| Citation: |

Qirui Xu, Zhiyin Ding, Debo Wang. MEMS microwave power detection chip based on fixed beams and its model[J]. Journal of Semiconductors, 2025, 46(6): 062301. doi: 10.1088/1674-4926/24100018

****

Q R Xu, Z Y Ding, and D B Wang, MEMS microwave power detection chip based on fixed beams and its model[J]. J. Semicond., 2025, 46(6), 062301 doi: 10.1088/1674-4926/24100018

|

MEMS microwave power detection chip based on fixed beams and its model

DOI: 10.1088/1674-4926/24100018

CSTR: 32376.14.1674-4926.24100018

More Information-

Abstract

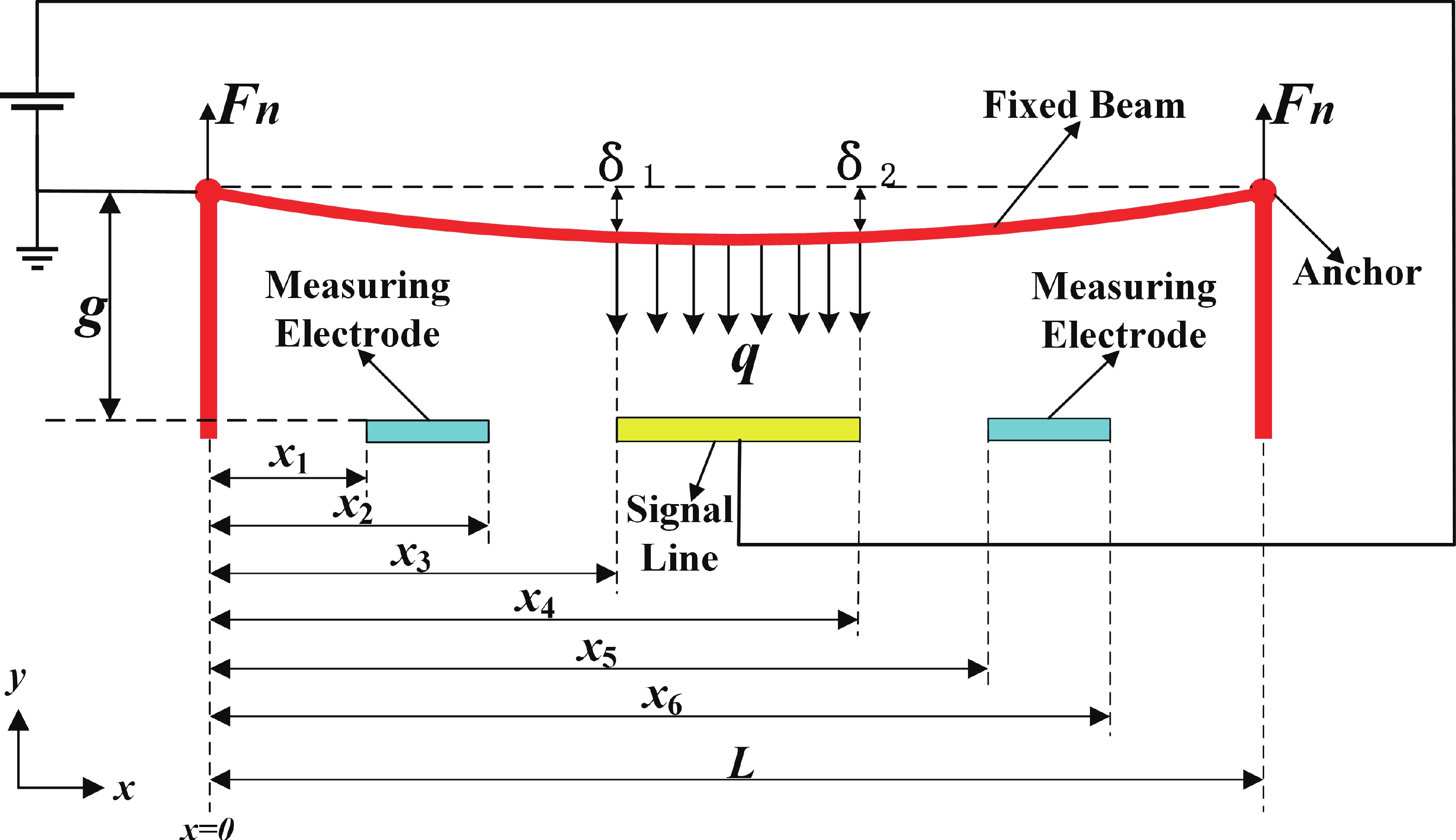

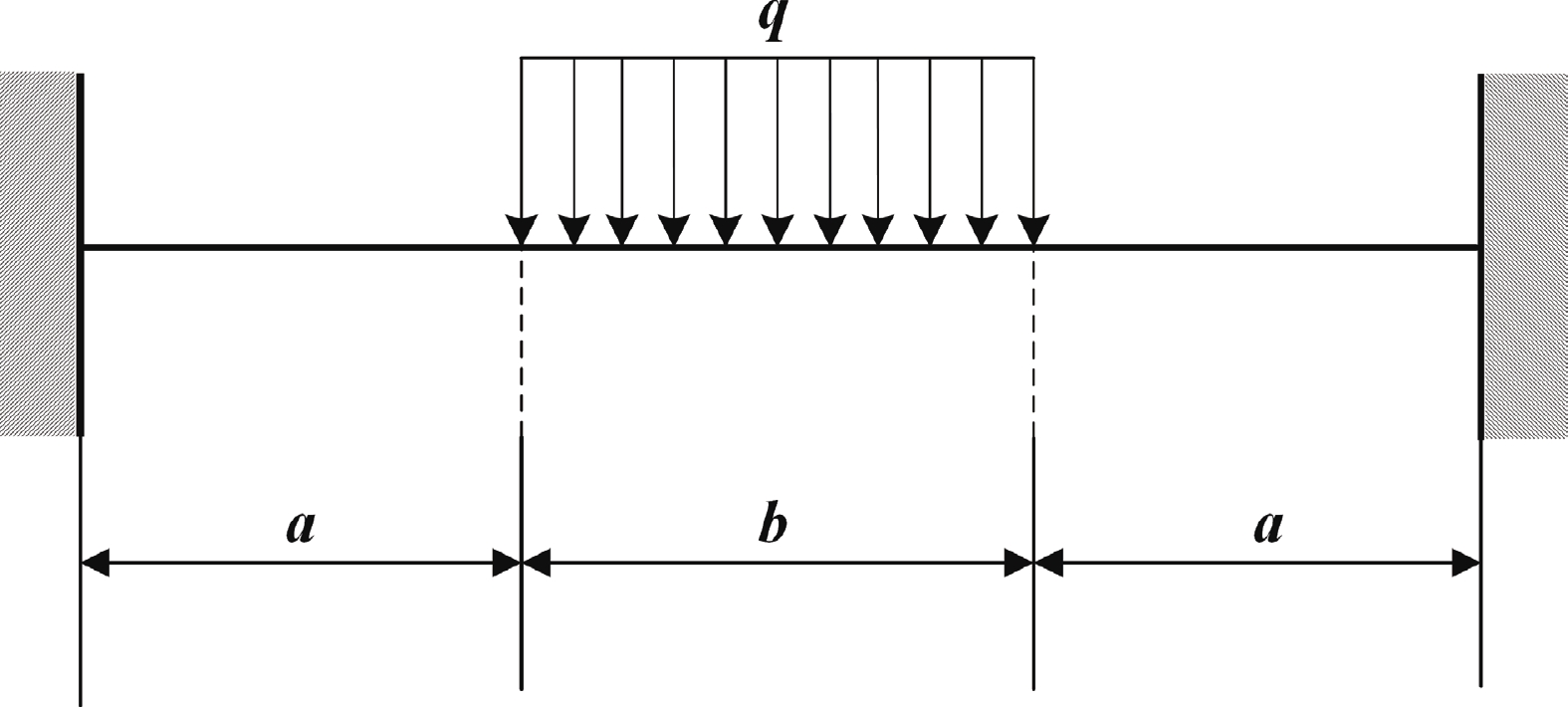

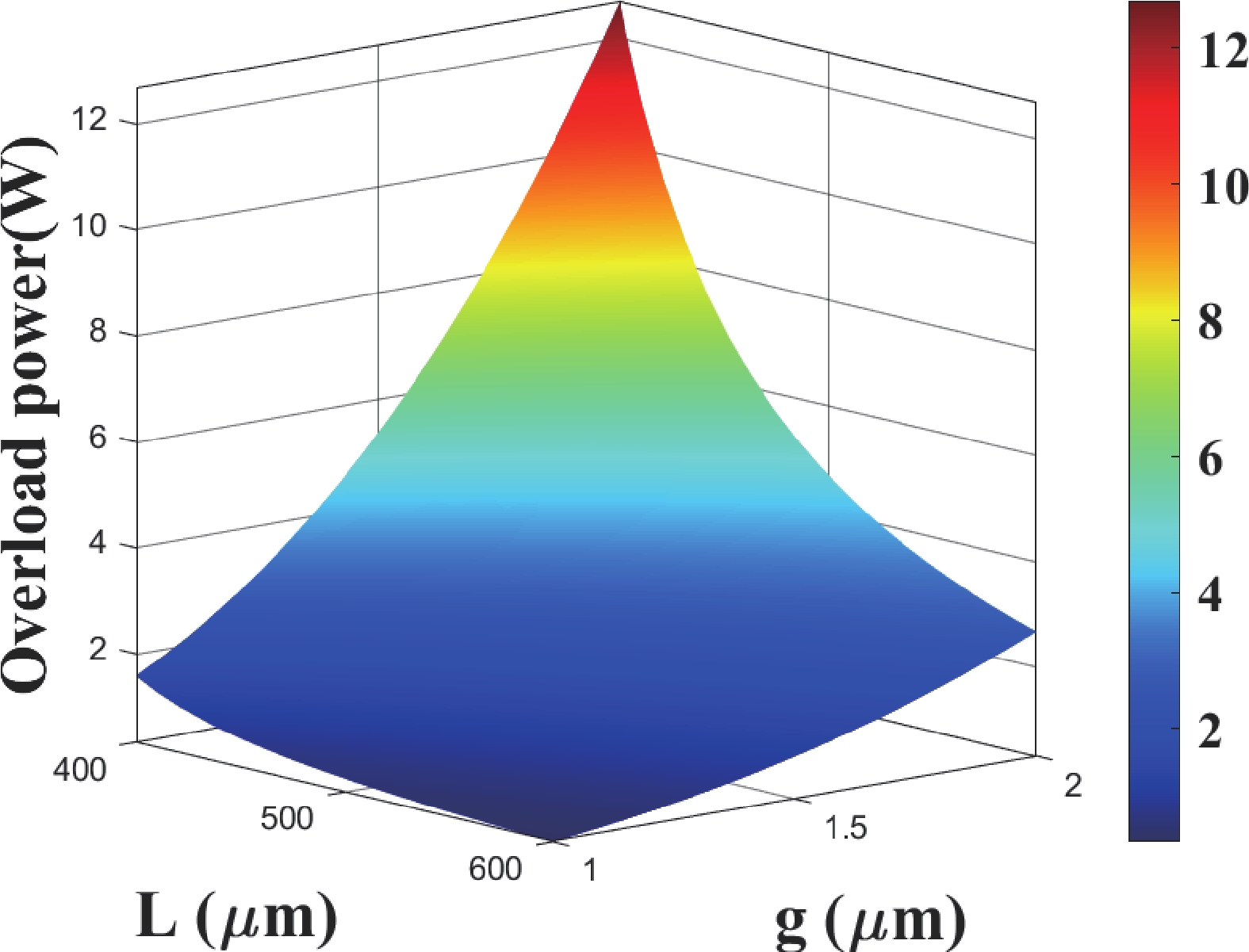

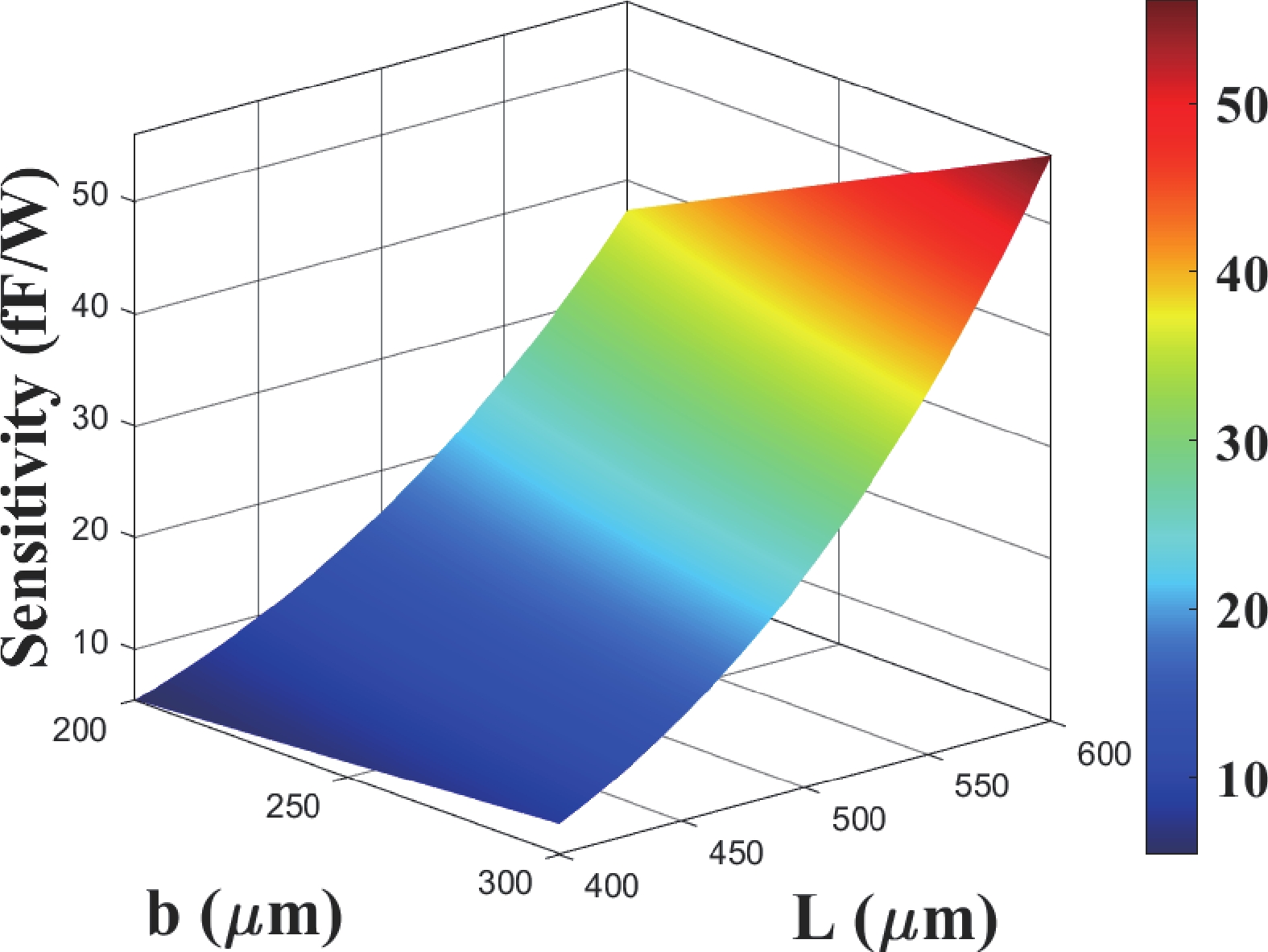

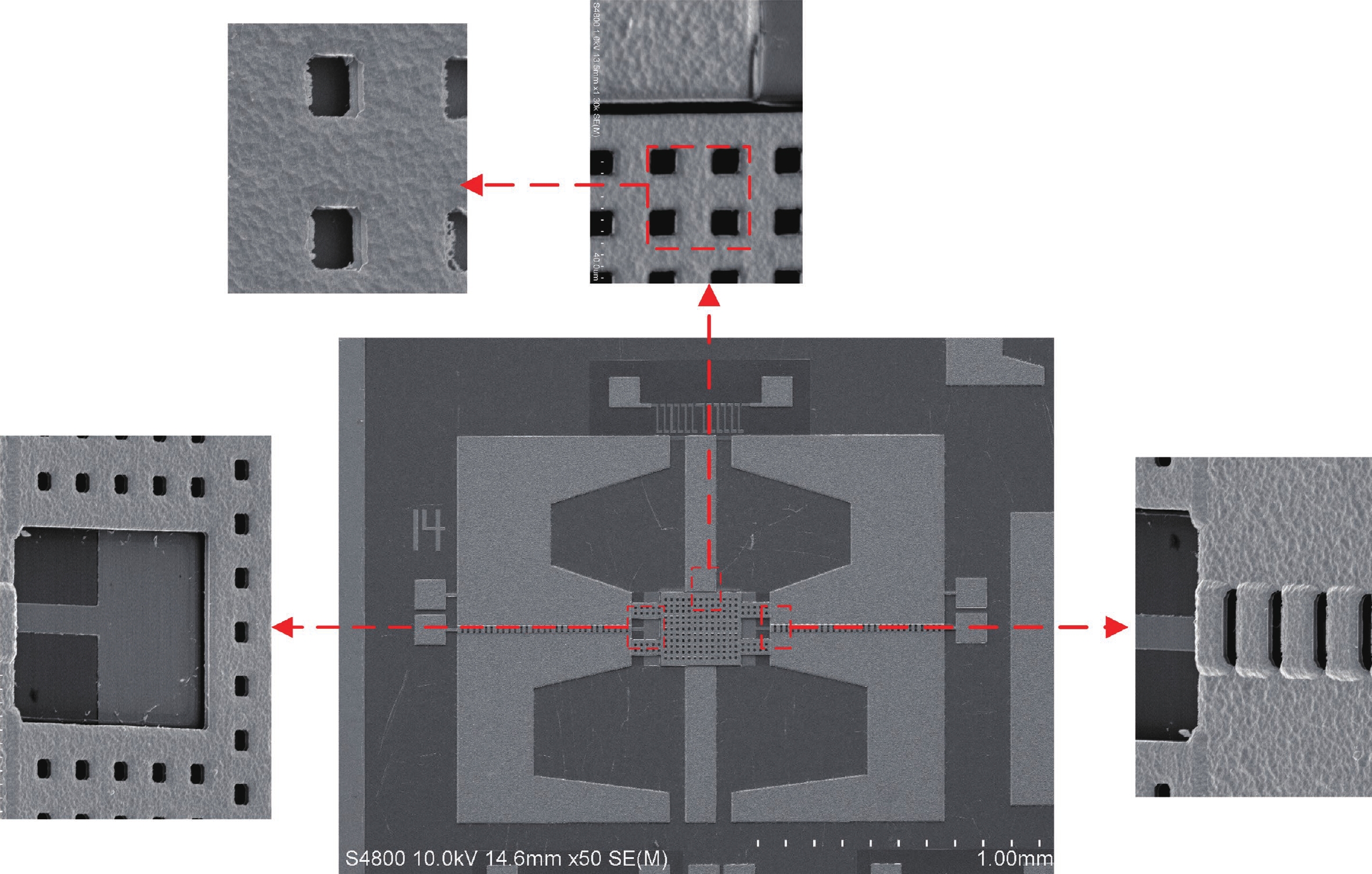

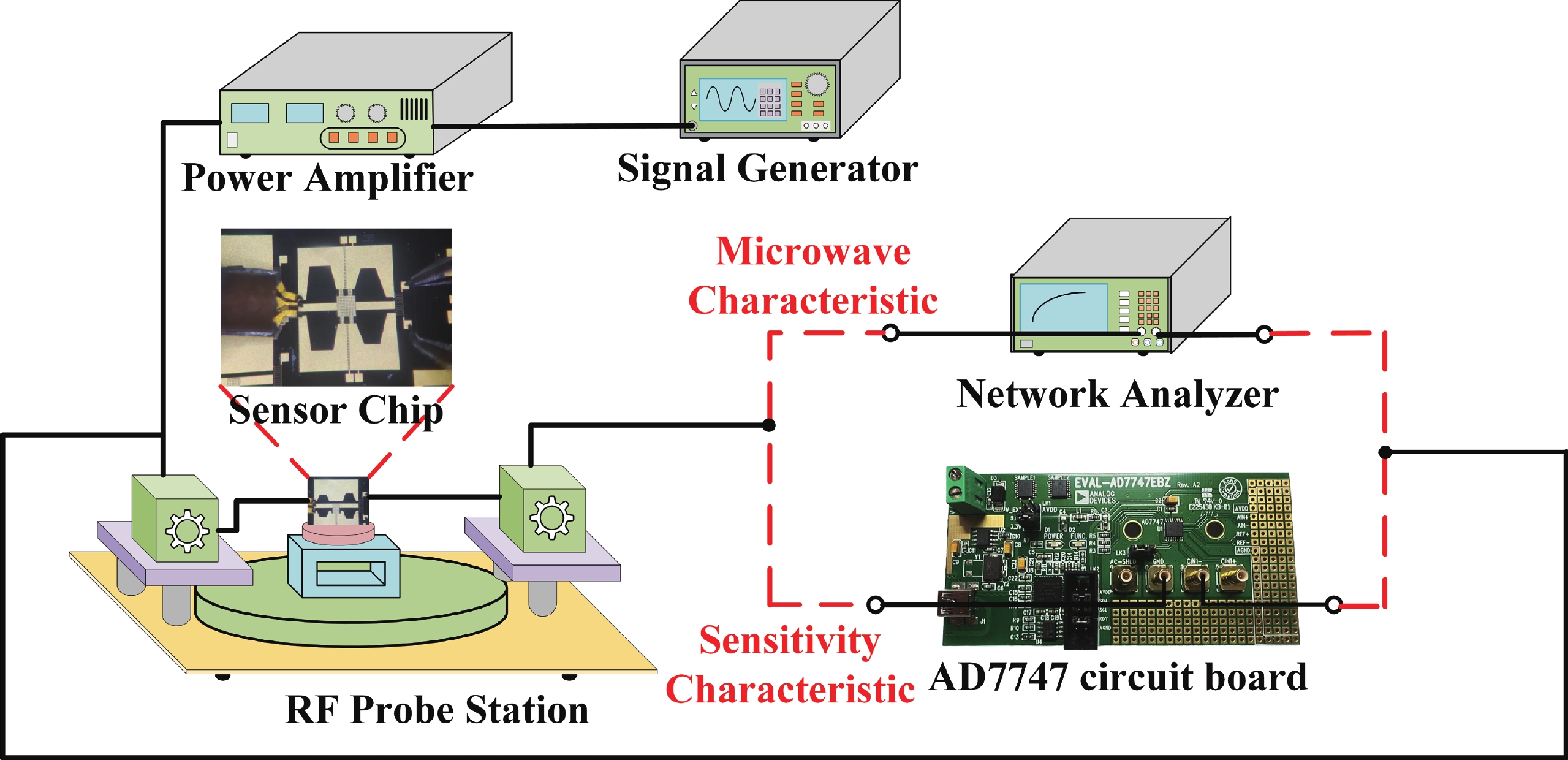

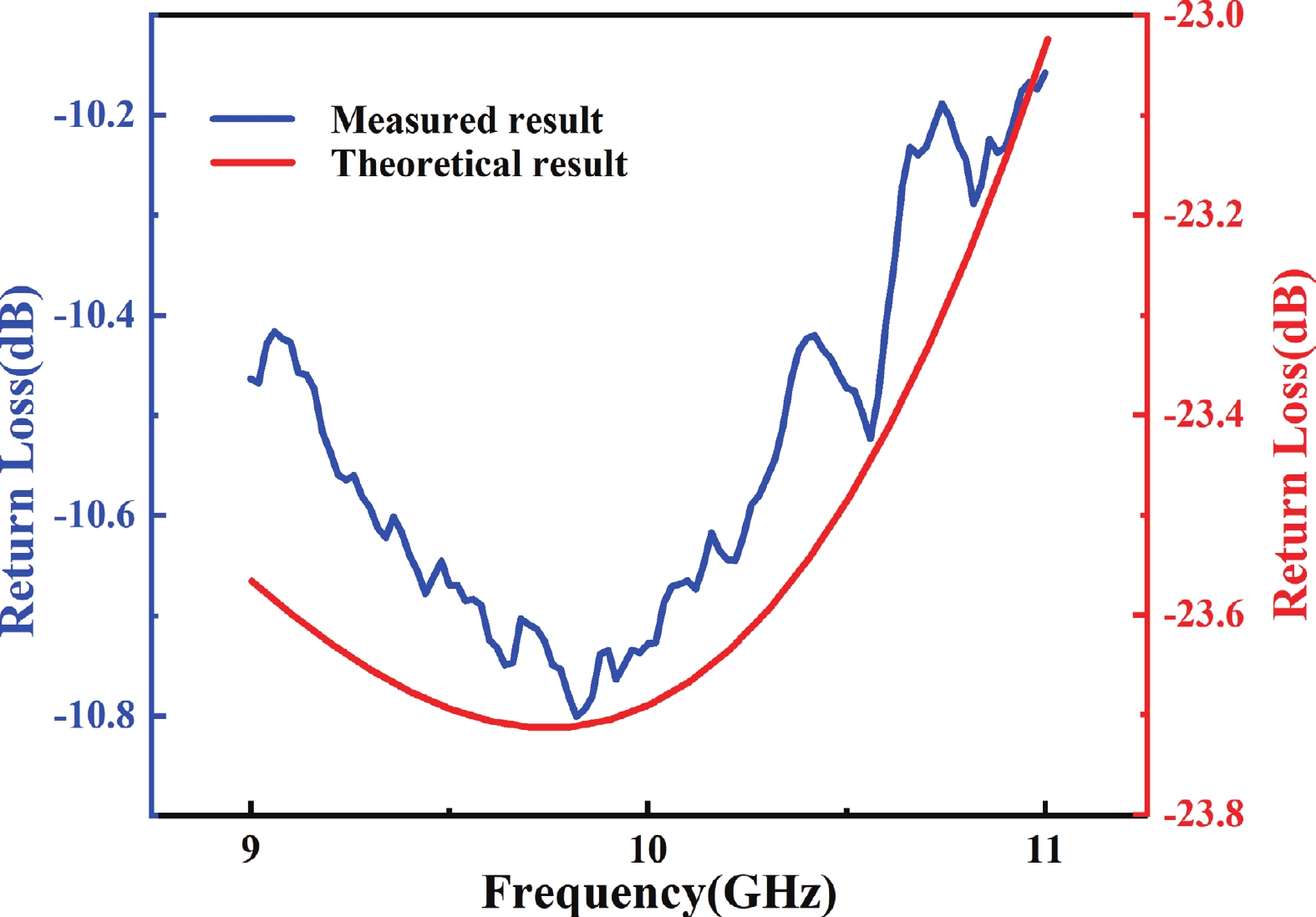

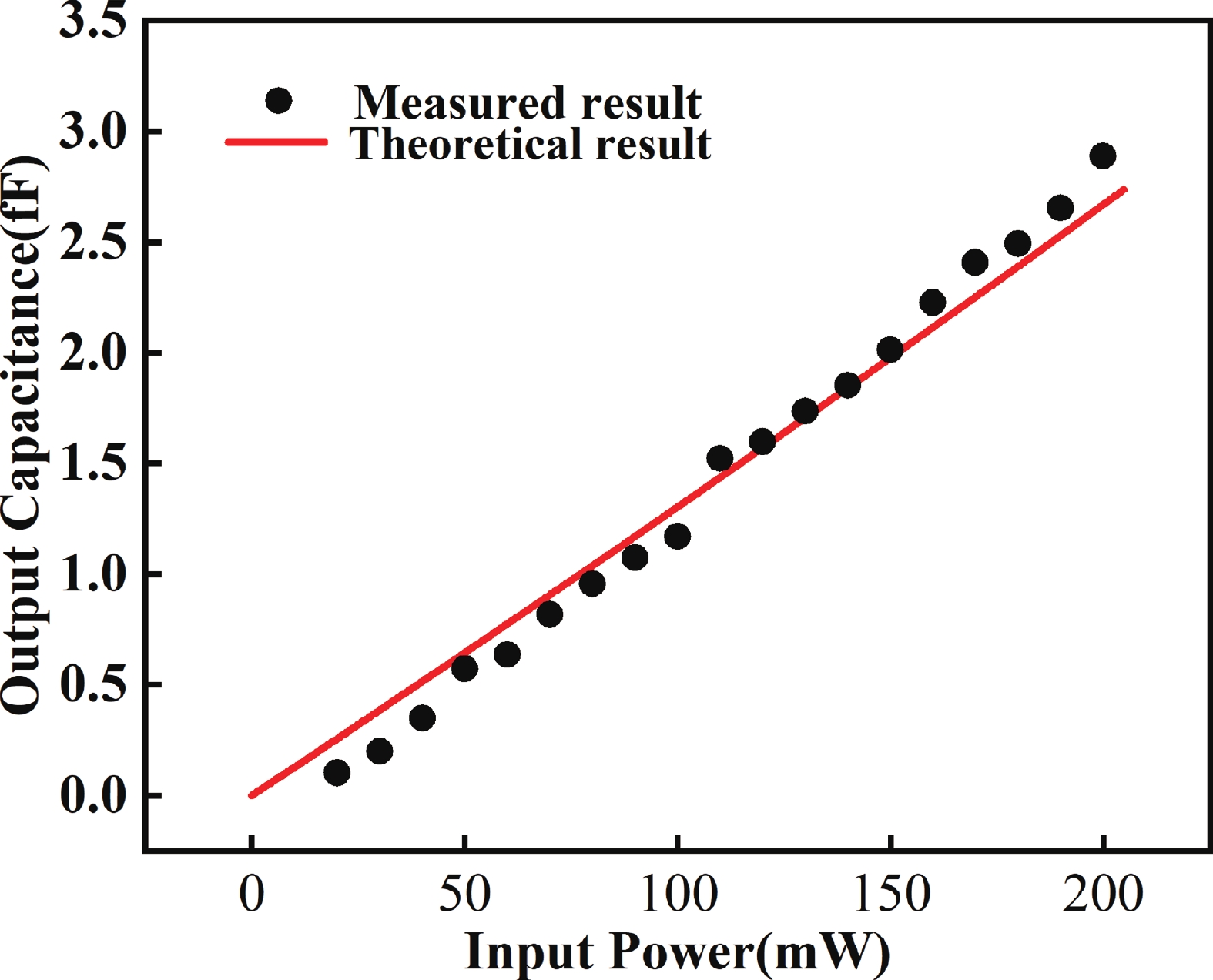

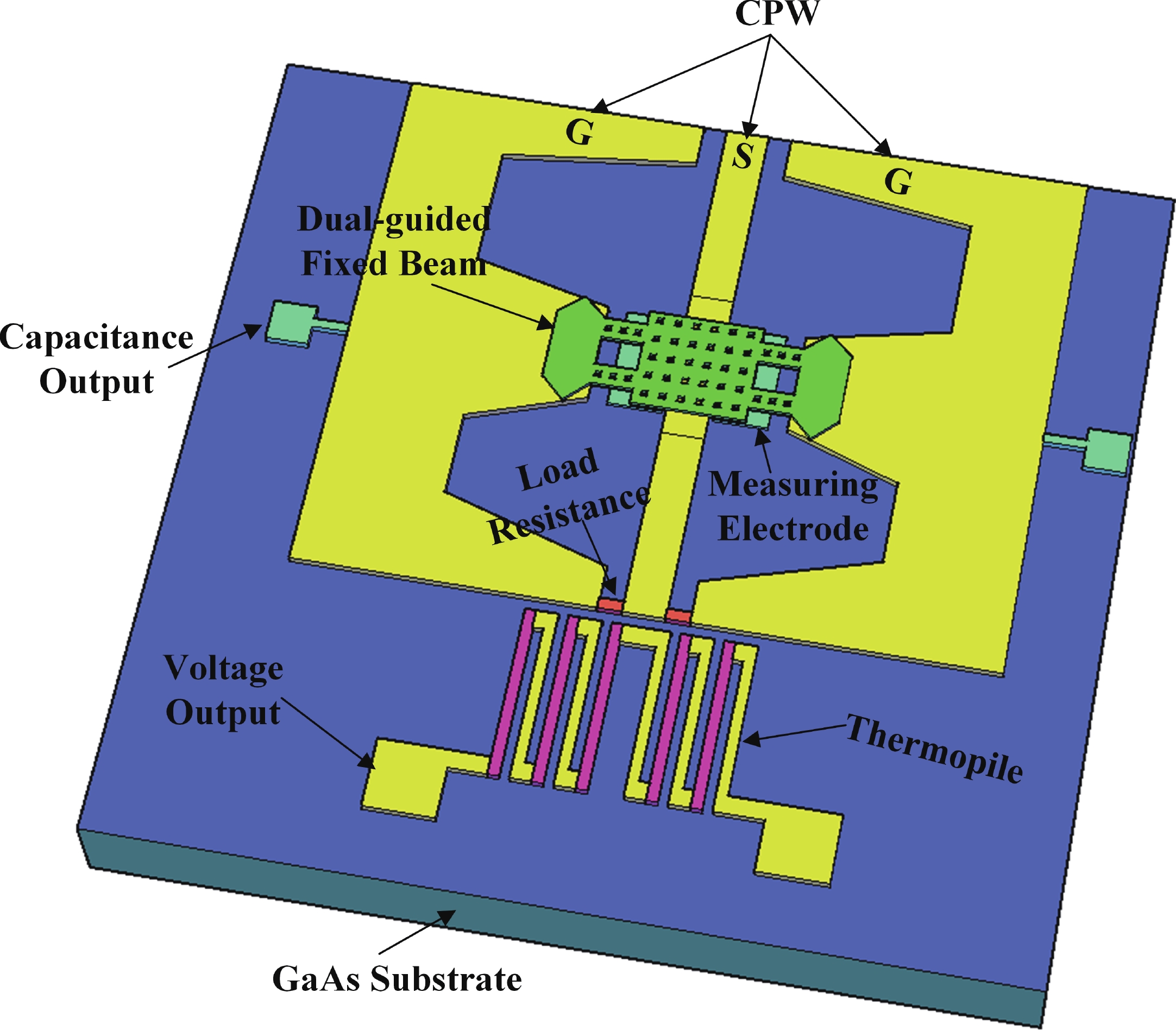

In order to solve the problems of low overload power in MEMS cantilever beams and low sensitivity in traditional MEMS fixed beams, a novel MEMS microwave power detection chip based on the dual-guided fixed beam is designed. A gap between guiding beams and measuring electrodes is designed to accelerate the release of the sacrificial layer, effectively enhancing chip performance. A load sensing model for the MEMS fixed beam microwave power detection chip is proposed, and the mechanical characteristics are analyzed based on the uniform load applied. The overload power and sensitivity are investigated using the load sensing model, and experimental results are compared with theoretical results. The detection chip exhibits excellent microwave characteristic in the 9−11 GHz frequency band, with a return loss less than −10 dB. At a signal frequency of 10 GHz, the theoretical sensitivity is 13.8 fF/W, closely matching the measured value of 14.3 fF/W, with a relative error of only 3.5%. These results demonstrate that the proposed load sensing model provides significant theoretical support for the design and performance optimization of MEMS microwave power detection chips.-

Keywords:

- detection chip,

- dual-guided fixed beam,

- MEMS,

- load sensing model,

- sensitivity

-

References

[1] Zhuang Q H, Yan J K, Liu X L, et al. Design and implementation of the microwave detection system based on DFB laser diode. 2018 International Applied Computational Electromagnetics Society Symposium-China (ACES), 2018, 1 doi: 10.23919/ACESS.2018.8669267[2] Wei H B, Chen S, Fang L, et al. Design of microwave power detection module for L-band. 2019 International Symposium on Antennas and Propagation (ISAP), 2019, 1[3] Gasper M R, Toonen R C, Varaljay N C, et al. Microwave power detection with voltage-gated graphene. IEEE Open J Nanotechnol, 2020, 1, 25 doi: 10.1109/OJNANO.2020.2995262[4] Zhang Z Q, Gu R Q, Liu J Q. A high-performance RF MEMS power sensor for near-zero detection applications. IEEE Electron Device Lett, 2023, 44, 1885 doi: 10.1109/LED.2023.3318558[5] Yi Z X, Liao X P. A cascaded terminating-type and capacitive-type power sensor for −10- to 22-dBm application. IEEE Electron Device Lett, 2016, 37, 489 doi: 10.1109/LED.2016.2532920[6] Cui Y, Liao X P. Modeling and design of a capacitive microwave power sensor for X-band applications based on GaAs technology. J Micromech Microeng, 2012, 22, 055013 doi: 10.1088/0960-1317/22/5/055013[7] Fernández L J, Wiegerink R J, Flokstra J, et al. A capacitive RF power sensor based on MEMS technology. J Micromech Microeng, 2006, 16, 1099 doi: 10.1088/0960-1317/16/7/001[8] Cui Y, Liao X P, Zhu Z. A novel microwave power sensor using MEMS fixed-fixed beam. SENSORS, 2011, 1305 doi: 10.1109/ICSENS.2011.6127109[9] Zhang Z Q, Liao X P, Wang X H. Research on thermocouple distribution for microwave power sensors based on GaAs MMIC process. IEEE Sens J, 2015, 15, 4178 doi: 10.1109/JSEN.2015.2424973[10] Chu C L, Liao X P, Chen C. Improved dynamic range of microwave power sensor by MEMS cantilever beam. J Microelectromech Syst, 2017, 26, 1183 doi: 10.1109/JMEMS.2017.2754506[11] Wang D B, Gu X F, Xie J C, et al. Research on a ka-band MEMS power sensor investigated with an MEMS cantilever beam. Chin J Electron, 2020, 29, 378 doi: 10.1049/cje.2020.02.002[12] Zuo W, Liu Q C, Zhang C C, et al. Research on MEMS microwave power sensor with symmetric double cantilever beam structure. Microelectronics, 2021, 51, 418 (in Chinese)[13] Xin Z H, Sun H Y, Wang D B. A high-performance dual-channel MEMS microwave power sensor with cantilever beam. IEEE Sens J, 2023, 23, 11540 doi: 10.1109/JSEN.2023.3269035[14] Li C, Guo X M, Xu A D, et al. Research on MEMS dual-channel microwave power sensor with fixed beam structure. J Micromech Microeng, 2023, 33, 105013 doi: 10.1088/1361-6439/acf2a6[15] Liang Y X, Sun H Y, Zhu S Y, et al. Study on the load model of microwave power detection chip based on MEMS fixed beams. IEEE Trans Electron Devices, 2024, 71, 4952 doi: 10.1109/TED.2024.3418368[16] Paolo Di Re, Daniela Addessi, Cristina Gatta, et al. Corotational force-based beam finite element with rigid joint offsets for 3D framed structures. Comput Methods Appl Mech Eng, 2024, 419, 116656 doi: 10.1016/j.cma.2023.116656[17] Sun Y G, Hou S H, Li B C, et al. Numerical simulation of micro-element cutting and milling force prediction in micro ball-end milling. Int J Adv Manuf Technol, 2023, 125, 2305 doi: 10.1007/s00170-023-10839-x[18] Shan H Z, Xie C F. Engineering mechanics: statics and mechanics of materials. Beijing: Higher Education Press, 2004 (in Chinese)[19] Liu C. Foundations of MEMS. Beijing: China Machine Press, 2007[20] Jia B N, Yu P, Song A G. Sensor Technology. Nanjing: Southeast University Press, 2007 (in Chinese)[21] Yi Z X, Liao X P. A capacitive power sensor based on the MEMS cantilever beam fabricated by GaAs MMIC technology. J Micromech Microeng, 2013, 23, 035001 doi: 10.1088/0960-1317/23/3/035001[22] Yi Z X, Liao X P, Zhu Z. An 8-12GHz capacitive power sensor based on MEMS cantilever beam. SENSORS, 2011, 1958 doi: 10.1109/ICSENS.2011.6127229[23] Li C, Xiong J J, Wang D B. A novel capacitive microwave power sensor based on double mems cantilever beams. IEEE Sens J, 2022, 22, 11803 doi: 10.1109/JSEN.2022.3174556[24] Chu C L, Liao X P. X-band monolithic microwave integrated detector based on MEMS thermoelectric power sensor. IEEE Sens Lett, 2019, 3, 3502804 doi: 10.1109/LSENS.2019.2947255[25] Feng Y R, Wei X C, Yi D, et al. An enhanced one-port waveguide method for sheet resistance extraction. IEEE Trans Electromagn Compat, 2020, 62, 1822 doi: 10.1109/TEMC.2019.2956543[26] Yan H, Liao X P. The high power up to 1 W characteristics of the capacitive microwave power sensor with grounded MEMS beam. IEEE Sens J, 2015, 15, 6765 doi: 10.1109/JSEN.2015.2466462[27] Yan H, Liao X P, Yi Z X. High-power handling capacity and output response of a capacitive microwave power sensor. 2016 IEEE SENSORS, 2016, 1 doi: 10.1109/ICSENS.2016.7808642[28] Li J H, Liao X P. High-power electro-mechanical behavior of a capacitive microwave power sensor with warped cantilever beam. Solid State Electron, 2020, 172, 107877 doi: 10.1016/j.sse.2020.107877[29] Jin Y, Wang D B. Study on static deflection model of MEMS capacitive microwave power sensors. Chin J Electron, 2024, 33, 1188 doi: 10.23919/cje.2023.00.087 -

Proportional views

Qirui Xu was born in China in 2004. He studies at Nanjing University of Posts and Telecommunications for his undergraduate degree. His interest is MEMS microwave power detection chip.

Qirui Xu was born in China in 2004. He studies at Nanjing University of Posts and Telecommunications for his undergraduate degree. His interest is MEMS microwave power detection chip. Zhiyin Ding was born in China in 2001. She received the B.S. degree in materials science and engineering from Nanjing Forestry University in 2023. She is currently pursuing a master's degree in Nanjing University of Posts and Telecommunications. The discipline of her research focuses on MEMS microwave power detection chips.

Zhiyin Ding was born in China in 2001. She received the B.S. degree in materials science and engineering from Nanjing Forestry University in 2023. She is currently pursuing a master's degree in Nanjing University of Posts and Telecommunications. The discipline of her research focuses on MEMS microwave power detection chips. Debo Wang was born in China in 1983. He received the B.S. degree in electronic science and technology from the Hebei University of Science and technology, Shijiazhuang, China, in 2007, the M.S. degree and the PhD degree in Key Laboratory of MEMS of the Ministry of Education from the Southeast University, Nanjing, China, in 2010 and 2012. He is now a post-doctor in Nanjing University and an associate professor of the Nanjing University of Posts and Telecommunication. The discipline of his research focuses on the RF MEMS devices, particularly on microwave power sensor and its package.

Debo Wang was born in China in 1983. He received the B.S. degree in electronic science and technology from the Hebei University of Science and technology, Shijiazhuang, China, in 2007, the M.S. degree and the PhD degree in Key Laboratory of MEMS of the Ministry of Education from the Southeast University, Nanjing, China, in 2010 and 2012. He is now a post-doctor in Nanjing University and an associate professor of the Nanjing University of Posts and Telecommunication. The discipline of his research focuses on the RF MEMS devices, particularly on microwave power sensor and its package.

DownLoad:

DownLoad: