| Citation: |

Luming Yu, Xun Wang, Zhibiao Hao, Yi Luo, Changzheng Sun, Bing Xiong, Yanjun Han, Jian Wang, Hongtao Li, Lin Gan, Lai Wang. Control of GaN inverted pyramids growth on c-plane patterned sapphire substrates[J]. Journal of Semiconductors, 2024, 45(6): 062501. doi: 10.1088/1674-4926/24010013

****

L M Yu, X Wang, Z B Hao, Y Luo, C Z Sun, B Xiong, Y J Han, J Wang, H T Li, L Gan, and L Wang, Control of GaN inverted pyramids growth on c-plane patterned sapphire substrates[J]. J. Semicond., 2024, 45(6), 062501 doi: 10.1088/1674-4926/24010013

|

Control of GaN inverted pyramids growth on c-plane patterned sapphire substrates

DOI: 10.1088/1674-4926/24010013

More Information

-

Abstract

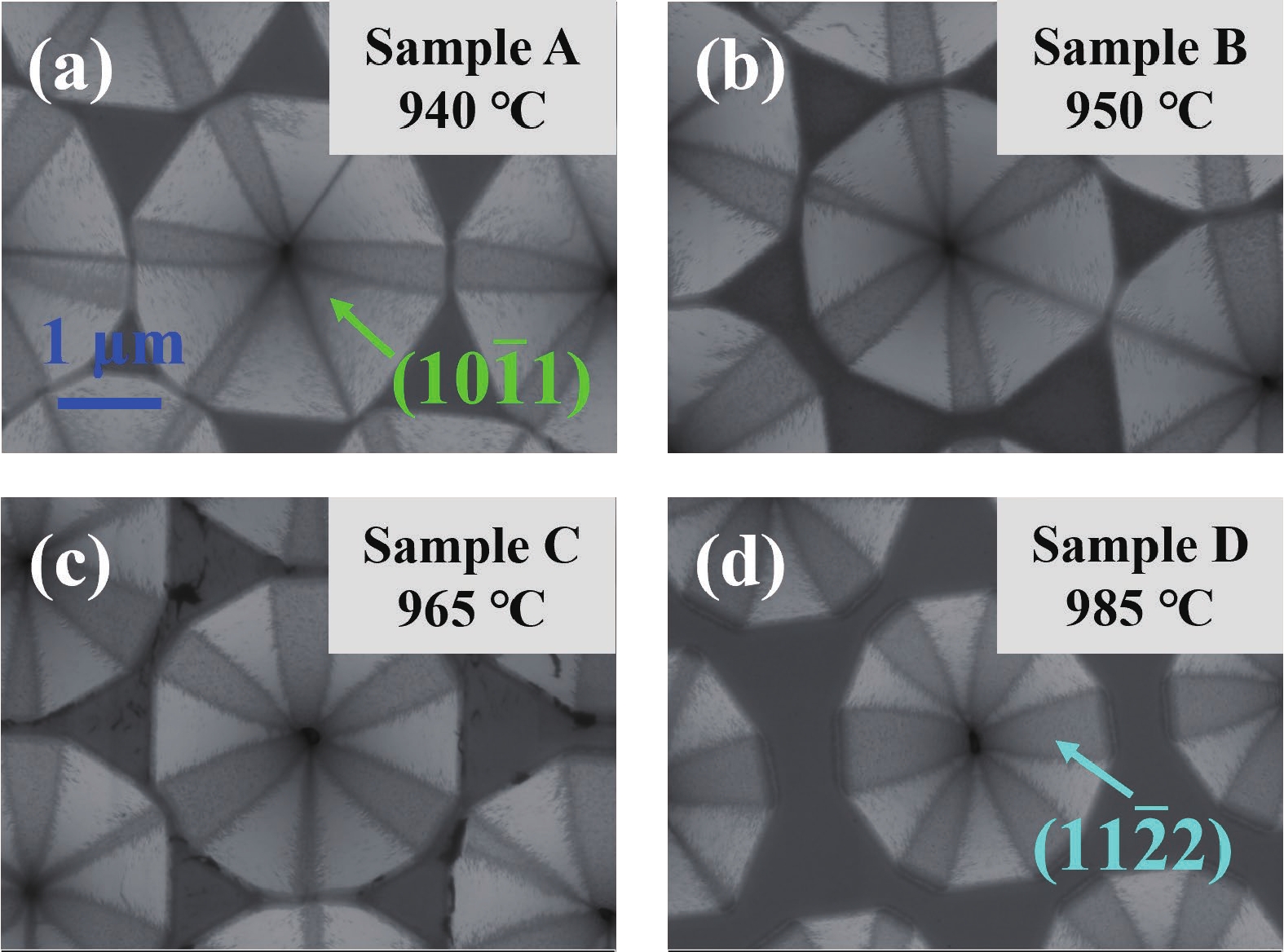

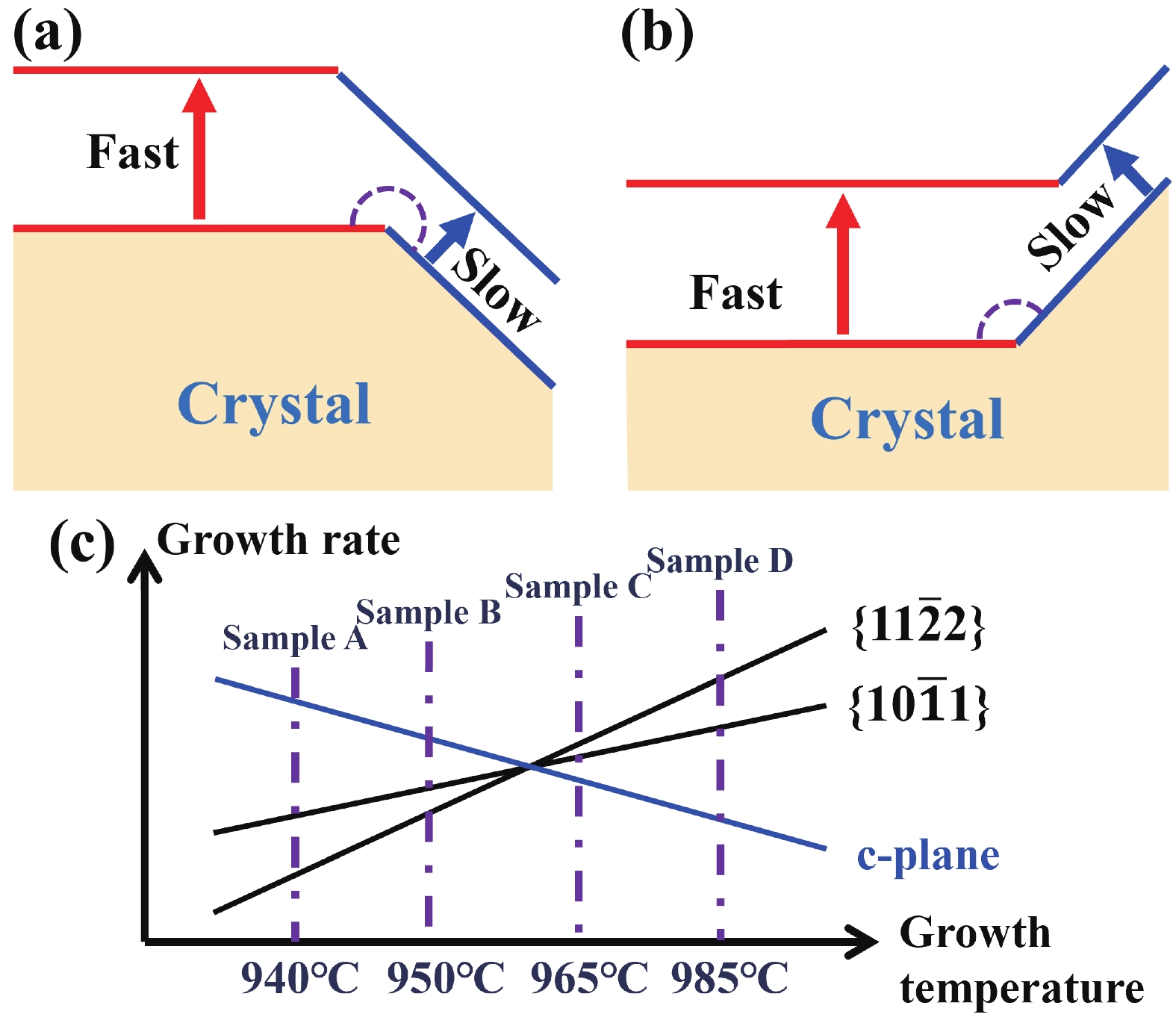

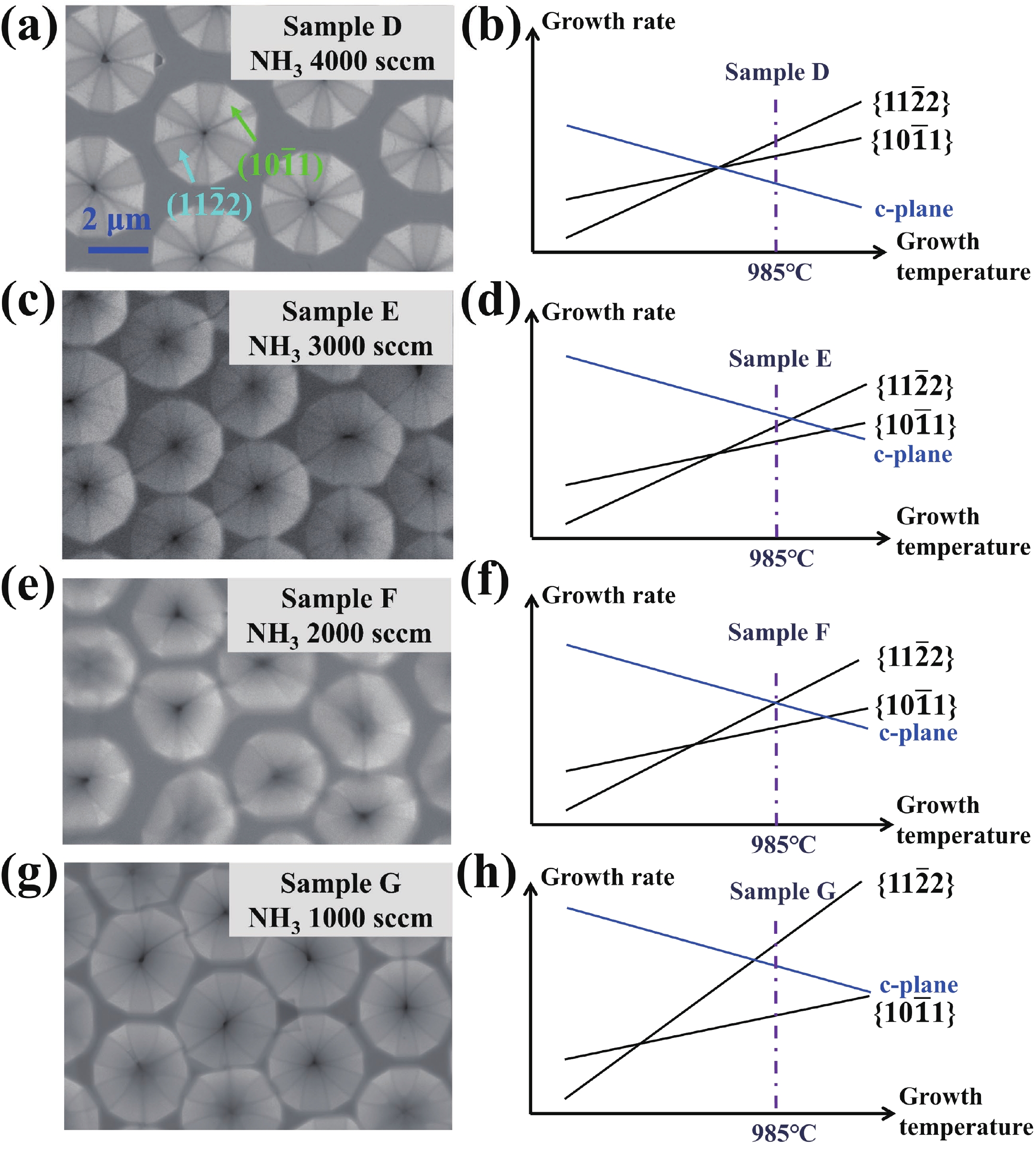

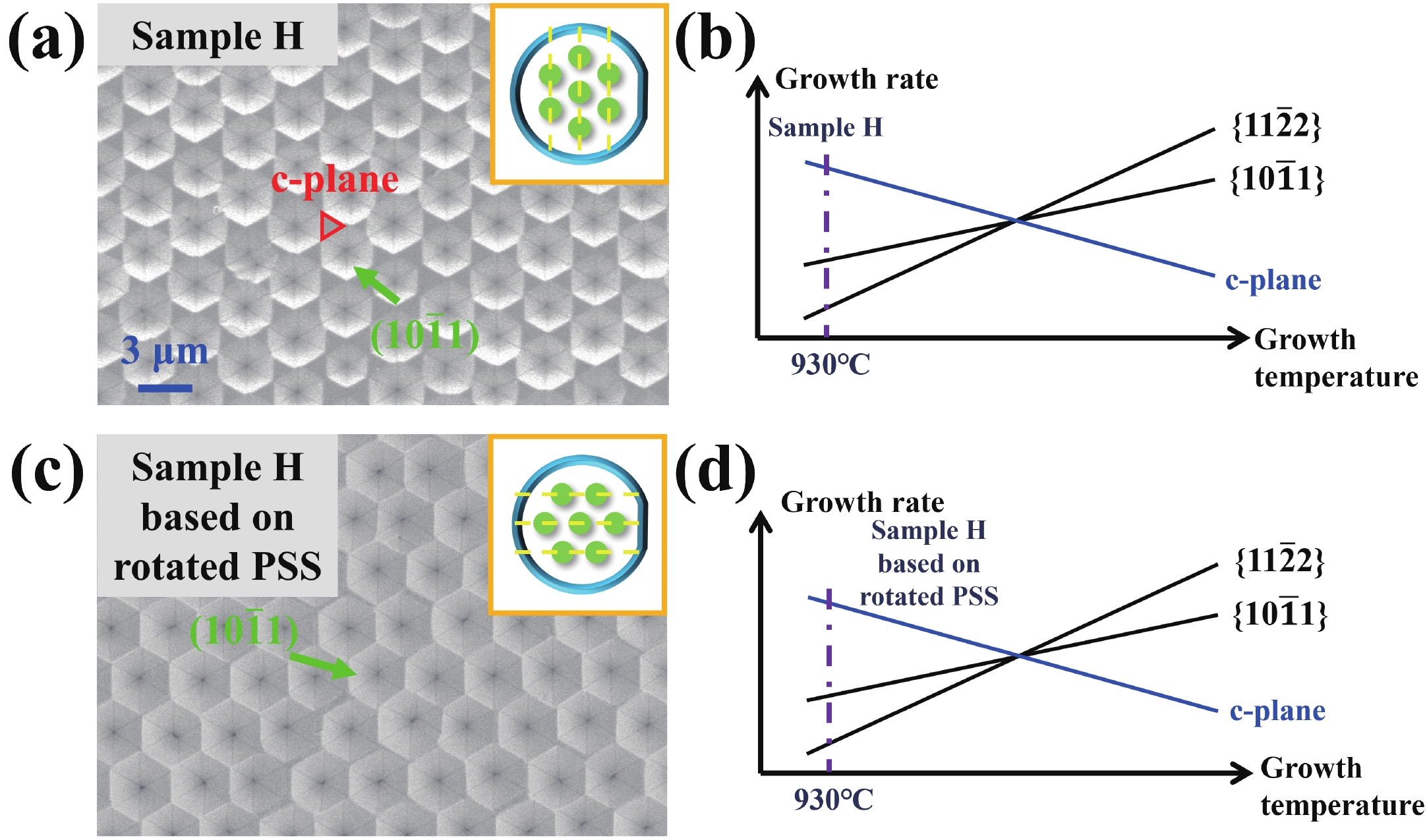

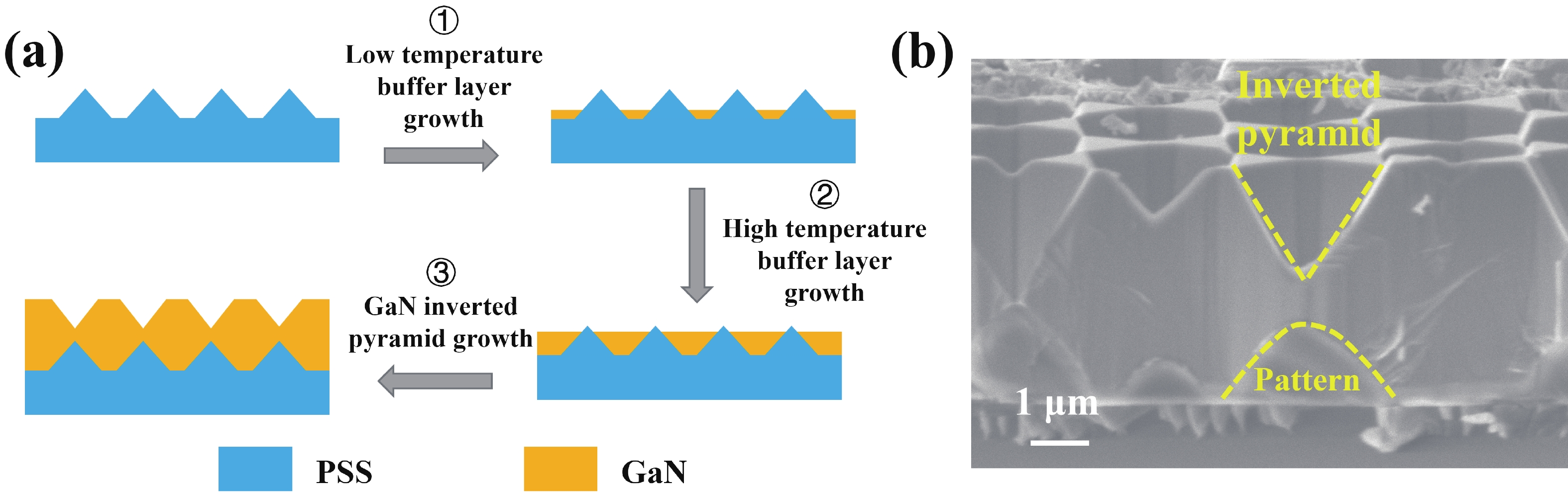

Growth of gallium nitride (GaN) inverted pyramids on c-plane sapphire substrates is benefit for fabricating novel devices as it forms the semipolar facets. In this work, GaN inverted pyramids are directly grown on c-plane patterned sapphire substrates (PSS) by metal organic vapor phase epitaxy (MOVPE). The influences of growth conditions on the surface morphology are experimentally studied and explained by Wulff constructions. The competition of growth rate among {0001}, {$ 10\bar{\text{1}}1 $}, and {$11 \bar{\text{2}}2 $} facets results in the various surface morphologies of GaN. A higher growth temperature of 985 °C and a lower Ⅴ/Ⅲ ratio of 25 can expand the area of {$ 11\bar{\text{2}}2 $} facets in GaN inverted pyramids. On the other hand, GaN inverted pyramids with almost pure {$10 \bar{\text{1}}1 $} facets are obtained by using a lower growth temperature of 930 °C, a higher Ⅴ/Ⅲ ratio of 100, and PSS with pattern arrangement perpendicular to the substrate primary flat.-

Keywords:

- inverted pyramids,

- GaN,

- MOVPE,

- crystal growth competition model

-

References

[1] Cai X L, Du C L, Sun Z X, et al. Recent progress of physical failure analysis of GaN HEMTs. J Semicond, 2021, 42, 051801 doi: 10.1088/1674-4926/42/5/051801[2] Meneghini M, De Santi C, Abid I, et al. GaN-based power devices: Physics, reliability, and perspectives. J Appl Phys, 2021, 130, 181101 doi: 10.1063/5.0061354[3] Li Y Q, Wang X W, Zhang N, et al. Improving the incorporation of indium component for InGaN-based green LED through inserting photonic crystalline in the GaN layer. J Semicond, 2022, 43, 072801 doi: 10.1088/1674-4926/43/7/072801[4] Liang F, Yang J, Zhao D G, et al. Room-temperature continuous-wave operation of GaN-based blue-violet laser diodes with a lifetime longer than 1000 H. J Semicond, 2019, 40, 022801 doi: 10.1088/1674-4926/40/2/022801[5] Liang F, Zhao D G, Liu Z S, et al. GaN-based blue laser diode with 6.0 W of output power under continuous-wave operation at room temperature. J Semicond, 2021, 42, 112801 doi: 10.1088/1674-4926/42/11/112801[6] Nakamura S. The roles of structural imperfections in InGaN-based blue light-emitting diodes and laser diodes. Science, 1998, 281, 955 doi: 10.1126/science.281.5379.956[7] Yang J, Zhao D G, Liu Z S, et al. A 357.9 nm GaN/AlGaN multiple quantum well ultraviolet laser diode. J Semicond, 2022, 43, 010501 doi: 10.1088/1674-4926/43/1/010501[8] Zhao D G. III-nitride based ultraviolet laser diodes. J Semicond, 2019, 40, 120402 doi: 10.1088/1674-4926/40/12/120402[9] Feezell D F, Schmidt M C, DenBaars S P, et al. Development of nonpolar and semipolar InGaN/GaN visible light-emitting diodes. MRS Bull, 2009, 34, 318 doi: 10.1557/mrs2009.93[10] Speck J S, Chichibu S F. Nonpolar and semipolar group III nitride-based materials. MRS Bull, 2009, 34, 304 doi: 10.1557/mrs2009.91[11] Cho J, Schubert E F, Kim J K. Efficiency droop in light-emitting diodes: Challenges and countermeasures. Laser Photonics Rev, 2013, 7, 408 doi: 10.1002/lpor.201200025[12] Xu C, Zheng C D, Wu X M, et al. Effects of V-pits covering layer position on the optoelectronic performance of InGaN green LEDs. J Semicond, 2019, 40, 052801 doi: 10.1088/1674-4926/40/5/052801[13] Rajabi K, Wang J X, Jin J, et al. Improving modulation bandwidth of c-plane GaN-based light-emitting diodes by an ultra-thin quantum wells design. Opt Express, 2018, 26, 24985 doi: 10.1364/OE.26.024985[14] Zhi T, Tao T, Liu X Y, et al. Low-threshold lasing in a plasmonic laser using nanoplate InGaN/GaN. J Semicond, 2021, 42, 122803 doi: 10.1088/1674-4926/42/12/122803[15] Peng R S, Xu S R, Fan X M, et al. Application of nano-patterned InGaN fabricated by self-assembled Ni nano-masks in green InGaN/GaN multiple quantum wells. J Semicond, 2023, 44, 042801 doi: 10.1088/1674-4926/44/4/042801[16] Wunderer T, Feneberg M, Lipski F, et al. Three-dimensional GaN for semipolar light emitters. Phys Status Solidi B, 2011, 248, 549 doi: 10.1002/pssb.201046352[17] Ward B L, Nam O H, Hartman J D, et al. Electron emission characteristics of GaN pyramid arrays grown via organometallic vapor phase epitaxy. J Appl Phys, 1998, 84, 5238 doi: 10.1063/1.368775[18] Scholz F, Wunderer T, Neubert B, et al. GaN-based light-emitting diodes on selectively grown semipolar crystal facets. MRS Bull, 2009, 34, 328 doi: 10.1557/mrs2009.95[19] Brubaker M D, Duff S M, Harvey T E, et al. Polarity-controlled GaN/AlN nucleation layers for selective-area growth of GaN nanowire arrays on Si(111) substrates by molecular beam epitaxy. Cryst Growth Des, 2016, 16, 596 doi: 10.1021/acs.cgd.5b00910[20] Wang L, Wang X, Bertram F, et al. Color-tunable 3D InGaN/GaN multi-quantum-well light-emitting-diode based on microfacet emission and programmable driving power supply. Adv Opt Mater, 2021, 9, 2001400 doi: 10.1002/adom.202001400[21] Herring C. Some theorems on the free energies of crystal surfaces. Phys Rev, 1951, 82, 87 doi: 10.1103/PhysRev.82.87[22] Hiramatsu K, Nishiyama K, Motogaito A, et al. Recent progress in selective area growth and epitaxial lateral overgrowth of III-nitrides: Effects of reactor pressure in MOVPE growth. Phys Stat Sol (a), 1999, 176, 535 doi: 10.1002/(SICI)1521-396X(199911)176:1<535::AID-PSSA535>3.0.CO;2-I[23] Kung P, Sun C J, Saxler A, et al. Crystallography of epitaxial growth of wurtzite-type thin films on sapphire substrates. J Appl Phys, 1994, 75, 4515 doi: 10.1063/1.355943 -

Proportional views

Luming Yu got his bachelor’s degree in 2019 from Department of Electronic Engineering of Tsinghua University. Now he is a doctoral student at Tsinghua University under the supervision of Prof. Lai Wang. His research focuses on MOCVD growth, quantum dots and Micro-LEDs for display and communication.

Luming Yu got his bachelor’s degree in 2019 from Department of Electronic Engineering of Tsinghua University. Now he is a doctoral student at Tsinghua University under the supervision of Prof. Lai Wang. His research focuses on MOCVD growth, quantum dots and Micro-LEDs for display and communication. Lai Wang received his bachelor's degree and doctor's degree respectively, both in the Department of Electronic Engineering of Tsinghua University in 2003 and 2008, respectively. His research interests include optoelectronic materials and devices based on wide-gap semiconductors, Micro-LEDs for display and communication, blue and green laser diodes, and in-sensor computing devices. He has published more than 150 SCI papers. In 2011, he won the second prize of National Science and Technology Progress Award. In 2022, he was supported by the National Science Fund for Distinguished Young Scholars.

Lai Wang received his bachelor's degree and doctor's degree respectively, both in the Department of Electronic Engineering of Tsinghua University in 2003 and 2008, respectively. His research interests include optoelectronic materials and devices based on wide-gap semiconductors, Micro-LEDs for display and communication, blue and green laser diodes, and in-sensor computing devices. He has published more than 150 SCI papers. In 2011, he won the second prize of National Science and Technology Progress Award. In 2022, he was supported by the National Science Fund for Distinguished Young Scholars.

DownLoad:

DownLoad: