| Citation: |

Lulu Guan, Xingyu Li, Dongchen Che, Kaidong Xu, Shiwei Zhuang. Plasma atomic layer etching of GaN/AlGaN materials and application: An overview[J]. Journal of Semiconductors, 2022, 43(11): 113101. doi: 10.1088/1674-4926/43/11/113101

****

L L Guan, X Y Li, D C Che, K D Xu, S W Zhuang. Plasma atomic layer etching of GaN/AlGaN materials and application: An overview[J]. J. Semicond, 2022, 43(11): 113101. doi: 10.1088/1674-4926/43/11/113101

|

Plasma atomic layer etching of GaN/AlGaN materials and application: An overview

DOI: 10.1088/1674-4926/43/11/113101

More Information

-

Abstract

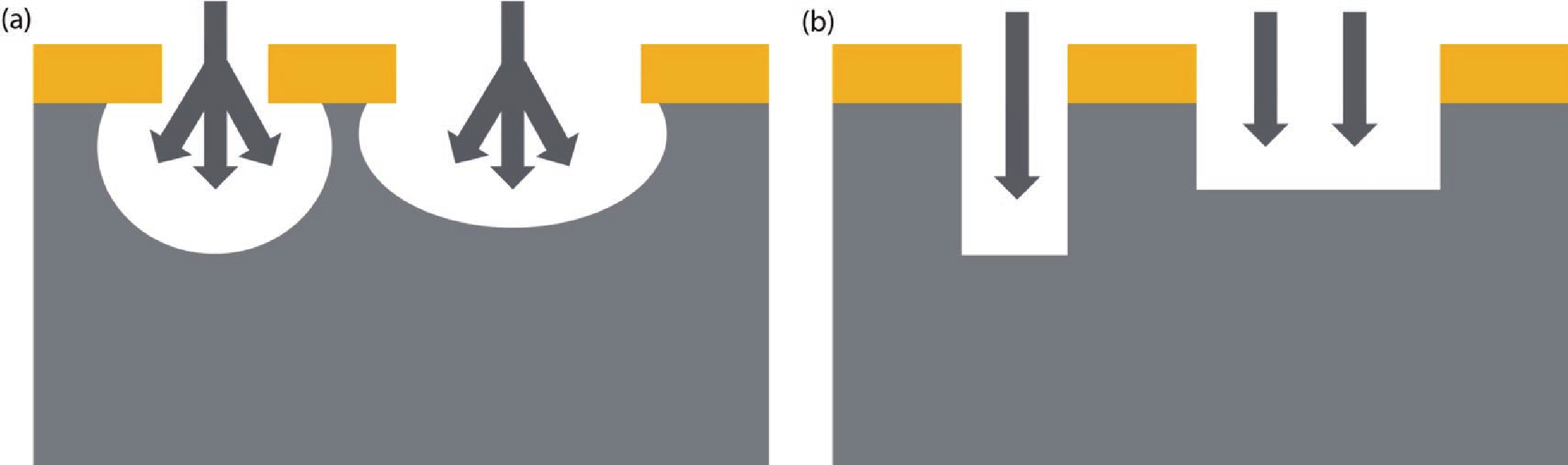

With the development of the third generation of semiconductor devices, it is essential to achieve precise etching of gallium nitride (GaN) materials that is close to the atomic level. Compared with the traditional wet etching and continuous plasma etching, plasma atomic layer etching (ALE) of GaN has the advantages of self-limiting etching, high selectivity to other materials, and smooth etched surface. In this paper the basic properties and applications of GaN are presented. It also presents the various etching methods of GaN. GaN plasma ALE systems are reviewed, and their similarities and differences are compared. In addition, the industrial application of GaN plasma ALE is outlined.-

Keywords:

- gallium nitride,

- plasma etching,

- atomic layer etching,

- self-limiting

-

References

[1] Stepanova M, Dew S. Nanofabrication: Techniques and principles. Springer Science & Business Media, 2011[2] Berger L I. Semiconductor devices. Semiconductor Materials. CRC Press, 2020[3] Look D. Electrical characterization of GaAs materials and devices. New York: Wiley, 1989[4] Lai R, Mei X B, Deal W R, et al. Sub 50 nm InP HEMT device with fmax greater than 1 THz. 2007 IEEE International Electron Devices Meeting, 2007, 609 doi: 10.1109/IEDM.2007.4419013[5] Zhang Y Q. The application of third generation semiconductor in power industry. E3S Web Conf, 2020, 198, 04011 doi: 10.1051/e3sconf/202019804011[6] Paskova T, Evans K R. GaN substrates — Progress, status, and prospects. IEEE J Sel Top Quantum Electron, 2009, 15, 1041 doi: 10.1109/JSTQE.2009.2015057[7] Zhu S, Mizuno M, Kagawa Y, et al. Monotonic tension, fatigue and creep behavior of SiC-fiber-reinforced SiC-matrix composites: A review. Compos Sci Technol, 1999, 59, 833 doi: 10.1016/S0266-3538(99)00014-7[8] Li M, Li G, Jiang J, et al. Ultraviolet resistance and antimicrobial properties of ZnO in the polypropylene materials: A review. J Mater Sci Technol, 2015, 31, 331 doi: 10.1016/j.jmst.2014.11.022[9] Chalker P R. Wide bandgap semiconductor materials for high temperature electronics. Thin Solid Films, 1999, 343/344, 616 doi: 10.1016/S0040-6090(98)01672-1[10] Moontragoon P, Ikonić Z, Harrison P. Band structure calculations of Si-Ge-Sn alloys: Achieving direct band gap materials. Semicond Sci Technol, 2007, 22, 742 doi: 10.1088/0268-1242/22/7/012[11] Zhang X, Jin Y, Yang K, et al. Resonant nonlinear susceptibility near the GaAs band gap. Phys Rev Lett, 1992, 69, 2303 doi: 10.1103/PhysRevLett.69.2303[12] Dingle R, Sell D D, Stokowski S E, et al. Absorption, reflectance, and luminescence of GaN epitaxial layers. Phys Rev B, 1971, 4, 1211 doi: 10.1103/PhysRevB.4.1211[13] Mishra U K, Parikh P, Wu Y F. AlGaN/GaN HEMTs — an overview of device operation and applications. Proc IEEE, 2002, 90, 1022 doi: 10.1109/JPROC.2002.1021567[14] Medjdoub F, Carlin J F, Gaquiere C, et al. Status of the emerging InAlN/GaN power HEMT technology. Open Electr Electron Eng J, 2008, 2, 1 doi: 10.2174/1874129000802010001[15] Hashizume T, Ootomo S, Oyama S, et al. Chemistry and electrical properties of surfaces of GaN and GaN/AlGaN heterostructures. J Vac Sci Technol B, 2001, 19, 1675 doi: 10.1116/1.1383078[16] Medjdoub F, Carlin J F, Gonschorek M, et al. Can InAlN/GaN be an alternative to high power/high temperature AlGaN/GaN devices. 2006 Int Electron Devices Meet, 2006, 1 doi: 10.1109/IEDM.2006.346935[17] Saito W, Takada Y, Kuraguchi M, et al. High breakdown voltage AlGaN-GaN power-HEMT design and high current density switching behavior. IEEE Trans Electron Devices, 2003, 50, 2528 doi: 10.1109/TED.2003.819248[18] Panda A K, Pavlidis D, Alekseev E. DC and high-frequency characteristics of GaN-based IMPATTs. IEEE Trans Electron Devices, 2001, 48, 820 doi: 10.1109/16.915735[19] Boutros K S, Chu R M, Hughes B. GaN power electronics for automotive application. 2012 IEEE Energytech, 2012, 1 doi: 10.1109/EnergyTech.2012.6304646[20] Gupta A, Chatterjee N, Tripathy M R, et al. Design and simulation of GaN HEMT and its application to RF amplifiers. 2016 Progress in Electromagnetic Research Symposium, 2016, 3815[21] Arakawa Y. Progress in GaN-based quantum dots for optoelectronics applications. IEEE J Sel Top Quantum Electron, 2002, 8, 823 doi: 10.1109/JSTQE.2002.801675[22] Jones E A, Wang F F, Costinett D. Review of commercial GaN power devices and GaN-based converter design challenges. IEEE J Emerg Sel Top Power Electron, 2016, 4, 707 doi: 10.1109/JESTPE.2016.2582685[23] Chen J, Du X, Luo Q M, et al. A review of switching oscillations of wide bandgap semiconductor devices. IEEE Trans Power Electron, 2020, 35, 13182 doi: 10.1109/TPEL.2020.2995778[24] Kanarik K J, Lill T, Hudson E A, et al. Overview of atomic layer etching in the semiconductor industry. J Vac Sci Technol A, 2015, 33, 020802 doi: 10.1116/1.4913379[25] Yoder M N. Atomic layer etching. Department of the Navy Washington DC, 1988[26] Horiike Y, Tanaka T, Nakano M, et al. Digital chemical vapor deposition and etching technologies for semiconductor processing. J Vac Sci Technol A, 1990, 8, 1844 doi: 10.1116/1.576814[27] Aoyagi Y, Shinmura K, Kawasaki K, et al. Molecular layer etching of GaAs. Appl Phys Lett, 1992, 60, 968 doi: 10.1063/1.106477[28] Agarwal A, Kushner M J. Plasma atomic layer etching using conventional plasma equipment. J Vac Sci Technol A, 2009, 27, 37 doi: 10.1116/1.3021361[29] Matsuura T, Murota J, Sawada Y, et al. Self-limited layer-by-layer etching of Si by alternated chlorine adsorption and Ar+ ion irradiation. Appl Phys Lett, 1993, 63, 2803 doi: 10.1063/1.110340[30] Negi S, Bhandari R. Silicon isotropic and anisotropic etching for MEMS applications. Microsyst Technol, 2013, 19, 203 doi: 10.1007/s00542-012-1552-7[31] Youtsey C, Bulman G, Adesida I. Dopant-selective photoenhanced wet etching of GaN. J Electron Mater, 1998, 27, 282 doi: 10.1007/s11664-998-0400-0[32] Peng L H, Chuang C W, Ho J K, et al. Deep ultraviolet enhanced wet chemical etching of gallium nitride. Appl Phys Lett, 1998, 72, 939 doi: 10.1063/1.120879[33] Weyher J L, Tichelaar F D, van Dorp D H, et al. The K2S2O8-KOH photoetching system for GaN. J Cryst Growth, 2010, 312, 2607 doi: 10.1016/j.jcrysgro.2010.04.020[34] Donnelly V M, Kornblit A. Plasma etching: Yesterday, today, and tomorrow. J Vac Sci Technol A, 2013, 31, 050825 doi: 10.1116/1.4819316[35] Pearton S J, Shul R J, Ren F. A review of dry etching of GaN and related materials. MRS Internet J Nitride Semicond Res, 2020, 5, 1 doi: 10.1557/S1092578300000119[36] Huard C M, Zhang Y T, Sriraman S, et al. Atomic layer etching of 3D structures in silicon: Self-limiting and nonideal reactions. J Vac Sci Technol A, 2017, 35, 031306 doi: 10.1116/1.4979661[37] Rahman F, Runyon J C. Atomic layer processes for material growth and etching — a review. IEEE Trans Semicond Manuf, 2021, 34, 500 doi: 10.1109/TSM.2021.3112502[38] Lee Y, George S M. Atomic layer etching of Al2O3 using sequential, self-limiting thermal reactions with Sn(acac)2 and hydrogen fluoride. ACS Nano, 2015, 9, 2061 doi: 10.1021/nn507277f[39] Clancey J W, Cavanagh A S, Smith J E T, et al. Volatile etch species produced during thermal Al2O3 atomic layer etching. J Phys Chem C, 2020, 124, 287 doi: 10.1021/acs.jpcc.9b06104[40] Lee Y, George S M. Thermal atomic layer etching of Al2O3, HfO2, and ZrO2 using sequential hydrogen fluoride and dimethylaluminum chloride exposures. J Phys Chem C, 2019, 123, 18455 doi: 10.1021/acs.jpcc.9b04767[41] George S M. Mechanisms of thermal atomic layer etching. Acc Chem Res, 2020, 53, 1151 doi: 10.1021/acs.accounts.0c00084[42] Sugiyama T, Matsuura T, Murota J. Atomic-layer etching of Ge using an ultraclean ECR plasma. Appl Surf Sci, 1997, 112, 187 doi: 10.1016/S0169-4332(96)01026-4[43] Athavale S D. Realization of atomic layer etching of silicon. J Vac Sci Technol B, 1996, 14, 3702 doi: 10.1116/1.588651[44] Lim W S, Park S D, Park B J, et al. Atomic layer etching of (100)/(111) GaAs with chlorine and low angle forward reflected Ne neutral beam. Surf Coat Technol, 2008, 202, 5701 doi: 10.1016/j.surfcoat.2008.06.123[45] Otsuka N, Oyama Y, Kikuchi H, et al. Digital etching of (001) InP substrate by intermittent injection of tertiarybutylphosphine in ultrahigh vacuum. Jpn J Appl Phys, 1998, 37, L1509 doi: 10.1143/JJAP.37.L1509[46] Lim W S, Kim Y Y, Kim H, et al. Atomic layer etching of graphene for full graphene device fabrication. Carbon, 2012, 50, 429 doi: 10.1016/j.carbon.2011.08.058[47] Vogli E, Metzler D, Oehrlein G S. Feasibility of atomic layer etching of polymer material based on sequential O2 exposure and Ar low-pressure plasma-etching. Appl Phys Lett, 2013, 102, 253105 doi: 10.1063/1.4812750[48] Posseme N, Pollet O, Barnola S. Alternative process for thin layer etching: Application to nitride spacer etching stopping on silicon germanium. Appl Phys Lett, 2014, 105, 051605 doi: 10.1063/1.4892543[49] Rauf S, Sparks T, Ventzek P L G, et al. A molecular dynamics investigation of fluorocarbon based layer-by-layer etching of silicon and SiO2. J Appl Phys, 2007, 101, 033308 doi: 10.1063/1.2464192[50] Park J B, Lim W S, Park S D, et al. Etch characteristics of TiO2 etched by using an atomic layer etching technique with BCl3 gas and an Ar neutral beam. J Korean Phy Soc, 2009, 54, 976 doi: 10.3938/jkps.54.976[51] Min K S, Kang S H, Kim J K, et al. Atomic layer etching of Al2O3 using BCl3/Ar for the interface passivation layer of III-V MOS devices. Microelectron Eng, 2013, 110, 457 doi: 10.1016/j.mee.2013.03.170[52] Ohba T, Yang W B, Tan S, et al. Atomic layer etching of GaN and AlGaN using directional plasma-enhanced approach. Jpn J Appl Phys, 2017, 56, 06HB06 doi: 10.7567/JJAP.56.06HB06[53] Ibbetson J P, Fini P T, Ness K D, et al. Polarization effects, surface states, and the source of electrons in AlGaN/GaN heterostructure field effect transistors. Appl Phys Lett, 2000, 77, 250 doi: 10.1063/1.126940[54] Lanford W B, Tanaka T, Otoki Y, et al. Recessed-gate enhancement-mode GaN HEMT with high threshold voltage. Electron Lett, 2005, 41, 449 doi: 10.1049/el:20050161[55] Cai Y, Zhou Y G, Chen K J, et al. Self-aligned enhancement-mode AlGaN/GaN HEMTs using fluoride-based plasma treatment. 63rd Device Res Conf Dig 2005 DRC '05, 2005, 1, 179 doi: 10.1109/DRC.2005.1553110[56] Khan M A, Hu X, Tarakji A, et al. AlGaN/GaN metal-oxide-semiconductor heterostructure field-effect transistors on SiC substrates. Appl Phys Lett, 2000, 77, 1339 doi: 10.1063/1.1290269[57] Jiang H X, Tang C W, Lau K M. Enhancement-mode GaN MOS-HEMTs with recess-free barrier engineering and high-k ZrO2 gate dielectric. IEEE Electron Device Lett, 2018, 39, 405 doi: 10.1109/LED.2018.2792839[58] Ren J, Tang C W, Feng H, et al. A novel 700 V monolithically integrated Si-GaN cascoded field effect transistor. IEEE Electron Device Lett, 2018, 39, 394 doi: 10.1109/LED.2018.2791586[59] Chiu H C, Yang C W, Chen C H, et al. Characterization of enhancement-mode AlGaN/GaN high electron mobility transistor using N2O plasma oxidation technology. Appl Phys Lett, 2011, 99, 153508 doi: 10.1063/1.3651331[60] Jiang Y, Wan Z Y, Zhou G N, et al. A novel oxygen-based digital etching technique for p-GaN/AlGaN structures without etch-stop layers. Chin Phys Lett, 2020, 37, 068503 doi: 10.1088/0256-307X/37/6/068503[61] Sokolovskij R, Sun J, Santagata F, et al. Precision recess of AlGaN/GaN with controllable etching rate using ICP-RIE oxidation and wet etching. Procedia Eng, 2016, 168, 1094 doi: 10.1016/j.proeng.2016.11.350[62] Buttari D, Chini A, Palacios T, et al. Origin of etch delay time in Cl2 dry etching of AlGaN/GaN structures. Appl Phys Lett, 2003, 83, 4779 doi: 10.1063/1.1632035[63] Wu J Y, Lei S Q, Cheng W C, et al. Oxygen-based digital etching of AlGaN/GaN structures with AlN as etch-stop layers. J Vac Sci Technol A, 2019, 37, 060401 doi: 10.1116/1.5115427[64] Burnham S D, Boutros K, Hashimoto P, et al. Gate-recessed normally-off GaN-on-Si HEMT using a new O2-BCl3 digital etching technique. Phys Status Solidi C, 2010, 7, 2010 doi: 10.1002/pssc.200983644[65] Burnham S, Boutros K. Two stage plasma etching method for enhancement mode GaN HFET. US Patent 8 124 505, 2012[66] Basu A, Kumar V, Adesida I. Study of fluorine bombardment on the electrical properties of AlGaN∕GaN heterostructures. J Vac Sci Technol B, 2007, 25, 2607 doi: 10.1116/1.2789444[67] Le Roux F, Possémé N, Burtin P, et al. XPS study of a selective GaN etching process using self-limiting cyclic approach for power devices application. Microelectron Eng, 2020, 228, 111328 doi: 10.1016/j.mee.2020.111328[68] Shah A P, Bhattacharya A. Inductively coupled plasma reactive-ion etching of β-Ga2O3: Comprehensive investigation of plasma chemistry and temperature. J Vac Sci Technol A, 2017, 35, 041301 doi: 10.1116/1.4983078[69] Hwang I H, Cha H Y, Seo K S. Low-damage and self-limiting (Al)GaN etching process through atomic layer etching using O2 and BCl3 plasma. Coatings, 2021, 11, 268 doi: 10.3390/coatings11030268[70] Hu Q L, Li S C, Li T Y, et al. Channel engineering of normally-OFF AlGaN/GaN MOS-HEMTs by atomic layer etching and high-k dielectric. IEEE Electron Device Lett, 2018, 39, 1377 doi: 10.1109/LED.2018.2856934[71] Du F Z, Jiang Y, Qiao Z P, et al. Atomic layer etching technique for InAlN/GaN heterostructure with AlN etch-stop layer. Mater Sci Semicond Process, 2022, 143, 106544 doi: 10.1016/j.mssp.2022.106544[72] Harafuji K, Kawamura K. Chemical sputtering of GaN crystal with a chlorine-adsorbed layer. Jpn J Appl Phys, 2010, 49, 08JE03 doi: 10.1143/jjap.49.08je03[73] Ohba T, Yang W, Tan S, et al. Atomic layer etching of GaN/AlGaN. 38th International Symposium on Dry Process, 2016[74] Kanarik K J, Tan S, Yang W B, et al. Predicting synergy in atomic layer etching. J Vac Sci Technol A, 2017, 35, 05C302 doi: 10.1116/1.4979019[75] Aroulanda S, Patard O, Altuntas P, et al. Cl2/Ar based atomic layer etching of AlGaN layers. J Vac Sci Technol A, 2019, 37, 041001 doi: 10.1116/1.5090106[76] Fukumizu H, Sekine M, Hori M, et al. Atomic layer etching of AlGaN using Cl2 and Ar gas chemistry and UV damage evaluation. J Vac Sci Technol A, 2019, 37, 021002 doi: 10.1116/1.5063795[77] Ziegler J F, Ziegler M D, Biersack J P. SRIM - The stopping and range of ions in matter (2010). Nucl Instrum Methods Phys Res Sect B, 2010, 268, 1818 doi: 10.1016/j.nimb.2010.02.091[78] Kauppinen C, Khan S A, Sundqvist J, et al. Atomic layer etching of gallium nitride (0001). J Vac Sci Technol A, 2017, 35, 060603 doi: 10.1116/1.4993996[79] Zhang Y C, Huang S, Wei K, et al. Millimeter-wave AlGaN/GaN HEMTs with 43.6% power-added-efficiency at 40 GHz fabricated by atomic layer etching gate recess. IEEE Electron Device Lett, 2020, 41, 701 doi: 10.1109/LED.2020.2984663[80] Mannequin C, Vallée C, Akimoto K, et al. Comparative study of two atomic layer etching processes for GaN. J Vac Sci Technol A, 2020, 38, 032602 doi: 10.1116/1.5134130[81] Berry I L, Kanarik K J, Lill T, et al. Applying sputtering theory to directional atomic layer etching. J Vac Sci Technol A, 2018, 36, 01B105 doi: 10.1116/1.5003393[82] Kawakami R, Inaoka T, Tominaga K, et al. Effects of capacitively coupled radio frequency krypton and argon plasmas on gallium nitride etching damage. Jpn J Appl Phys, 2009, 48, 08HF01 doi: 10.1143/JJAP.48.08HF01[83] Ruel S, Pimenta-Barros P, Le Roux F, et al. Atomic layer etching of GaN using Cl2 and He or Ar plasma. J Vac Sci Technol A, 2021, 39, 022601 doi: 10.1116/6.0000830[84] Zhang A P, Dang G T, Ren F, et al. Effect of N2 discharge treatment on AlGaN/GaN high electron mobility transistor ohmic contacts using inductively coupled plasma. J Vac Sci Technol A, 2000, 18, 1149 doi: 10.1116/1.582315 -

Proportional views

DownLoad:

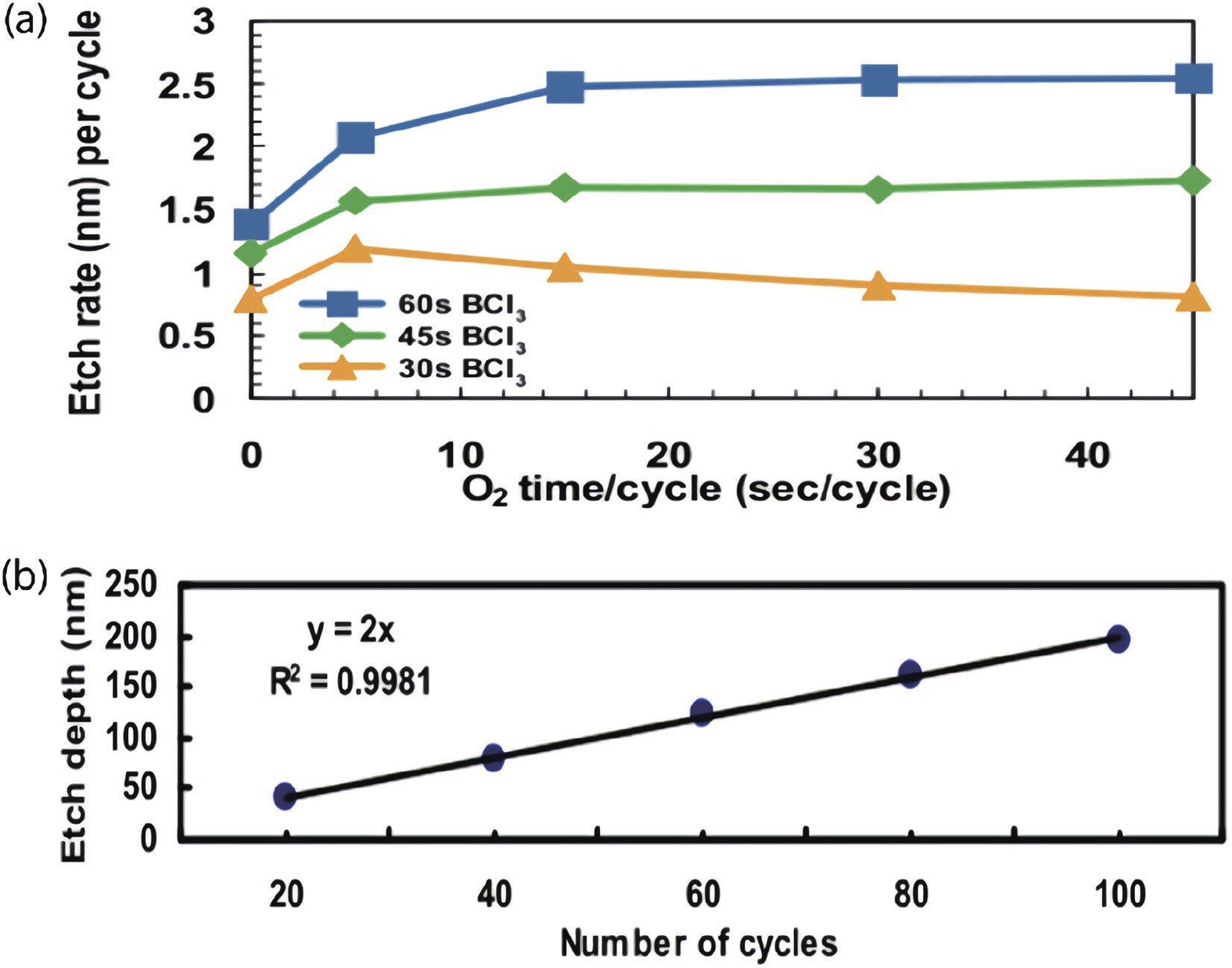

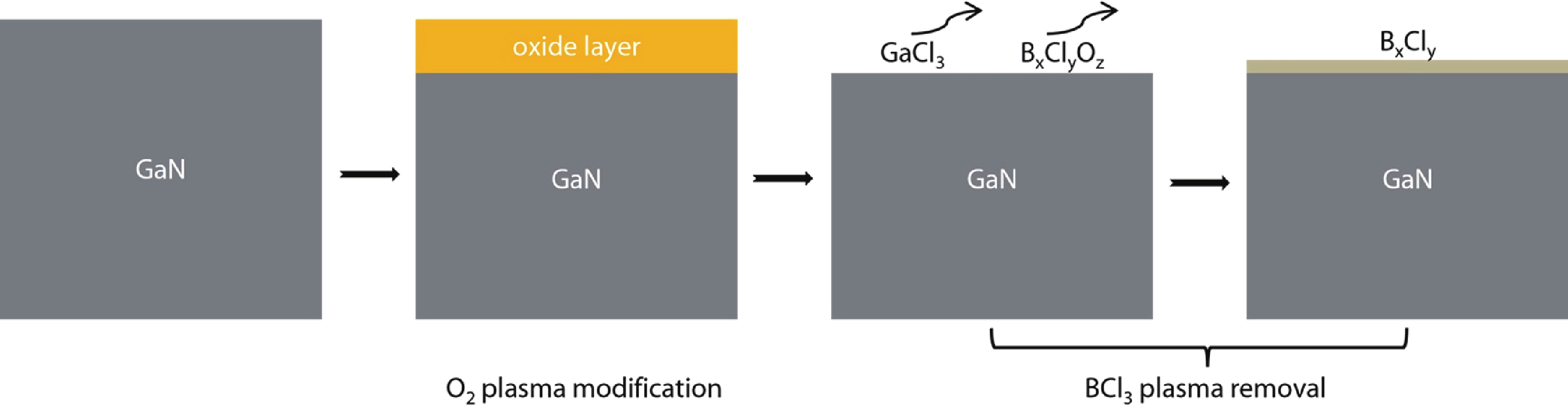

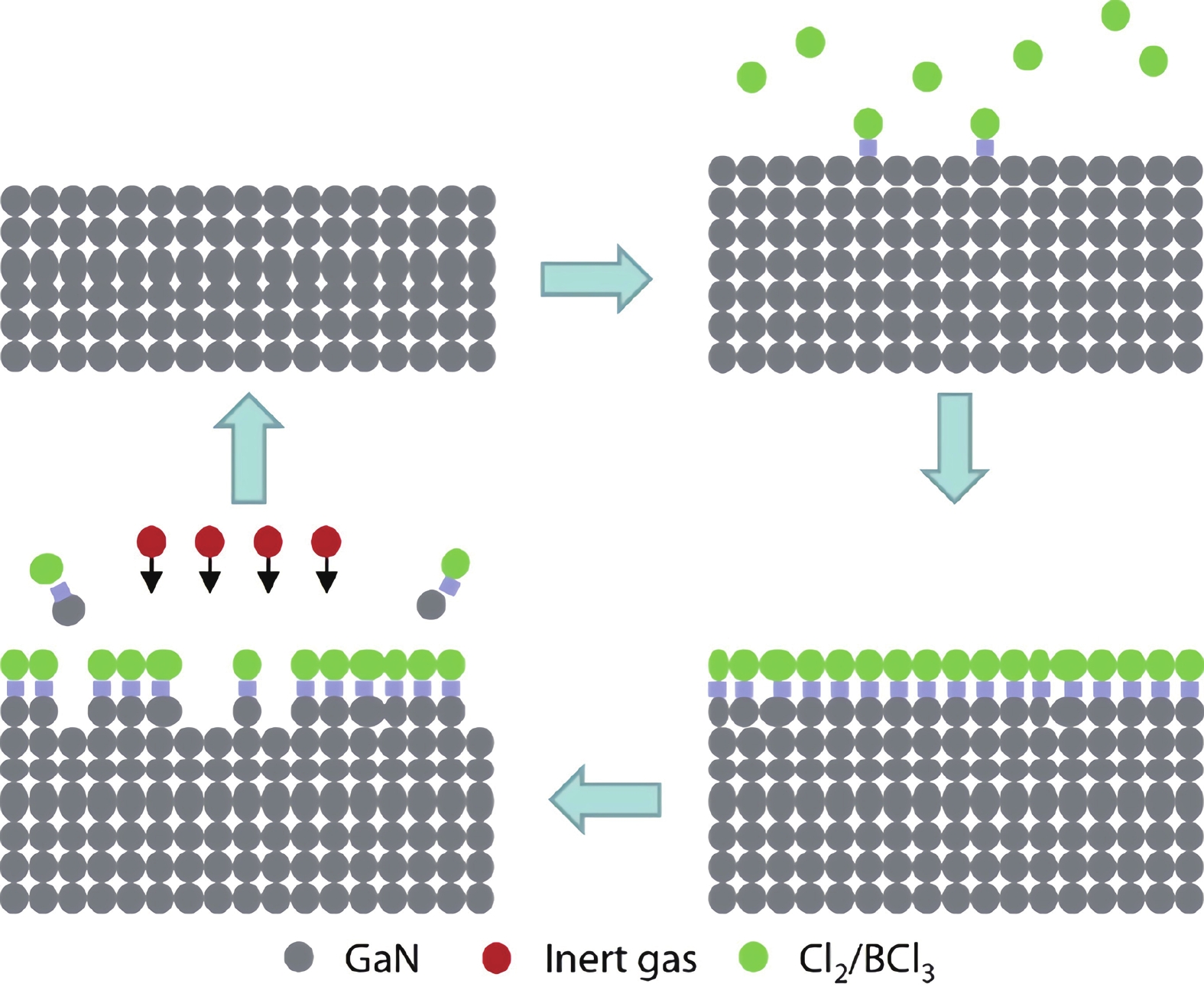

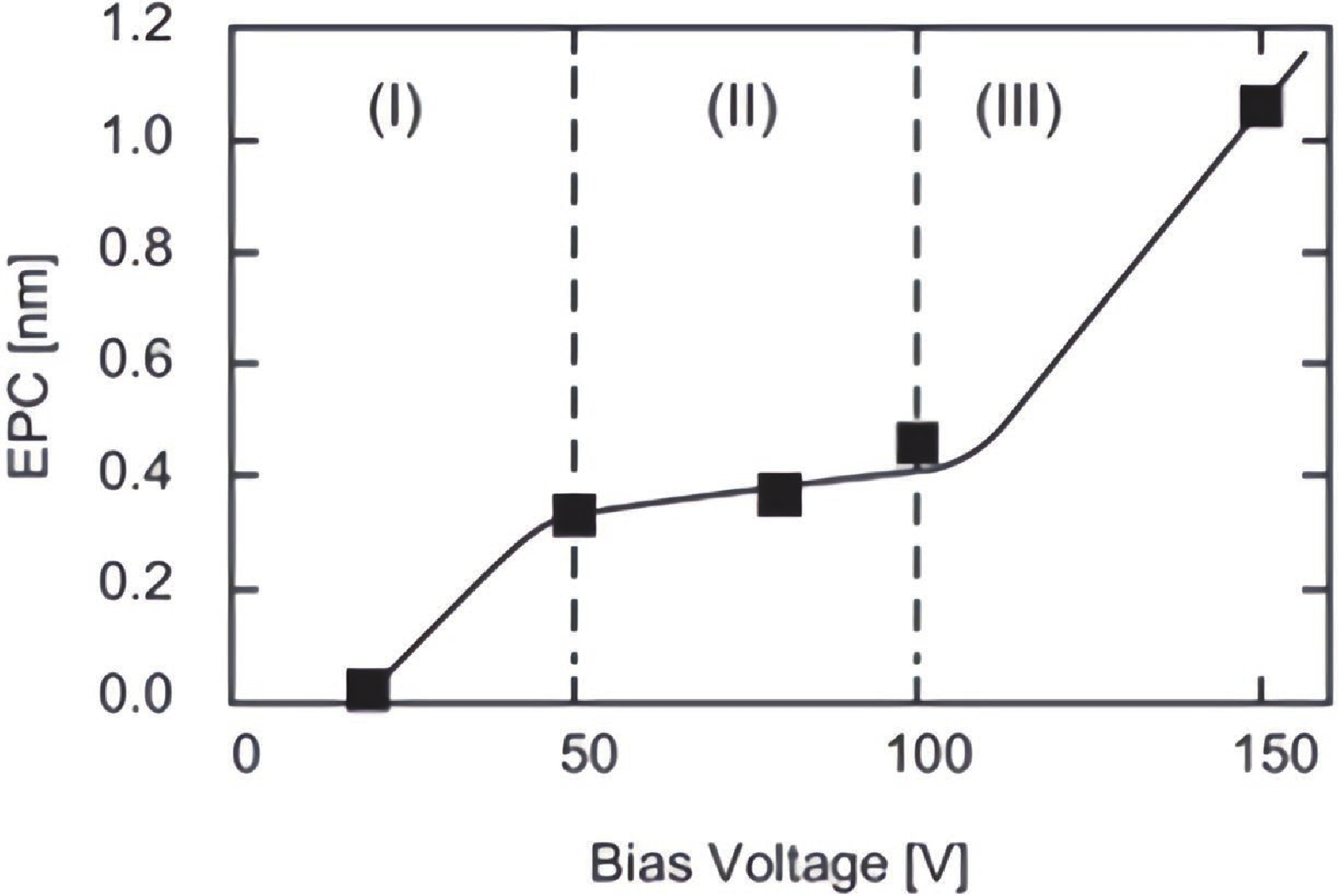

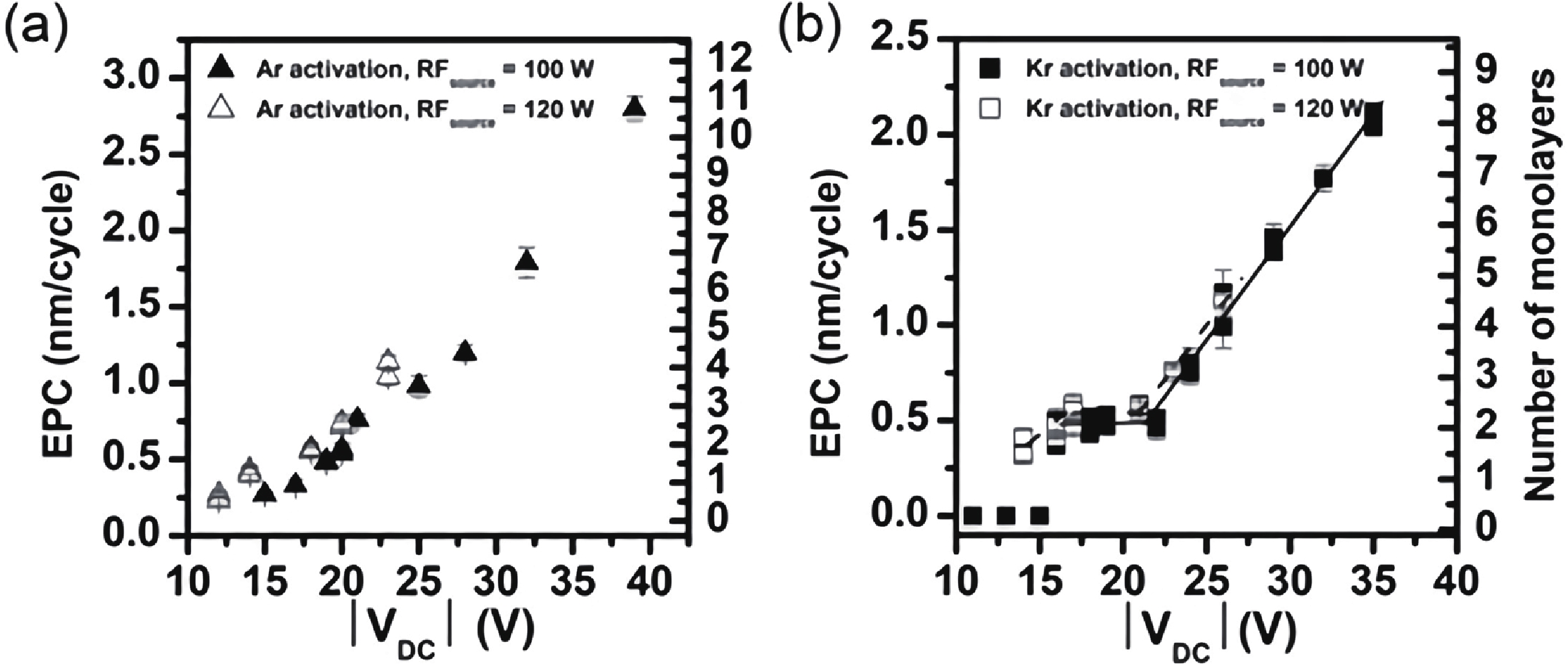

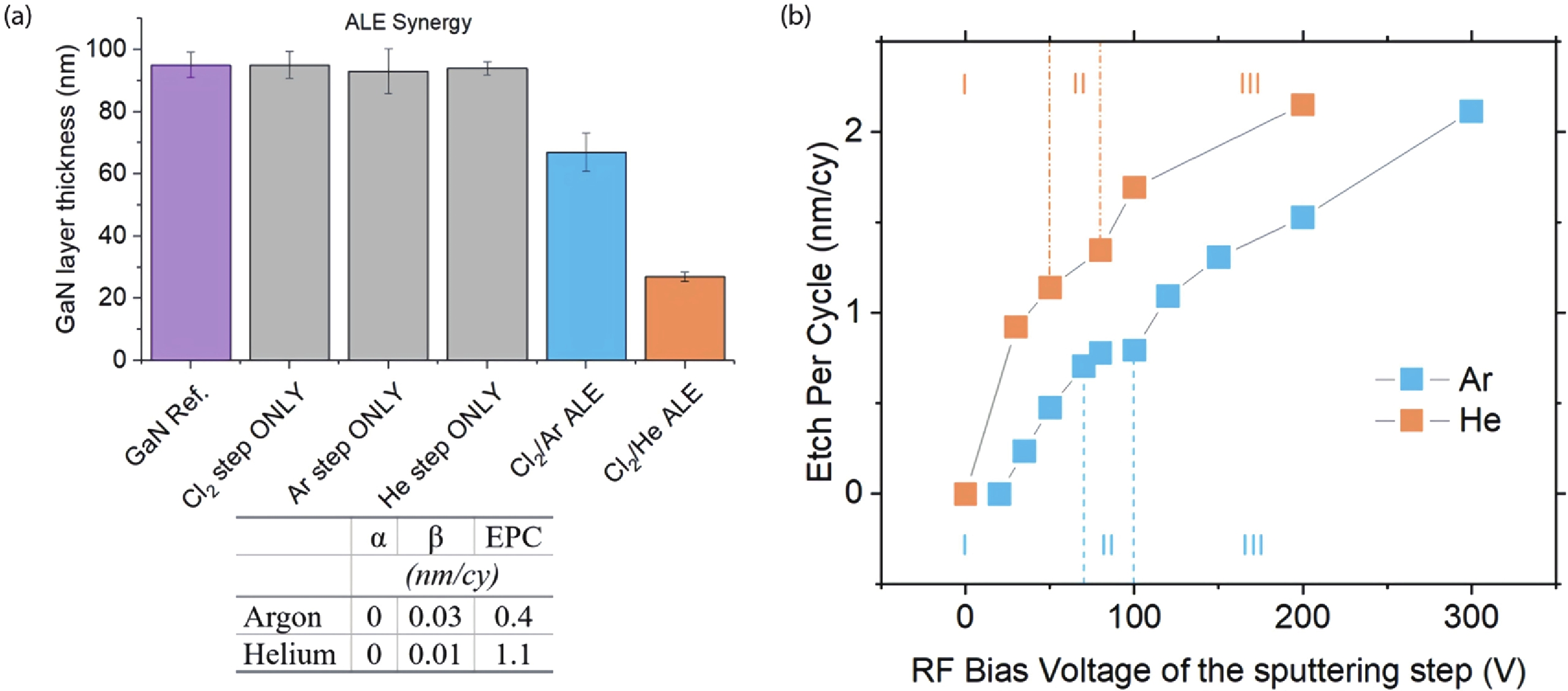

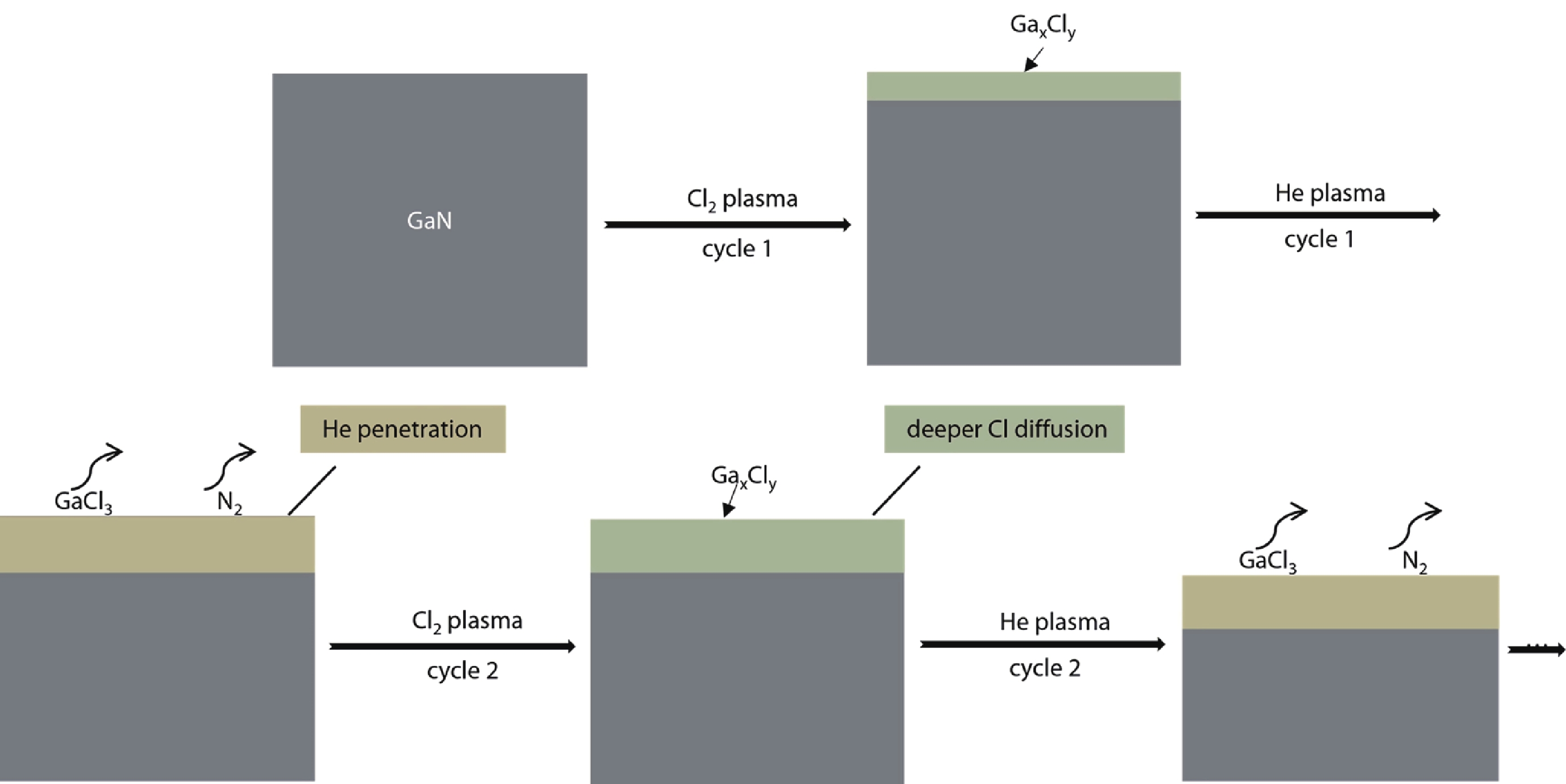

DownLoad: