| Citation: |

Zhou Wang, Xinyi Shan, Xugao Cui, Pengfei Tian. Characteristics and techniques of GaN-based micro-LEDs for application in next-generation display[J]. Journal of Semiconductors, 2020, 41(4): 041606. doi: 10.1088/1674-4926/41/4/041606

****

Z Wang, X Y Shan, X G Cui, P F Tian, Characteristics and techniques of GaN-based micro-LEDs for application in next-generation display[J]. J. Semicond., 2020, 41(4): 041606. doi: 10.1088/1674-4926/41/4/041606.

|

Characteristics and techniques of GaN-based micro-LEDs for application in next-generation display

DOI: 10.1088/1674-4926/41/4/041606

More Information

-

Abstract

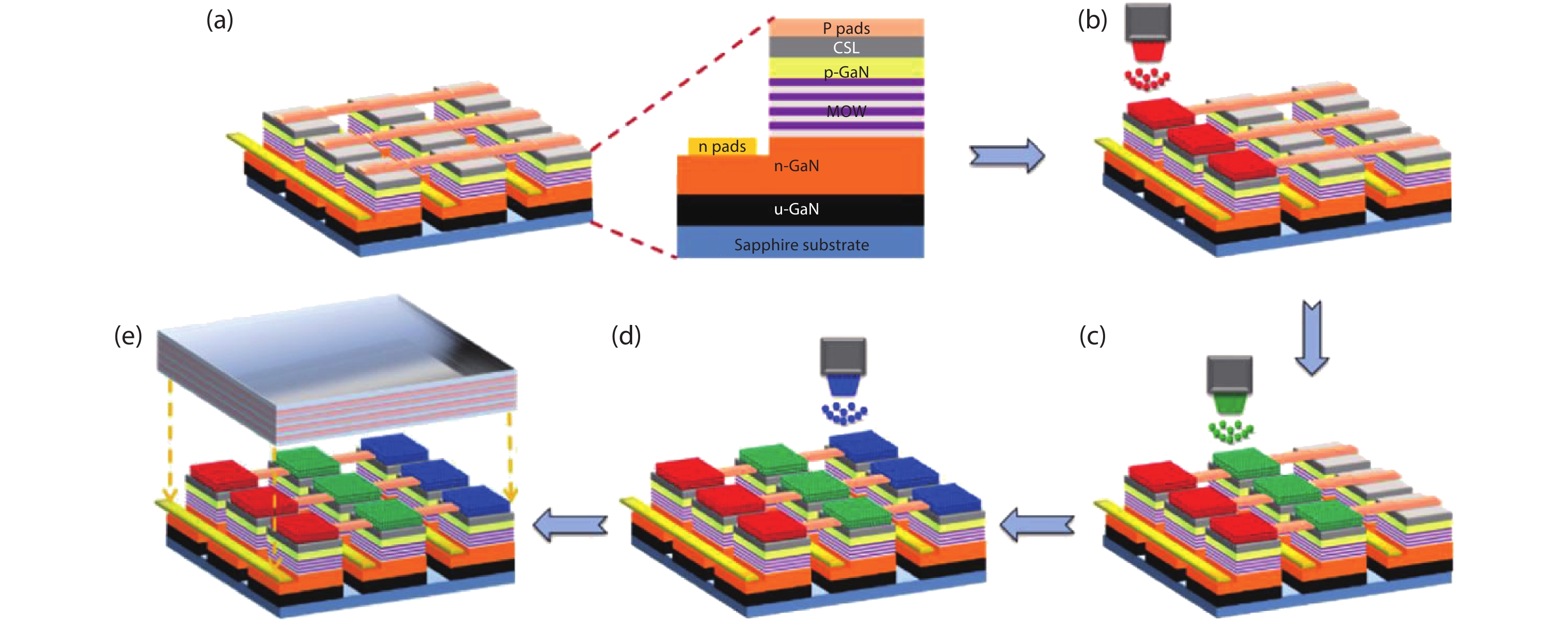

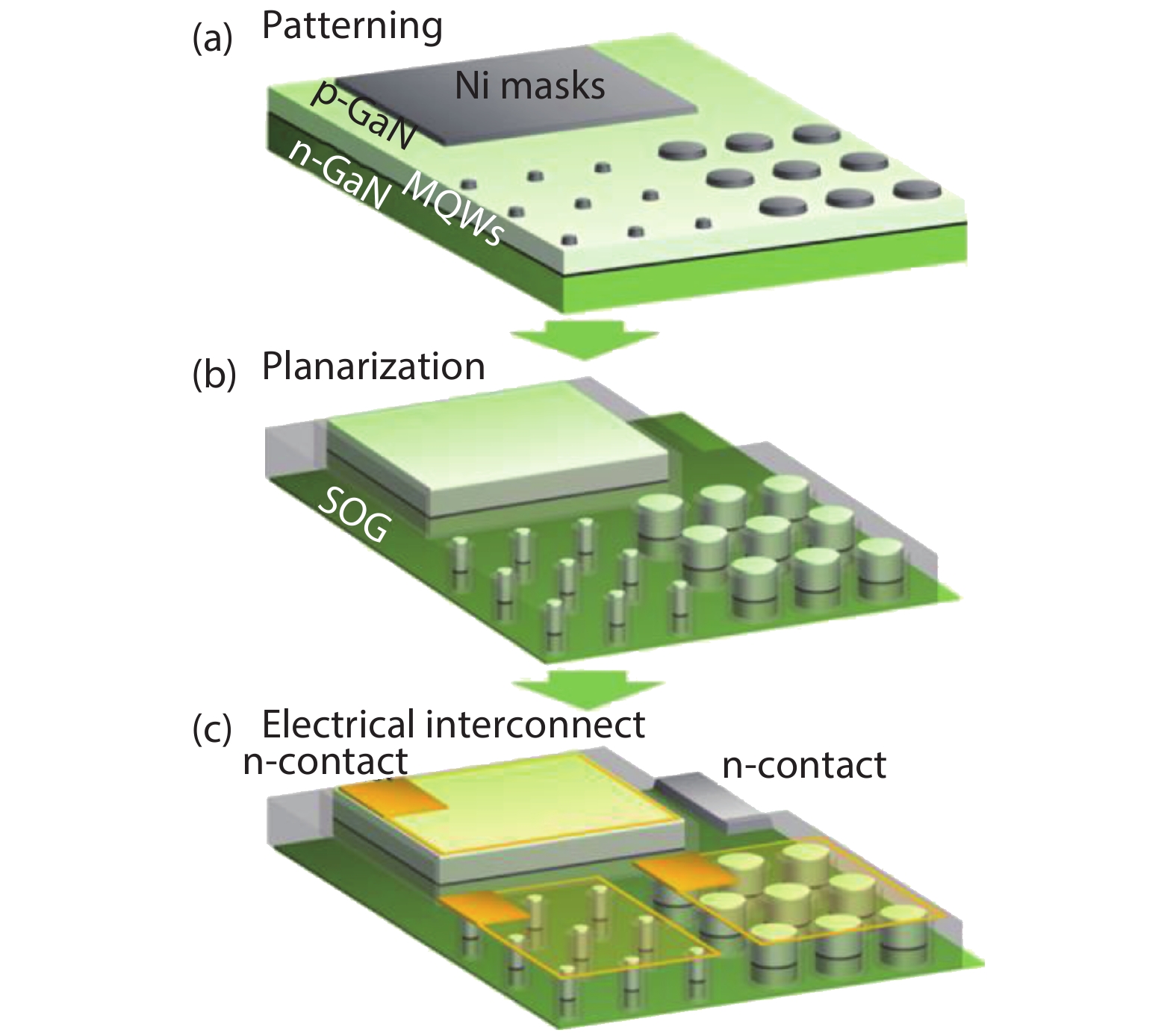

Due to the excellent optoelectronic properties, fast response time, outstanding power efficiency and high stability, micro-LED plays an increasingly important role in the new generation of display technology compared with LCD and OLED display. This paper mainly introduces the preparation methods of the GaN-based micro-LED array, the optoelectronic characteristics, and several key technologies to achieve full-color display, such as transfer printing, color conversion by quantum dot and local strain engineering.-

Keywords:

- micro-LED,

- GaN,

- full-color display,

- transfer printing,

- color conversion

-

References

[1] Lee H E, Shin J H, Park J H, et al. Micro light-emitting diodes for display and flexible biomedical applications. Adv Funct Mater, 2019, 29, 1808075 doi: 10.1002/adfm.201808075[2] Lee H E, Choi J, Lee S H, et al. Monolithic flexible vertical GaN light-emitting diodes for a transparent wireless brain optical stimulator. Adv Mater, 2018, 30, 1800649 doi: 10.1002/adma.201800649[3] Yang P, Zhang L, Kang D J, et al. High-resolution inkjet printing of quantum dot light-emitting microdiode arrays. Adv Opt Mater, 2019, 8, 1901429 doi: 10.1002/adom.201901429[4] Yang W, Zhang S, McKendry J J D, et al. Size-dependent capacitance study on InGaN-based micro-light-emitting diodes. J Appl Phys, 2014, 116, 044512 doi: 10.1063/1.4891233[5] Tian P, McKendry J J D, Gong Z, et al. Characteristics and applications of micro-pixelated GaN-based light emitting diodes on Si substrates. J Appl Phys, 2014, 115, 033112 doi: 10.1063/1.4862298[6] Li Y, Wu Q, Meng F Y, et al. Enhanced performance of large-area vertical light-emitting diodes treated by laser irradiation. Micro Nano Lett, 2017, 12, 369 doi: 10.1049/mnl.2016.0699[7] Chen X, Kong F, Li K, et al. Study of light extraction efficiency of flip-chip GaN-based LEDs with different periodic arrays. Opt Commun, 2014, 314, 90 doi: 10.1016/j.optcom.2013.09.006[8] Yao Y C, Hwang J M, Yang Z P, et al. Enhanced external quantum efficiency in GaN-based vertical-type light-emitting diodes by localized surface plasmons. Sci Rep, 2016, 6, 22659 doi: 10.1038/srep22659[9] Liu Z, Chong W C, Wong K M, et al. GaN-based LED micro-displays for wearable applications. Microelectron Eng, 2015, 148, 98 doi: 10.1016/j.mee.2015.09.007[10] Lin C C, Fang Y H, Kao M J, et al. Ultra-fine pitch thin-film micro LED display for indoor applications. SID Symp Dig Tech Pap, 2018, 49, 782 doi: 10.1002/sdtp.12373[11] Yoon J K, Park E M, Son J S, et al. The study of picture quality of OLED TV with WRGB OLEDs structure. SID Symp Dig Tech Pap, 2013, 44, 326 doi: 10.1002/j.2168-0159.2013.tb06212.x[12] Katsui S, Kobayashi H, Nakagawa T, et al. 5291-PPI organic light-emitting diode display using field-effect transistors including a c-axis aligned crystalline oxide semiconductor. SID Symp Dig Tech Pap, 2019, 50, 311 doi: 10.1002/sdtp.12918[13] Liu Z, Zhang K, Liu Y, et al. Fully multi-functional GaN-based micro-LEDs for 2500 PPI micro-displays, temperature sensing, light energy harvesting, and light detection. 64th IEEE Annual International Electron Devices Meeting, 2018, 871[14] JBD exhibits 2000000 nit and 10000 PPI micro-LED displays [EB/OL]. https://www.toutiao.com/i6705923322162446856/[15] Santos J M M, Jones B E, Schlosser P J, et al. Hybrid GaN LED with capillary-bonded II–VI MQW color-converting membrane for visible light communications. Semicond Sci Tech, 2015, 30, 035012 doi: 10.1088/0268-1242/30/3/035012[16] Hori A, Yasunaga D, Satake A, et al. Temperature and injection current dependence of electroluminescence intensity in green and blue InGaN single-quantum-well light-emitting diodes. J Appl Phys, 2003, 93, 3152 doi: 10.1063/1.1554475[17] Chong W C, Cho W K, Liu Z J, et al. 1700 pixels per inch (PPI) passive-matrix micro-LED display powered by ASIC. 2014 IEEE Compound Semiconductor Integrated Circuit Symposium (CSICS), 2014, 978-1-4799-3622-9[18] Fei M Q, Fei Y. The wide view-angle technique of TFT-LCD. Adv Display, 2008, 11, 22[19] Trindade A J, Guilhabert B, Xie E Y, et al. Heterogeneous integration of gallium nitride light-emitting diodes on diamond and silica by transfer printing. Opt Express, 2015, 23, 9329 doi: 10.1364/OE.23.009329[20] Han H V, Lin H Y, Lin C C, et al. Resonant-enhanced full-color emission of quantum-dot-based micro LED display technology. Opt Express, 2015, 23, 32504 doi: 10.1364/OE.23.032504[21] Chung K, Sui J, Demory B, et al. Color mixing from monolithically integrated InGaN-based light-emitting diodes by local strain engineering. Appl Phys Lett, 2017, 111, 041101 doi: 10.1063/1.4995561[22] Jiang F, Zhang J, Xu L, et al. Efficient InGaN-based yellow-light-emitting diodes. Photonics Res, 2019, 7, 144 doi: 10.1364/PRJ.7.000144[23] Tian P, McKendry J J, Gu E, et al. Fabrication, characterization and applications of flexible vertical InGaN micro-light emitting diode arrays. Opt Express, 2016, 24, 699 doi: 10.1364/OE.24.000699[24] Tian P, Althumali A, Gu E, et al. Aging characteristics of blue InGaN micro-light emitting diodes at an extremely high current density of 3.5 kA cm−2. Semicond Sci Tech, 2016, 31, 045005 doi: 10.1088/0268-1242/31/4/045005[25] Tian P, McKendry J J D, Herrnsdorf J, et al. Temperature-dependent efficiency droop of blue InGaN micro-light emitting diodes. Appl Phys Lett, 2014, 105, 171107 doi: 10.1063/1.4900865[26] Gong Z, Jin S, Chen Y, et al. Size-dependent light output, spectral shift, and self-heating of 400 nm InGaN light-emitting diodes. J Appl Phys, 2010, 107, 013103 doi: 10.1063/1.3276156[27] Zhang K, Peng D, Lau K M, et al. Fully-integrated active matrix programmable UV and blue micro-LED display system-on-panel (SoP). J Soc Inf Display, 2017, 25, 240 doi: 10.1002/jsid.550[28] Herrnsdorf J, McKendry J J D, Zhang S, et al. Active-matrix GaN micro light-emitting diode display with unprecedented brightness. IEEE T Electron Dev, 2015, 62, 1918 doi: 10.1109/TED.2015.2416915[29] Tull B R, Twu N, Hsu Y J, et al. Micro-LED microdisplays by integration of III–V LEDs with silicon thin film transistors. SID Symp Dig Tech Pap, 2017, 48, 246 doi: 10.1002/sdtp.11680[30] Cao J, Liu X, Khan M A, et al. RGB tricolor produced by white-based top-emitting organic light-emitting diodes with microcavity structure. Curr Appl Phys, 2007, 7, 300 doi: 10.1016/j.cap.2006.09.002[31] Sato Y, Takahashi N, Sato S. Full-color fluorescent display devices using a near-UV light-emitting diode. Jpn J Appl Phys, 1996, 35, L838 doi: 10.1143/JJAP.35.L838[32] Kim B H, Nam S, Oh N, et al. Multilayer transfer printing for pixelated, multi-color quantum dot light-emitting diodes. ACS Nano, 2016, 10, 4920 doi: 10.1021/acsnano.5b06387[33] Lin H Y, Sher C W, Hsieh D H, et al. Optical cross-talk reduction in a quantum-dot-based full-color micro-light-emitting-diode display by a lithographic-fabricated photoresist mold. Photonics Res, 2017, 5, 411 doi: 10.1364/PRJ.5.000411[34] Liu Z, Chong W C, Wong K M, et al. A novel BLU-free full-color LED projector using LED on silicon micro-displays. IEEE Photonic Tech Lett, 2013, 25, 2267 doi: 10.1109/LPT.2013.2285229[35] Display technology of micro-LED has the most potential application in AR/VR display device [EB/OL]. http://www.51touch.com/lcd/news/dynamic/2017/1031/48607.html[36] Color conversion is a feasible way for micro LED display technology to achieve mass production [EB/OL]. http://www.yejibang.com/news-details-23615.html -

Proportional views

DownLoad:

DownLoad: