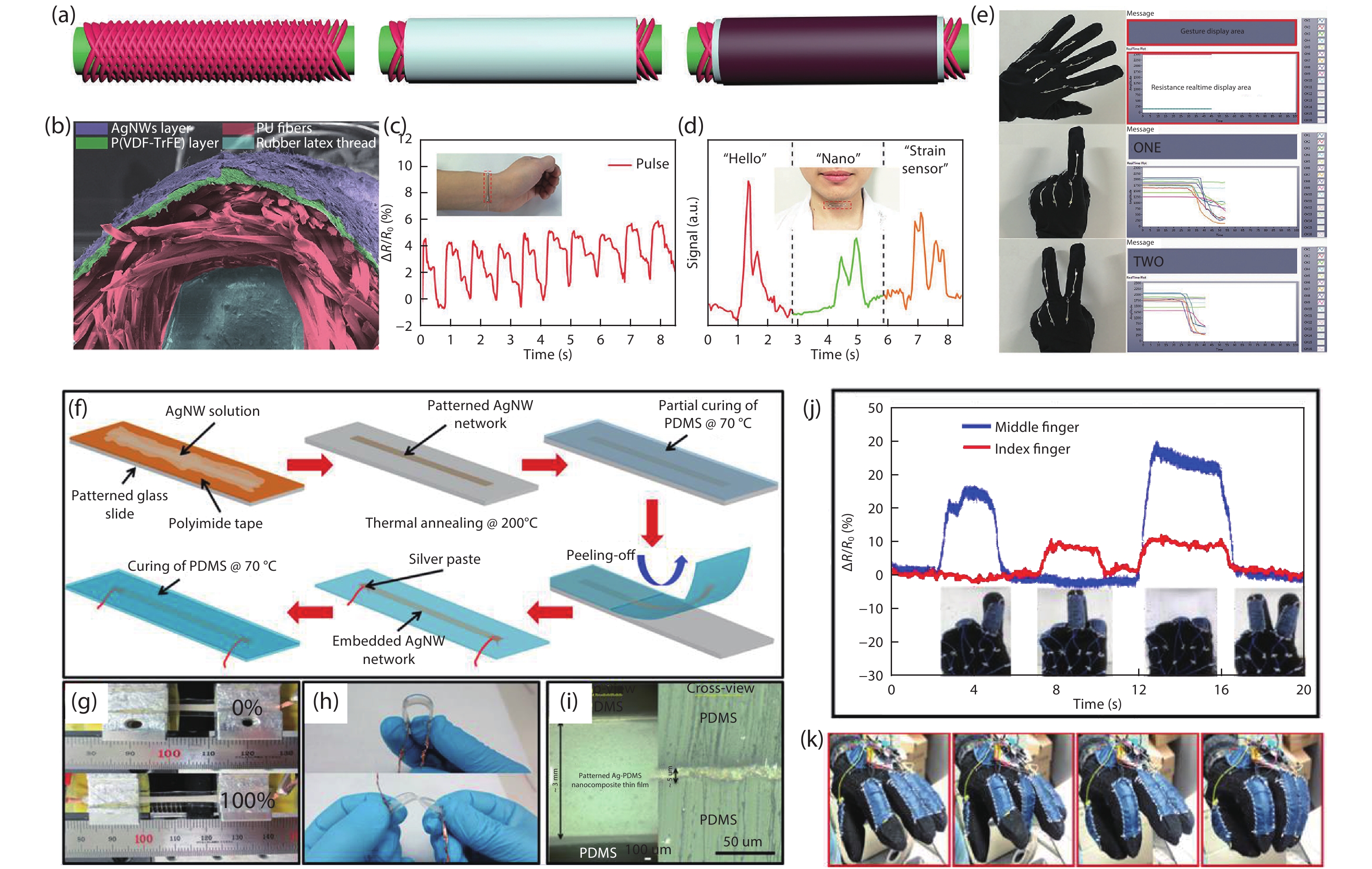

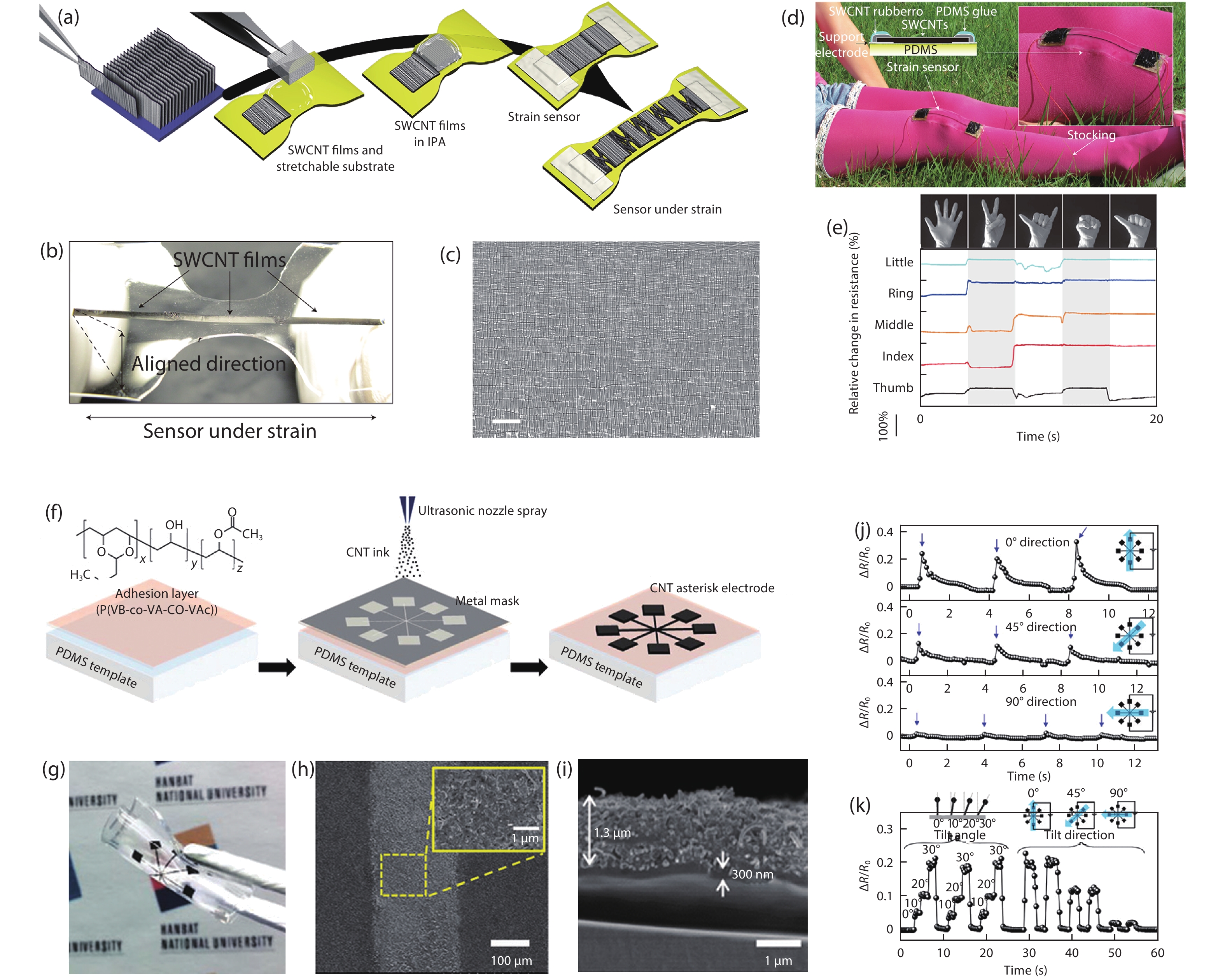

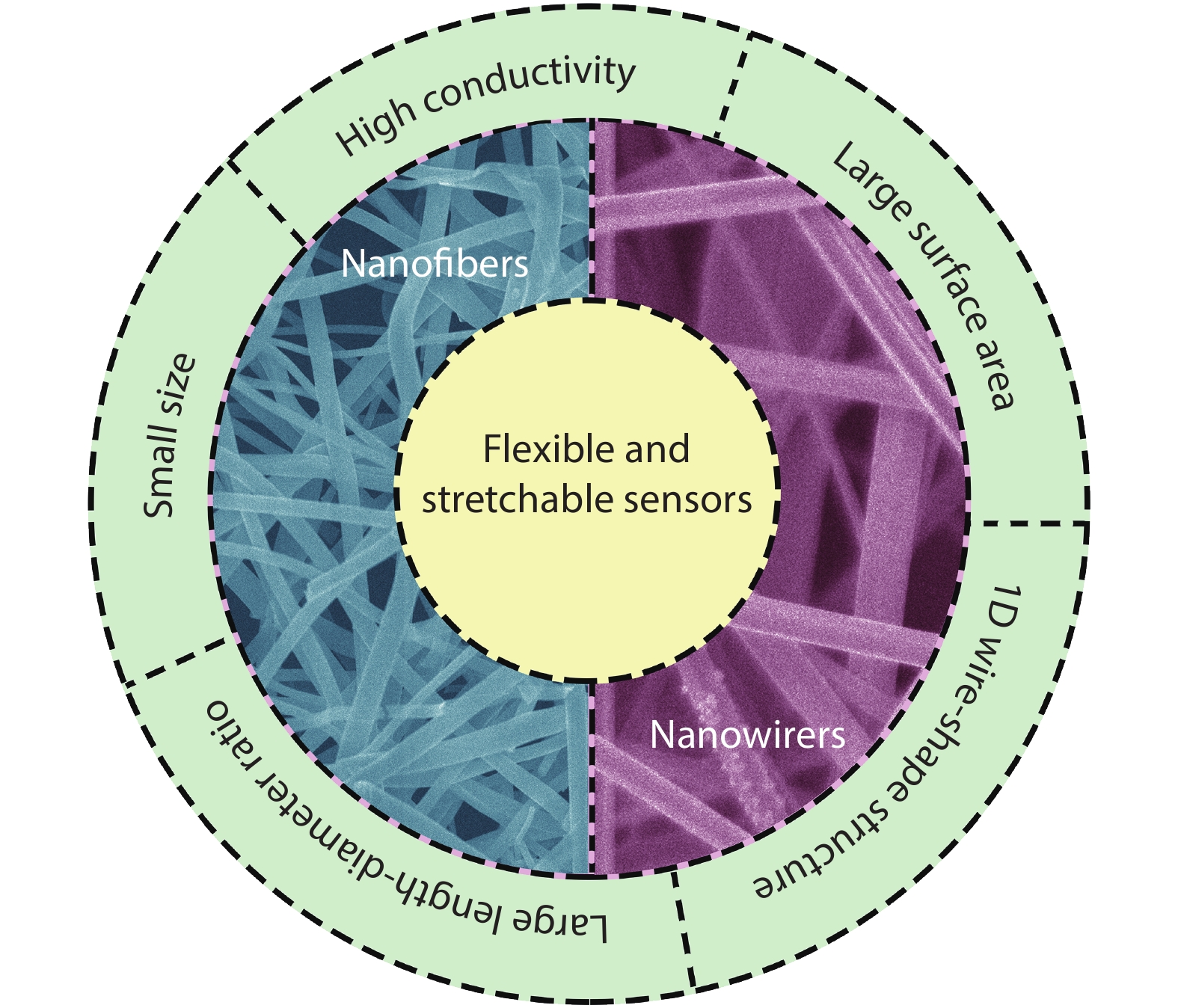

Nanofibers/nanowires with one-dimension (1D) nanostructure or well-patterned microstructure have shown distinctly advantages in flexible and stretchable sensor fields, owing to their remarkable tolerance against mechanical bending or stretching, outstanding electronic/optoelectronic properties, good transparency, and excellent geometry. Herein, latest summaries in the unique structure and properties of nanofiber/nanowire function materials and their applications for flexible and stretchable sensor are highlighted. Several types of high-performance nanofiber/nanowire-based flexible pressure and stretchable sensors are also reviewed. Finally, a conclusion and prospect for 1D nanofiber/nanowires-based flexible and stretchable sensors are also intensively discussed. This summary offers new insights for the development of flexible and stretchable sensor based 1D nanostructure in next-generation flexible electronics. -

References

[1] Wang L L, Chen D, Jiang K, et al. New insights and perspectives into biological materials for flexible electronics. Chem Soc Rev, 2017, 46, 6764 doi: 10.1039/C7CS00278E[2] Zhao L, Wang K, Wei W, et al. High-performance flexible sensing devices based on polyaniline/MXene nanocomposites. InfoMat, 2019, 1, 407 doi: 10.1002/inf2.12032[3] Wang K, Lou Z, Wang L, et al. Bioinspired interlocked structure-induced high deformability for two-dimensional titanium carbide (MXene)/natural microcapsule-based flexible pressure sensors. ACS Nano, 2019, 13, 9139 doi: 10.1021/acsnano.9b03454[4] Lou Z, Wang L, Jiang K, et al. Programmable three-dimensional advanced materials based on nanostructures as building blocks for flexible sensors. Nano Today, 2019, 26, 176 doi: 10.1016/j.nantod.2019.03.002[5] Bao Z N, Chen X D. Flexible and stretchable device. Adv Mater, 2016, 28, 4177 doi: 10.1002/adma.201601422[6] Ye D, Ding Y, Duan Y, et al. Large-scale direct-writing of aligned nanofibers for flexible electronics. Small, 2018, 14, 1703521 doi: 10.1002/smll.201703521[7] Jin J H, Lee D, Im H G, et al. Chitin nanofiber transparent paper for flexible green electronics. Adv Mater, 2016, 28, 5169 doi: 10.1002/adma.201600336[8] Wang K, Wei W, Lou Z, et al. 1D/2D heterostructure nanofiber flexible sensing device with efficient gas detectivity. Appl Surf Sci, 2019, 479, 209 doi: 10.1016/j.apsusc.2019.02.094[9] Wang K, Li J, Li W, et al. Highly active co-based catalyst in nanofiber matrix as advanced sensing layer for high selectivity of flexible sensing device. Adv Mater Technol, 2019, 4, 1800521 doi: 10.1002/admt.201800521[10] Wang L, Chen S, Li W, et al. Grain-boundary-induced drastic sensing performance enhancement of polycrystalline-microwire printed gas sensors. Adv Mater, 2019, 31, 1804583 doi: 10.1002/adma.201804583[11] Lou Z, Shen G Z. Flexible photodetectors based on 1D inorganic nanostructures. Adv Sci, 2016, 3, 1500287 doi: 10.1002/advs.201500287[12] Wang L, Deng J, Lou Z, et al. Cross-linked p-type Co3O4 octahedral nanoparticles in 1D n-type TiO2 nanofibers for high-performance sensing devices. J Mater Chem A, 2014, 2, 10022 doi: 10.1039/c4ta00651h[13] Li J, Wang L, Li L, et al. Metal sulfides@carbon microfiber networks for boosting lithium ion/sodium ion storage via a general metal–aspergillus niger bioleaching strategy. ACS Appl Mater Interfaces, 2019, 11, 8072 doi: 10.1021/acsami.8b21976[14] Zhuang X J, Ning C Z, Pan A. Composition and bandgap-graded semiconductor alloy nanowires. Adv Mater, 2012, 24, 13 doi: 10.1002/adma.201103191[15] Menzel A, Subannajui K, Güder F. Multifunctional ZnO-nanowire-based sensor. Adv Funct Mater, 2011, 21, 4342 doi: 10.1002/adfm.201101549[16] Wen B M, Sader J E, Boland J J, et al. Mechanical properties of ZnO nanowires. Phys Rev Lett, 2008, 101, 175502 doi: 10.1103/PhysRevLett.101.175502[17] Liu Z, Xu J, Chen D, et al. Flexible electronics based on inorganic nanowires. Chem Soc Rev, 2015, 44, 161 doi: 10.1039/C4CS00116H[18] Chowdhury S A, Saha M C, Patterson S, et al. Highly conductive polydimethylsiloxane/carbon nanofiber composites for flexible sensor applications. Adv Mater Technol, 2019, 4, 1800398 doi: 10.1002/admt.201800398[19] Nan N, He J, You X, et al. A stretchable, highly sensitive, and multimodal mechanical fabric sensor based on electrospun conductive nanofiber yarn for wearable electronics. Adv Mater Technol, 2019, 4, 1800338 doi: 10.1002/admt.201800338[20] Chen L F, Feng Y, Liang H W, et al. Macroscopic-scale three-dimensional carbon nanofiber architectures for electrochemical energy storage devices. Adv Energy Mater, 2017, 7, 1700826 doi: 10.1002/aenm.201700826[21] Choi S J, Persano L, Camposeo A, et al. Electrospun nanostructures for high performance chemiresistive and optical sensors. Macromol Mater Eng, 2017, 302, 1600569 doi: 10.1002/mame.201600569[22] Rasouli R, Barhoum A, Bechelany M. Nanofibers for biomedical and healthcare applications. Macromol Biosci, 2019, 19, 1800256 doi: 10.1002/mabi.201800256[23] Camposeo A, Persano L, Pisignano D, et al. Light-emitting electrospun nanofibers for nanophotonics and optoelectronics. Macromol Mater Eng, 2013, 298, 487 doi: 10.1002/mame.201200277[24] Nguyen L T H, Chen S, Elumalai N K, et al. Biological, chemical, and electronic applications of nanofibers. Macromol Mater Eng, 2013, 298, 822 doi: 10.1002/mame.201200143[25] Wang J, Lu C, Zhang K. Textile-based strain sensor for human motion detection. Energy Environ Mater, 2019, 0, 1 doi: 10.1002/eem2.12041[26] Sill T J, Recum H A. Electrospinning: applications in drug delivery and tissue engineering. Biomaterials, 2008, 29, 1989 doi: 10.1016/j.biomaterials.2008.01.011[27] Zhang Y, Yuan S, Feng X, et al. Preparation of nanofibrous metal–organic framework filters for efficient air pollution control. J Am Chem Soc, 2016, 138, 5785 doi: 10.1021/jacs.6b02553[28] Shuai X T, Zhu P L, Zeng W J, et al. Highly sensitive flexible pressure sensor based on silver nanowires-embedded polydimethylsiloxane electrode with microarray structure. ACS Appl Mater Interfaces, 2017, 9, 26314 doi: 10.1021/acsami.7b05753[29] Wan L Y. Nanofibers for smart textiles. Wiley, 2018[30] Ko F K, Kuznetsov V, Flahaut E. Formation of nanofibers and nanotubes production. Nanoeng Nanofibrous Mater, 2004 doi: 10.1007/978-1-4020-2550-1_1[31] Nabet B. When is small good? on unusual electronic properties of nanowires ECE Department, Philadelphia, 2002, 19104[32] El-Aufy A, Nabet B, Ko F. Carbon nanotube reinforced (PEDT/PAN) nanocomposite for wearable electronics. Polym Prepr, 2003, 44, 134[33] Wang L, Wang K, Lou Z, et al. Plant-based modular building blocks for “green” electronic skins. Adv Funct Mater, 2018, 28, 1804510 doi: 10.1002/adfm.201804510[34] Wang L, Jackman J A, Ng W B, et al. Flexible, graphene-coated biocomposite for highly sensitive, real-time molecular detection. Adv Funct Mater, 2016, 26, 8623 doi: 10.1002/adfm.201603550[35] Wang L, Jackman J A, Park J H, et al. A flexible, ultra-sensitive chemical sensor with 3D biomimetic templating for diabetes-related acetone detection. J Mater Chem B, 2017, 5, 4019 doi: 10.1039/C7TB00787F[36] Ren G Y, Cai F Y, Li B Z, et al. Flexible pressure sensor based on a poly(VDF-TrFE) nanofiber web. Macromol Mater Eng, 2013, 298, 541 doi: 10.1002/mame.201200218[37] Lee J H, Kim J, Liu D, et al. Highly aligned, anisotropic carbon nanofiber films for multidirectional strain sensors with exceptional selectivity. Adv Funct Mater, 2019, 29, 1901623 doi: 10.1002/adfm.201901623[38] Wang Q, Jian M Q, Wang C Y, et al. Carbonized silk nanofiber membrane for transparent and sensitive electronic skin. Adv Funct Mater, 2017, 27, 1605657 doi: 10.1002/adfm.201605657[39] Zhao G R, Huang B S, Zhang J X, et at. Electrospun poly(l-lactic acid) nanofibers for nanogenerator and diagnostic sensor applications. Macromol Mater Eng, 2017, 302, 1600476 doi: 10.1002/mame.201600476[40] Gao Q, Meguro H, Okamoto S, et al. Flexible tactile sensor using the reversible deformation of poly(3-hexylthiophene) nanofiber assemblies. Langmuir, 2012, 28, 17593 doi: 10.1021/la304240r[41] Wang J, Suzuki R, Shao M, et al. Capacitive pressure sensor with wide-range, bendable, and high sensitivity based on the bionic komochi konbu structure and Cu/Ni nanofiber network. ACS Appl Mater Interfaces, 2019, 11, 11928 doi: 10.1021/acsami.9b00941[42] Roy K, Ghosh S K, Sultana A, et al. A self-powered wearable pressure sensor and pyroelectric breathing sensor based on GO interfaced PVDF nanofibers. ACS Appl Nano Mater, 2019, 2, 2013 doi: 10.1021/acsanm.9b00033[43] Zhao G R, Zhang X D, Cui X, et al. Piezoelectric polyacrylonitrile nanofiber film-based dual-function self-powered flexible sensor. ACS Appl Mater Interfaces, 2018, 10, 15855 doi: 10.1021/acsami.8b02564[44] Qi K, He J X, Wang H B, et al. A highly stretchable nanofiber-based electronic skin with pressure-, strain-, and flexion-sensitive properties for health and motion monitoring. ACS Appl Mater Interfaces, 2017, 9, 42951 doi: 10.1021/acsami.7b07935[45] Lou M, Abdalla I, Zhu M M, et al. Hierarchically rough structured and self-powered pressure sensor textile for motion sensing and pulse monitoring. ACS Appl Mater Interfaces, 2020, 12, 1597 doi: 10.1021/acsami.9b19238[46] Wu S Y, Zhang J, Ladani R B, et al. Novel electrically conductive porous PDMS/Carbon nanofiber composites for deformable strain sensors and conductors. ACS Appl Mater Interfaces, 2017, 9, 14207 doi: 10.1021/acsami.7b00847[47] Garain S, Jana S, Kumar T, et al. Design of in situ poled Ce3+-doped electrospun PVDF/graphene composite nanofibers for fabrication of nanopressure sensor and ultrasensitive acoustic nanogenerator. ACS Appl Mater Interfaces, 2016, 8, 4532 doi: 10.1021/acsami.5b11356[48] Deng W L, Yang T, Jing L, et al. Cowpea-structured PVDF/ZnO nanofibers based flexible self-powered piezoelectric bending motion sensor towards remote control of gestures. Nano Energy, 2019, 55, 516 doi: 10.1016/j.nanoen.2018.10.049[49] Gao J F, Li B, Huang X W, et al. Electrically conductive and fluorine free superhydrophobic strain sensors based on SiO2/graphene-decorated electrospun nanofibers for human motion monitoring. Chem Eng J, 2019, 373, 298 doi: 10.1016/j.cej.2019.05.045[50] Yan T, Wang Z, Wang Y Q, et al. Carbon/graphene composite nanofiber yarns for highly sensitive strain sensors. Mater Des, 2018, 143, 214 doi: 10.1016/j.matdes.2018.02.006[51] Lin M F, Xiong J Q, Wang J X, et al. Core-shell nanofiber mats for tactile pressure sensor and nanogenerator applications. Nano Energy, 2018, 44, 248 doi: 10.1016/j.nanoen.2017.12.004[52] Jiang D W, Wang Y, Li B, et al. Flexible sandwich structural strain sensor based on silver nanowires decorated with self-healing substrate. Macromol Mater Eng, 2019, 304, 1900074 doi: 10.1002/mame.201900074[53] Kang M, Park J H, Lee K I, et al. Fully flexible and transparent piezoelectric touch sensors based on ZnO nanowires and BaTiO3-added SiO2 capping layers. Phys Status Solidi A, 2015, 212, 2005 doi: 10.1002/pssa.201431829[54] Wang Y, Zhu L P, Du C F. Flexible difunctional (pressure and light) sensors based on ZnO nanowires/graphene heterostructures. Adv Mater Interfaces, 2000, 7, 1901932 doi: 10.1002/admi.201901932[55] Lee T, Lee W, Kim S W, et al. Flexible textile strain wireless sensor functionalized with hybrid carbon nanomaterials supported ZnO nanowires with controlled aspect ratio. Adv Funct Mater, 2016, 26, 6206 doi: 10.1002/adfm.201601237[56] Shi X Q, Peng M Z, Kou J Z, et al. A flexible GaN nanowire array-based schottky-type visible light sensor with strain-enhanced photoresponsivity. Adv Electron Mater, 2015, 1, 1500169 doi: 10.1002/aelm.201500169[57] Kim Y, Kim J W. Silver nanowire networks embedded in urethane acrylate for flexible capacitive touch sensor. Appl Surf Sci, 2016, 363, 1 doi: 10.1016/j.apsusc.2015.11.052[58] Peng Y Y, Que M L, Lee H E, et al. Achieving high-resolution pressure mapping via flexible GaN/ZnO nanowire LEDs array by piezo-phototronic effect. Nano Energy, 2019, 58, 633 doi: 10.1016/j.nanoen.2019.01.076[59] Xu X J, Wang R R, Nie P, et al. Copper nanowire-based aerogel with tunable pore structure and its application as flexible pressure sensor. ACS Appl Mater Interfaces, 2017, 9, 14273 doi: 10.1021/acsami.7b02087[60] Amjadi M, Pichitpajongkit A, Lee S, et al. Highly stretchable and sensitive strain sensor based on silver nanowire–elastomer nanocomposite. ACS Nano, 2014, 8, 5154 doi: 10.1021/nn501204t[61] Lou C, Liu N S, Zhang H, et al. A new approach for ultrahigh-performance piezoresistive sensor based on wrinkled PPy film with electrospun PVA nanowires as spacer. Nano Energy, 2017, 41, 527 doi: 10.1016/j.nanoen.2017.10.007[62] Xu S Y, Yeh Y W, Poirier G. Flexible piezoelectric PMN–PT nanowire-based nanocomposite and device. Nano Lett, 2013, 13, 2393 doi: 10.1021/nl400169t[63] Wang L, Jackman J A, Tan E L, et al. High-performance, flexible electronic skin sensor incorporating natural microcapsule actuators. Nano Energy, 2017, 36, 38 doi: 10.1016/j.nanoen.2017.04.015[64] Lou Z, Chen S, Wang L. Ultrasensitive and ultraflexible e-skins with dual functionalities for wearable electronics. Nano Energy, 2017, 38, 28 doi: 10.1016/j.nanoen.2017.05.024[65] Tao L Q, Zhang K N, Tian H, et al. Graphene-paper pressure sensor for detecting human motions. ACS Nano, 2017, 11, 8790 doi: 10.1021/acsnano.7b02826[66] Ren Y, Zou Y D, Liu Y, et al. Synthesis of orthogonally assembled 3D cross-stacked metal oxide semiconducting nanowires. Nat Mater, 2020, 19, 203 doi: 10.1038/s41563-019-0542-x[67] Wang L, Luo X, Zheng X, et al. Direct annealing of electrospun synthesized high-performance porous SnO2 hollow nanofibers for gas sensors. RSC Adv, 2013, 3, 9723 doi: 10.1039/c3ra41032c[68] Lou Z, Wang L, Wang R, et al. Synthesis and ethanol sensing properties of SnO2 nanosheets via a simple hydrothermal route. Solid-State Electron, 2012, 76, 91 doi: 10.1016/j.sse.2012.05.062[69] Han S J, Liu C R, Xu H H, et al. Multiscale nanowire-microfluidic hybrid strain sensors with high sensitivity and stretchability. npj Flex Electron, 2018, 2, 16 doi: 10.1038/s41528-018-0029-x[70] Gong S, Schwalb W, Wang Y, et al. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat Commun, 2014, 5, 3132 doi: 10.1038/ncomms4132[71] Zhu B, Ling Y, Yap L W, et al. Hierarchically structured vertical gold nanowire array-based wearable pressure sensors for wireless health monitoring. ACS Appl Mater Interfaces, 2019, 11, 29014 doi: 10.1021/acsami.9b06260[72] Lou Z, Chen S, Wang L, et al. An ultra-sensitive and rapid response speed graphene pressure sensors for electronic skin and health monitoring. Nano Energy, 2016, 23, 7 doi: 10.1016/j.nanoen.2016.02.053[73] Wang G, Liu T, Sun X C, et al. Flexible pressure sensor based on PVDF nanofiber. Sens Actuators A, 2018, 280, 319 doi: 10.1016/j.sna.2018.07.057[74] Han X, Du W, Chen M, et al. Visualization recording and storage of pressure distribution through a smart matrix based on the piezotronic effect. Adv Mater, 2017, 29, 1701253 doi: 10.1002/adma.201701253[75] Chen Z, Wang Z, Li X, et al. Flexible piezoelectric-induced pressure sensors for static measurements based on nanowires/graphene heterostructures. ACS Nano, 2017, 11, 4507 doi: 10.1021/acsnano.6b08027[76] Li Y Q, Samad Y, Taha T, et al. Highly flexible strain sensor from tissue paper for wearable electronics. ACS Sustain Chem Eng, 2016, 4, 4288 doi: 10.1021/acssuschemeng.6b00783[77] Oh J, Yang J C, Kim J O, et al. Pressure insensitive strain sensor with facile solution-based process for tactile sensing applications. ACS Nano, 2018, 12, 8, 7546 doi: 10.1021/acsnano.8b03488[78] Zhang J, Liu J, Zhuang R, et al. Single MWNT-glass fiber as strain sensor and switch. Adv Mater, 2011, 23, 3392 doi: 10.1002/adma.201101104[79] Peng Y, Lu J, Peng D, et al. Dynamically modulated GaN whispering gallery lasing mode for strain sensor. Adv Funct Mater, 2019, 29, 1905051 doi: 10.1002/adfm.201905051[80] Zhou W, Li Y, Li P, et al. Metal mesh as a transparent omnidirectional strain sensor. Adv Mater Technol, 2019, 4, 1800698 doi: 10.1002/admt.201800698[81] Ren J, Zhang W, Wang Y, et al. A graphene rheostat for highly durable and stretchable strain sensor. InfoMat, 2019, 1, 396 doi: 10.1002/inf2.12030[82] Chen S, Song Y, Ding D, et al. Flexible and anisotropic strain sensor based on carbonized crepe paper with aligned cellulose fibers. Adv Funct Mater, 2018, 28, 1802547 doi: 10.1002/adfm.201802547[83] Lee B M, Oh J Y, Cho H, et al. Ultraflexible and transparent electroluminescent skin for real-time and super-resolution imaging of pressure distribution. Nat Commun, 2020, 11, 663 doi: 10.1038/s41467-020-14485-9[84] Sun Q J, Seung W, Kim B J, et al. Active matrix electronic skin strain sensor based on piezopotential-powered graphene transistors. Adv Mater, 2015, 27, 3411 doi: 10.1002/adma.201500582[85] Chen S, Lou Z, Chen D, et al. Polymer-enhanced highly stretchable conductive fiber strain sensor used for electronic data gloves. Adv Mater Technol, 2016, 1600136 doi: 10.1002/admt.201600136[86] Roh E, Hwang B U, Kim D, et al. Stretchable, transparent, ultrasensitive, and patchable strain sensor for human–machine interfaces comprising a nanohybrid of carbon nanotubes and conductive elastomers. ACS Nano, 2015, 9, 6252 doi: 10.1021/acsnano.5b01613[87] Yamada T, Hayamizu Y, Yamamoto Y, et al. A stretchable carbon nanotube strain sensor for human-motion detection. Nat Nanotechnol, 2011, 6, 296 doi: 10.1038/nnano.2011.36[88] Choi G, Jang H, Oh S, et al. A highly sensitive and stress-direction-recognizing asterisk-shaped carbon nanotube strain sensor. J Mater Chem C, 2019, 7, 9504 doi: 10.1039/C9TC02486G -

Proportional views

DownLoad:

DownLoad: