| Citation: |

V. V. Kaminskii, N. V. Sharenkova, G. A. Kamenskaya, M. A. Grevtsev, Yu. V. Lyubimova. Anomalies in Young's modulus behavior after annealing in polycrystalline SmS[J]. Journal of Semiconductors, 2021, 42(3): 032101. doi: 10.1088/1674-4926/42/3/032101

****

V V Kaminskii, N V Sharenkova, G A Kamenskaya, M A Grevtsev, Y V Lyubimova, Anomalies in Young\'s modulus behavior after annealing in polycrystalline SmS[J]. J. Semicond., 2021, 42(3): 032101. doi: 10.1088/1674-4926/42/3/032101.

|

Anomalies in Young's modulus behavior after annealing in polycrystalline SmS

DOI: 10.1088/1674-4926/42/3/032101

More Information

-

Abstract

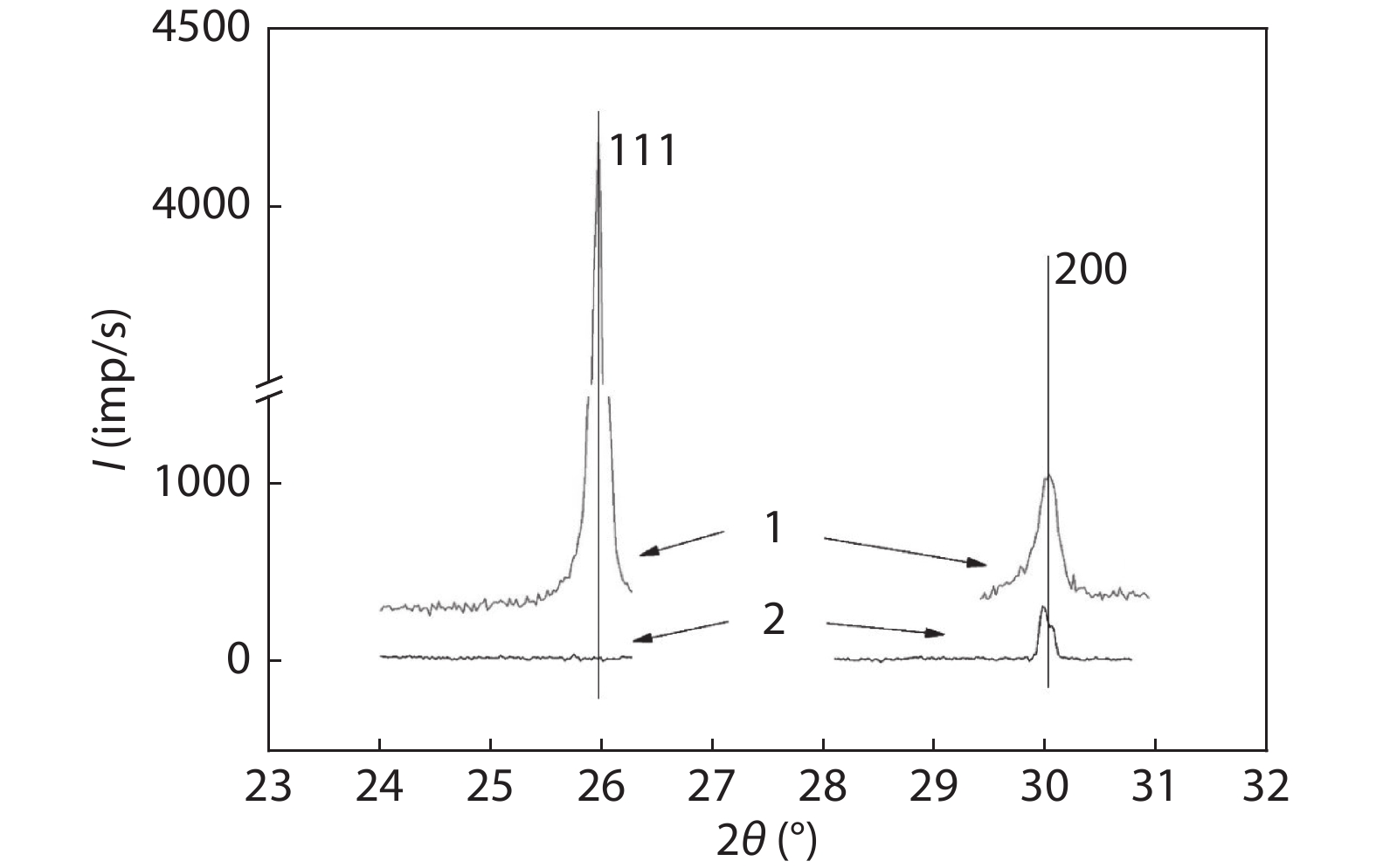

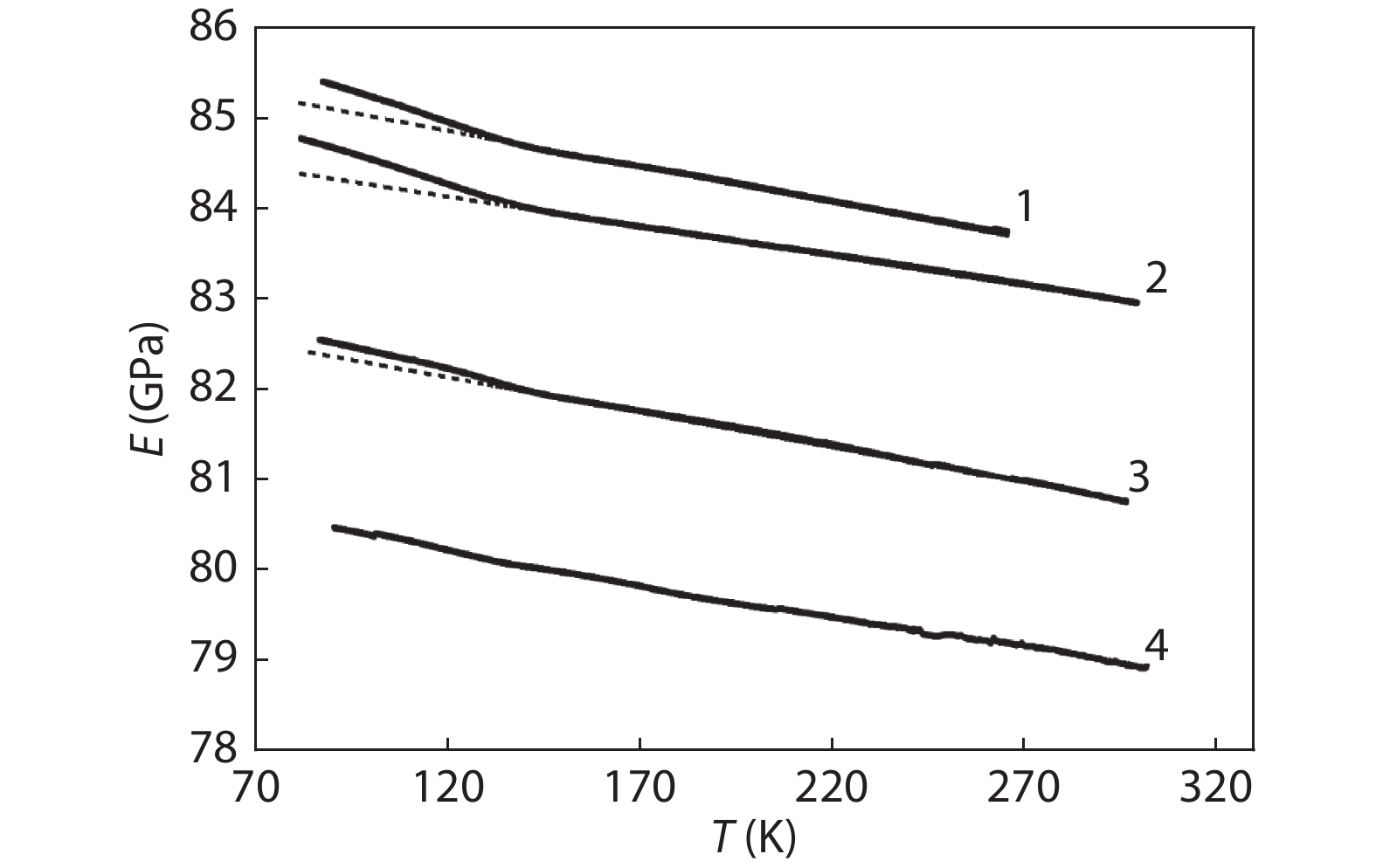

In this paper, the dependencies of Young's modulus and attenuation decrement on samarium sulfide polycrystals (SmS) under various annealing temperatures are studied by the piezoelectric ultrasonic composite oscillator technique at a frequency of 100 kHz in the temperature range of 80–300 K. A decrease in Young's modulus with an increase of the annealing temperature due to the texturing of the material was revealed. At the same time, attenuation peaks were observed at temperatures about 90 and 125 K, presumably due to Niblett-Wilks and Bordoni relaxations. -

References

[1] Takenaka K, Asai D, Kaizu R, et al. Giant isotropic negative thermal expansion in Y-doped samarium monosulfides by intra-atomic charge transfer. Sci Rep, 2019, 9, 122 doi: 10.1038/s41598-018-36568-w[2] Kaminsky V V, Soloviev S M, Khavrov G D, et al. Mechanism of the semiconductor –metal phase transition in Sm 1 – xGdxS thin films. Semiconductors, 2018, 52(1), 41 doi: 10.1134/S1063782618010116[3] Sharenkova N V, Kaminskii V V, Golubkov A V, et al. The structure of a metallic-phase film produced by mechanical polishing of polycrystalline SmS. Phys Solid State, 2005, 47, 622 doi: 10.1134/1.1913970[4] Kaminskii V V, Lanyi S. Semiconductor–metal phase transition under a strain induced by a spherical indenter. Tech Phys, 1998, 43, 314 doi: 10.1134/1.1258916[5] Sousanis A, Smet P F, Poelman D. Samarium monosulfide (SmS): reviewing properties and applications. Materials, 2017, 10, 953 doi: 10.3390/ma10080953[6] Kaminskiĭ V V, Didik V A, Kazanin M M, et al. Thermovoltaic effect in polycrystalline samarium sulfide. Tech Phys Lett, 2009, 35, 981 doi: 10.1134/S1063785009110030[7] Kaminskii V V, Solov’ev S M, Khavrov G D, et al. Structural features of Sm1 – xEuxS thin polycrystalline films. Semiconductors, 2017, 51(6), 828 doi: 10.1134/S1063782617060124[8] Pronin I A, Averin I A, Bozhinov A S, et al. The thermovoltaic effect in zinc oxide inhomogeneously doped with mixed-valence impurities. Tech Phys Lett, 2015, 41, 930 doi: 10.1134/S1063785015100132[9] Kaminsky V V, Molodykh A A, Stepanov N N, et al. The application peculiarities of semi-conducting resistive-strain sensors and baroresistors on the basis of samarium sulphide. Nauchnoe Priborostroenie (Scientific Instrumentation), 2011, 2, 53[10] Kustov S, Golyabdin S, Ichino A, et al. A new design of automated piezoelectric composite oscillator technique. Mater Sci Eng A, 2006, 442(1), 532 doi: 10.1016/j.msea.2006.02.230[11] Robinson W H, Edgar A. The piezoelectric method of determining mechanical damping at frequencies of 30 to 200 kHz. IEEE Trans Sonics Ultrason, 1974, 21(2), 98 doi: 10.1109/T-SU.1974.29798[12] Pal’-Val’ P P, Pal’-Val’ L N. Low-temperature internal friction and nanostructured metal stability. Met Sci Heat Treat, 2012, 54, 234 doi: 10.1007/s11041-012-9488-1[13] Lin D, Xu L, Jing H, et al. Effects of annealing on the structure and mechanical properties of FeCoCrNi high-entropy alloy fabricated via selective laser melting. Addit Manufact, 2020, 32, 101058 doi: 10.1016/j.addma.2020.101058[14] Wang Z, Baker I. Effects of annealing and thermo-mechanical treatment on the microstructures and mechanical properties of a carbon-doped FeNiMnAl multi-component alloy. Mater Sci Eng A, 2017, 693, 101 doi: 10.1016/j.msea.2017.03.099[15] Pal-Val P P, Loginov Yu N, Demakov S L, et al. Unusual Young׳s modulus behavior in ultrafine-grained and microcrystalline copper wires caused by texture changes during processing and annealing. Mater Sci Eng A, 2014, 618, 9 doi: 10.1016/j.msea.2014.08.069[16] Scharer U, Wachter P. Brillouin spectroscopy on doped SmS. Physica B, 1997, 721, 230 doi: 10.1016/S0921-4526(96)00817-4[17] Blanter M, Golovin I S. Internal Friction. Encyclopedia of iron, steel, and their alloys. New York: Taylor and Francis, 2016[18] Blanter M S, Golovin I S, Neuhäuser H, et al. Internal friction in metallic materials. Berlin: Springer, 2007[19] Zeger A, Shiller P. Kinks at dislocations and their effect on internal friction in crystals. Physical Acoustics (Russian translation). Moscow: Mir, 1969[20] Kaminskii V V, Lyubimova Y V, Romanov A E. Probing of polycrystalline magnesium at ultrasonic frequencies by mechanical spectroscopy. Mater Phys Mechan, 2020, 44, 19 doi: 10.18720/MPM.4412020_3 -

Proportional views

DownLoad:

DownLoad: