| Citation: |

Lu Wang, Xulei Qin, Li Zhang, Kun Xu, Feng Yang, Shaoqian Lu, Yifei Li, Bosen Liu, Guohao Yu, Zhongming Zeng, Baoshun Zhang. Effects of gallium surfactant on AlN thin films by microwave plasma chemical vapor deposition[J]. Journal of Semiconductors, 2024, 45(9): 092501. doi: 10.1088/1674-4926/24020017

****

L Wang, X L Qin, L Zhang, K Xu, F Yang, S Q Lu, Y F Li, B S Liu, G H Yu, Z M Zeng, and B S Zhang, Effects of gallium surfactant on AlN thin films by microwave plasma chemical vapor deposition[J]. J. Semicond., 2024, 45(9), 092501 doi: 10.1088/1674-4926/24020017

|

Effects of gallium surfactant on AlN thin films by microwave plasma chemical vapor deposition

DOI: 10.1088/1674-4926/24020017

More Information

-

Abstract

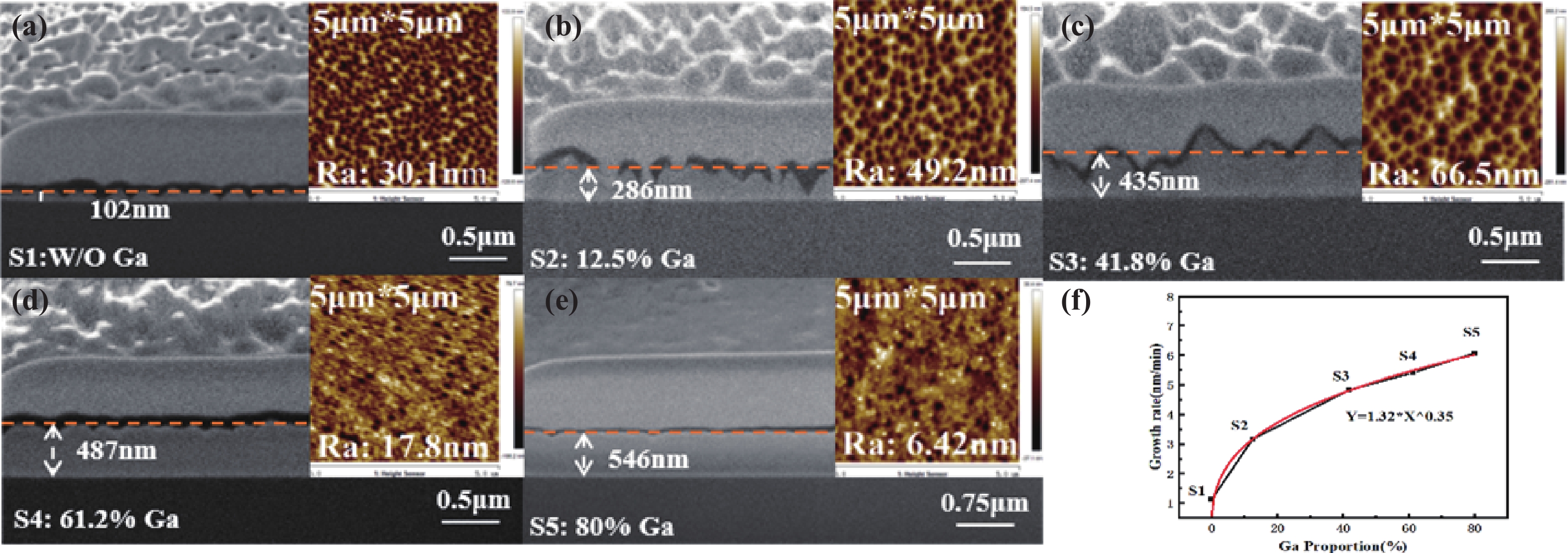

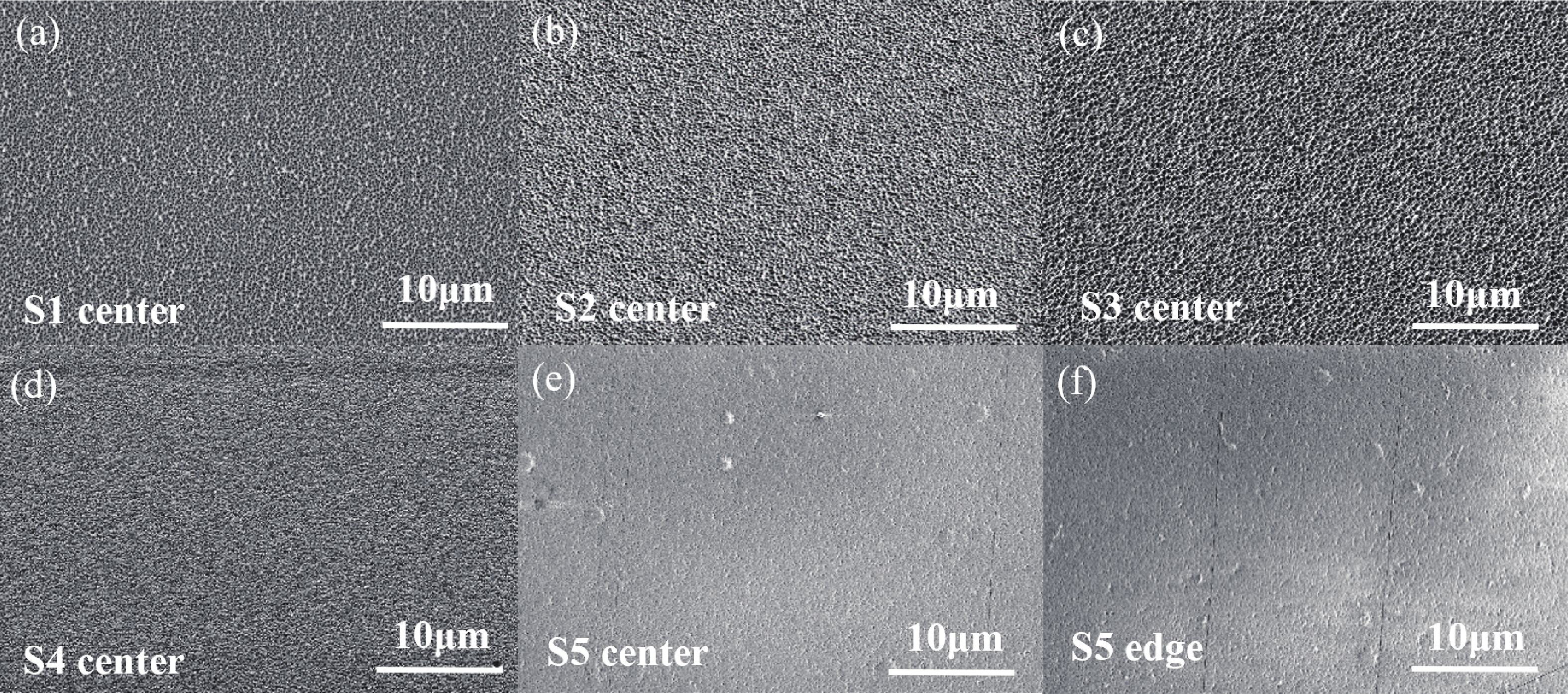

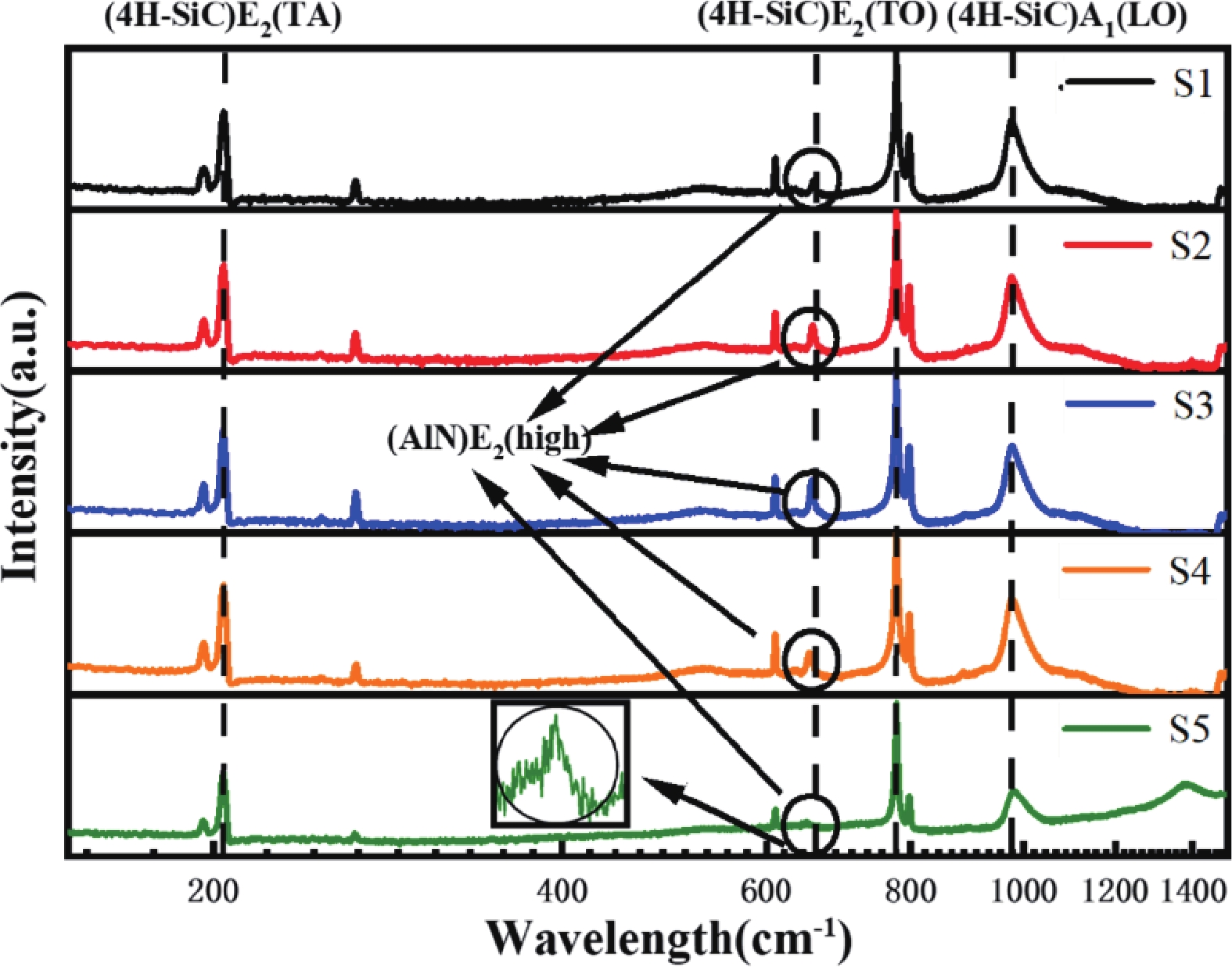

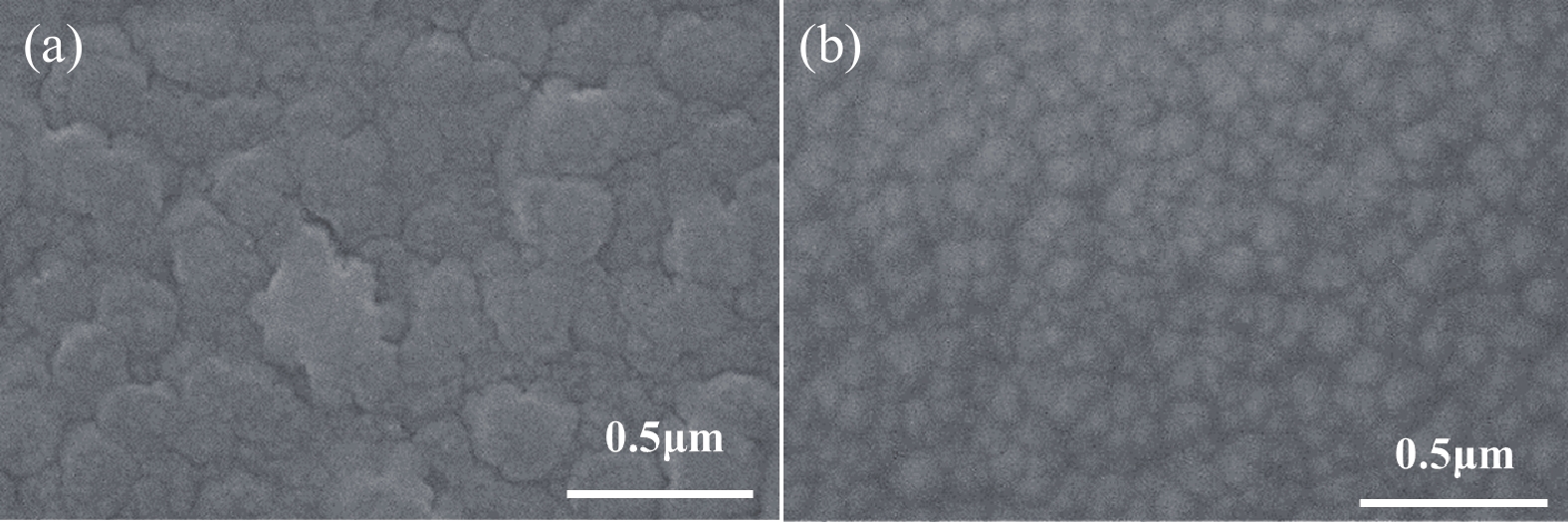

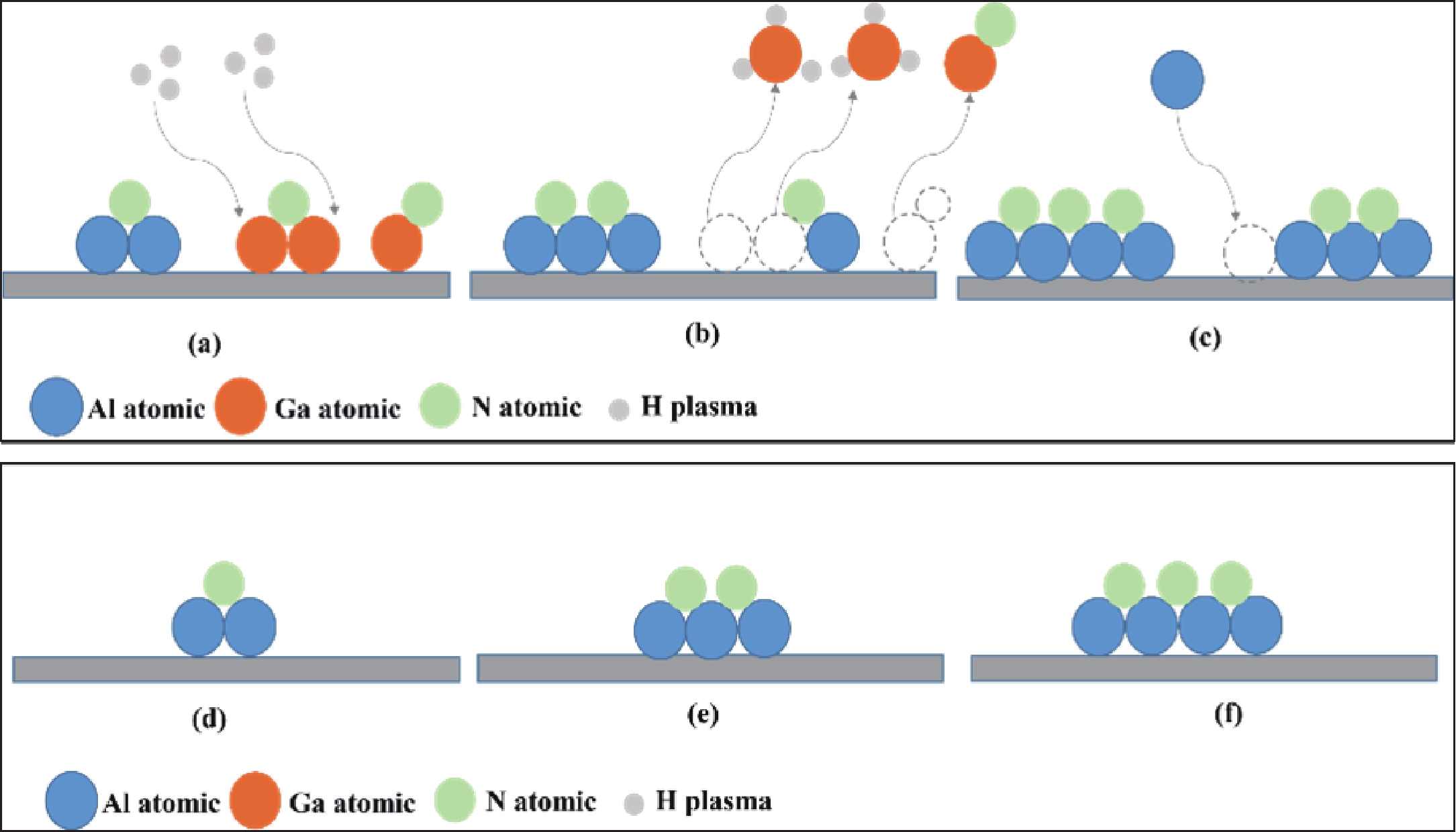

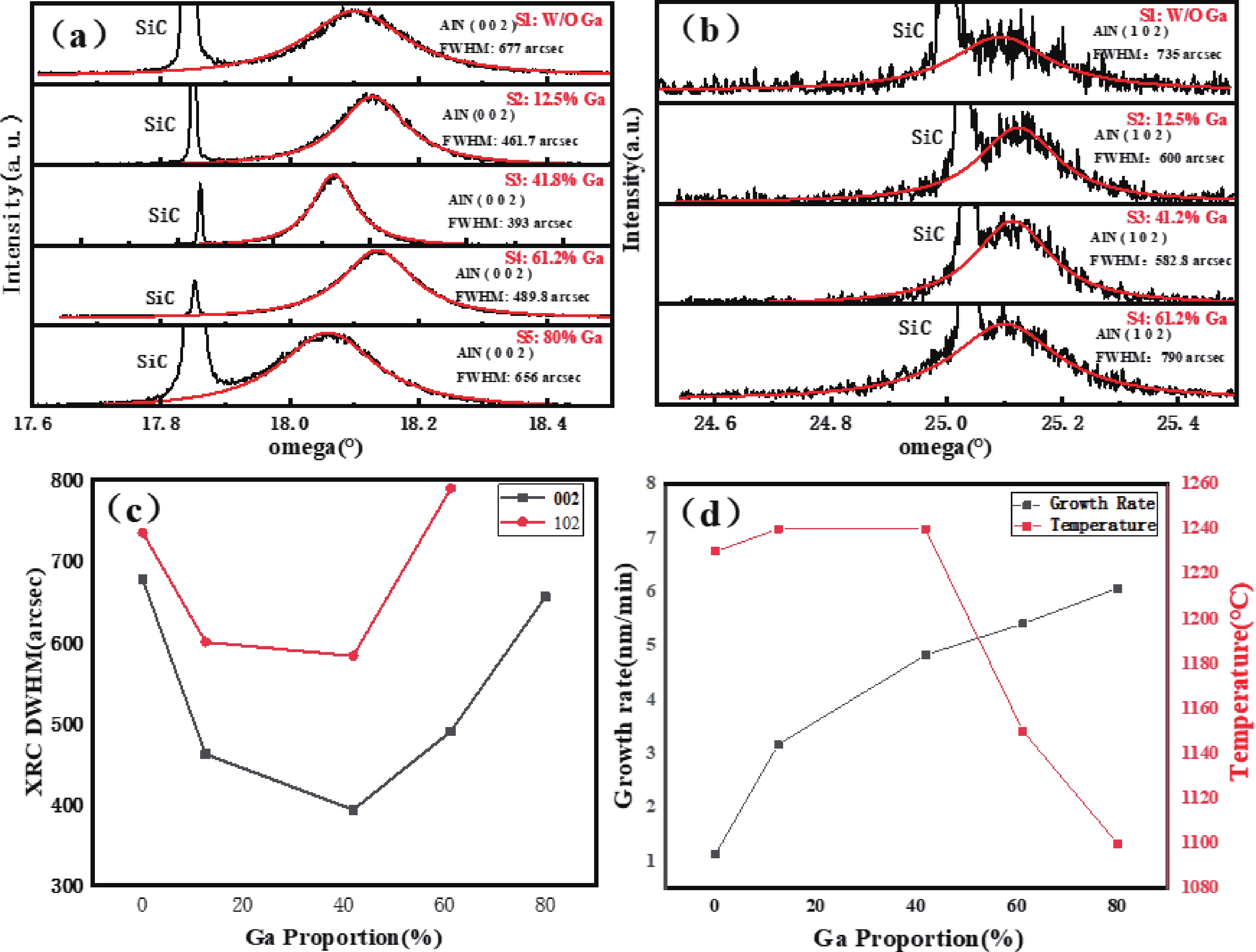

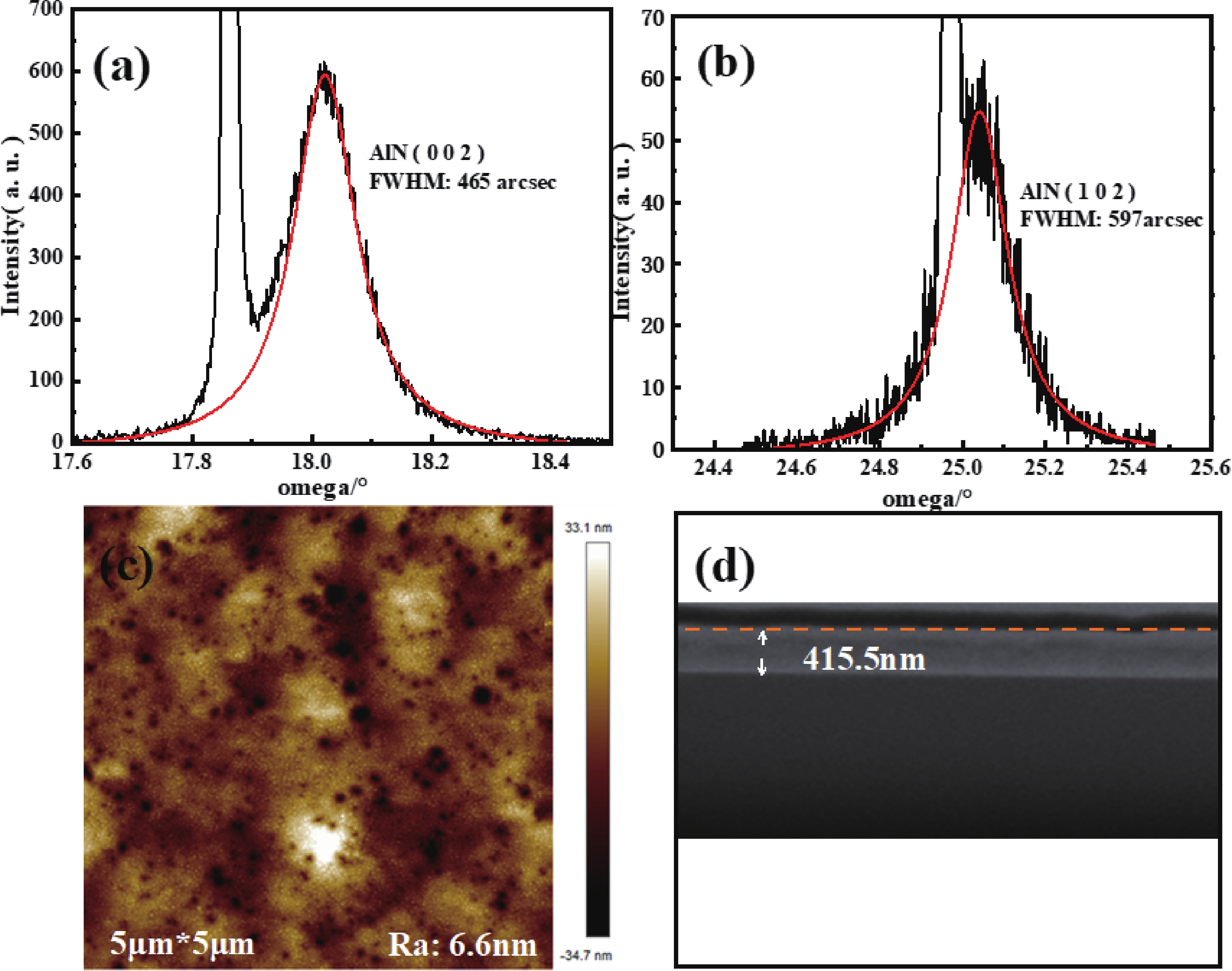

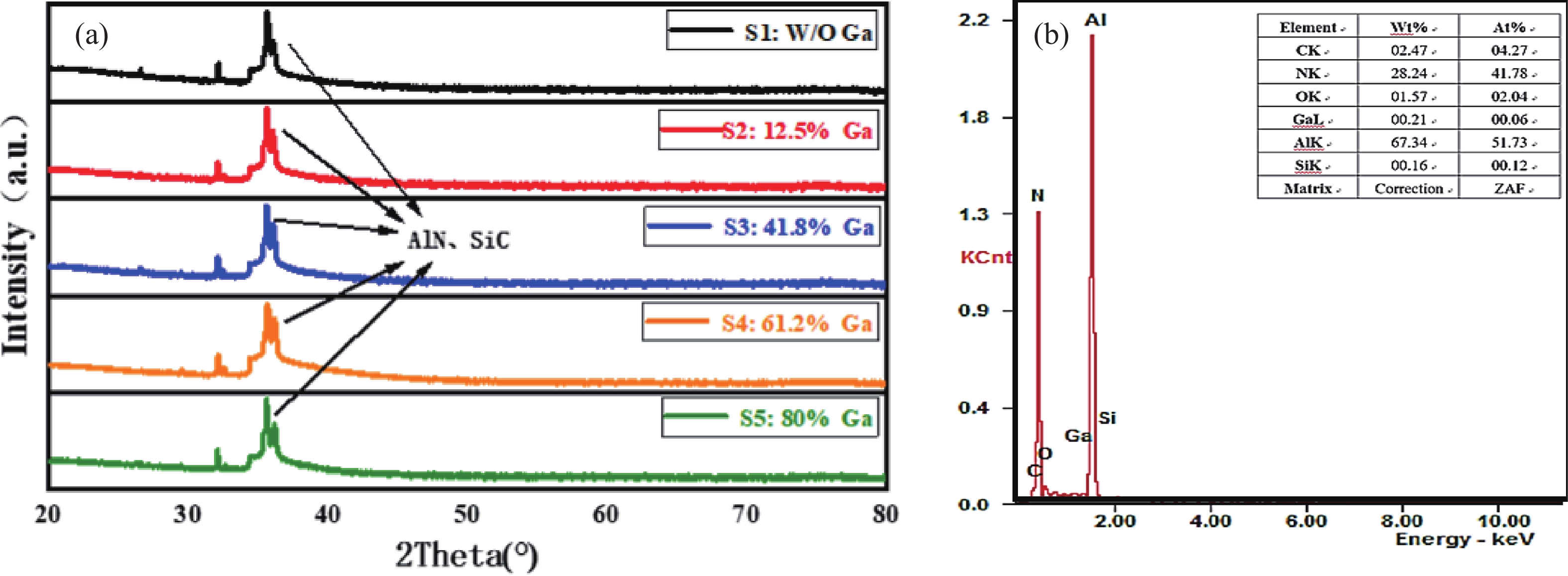

In this work, AlN films were grown using gallium (Ga) as surfactant on 4° off-axis 4H-SiC substrates via microwave plasma chemical vapor deposition (MPCVD). We have found that AlN growth rate can be greatly improved due to the catalytic effect of trimethyl-gallium (TMGa), but AlN crystal structure and composition are not affected. When the proportion of TMGa in gas phase was low, crystal quality of AlN can be improved and three-dimensional growth mode of AlN was enhanced with the increase of Ga source. When the proportion of TMGa in gas phase was high, two-dimensional growth mode of AlN was presented, with the increase of Ga source results in the deterioration of AlN crystal quality. Finally, employing a two-step growth approach, involving the initial growth of Ga-free AlN nucleation layer followed by Ga-assisted AlN growth, high quality of AlN film with flat surface was obtained and the full width at half maximum (FWHM) values of 415 nm AlN (002) and (102) planes were 465 and 597 arcsec.-

Keywords:

- AlN thin film,

- MPCVD,

- gallium surfactant,

- nucleation layer,

- laser

-

References

[1] Zhao L, Yang K, Ai Y J, et al. Crystal quality improvement of sputtered AlN film on sapphire substrate by high-temperature annealing. J Mater Sci Mater Electron, 2018, 29, 13766 doi: 10.1007/s10854-018-9507-0[2] Zollner C J, Almogbel A, Yao Y F, et al. Reduced dislocation density and residual tension in AlN grown on SiC by metalorganic chemical vapor deposition. Appl Phys Lett, 2019, 115, 161101 doi: 10.1063/1.5123623[3] Gautam L, Lee J, Brown G, et al. Low dark current deep UV AlGaN photodetectors on AlN substrate. IEEE J Quantum Electron, 2022, 58, 4000205 doi: 10.1109/JQE.2022.3154475[4] Grandusky J R, Cui Y J, Mendrick M C, et al. Reliability and performance of pseudomorphic ultraviolet light emitting diodes on bulk aluminum nitride substrates. Phys Status Solidi C, 2011, 8(5), 1528 doi: 10.1002/pssc.201000892[5] Wei M, Liu Y, Qu Y H, et al. Development of temperature sensor based on AlN/ScAlN SAW resonators. Electronics, 2023, 12, 3863 doi: 10.3390/electronics12183863[6] Chirumamilla M, Krekeler T, Wang D Y, et al. Magnetron sputter deposition of nanostructured AlN thin films. Appl Nano, 2023, 4, 280 doi: 10.3390/applnano4040016[7] McLeod A J, Ueda S T, Lee P C, et al. Pulsed chemical vapor deposition for crystalline aluminum nitride thin films and buffer layers on silicon and silicon carbide. Thin Solid Films, 2023, 768, 139717 doi: 10.1016/j.tsf.2023.139717[8] Wang E D, Zhang H, Xie X J, et al. AlN thin films grown on different substrates by metal nitride vapor phase epitaxy. Cryst Res Technol, 2023, 58, 2200196 doi: 10.1002/crat.202200196[9] Hu J Z, Yan L, Zhou N, et al. Study of AlN growth using AMEC Prismo HiT3 MOCVD reactor. J Cryst Growth, 2024, 626, 127463 doi: 10.1016/j.jcrysgro.2023.127463[10] Li D B, Jiang K, Sun X J, et al. AlGaN photonics: Recent advances in materials and ultraviolet devices. Adv Opt Photonics, 2018, 10, 43 doi: 10.1364/AOP.10.000043[11] Kneissl M, Seong T Y, Han J, et al. The emergence and prospects of deep-ultraviolet light-emitting diode technologies. Nat Photonics, 2019, 13, 233 doi: 10.1038/s41566-019-0359-9[12] Amano H, Collazo R, De Santi C, et al. The 2020 UV emitter roadmap. J Phys D Appl Phys, 2020, 53, 503001 doi: 10.1088/1361-6463/aba64c[13] Zhang Q H, Parimoo H, Martel E, et al. Vertical semiconductor deep ultraviolet light emitting diodes on a nanowire-assisted aluminum nitride buffer layer. Sci Rep, 2022, 12, 7230 doi: 10.1038/s41598-022-11246-0[14] Nallusamy N, Singhal R, Sharma S K, et al. High-electron-mobility transistor-inspired freestanding AlGaN/GaN/AlN optical waveguide for high-pressure sensing applications. Phys Status Solidi A, 2023, 220, 2200637 doi: 10.1002/pssa.202200637[15] Honda H, Umeda S, Shojiki K, et al. 229 nm far-ultraviolet second harmonic generation in a vertical polarity inverted AlN bilayer channel waveguide. Appl Phys Express, 2023, 16, 062006 doi: 10.35848/1882-0786/acda79[16] Wang X J, Zhao S, Fang H H, et al. Quantum emitters with narrow band and high debye–waller factor in aluminum nitride written by femtosecond laser. Nano Lett, 2023, 23, 2743 doi: 10.1021/acs.nanolett.3c00019[17] Lin B H, Cai Y, Wang Y X, et al. Effects of growth temperature and reactor pressure on AlN thin film grown by metal-organic chemical vapor deposition. Thin Solid Films, 2023, 783, 140037 doi: 10.1016/j.tsf.2023.140037[18] Shojiki K, Uesugi K, Xiao S Y, et al. Polarity control of sputter-deposited AlN with high-temperature face-to-face annealing. Mater Sci Semicond Process, 2023, 166, 107736 doi: 10.1016/j.mssp.2023.107736[19] Seredin P V, Goloshchapov D L, Kurilo N A, et al. Comparative studies of nanoscale columnar AlxGa1-xN/AlN heterostructures grown by plasma-assisted molecular-beam epitaxy on cSi, porSi/cSi and SiC/porSi/cSi substrates. Opt Mater, 2023, 145, 114451 doi: 10.1016/j.optmat.2023.114451[20] Saha R, Anderson J, Holtz M W, et al. Atomic layer deposition of Al2O3 interlayer for improving AlN growth on silicon substrates. J Vac Sci Technol A Vac Surf Films, 2023, 41, 053208 doi: 10.1116/6.0002760[21] Raghuvansy S, McCandless J P, Schowalter M, et al. Growth of β-Ga2O3 and ϵ/κ-Ga2O3 on AlN(0001) by molecular-beam epitaxy. APL Mater, 2023, 11, 111113 doi: 10.1063/5.0174373[22] Zhang Y, Xing Y H, Han J, et al. Improving AlN crystalline quality by high-temperature ammonia-free microwave plasma chemical vapor deposition. Appl Phys Express, 2021, 14, 055503 doi: 10.35848/1882-0786/abf31a[23] Xing Y H, Dong S Y, Zhang X, et al. Effect of H plasma treatment of the nucleation layer on AlN epitaxy in microwave plasma chemical vapor deposition. Cryst Growth Des, 2023, 23, 2257 doi: 10.1021/acs.cgd.2c01307[24] Grandjean N, Massies J, Etgens V H. Delayed relaxation by surfactant action in highly strained III-V semiconductor epitaxial layers. Phys Rev Lett, 1992, 69, 796 doi: 10.1103/PhysRevLett.69.796[25] Keller S, Heikman S, Ben-Yaacov I, et al. Indium surfactant assisted growth of AlN/GaN heterostructures by metal-organic chemical vapor deposition. Phys Status Solidi Appl Res, 2001, 188, 775 doi: 10.1002/1521-396X(200112)188:2<775::AID-PSSA775>3.0.CO;2-S[26] Nicolay S, Feltin E, Carlin J F, et al. Indium surfactant effect on AlN∕GaN heterostructures grown by metal-organic vapor-phase epitaxy: Applications to intersubband transitions. Appl Phys Lett, 2006, 88, 151902 doi: 10.1063/1.2186971[27] Rodak L E, Miller C M, Korakakis D. Surfactant effects of indium on cracking in AlN/GaN distributed Bragg reflectors grown via metal organic vapor phase epitaxy. Superlattices Microstruct, 2011, 49, 52 doi: 10.1016/j.spmi.2010.11.001[28] Neugebauer J. Surfactants and antisurfactants on group-III-nitride surfaces. Phys Status Solidi C, 2003, 6, 1651 doi: 10.1002/pssc.200303132[29] Zhao Z F, Li Y, Xia X J, et al. Growth of high-quality 4H-SiC epitaxial layers on 4° off-axis C-face 4H-SiC substrates. J Cryst Growth, 2020, 531, 125355 doi: 10.1016/j.jcrysgro.2019.125355[30] Galizia B, Fiorenza P, Bongiorno C, et al. Structural and electrical correlation in aluminum nitride thin films grown by plasma enhanced atomic layer deposition as interface insulating layers on silicon carbide (4H-SiC). Microelectron Eng, 2024, 283, 112103 doi: 10.1016/j.mee.2023.112103[31] Narang K, Pandey A, Khan R, et al. High-quality AlN nucleation layer on SiC substrate grown by MOVPE: Growth, structural and optical characteristics. Mater Sci Eng B, 2022, 278, 115635 doi: 10.1016/j.mseb.2022.115635[32] Wang P, Wang D, Bi Y T, et al. Quaternary alloy ScAlGaN: A promising strategy to improve the quality of ScAlN. Appl Phys Lett, 2022, 120, 012104 doi: 10.1063/5.0060608[33] Wang H, Li S L, Xiong H, et al. The effect of AlN nucleation temperature on the growth of AlN films via metalorganic chemical vapor deposition. J Electron Mater, 2012, 41, 466 doi: 10.1007/s11664-011-1798-3[34] Cho E, Mogilatenko A, Brunner F, et al. Impact of AlN nucleation layer on strain in GaN grown on 4H-SiC substrates. J Cryst Growth, 2013, 371, 45 doi: 10.1016/j.jcrysgro.2013.02.001[35] Zhang L, Li J S, Deng X G, et al. Effect of V–III ratio based growth mode on the surface morphology, strain relaxation, and dislocation density of AlN films grown by MOCVD. Phys Status Solidi B, 2022, 260, 2200279 doi: 10.1002/pssb.202200279[36] Chang H L, Liu Z T, Yang S Y, et al. Graphene-driving strain engineering to enable strain-free epitaxy of AlN film for deep ultraviolet light-emitting diode. Light Sci Appl, 2022, 11, 88 doi: 10.1038/s41377-022-00756-1[37] Birgit S, Jerry H, Morse Daniel E. Correlated compositions, structures, and photoluminescence properties of gallium nitride nanoparticles. Adv Mater Deerfield Beach Fla, 2011, 23, 2278 doi: 10.1002/adma.201003750[38] Frenklach M. The role of hydrogen in vapor deposition of diamond. J Appl Phys, 1989, 65, 5142 doi: 10.1063/1.343193[39] Laurent M A, Malakoutian M, Chowdhury S. A study on the nucleation and MPCVD growth of thin, dense, and contiguous nanocrystalline diamond films on bare and Si3N4-coated N-polar GaN. Semicond Sci Technol, 2020, 35, 015003 doi: 10.1088/1361-6641/ab4f16[40] Sekiguchi K, Shirakawa H, Chokawa K, et al. Thermodynamic analysis of trimethylgallium decomposition during GaN metal organic vapor phase epitaxy. Jpn J Appl Phys, 2018, 57, 04FJ03 doi: 10.7567/JJAP.57.04FJ03[41] Wang B, Weng J, Wang Z T, et al. Investigation on the influence of the gas flow mode around substrate on the deposition of diamond films in an overmoded MPCVD reactor chamber. Vacuum, 2020, 182, 109659 doi: 10.1016/j.vacuum.2020.109659[42] Chen Q S, Gao J H, Chen C, et al. Evolution of dislocations and strains in AlN grown by high-temperature metal–organic chemical vapor deposition. Cryst Growth Des, 2024, 24, 1784 doi: 10.1021/acs.cgd.3c01450[43] Li X H, Wei Y O, Wang S, et al. Temperature dependence of the crystalline quality of AlN layer grown on sapphire substrates by metalorganic chemical vapor deposition. J Cryst Growth, 2015, 414, 76 doi: 10.1016/j.jcrysgro.2014.10.007 -

Proportional views

Lu Wang Wang Lu obtained her Bachelor's degree from Heilongjiang University in 2021. She is currently a Master's student at Changchun University of Science and Technology, under the supervision of Professor Xulei Qin. Her research focuses on the study of GaN laser interfaces and the characteristics of their buffer layers.

Lu Wang Wang Lu obtained her Bachelor's degree from Heilongjiang University in 2021. She is currently a Master's student at Changchun University of Science and Technology, under the supervision of Professor Xulei Qin. Her research focuses on the study of GaN laser interfaces and the characteristics of their buffer layers. Xulei Qin received his PhD degree from Changchun University of Science and Technology in 2015. Currently, he is an associate professor at Changchun University of Science and Technology. His main research interests include optoelectronic thin film materials and imaging devices.

Xulei Qin received his PhD degree from Changchun University of Science and Technology in 2015. Currently, he is an associate professor at Changchun University of Science and Technology. His main research interests include optoelectronic thin film materials and imaging devices. Li Zhang received her M.S. degree from Nanjing University. In 2014, she joined in HC Photoelectric Co., LTD and engaged in LED epitaxial process development. Then she joined in Suzhou Institute of Nano-Tech and Nano-Bionics (Sinano), Chinese Academy of Sciences in 2017, and focuses on ultra wide band gap semiconductor materials epitaxy using MOCVD and related device fabrication.

Li Zhang received her M.S. degree from Nanjing University. In 2014, she joined in HC Photoelectric Co., LTD and engaged in LED epitaxial process development. Then she joined in Suzhou Institute of Nano-Tech and Nano-Bionics (Sinano), Chinese Academy of Sciences in 2017, and focuses on ultra wide band gap semiconductor materials epitaxy using MOCVD and related device fabrication. Baoshun Zhang received his BS degree from Changchun University of Science and Technology in 1994 and his PhD degree from the Institute of Semiconductors, Chinese Academy of Sciences in 2003. Then he joined in Hong Kong University of Science and Technology. Currently, he is a researcher at Suzhou Institute of Nano-Tech and Nano-Bionics, Chinese Academy of Sciences, and his research interests include semiconductor material growth and device technology research.

Baoshun Zhang received his BS degree from Changchun University of Science and Technology in 1994 and his PhD degree from the Institute of Semiconductors, Chinese Academy of Sciences in 2003. Then he joined in Hong Kong University of Science and Technology. Currently, he is a researcher at Suzhou Institute of Nano-Tech and Nano-Bionics, Chinese Academy of Sciences, and his research interests include semiconductor material growth and device technology research.

DownLoad:

DownLoad: