| Citation: |

Yan Pei, Wenhao Geng, Lingbo Xu, Can Cui, Xiaodong Pi, Deren Yang, Rong Wang. Demonstration of irradiation-resistant 4H-SiC based photoelectrochemical water splitting[J]. Journal of Semiconductors, 2024, 45(11): 112503. doi: 10.1088/1674-4926/24050011

****

Y Pei, W H Geng, L B Xu, C Cui, X D Pi, D R Yang, and R Wang, Demonstration of irradiation-resistant 4H-SiC based photoelectrochemical water splitting[J]. J. Semicond., 2024, 45(11), 112503 doi: 10.1088/1674-4926/24050011

|

Demonstration of irradiation-resistant 4H-SiC based photoelectrochemical water splitting

DOI: 10.1088/1674-4926/24050011

More Information

-

Abstract

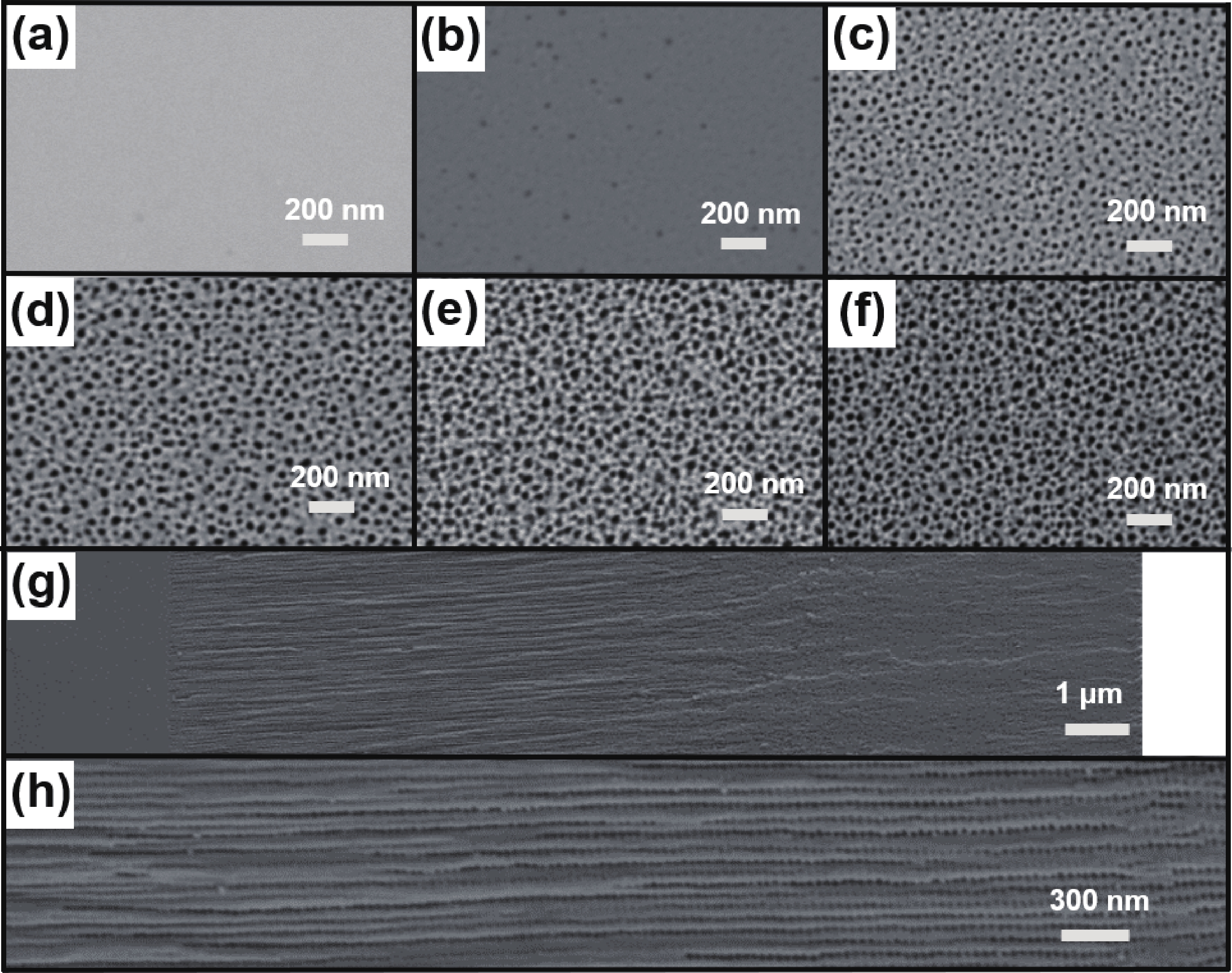

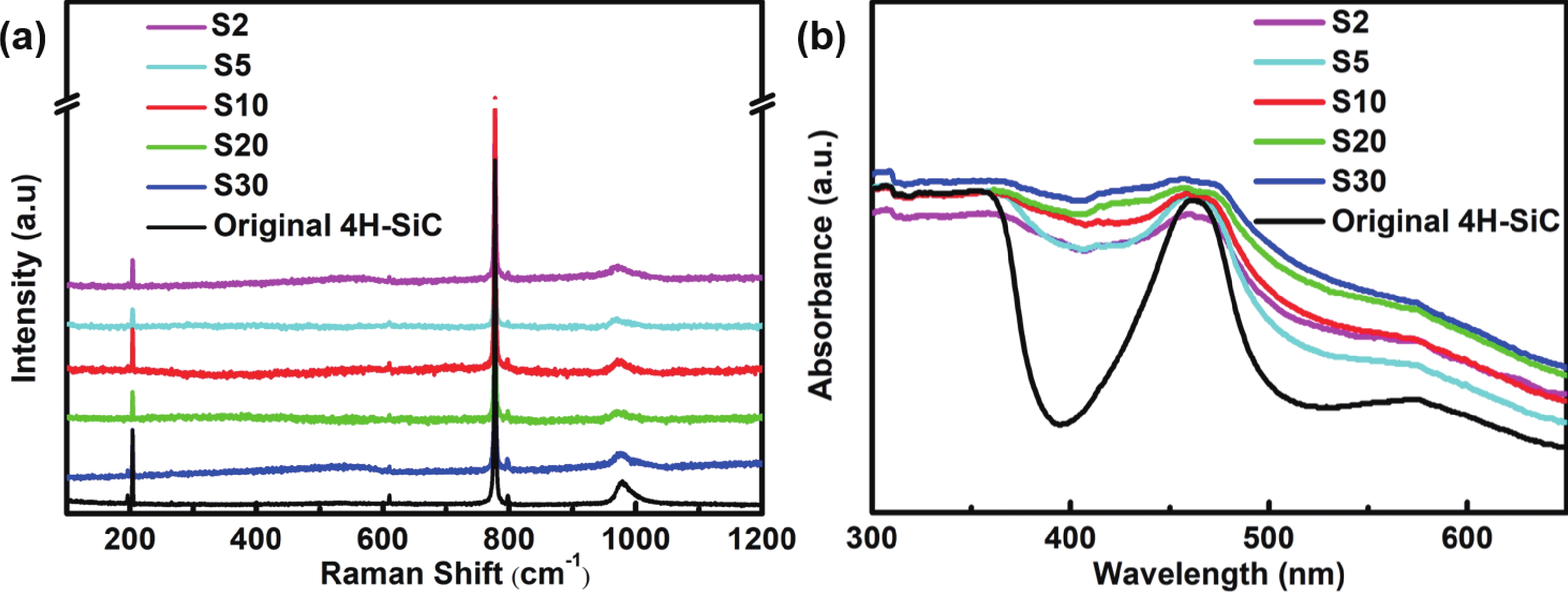

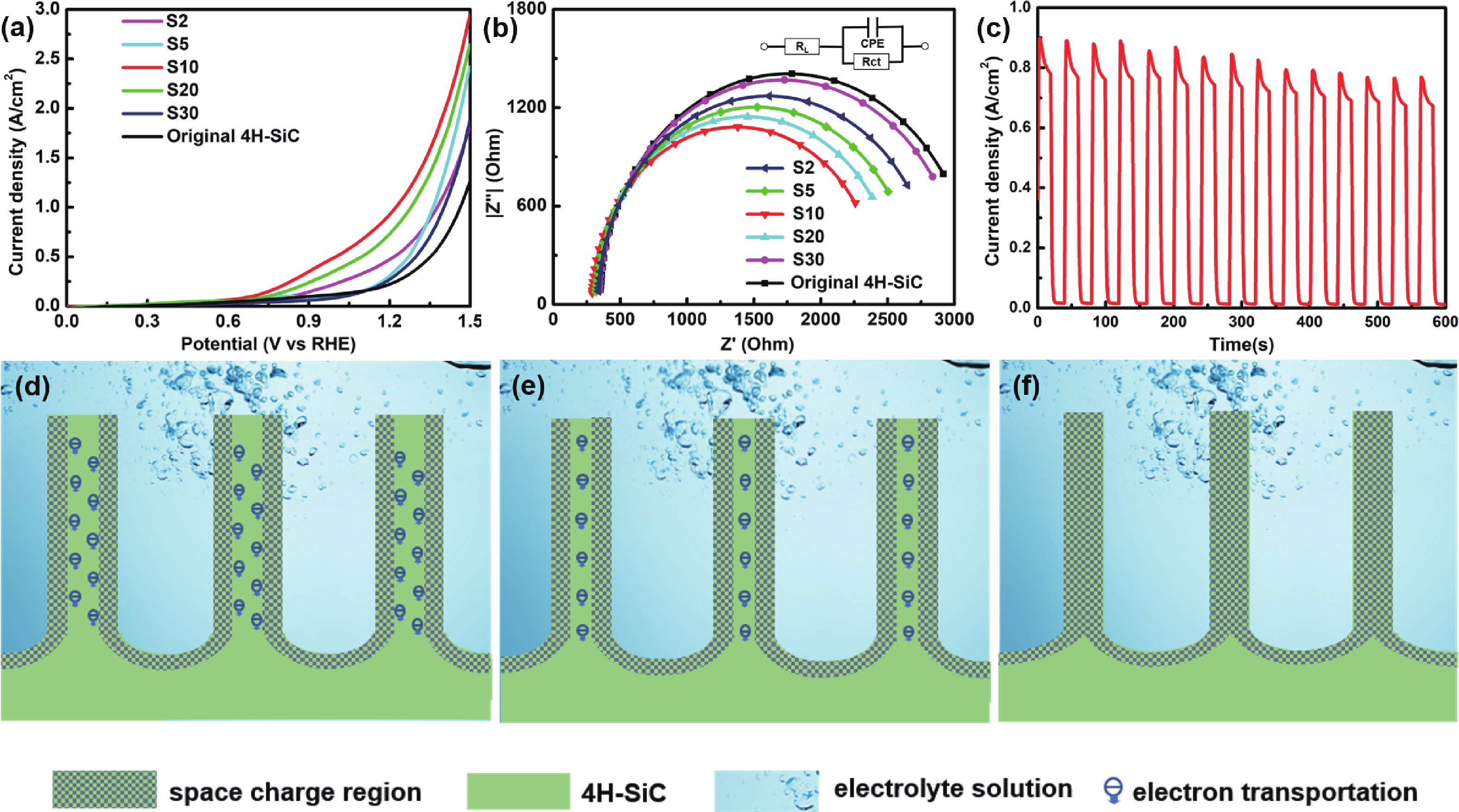

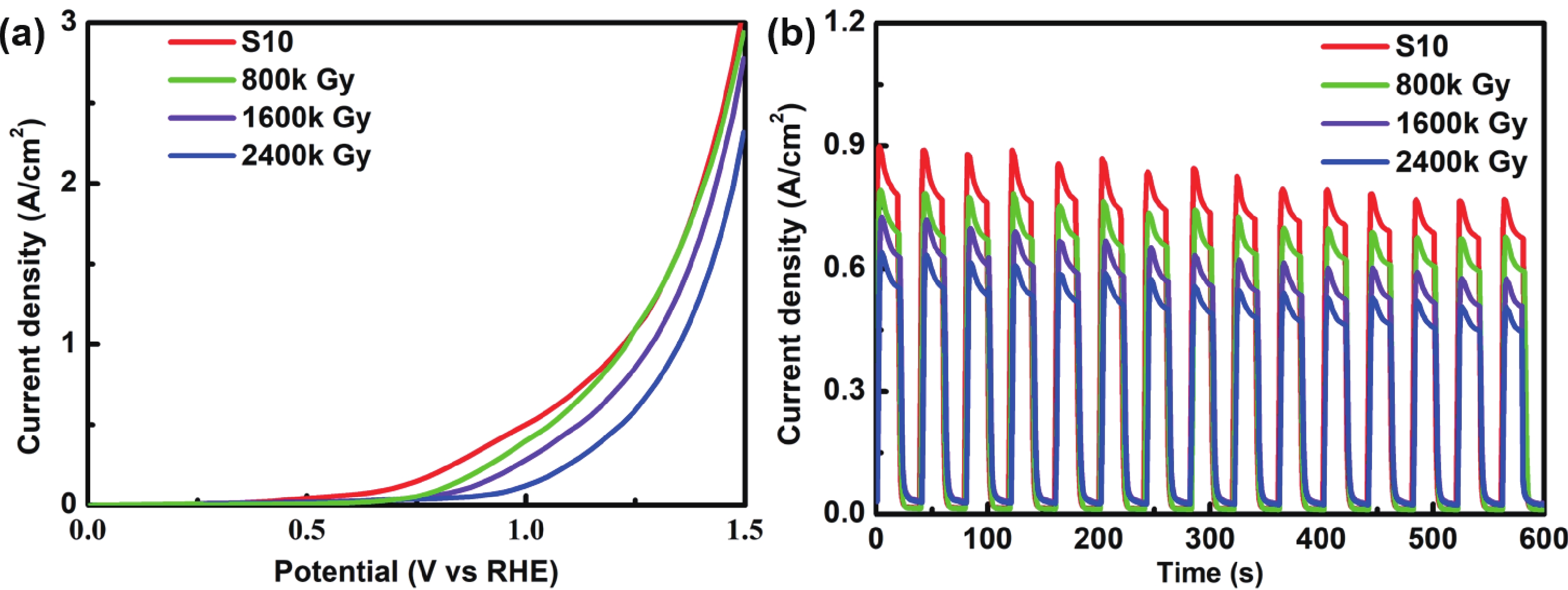

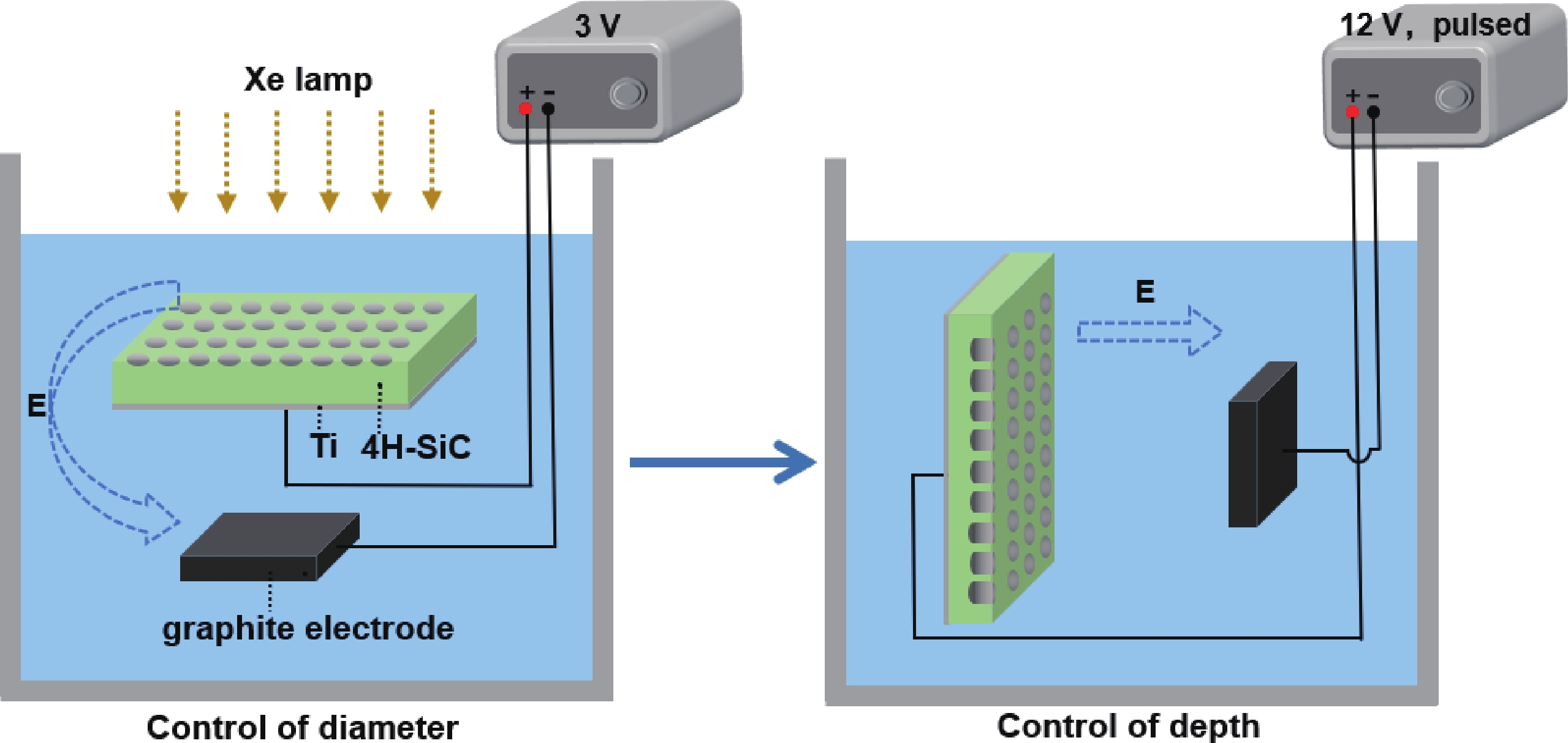

4H silicon carbide (4H-SiC) has gained a great success in high-power electronics, owing to its advantages of wide bandgap, high breakdown electric field strength, high carrier mobility, and high thermal conductivity. Considering the high carrier mobility and high stability of 4H-SiC, 4H-SiC has great potential in the field of photoelectrochemical (PEC) water splitting. In this work, we demonstrate the irradiation-resistant PEC water splitting based on nanoporous 4H-SiC arrays. A new two-step anodizing approach is adopted to prepare 4H-SiC nanoporous arrays with different porosity, that is, a constant low-voltage etching followed by a pulsed high-voltage etching. The constant-voltage etching and pulsed-voltage etching are adopted to control the diameter of the nanopores and the depth of the nanoporous arrays, respectively. It is found that the nanoporous arrays with medium porosity has the highest PEC current, because of the enhanced light absorption and the optimized transportation of charge carriers along the walls of the nanoporous arrays. The performance of the PEC water splitting of the nanoporous arrays is stable after the electron irradiation with the dose of 800 and 1600 kGy, which indicates that 4H-SiC nanoporous arrays has great potential in the PEC water splitting under harsh environments.-

Keywords:

- 4H-SiC,

- nanoporous arrays,

- water splitting,

- irradiation resistance,

- photoanodes

-

References

[1] Endo N, Goshome K, Tetsuhiko M, et al. Thermal management and power saving operations for improved energy efficiency within a renewable hydrogen energy system utilizing metal hydride hydrogen storage. Int J Hydrogen Energ, 2021, 46, 262 doi: 10.1016/j.ijhydene.2020.10.002[2] Singh R, Altaee A, Gautam S. Nanomaterials in the advancement of hydrogen energy storage. Heliyon, 2020, 6, e04487 doi: 10.1016/j.heliyon.2020.e04487[3] Tarhan C, Çil M A. A study on hydrogen, the clean energy of the future: Hydrogen storage methods. J Energy Storage, 2021, 40, 102676 doi: 10.1016/j.est.2021.102676[4] Farrell A E, Keith D W, Corbett J J. A strategy for introducing hydrogen into transportation. Energy Policy, 2003, 31, 1357 doi: 10.1016/S0301-4215(02)00195-7[5] Murray L J, Dinca M, Long J R. Hydrogen storage in metal-organic frameworks. Chem Soc Rev, 2009, 38, 1294 doi: 10.1039/b802256a[6] Zhang C, Shao M, Ning F, et al. Au nanoparticles sensitized ZnO nanorod@nanoplatelet core–shell arrays for enhanced photoelectrochemical water splitting. Nano Energy, 2015, 12, 231 doi: 10.1016/j.nanoen.2014.12.037[7] Fang X, Wu L, Hu L. ZnS nanostructure arrays: A developing material star. Adv Mater, 2011, 23, 585 doi: 10.1002/adma.201003624[8] Mi Y, Wen L, Xu R, et al. Constructing a AZO/TiO2 core/shell nanocone array with uniformly dispersed au nps for enhancing photoelectrochemical water splitting. Adv Energy Mater, 2016, 6, 1501496 doi: 10.1002/aenm.201501496[9] Nishioka S, Osterloh F E, Wang X C, et al. Photocatalytic water splitting. Nat Rev Methods Primers, 2023, 3, 42 doi: 10.1038/s43586-023-00226-x[10] She X, Huang A Q, Lucía O, et al. Review of silicon carbide power devices and their applications. IEEE Trans Ind Electron, 2017, 64, 8193 doi: 10.1109/TIE.2017.2652401[11] Pan J, Yan X, Cheng X, et al. In situ synthesis and electrical properties of porous SiOC ceramics decorated with sic nanowires. Ceram Int, 2016, 42, 12345 doi: 10.1016/j.ceramint.2016.05.007[12] Chen J, Guan M, Yang S, et al. Characterization of epitaxial layers grown on 4H-SiC ${( 000\bar{1} )} $. J Cryst Growth, 2023, 604, 127048 doi: 10.1016/j.jcrysgro.2022.127048[13] Wang R, Huang Y, Yang D, et al. Impurities and defects in 4H silicon carbide. Appl Phys Lett, 2023, 122, 181501 doi: 10.1063/5.0145350REF[14] Hou Y, Wen Z, Cui S, et al. Strongly coupled ternary hybrid aerogels of n-deficient porous graphitic-C3N4 nanosheets/n-doped graphene/NiFe-layered double hydroxide for solar-driven photoelectrochemical water oxidation. Nano Lett, 2016, 16, 2268 doi: 10.1021/acs.nanolett.5b04496[15] Mohamed A G A, Zhang X, Wang Y. Facile synthesis of RuOx/SiC/C for photoelectrocatalysis. Inorg Chem Front, 2021, 8, 3733 doi: 10.1039/D1QI00552A[16] Kormányos A, Ondok R, Janáky C. Electrosynthesis and photoelectrochemical properties of polyaniline/SiC nanohybrid electrodes. Electrochimica Acta, 2017, 256, 73 doi: 10.1016/j.electacta.2017.10.019[17] Jian J, Shi Y, Syväjärvi M, et al. Cubic SiC photoanode coupling with Ni: FeOOH oxygen-evolution cocatalyst for sustainable photoelectrochemical water oxidation. Sol RRL, 2019, 4, 1900364 doi: 10.1002/solr.201900364[18] Guo X, Tong X, Wang Y, et al. High photoelectrocatalytic performance of a MoS2–SiC hybrid structure for hydrogen evolution reaction. J Mater Chem A, 2013, 1, 4657 doi: 10.1039/c3ta10600d[19] Baig U, Khan A, Gondal M A, et al. Single-step synthesis of silicon carbide anchored graphitic carbon nitride nanocomposite photo-catalyst for efficient photoelectrochemical water splitting under visible-light irradiation. Colloid Surface A, 2021, 611, 125886 doi: 10.1016/j.colsurfa.2020.125886[20] Shor J S, Kurtz A D, Grimberg I, et al. Dopant-selective etch stops in 6H and 3C SiC. J Appl Phys, 1997, 81, 1546 doi: 10.1063/1.363890[21] Shishkin Y, Choyke W J, Devaty R P. Photoelectrochemical etching of n-type 4H silicon carbide. J Appl Phys, 2004, 96, 2311 doi: 10.1063/1.1768612[22] Michaels J A, Janavicius L, Wu X, et al. Producing silicon carbide micro and nanostructures by plasma-free metal-assisted chemical etching. Adv Funct Mater, 2021, 31, 2103298 doi: 10.1002/adfm.202103298[23] Tan J H, Chen, Z Z, Lu W Y. et al. Fabrication of uniform 4H-SiC mesopores by pulsed electrochemical etching. Nanoscale Res Lett, 2014, 9, 570 doi: 10.1186/1556-276X-9-570[24] Chen C, Chen S, Shang M, et al. Fabrication of highly oriented 4H-SiC gourd-shaped nanowire arrays and their field emission properties. J Mater Chem C, 2016, 4, 5195 doi: 10.1039/C6TC00450D[25] Xu S, Jiang F, Gao F, et al. Single-crystal integrated photoanodes based on 4H-SiC nanohole arrays for boosting photoelectrochemical water splitting activity. ACS Appl Mater Inter, 2020, 12, 20469 doi: 10.1021/acsami.0c02893[26] Mahadik N A, Stahlbush R E, Qadri S B, et al. Structure and morphology of inclusions in 4° offcut 4H-SiC epitaxial layers. J Electron Mater, 2011, 40, 413 doi: 10.1007/s11664-011-1570-8[27] Bauer M, Gigler A M, Huber A J, et al. Temperature-depending raman line-shift of silicon carbide. J Raman Spectrosc, 2009, 40, 1867 doi: 10.1002/jrs.2334[28] Harima H, Nakashima S I, Uemura T. Raman scattering from anisotropic LO-phonon–plasmon–coupled mode in n-type 4H– and 6H–SiC. J Appl Phys, 1995, 78, 1996 doi: 10.1063/1.360174[29] Chen D, Xiao H, Han J. Nanopores in gan by electrochemical anodization in hydrofluoric acid: Formation and mechanism. J Appl Phys, 2012, 112, 064303 doi: 10.1063/1.4752259[30] Konstantinov A O, Harris C I, Janzén E. Electrical properties and formation mechanism of porous silicon carbide. Appl Phys Lett, 1994, 65, 2699 doi: 10.1063/1.112610[31] Danno K, Nakamura D, Kimoto T. Investigation of carrier lifetime in 4H-SiC epilayers and lifetime control by electron irradiation. Appl Phys Lett, 2007, 90, 202109 doi: 10.1063/1.2740580[32] Hadi M, Younes J, Soueidan M, et al. Ir photothermal and spectroscopic analysis of proton-irradiated 4H-SiC. Infrared Phys Techn, 2021, 118, 103891 doi: 10.1016/j.infrared.2021.103891[33] Nan S, Xiao M, Guan Z, et al. Atomic-scale revealing defects in ion irradiated 4H-SiC. Mater Charact, 2023, 203, 113125 doi: 10.1016/j.matchar.2023.113125 -

Supplements

24050011Supporting_Information.pdf

24050011Supporting_Information.pdf

-

Proportional views

Yan Pei is a master’s degree student of the School of Science, Zhejiang Sci-Tech University. His research focuses on application of 4H-SiC in photoelectrochemical water splitting.

Yan Pei is a master’s degree student of the School of Science, Zhejiang Sci-Tech University. His research focuses on application of 4H-SiC in photoelectrochemical water splitting. Can Cui received his PhD degree at Zhejiang University in 2006. He then carried out research at Tohoku University and National Institute for Materials Science. He is now a professor in Zhejiang Sci-Tech University. His research mainly focuses on crystal growth and optoelectronic devices.

Can Cui received his PhD degree at Zhejiang University in 2006. He then carried out research at Tohoku University and National Institute for Materials Science. He is now a professor in Zhejiang Sci-Tech University. His research mainly focuses on crystal growth and optoelectronic devices. Xiaodong Pi received his PhD degree at the University of Bath in 2004. He then carried out research at McMaster University and the University of Minnesota at Twin Cities. He joined Zhejiang University as an associate professor in 2008. He is now a professor in the State Key Laboratory of Silicon and Advanced Semiconductor Materials, the School of Materials Science and Engineering of Zhejiang University. His research mainly concerns semiconductor materials and devices.

Xiaodong Pi received his PhD degree at the University of Bath in 2004. He then carried out research at McMaster University and the University of Minnesota at Twin Cities. He joined Zhejiang University as an associate professor in 2008. He is now a professor in the State Key Laboratory of Silicon and Advanced Semiconductor Materials, the School of Materials Science and Engineering of Zhejiang University. His research mainly concerns semiconductor materials and devices. Deren Yang is an academician of the Chinese Academy of Science, presently of NingboTech University, director of the State Key Laboratory of Silicon and Advanced Semiconductor Materials, and chief scientist of Zhejiang University-Hangzhou Global Scientific and Technological Innovation Center. He received his PhD in 1991, at Zhejiang University. In the 1990s, he worked in Japan, Germany, and Sweden for several years as a visiting researcher. He has been engaged in research on silicon materials for microelectronic devices, solar cells, and nanodevices.

Deren Yang is an academician of the Chinese Academy of Science, presently of NingboTech University, director of the State Key Laboratory of Silicon and Advanced Semiconductor Materials, and chief scientist of Zhejiang University-Hangzhou Global Scientific and Technological Innovation Center. He received his PhD in 1991, at Zhejiang University. In the 1990s, he worked in Japan, Germany, and Sweden for several years as a visiting researcher. He has been engaged in research on silicon materials for microelectronic devices, solar cells, and nanodevices. Rong Wang received her PhD degree at Zhejiang University in 2014. She then carried out research at Taiyuan University of Technology and China Academy of Engineering Physics. She joined the Zhejiang University-Hangzhou Global Scientific and Technological Innovation Center in 2020. Her research mainly focuses on defects in wide-bandgap semiconductors.

Rong Wang received her PhD degree at Zhejiang University in 2014. She then carried out research at Taiyuan University of Technology and China Academy of Engineering Physics. She joined the Zhejiang University-Hangzhou Global Scientific and Technological Innovation Center in 2020. Her research mainly focuses on defects in wide-bandgap semiconductors.

DownLoad:

DownLoad: