| Citation: |

Lixiu Zhang, Chuantian Zuo, Liming Ding. Efficient MAPbI3 solar cells made via drop-coating at room temperature[J]. Journal of Semiconductors, 2021, 42(7): 072201. doi: 10.1088/1674-4926/42/7/072201

****

L X Zhang, C T Zuo, L M Ding, Efficient MAPbI3 solar cells made via drop-coating at room temperature[J]. J. Semicond., 2021, 42(7): 072201. doi: 10.1088/1674-4926/42/7/072201.

|

Efficient MAPbI3 solar cells made via drop-coating at room temperature

DOI: 10.1088/1674-4926/42/7/072201

More Information

-

Abstract

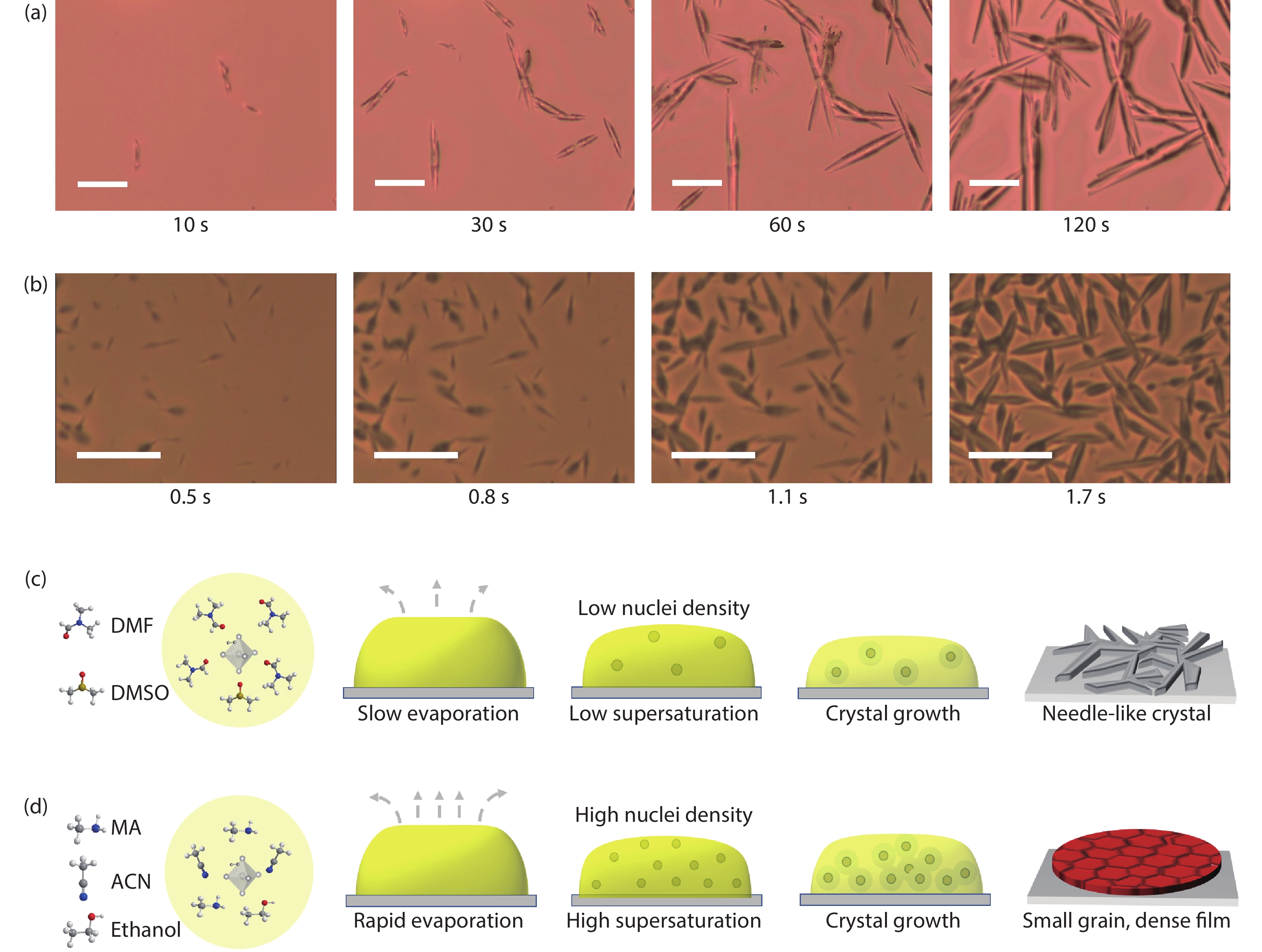

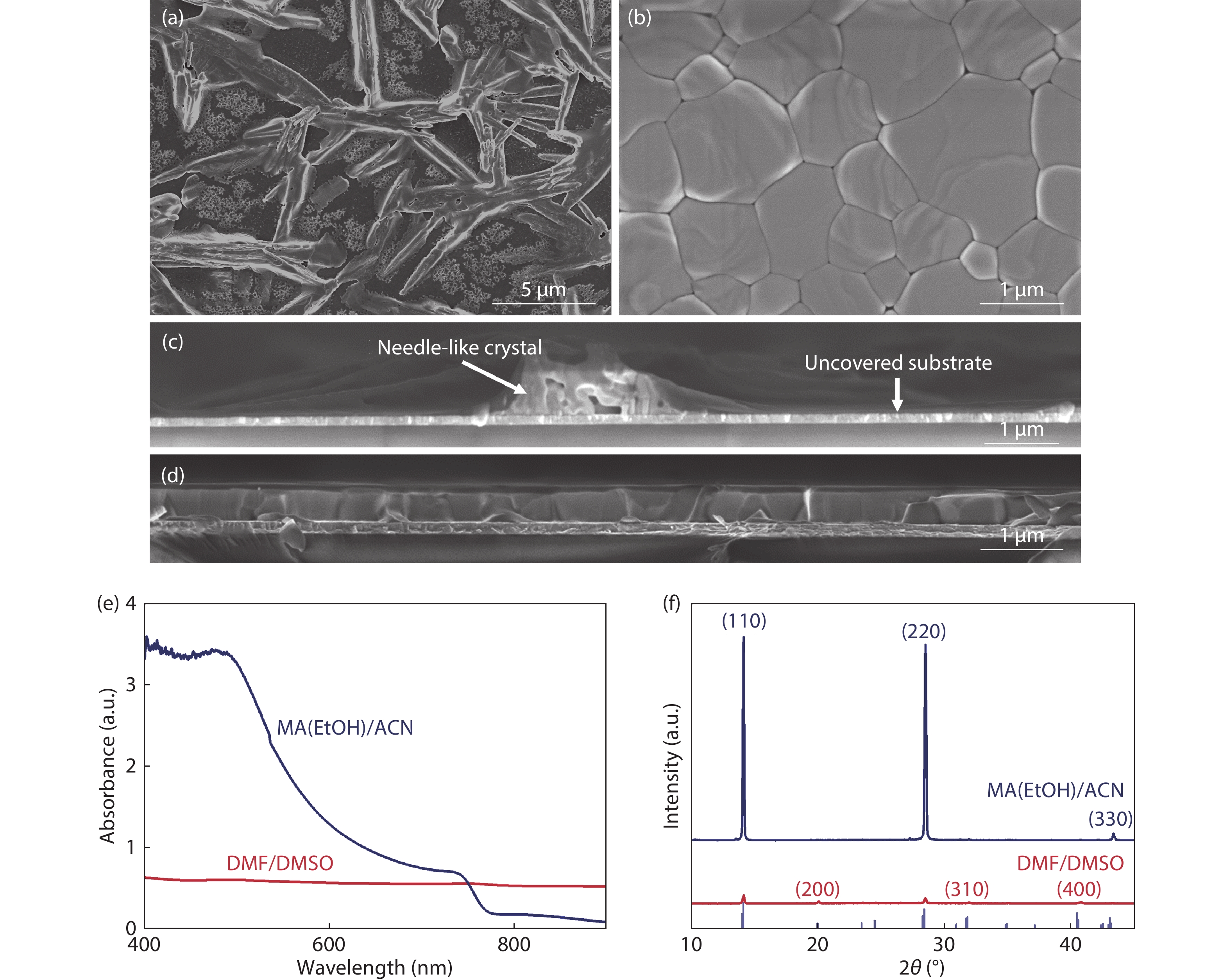

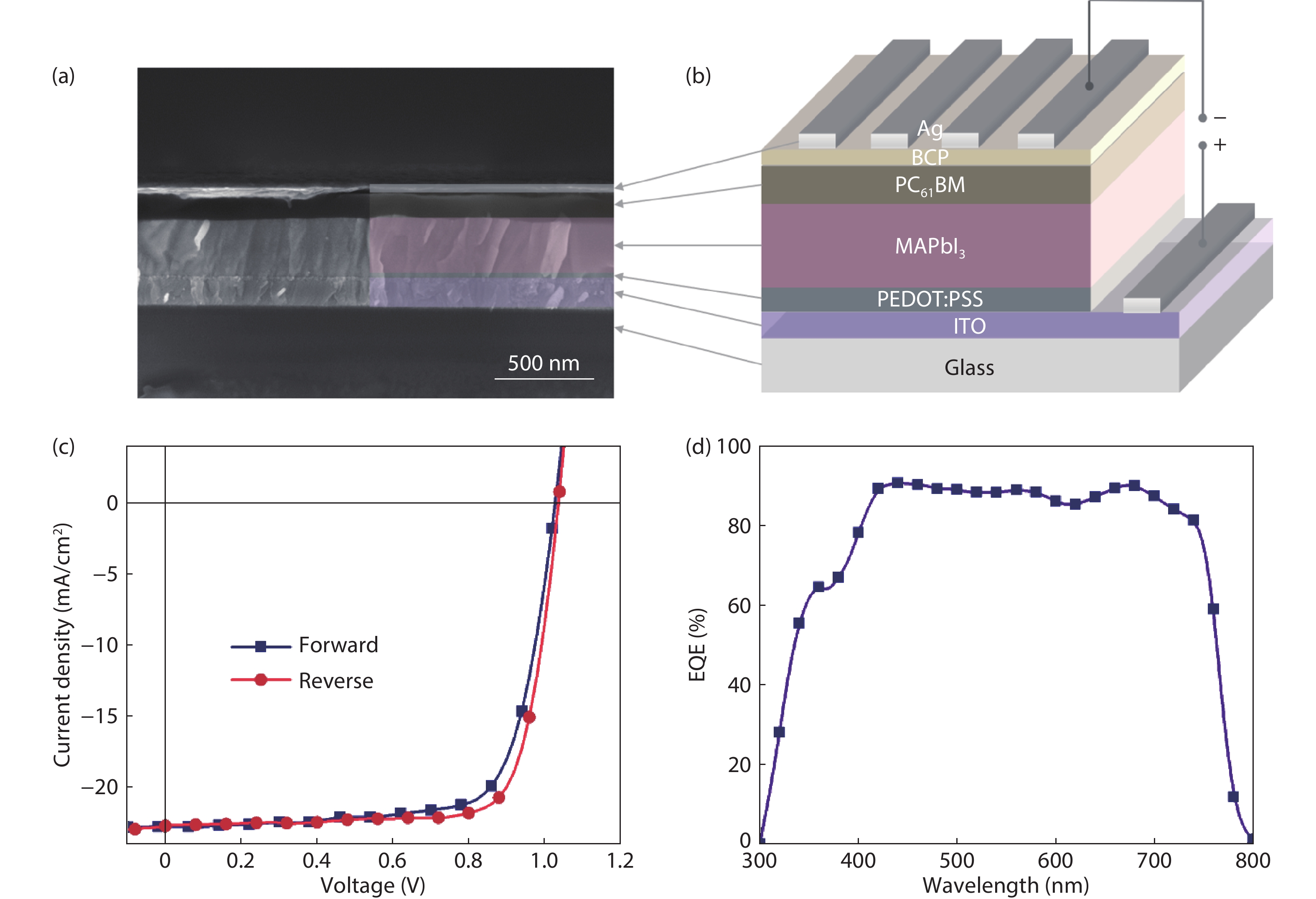

Here we demonstrate a room-temperature drop-coating method for MAPbI3 films. By using low-boiling-point solvent, high-quality MAPbI3 films were made by simply casting a drop of solution onto the substrate at room temperature. This approach took advantage of the synergistic effect of good wettability and volatility of the solvent, enabling high nuclei density and compact film at room temperature. The crystal growth in different solvents was in-situ observed by using optical microscope, which helped us to understand the mechanism for the formation of different film morphology. Perovskite solar cells gave a PCE of 18.21%. -

References

[1] Yoo J J, Seo G, Chua M R, et al. Efficient perovskite solar cells via improved carrier management. Nature, 2021, 590, 587 doi: 10.1038/s41586-021-03285-w[2] Jeong M, Choi I W, Go E M, et al. Stable perovskite solar cells with efficiency exceeding 24.8% and 0.3 V voltage loss. Science, 2020, 369, 1615 doi: 10.1126/science.abb7167[3] Kim G, Min H, Lee K S, et al. Impact of strain relaxation on performance of α-formamidinium lead iodide perovskite solar cells. Science, 2020, 370, 108 doi: 10.1126/science.abc4417[4] Best research-cell efficiencies. https://www.nrel.gov/pv/assets/pdfs/best-research-cell-efficiencies.20200104.pdf[5] Du M, Zhu X, Wang L, et al. High-pressure nitrogen-extraction and effective passivation to attain highest large-area perovskite solar module efficiency. Adv Mater, 2020, 32, 2004979 doi: 10.1002/adma.202004979[6] Subbiah A S, Isikgor F H, Howells C T, et al. High-performance perovskite single-junction and textured perovskite/silicon tandem solar cells via slot-die coating. ACS Energy Lett, 2020, 5, 3034 doi: 10.1021/acsenergylett.0c01297[7] Chen S, Xiao X, Gu H, et al. Iodine reduction for reproducible and high-performance perovskite solar cells and modules. Sci Adv, 2021, 7, eabe8130 doi: 10.1126/sciadv.abe8130[8] Wu W Q, Rudd P N, Ni Z, et al. Reducing surface halide deficiency for efficient and stable iodide-based perovskite solar cells. J Am Chem Soc, 2020, 142, 3989 doi: 10.1021/jacs.9b13418[9] Jeong D N, Lee D K, Seo S, et al. Perovskite cluster-containing solution for scalable D-bar coating toward high-throughput perovskite solar cells. ACS Energy Lett, 2019, 4, 1189 doi: 10.1021/acsenergylett.9b00042[10] Bishop J E, Read C D, Smith J A, et al. Fully spray-coated triple-cation perovskite solar cells. Sci Rep, 2020, 10, 6610 doi: 10.1038/s41598-020-63674-5[11] Zuo C, Scully A D, Tan W L, et al. Crystallisation control of drop-cast quasi-2D/3D perovskite layers for efficient solar cells. Commun Mater, 2020, 1, 33 doi: 10.1038/s43246-020-0036-z[12] Zuo C, Scully A, Yak D, et al. Self-assembled 2D perovskite layers for efficient printable solar cells. Adv Energy Mater, 2019, 9, 1803258 doi: 10.1002/aenm.201803258[13] Zuo C, Ding L. Drop-casting enables making efficient perovskite solar cells under high humidity. Angew Chem Int Ed, 2021, 60, 11242 doi: 10.1002/anie.202101868[14] Xiao H, Zuo C, Liu F, et al. Drop-coating produces efficient CsPbI2Br solar cells. J Semicond, 2021, 42, 050502 doi: 10.1088/1674-4926/42/5/050502[15] Noel N K, Habisreutinger S N, Wenger B, et al. A low viscosity, low boiling point, clean solvent system for the rapid crystallisation of highly specular perovskite films. Energy Environ Sci, 2017, 10, 145 doi: 10.1039/C6EE02373H[16] Wang K, Wu C, Hou Y, et al. Isothermally crystallize perovskites at room-temperature. Energy Environ Sci, 2020, 5, 3034 doi: 10.1039/D0EE01967D[17] Dou B, Whitaker J B, Bruening K, et al. Roll-to-roll printing of perovskite solar cells. ACS Energy Lett, 2018, 3, 2558 doi: 10.1021/acsenergylett.8b01556[18] Chu D B K, Owen J S, Peters B. Nucleation and growth kinetics from lamer burst data. J Phys Chem A, 2017, 121, 7511 doi: 10.1021/acs.jpca.7b08368 -

Supplements

21040008suppl.pdf

21040008suppl.pdf

-

Proportional views

DownLoad:

DownLoad: