| Citation: |

Hao Zhu, Zhelin Jin, Tie Li, Guanggui Cheng, Jianning Ding. Breathable and skin-conformal electronic skin with dual-modality synchronous perception of pressure and temperature[J]. Journal of Semiconductors, 2025, In Press. doi: 10.1088/1674-4926/25020031

****

H Zhu, Z L Jin, T Li, G G Cheng, and J N Ding, Breathable and skin-conformal electronic skin with dual-modality synchronous perception of pressure and temperature[J]. J. Semicond., 2025, 46(12), 122601 doi: 10.1088/1674-4926/25020031

|

Breathable and skin-conformal electronic skin with dual-modality synchronous perception of pressure and temperature

DOI: 10.1088/1674-4926/25020031

CSTR: 32376.14.1674-4926.25020031

More Information-

Abstract

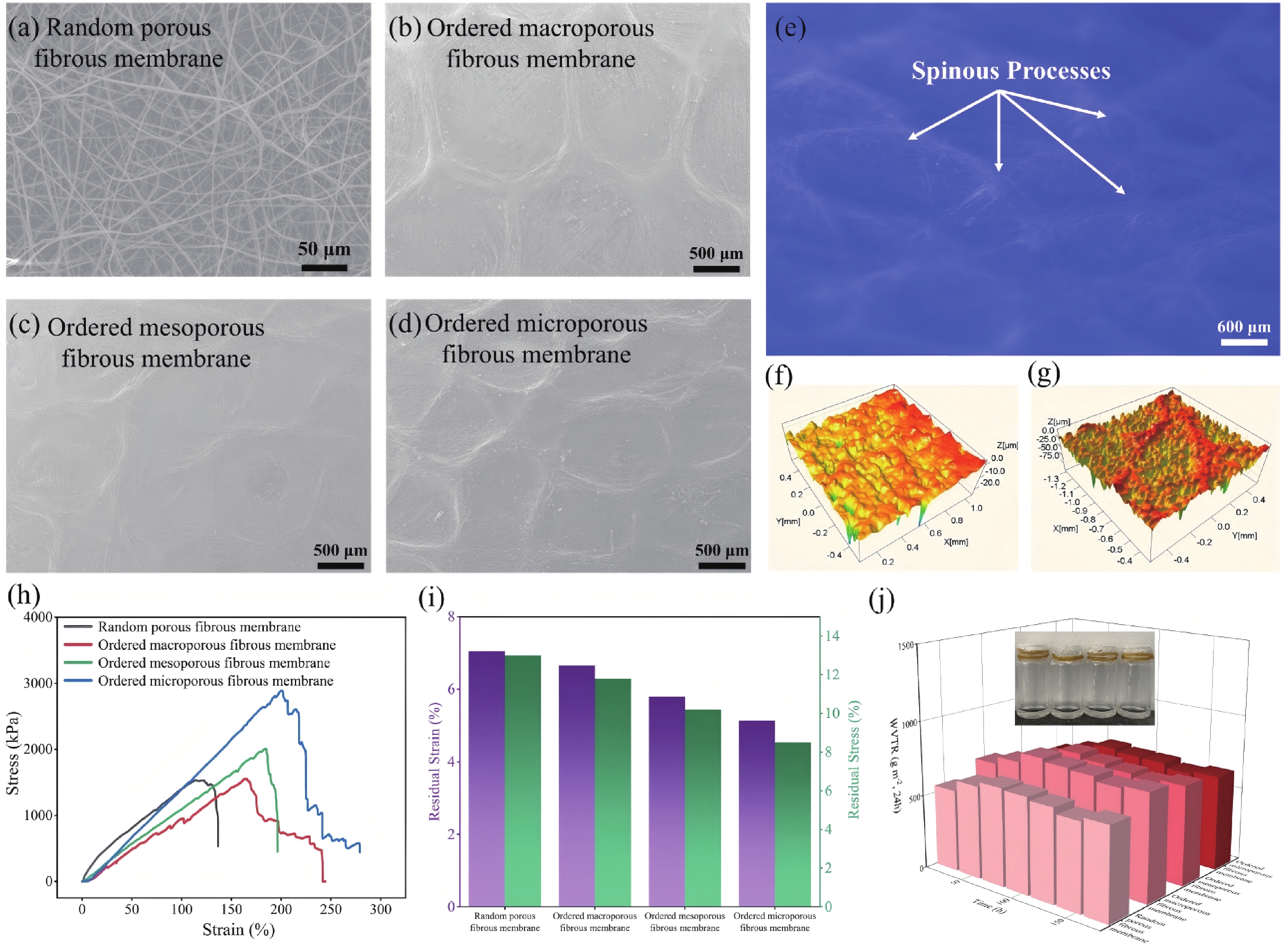

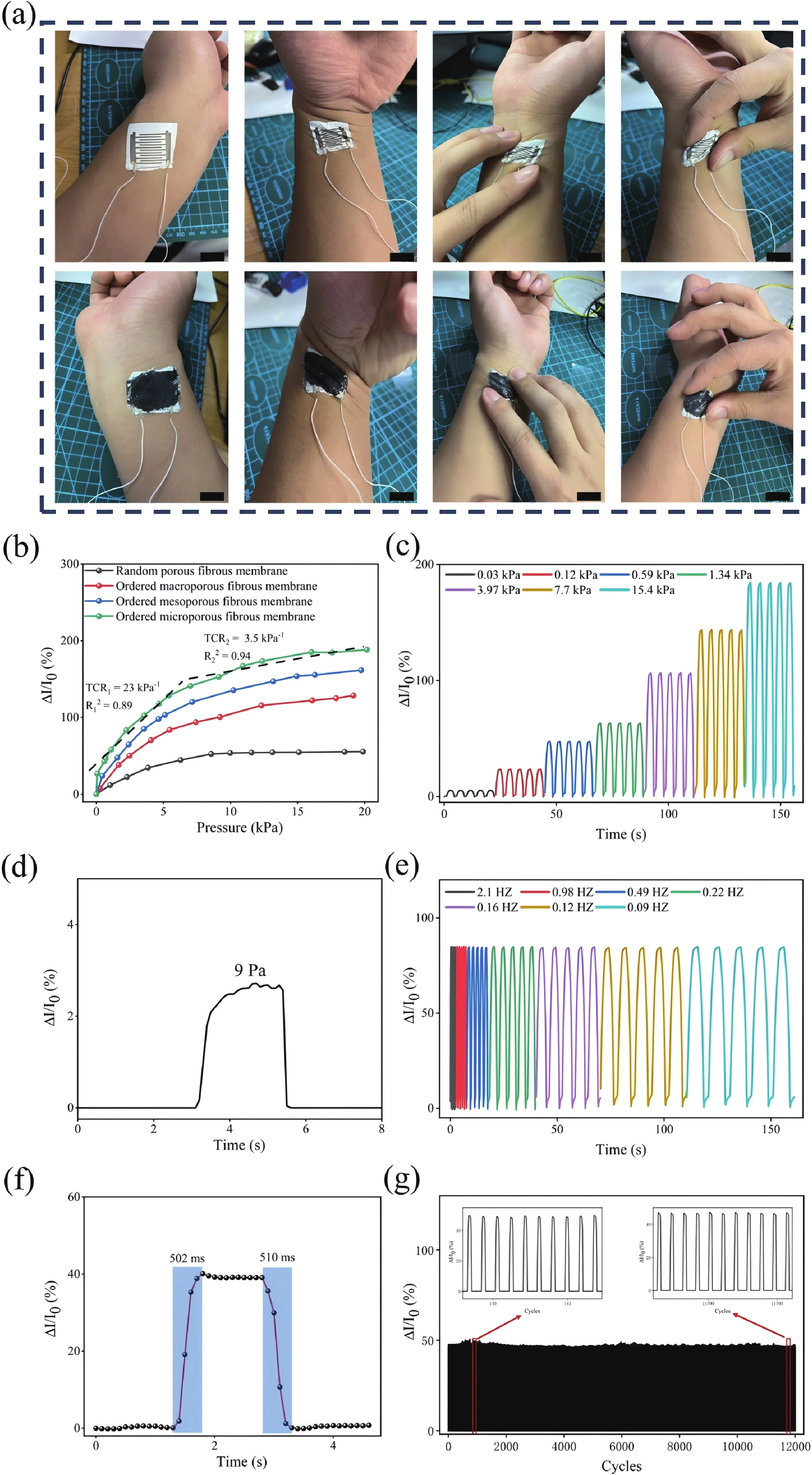

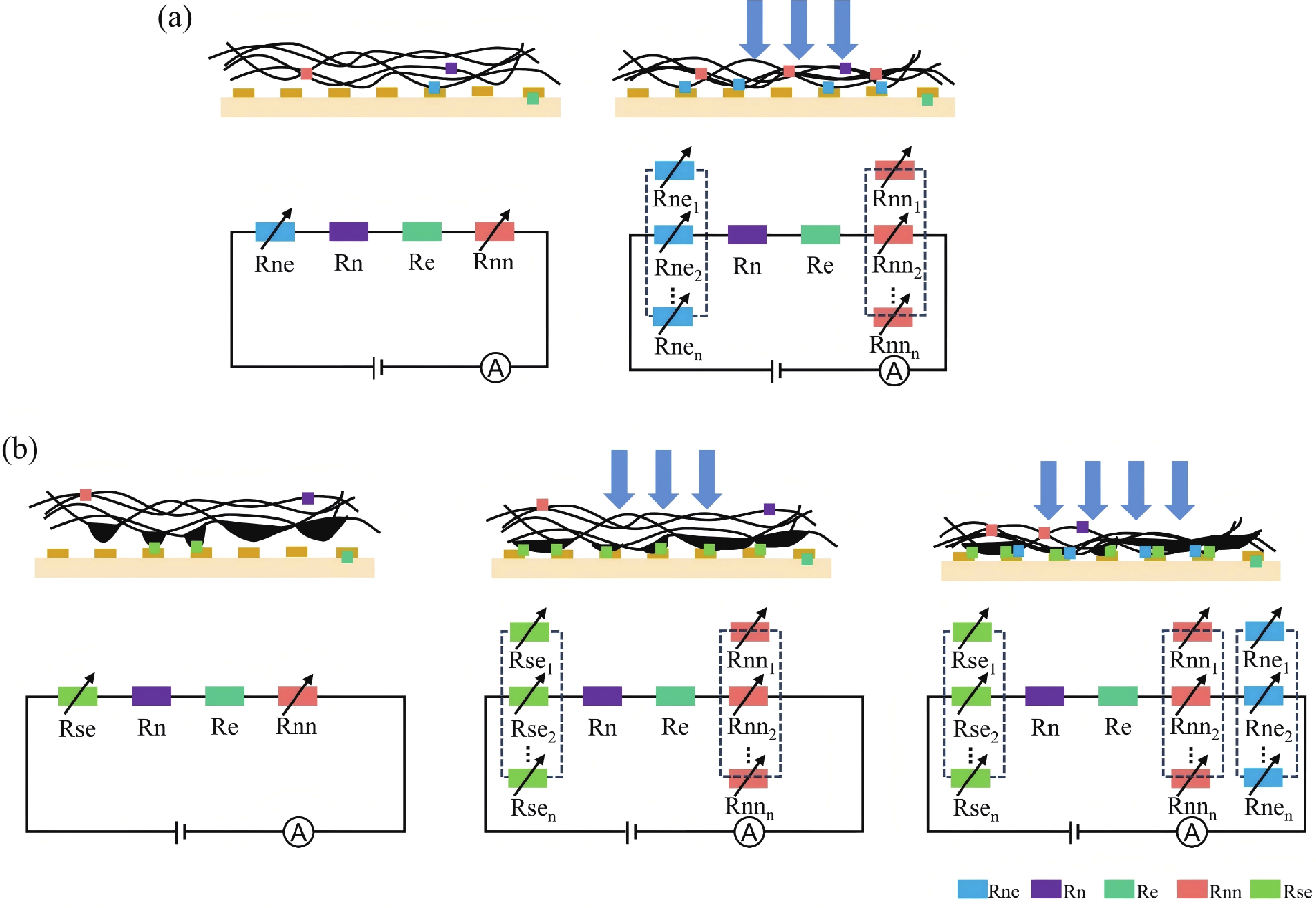

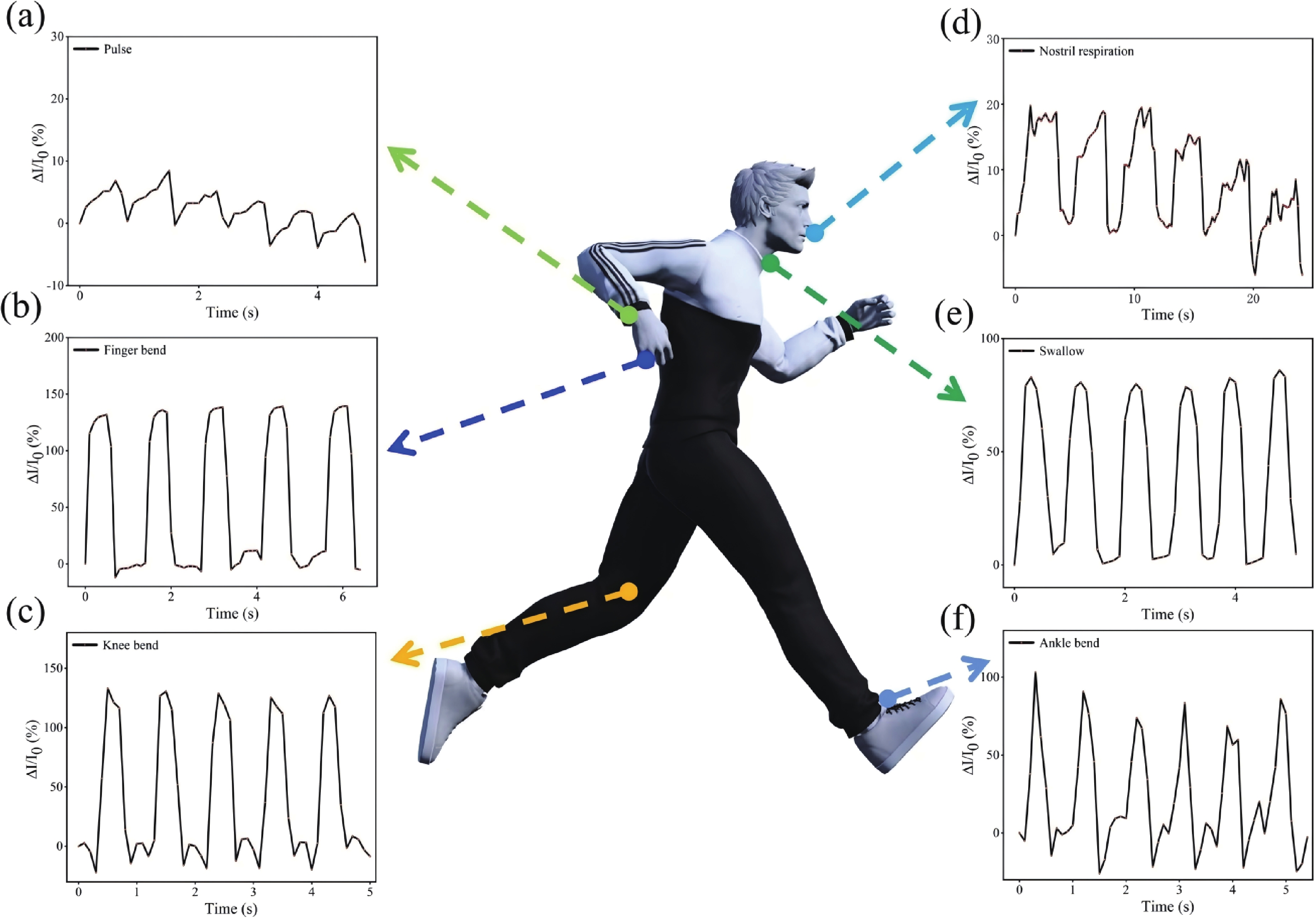

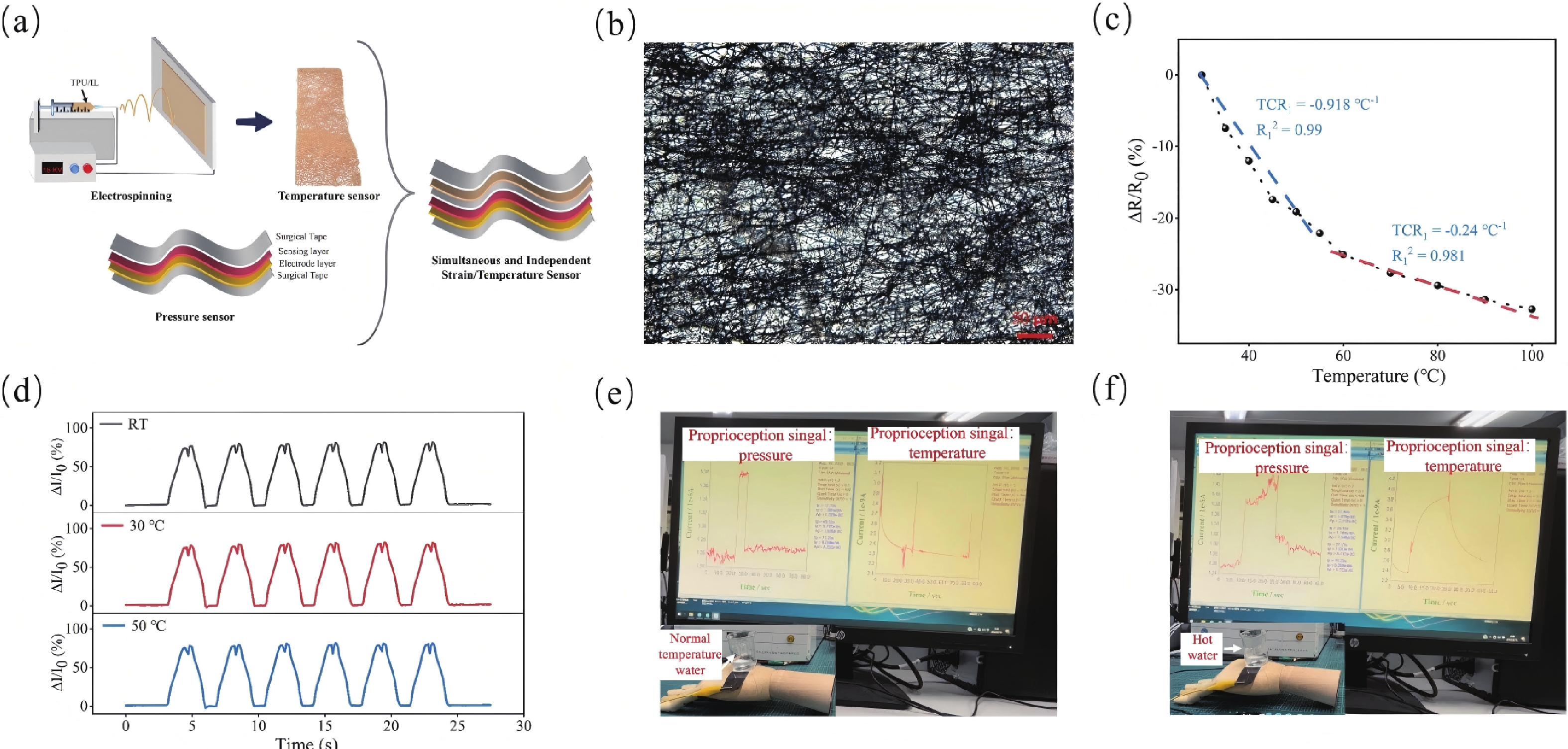

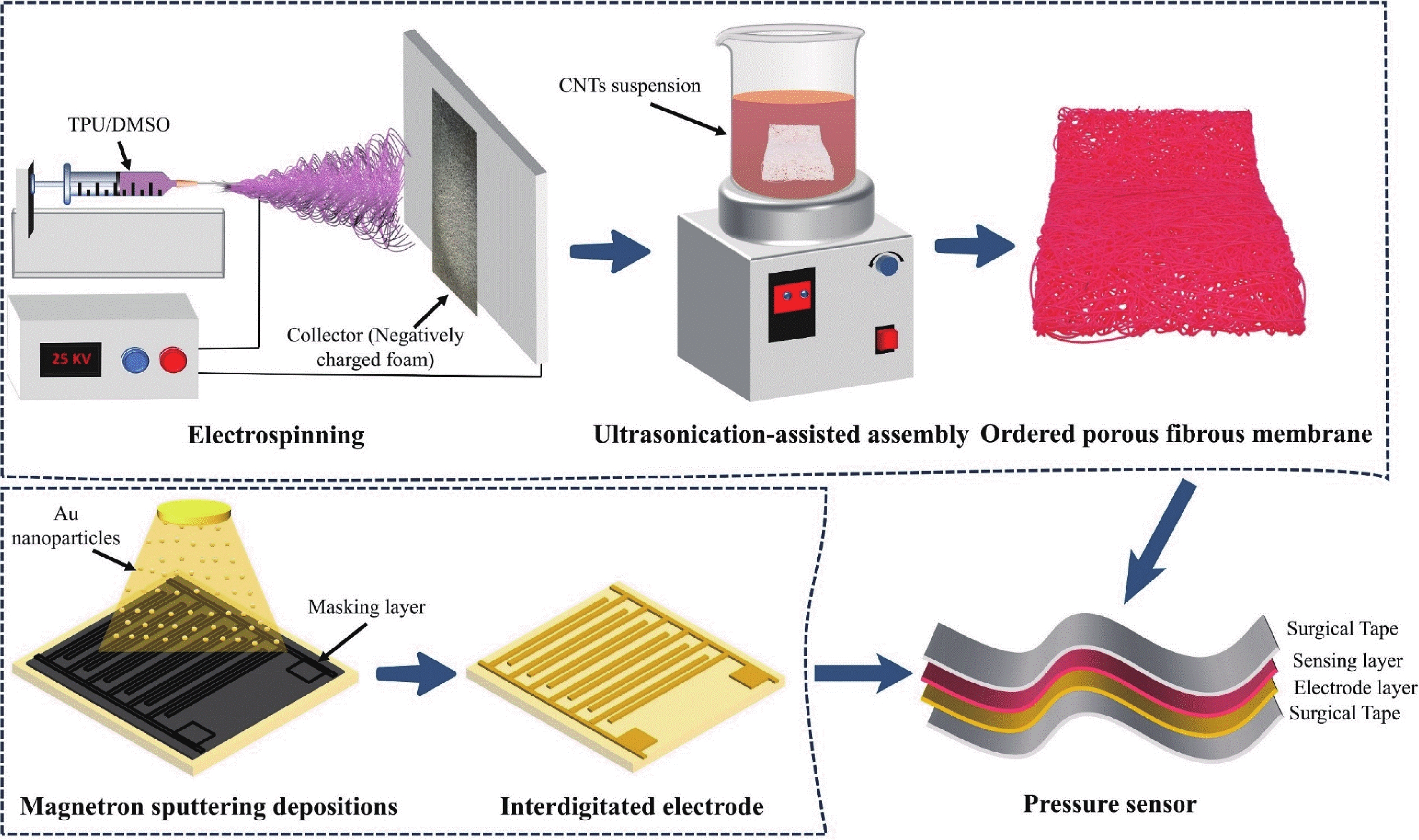

The random nanofiber distribution in traditional electrospun membranes restricts the pressure sensing sensitivity and measurement range of electronic skin. Moreover, current multimodal sensing suffers from issues like overlapping signal outputs and slow response. Herein, a novel electrospinning method is proposed to prepare double-coupled microstructured nanofibrous membranes. Through the effect of high voltage electrostatic field in the electrospinning, the positively charged nanofibers are preferentially attached to the negatively charged foam surface, forming the ordered two-dimensional honeycomb porous nanofibrous membrane with three-dimensional spinous microstructure. Compared with the conventional random porous nanofibrous membrane, the bionic two-dimensional honeycomb and three-dimensional spinous dual-coupled microstructures in the ordered porous nanofibrous membrane endows the electronic skin with significantly improved mechanical properties (maximum tensile strain increased by 77% and fatigue resistance increased by 35%), air permeability (water vapor transmission rate increased by 16%) and sensing properties (pressure sensitivity increased by 276% and detection range increased by 137%). Furthermore, the electronic skin was constructed by means of a conformal composite ionic liquid functionalized nanofibrous membrane, and the real-time and interference-free dual-signal monitoring of pressure and temperature (maximum temperature coefficient of resistance: −0.918 °C−1) was realized. -

References

[1] Wang X, Qu M C, Wu K Q, et al. High sensitive electrospun thermoplastic polyurethane/carbon nanotubes strain sensor fitting by a novel optimization empirical model. Adv Compos Hybrid Mater, 2023, 6(2), 63 doi: 10.1007/s42114-023-00648-x[2] Huang X W, Zou X B, Shi J Y, et al. Colorimetric sensor arrays based on chemo-responsive dyes for food odor visualization. Trends Food Sci Technol, 2018, 81, 90 doi: 10.1016/j.jpgs.2018.09.001[3] Huang X Y, Pan S H, Sun Z Y, et al. Evaluating quality of tomato during storage using fusion information of computer vision and electronic nose. J Food Process Eng, 2018, 41(6), e12832 doi: 10.1111/jfpe.12832[4] Jing Z F, Ding J C, Zhang T, et al. Flexible, versatility and superhydrophobic biomass carbon aerogels derived from corn bracts for efficient oil/water separation. Food Bioprod Process, 2019, 115, 134 doi: 10.1016/j.fbp.2019.03.010[5] Han F K, Huang X Y, Aheto J H, et al. Detection of beef adulterated with pork using a low-cost electronic nose based on colorimetric sensors. Foods, 2020, 9(2), 193 doi: 10.3390/foods9020193[6] Zou Q, Zhou S L, Su Q, et al. Flexible pressure and temperature dual-modality sensor based on stretchable electrode for human−machine interaction. J Micromech Microeng, 2023, 33(4), 045005 doi: 10.1088/1361-6439/acbe4b[7] Adade S Y S, Lin H, Nunekpeku X, et al. Flexible paper-based AuNP sensor for rapid detection of diabenz (a, h)anthracene (DbA) and benzo(b)fluoranthene (BbF) in mussels coupled with deep learning algorithms. Food Contr, 2025, 168, 110966 doi: 10.1016/j.foodcont.2024.110966[8] Kedambaimoole V, Kumar N, Shirhatti V, et al. Laser-induced direct patterning of free-standing Ti3C2-MXene films for skin conformal tattoo sensors. ACS Sens, 2020, 5(7), 2086 doi: 10.1021/acssensors.0c00647[9] Niu H S, Li H, Gao S, et al. Perception-to-cognition tactile sensing based on artificial-intelligence-motivated human full-skin bionic electronic skin. Adv Mater, 2022, 34(31), e2202622 doi: 10.1002/adma.202202622[10] Niu H S, Wei X, Li H, et al. Micropyramid array bimodal electronic skin for intelligent material and surface shape perception based on capacitive sensing. Adv Sci, 2024, 11(3), e2305528 doi: 10.1002/advs.202305528[11] Wang C W, Niu H S, Shen G Z, et al. Self-healing hydrogel-based triboelectric nanogenerator in smart glove system for integrated drone safety protection and motion control. Adv Funct Materials, 2025, 35(17), 2419809 doi: 10.1002/adfm.202419809[12] Niu H S, Li H, Li N, et al. Fringing-effect-based capacitive proximity sensors. Adv Funct Materials, 2024, 34(51), 2409820 doi: 10.1002/adfm.202409820[13] Wang L, Chen Y, Lin L W, et al. Highly stretchable, anti-corrosive and wearable strain sensors based on the PDMS/CNTs decorated elastomer nanofiber composite. Chem Eng J, 2019, 362, 89 doi: 10.1016/j.cej.2019.01.014[14] Wang X Y, You T T, Zheng W Q, et al. Efficient fabrication of cellulose nanofibers with novel superbase-derived ionic liquid/co-solvents: Rapid cellulose dissolution and improved solution electrospinnability. Chem Eng J, 2024, 483, 148841 doi: 10.1016/j.cej.2024.148841[15] Zhu Q Y, Li P H, Gao J Q, et al. A facile fabrication strategy constructed multilayer piezoresistive pressure sensor for intelligent recognition system towards privacy protection. Chem Eng J, 2024, 486, 150201 doi: 10.1016/j.cej.2024.150201[16] Jiang N, Li H, Hu D W, et al. Stretchable strain and temperature sensor based on fibrous polyurethane film saturated with ionic liquid. Compos Commun, 2021, 27, 100845 doi: 10.1016/j.coco.2021.100845[17] Zhao S, Zhu R. Flexible bimodal sensor for simultaneous and independent perceiving of pressure and temperature stimuli. Adv Mater Technol, 2017, 2(11), 1700183 doi: 10.1002/admt.201700183[18] Wan S, Zhu Z H, Yin K B, et al. Strain sensors: A highly skin-conformal and biodegradable graphene-based strain sensor (small methods 10/2018). Small Meth, 2018, 2(10), 1800047 doi: 10.1002/smtd.201870047[19] Yan J F, Ma Y N, Jia G, et al. Bionic MXene based hybrid film design for an ultrasensitive piezoresistive pressure sensor. Chem Eng J, 2022, 431, 133458 doi: 10.1016/j.cej.2021.133458[20] Zhao X F, Hang C Z, Lu H L, et al. A skin-like sensor for intelligent Braille recognition. Nano Energy, 2020, 68, 104346 doi: 10.1016/j.nanoen.2019.104346[21] Chang K Q, Dong J C, Mao Y H, et al. Presenting the shape of sound through a dual-mode strain/tactile sensor. J Mater Chem A, 2023, 11(34), 18179 doi: 10.1039/D3TA03398H[22] Gao F L, Liu J, Li X P, et al. Ti3C2Tx MXene-based multifunctional tactile sensors for precisely detecting and distinguishing temperature and pressure stimuli. ACS Nano, 2023, 17(16), 16036 doi: 10.1021/acsnano.3c04650[23] Yuan T K, Yin R L, Li C W, et al. Ti3C2Tx MXene-based all-resistive dual-mode sensor with near-zero temperature coefficient of resistance for crosstalk-free pressure and temperature detections. Chem Eng J, 2024, 487, 150396 doi: 10.1016/j.cej.2024.150396[24] Ma X L, Wang C F, Wei R L, et al. Bimodal tactile sensor without signal fusion for user-interactive applications. ACS Nano, 2022, 16(2), 2789 doi: 10.1021/acsnano.1c09779[25] He Q, Zhou Z L, Swe M M, et al. Skin-inspired flexible and printed iontronic sensor enables bimodal sensing of robot skin for machine-learning-assisted object recognition. Nano Energy, 2025, 134, 110583 doi: 10.1016/j.nanoen.2024.110583[26] Liu Y F, He C L, Fang J H, et al. A tri-modal tactile sensor based on porous ionic hydrogel for decoupled sensing of temperature and pressure. Mater Today Phys, 2024, 41, 101331 doi: 10.1016/j.mtphys.2024.101331[27] Chen Y F, Lei H, Gao Z Q, et al. Energy autonomous electronic skin with direct temperature-pressure perception. Nano Energy, 2022, 98, 107273 doi: 10.1016/j.nanoen.2022.107273[28] Cao H L, Chai S S, Tan Z F, et al. Recent advances in physical sensors based on electrospinning technology. ACS Mater Lett, 2023, 5(6), 1627 doi: 10.1021/acsmaterialslett.3c00144[29] Chen X, Wang J H, Zhang J T, et al. Development and application of electrospun fiber-based multifunctional sensors. Chem Eng J, 2024, 486, 150204 doi: 10.1016/j.cej.2024.150204[30] Chang K B, Parashar P, Shen L C, et al. A triboelectric nanogenerator-based tactile sensor array system for monitoring pressure distribution inside prosthetic limb. Nano Energy, 2023, 111, 108397 doi: 10.1016/j.nanoen.2023.108397[31] Zhu Q Z, Zhu Z H, Zhang H Y, et al. Design of an electronically controlled fertilization system for an air-assisted side-deep fertilization machine. Agriculture, 2023, 13(12), 2210 doi: 10.3390/agriculture13122210[32] Gou X, Yang J, Li P, et al. Biomimetic nanofiber-iongel composites for flexible pressure sensors with broad range and ultra-high sensitivity. Nano Energy, 2024, 120, 109140 doi: 10.1016/j.nanoen.2023.109140[33] Guo Y C, Zhang H N, Fang L, et al. A self-powered flexible piezoelectric sensor patch for deep learning-assisted motion identification and rehabilitation training system. Nano Energy, 2024, 123, 109427 doi: 10.1016/j.nanoen.2024.109427[34] Wang P, Liu G S, Sun G F, et al. An integrated bifunctional pressure‒temperature sensing system fabricated on a breathable nanofiber and powered by rechargeable zinc−air battery for long-term comfortable health care monitoring. Adv Fiber Mater, 2024, 6(4), 1037 doi: 10.1007/s42765-024-00398-5[35] Han L H, Kumi F, Mao H P, et al. Design and tests of a multi-pin flexible seedling pick-up gripper for automatic transplanting. Appl Eng Agric, 2019, 35(6), 949 doi: 10.13031/aea.13426[36] Pi J, Liu J, Zhou K H, et al. An octopus-inspired bionic flexible gripper for apple grasping. Agriculture, 2021, 11(10), 1014 doi: 10.3390/agriculture11101014[37] Zhou K H, Xia L R, Liu J, et al. Design of a flexible end-effector based on characteristics of tomatoes. Int J Agric Biol Eng, 2022, 15(2), 13[38] Wu Z J, Huang J R, Zhao Y K, et al. Lotus leaf-inspired superhydrophobic piezoelectric nanofiber films for moisture-proof pressure sensing and energy harvesting. Chem Eng J, 2025, 504, 158874 doi: 10.1016/j.cej.2024.158874[39] Ding S S, Jin X, Guo J, et al. A biomimetic asymmetric structured intelligent wound dressing with dual-modality humidity-pressure sensing for non-invasive and real-time wound healing monitoring. Adv Fiber Mater, 2025, 7(1), 156 doi: 10.1007/s42765-024-00473-x[40] Zhang Y B, Dai X, Zhou Y, et al. Ultra-thin and sensitive pressure sensor based on MXene/PVDF-HFP composite fiber TENG for self-diagnosis of ligament injuries. Nano Energy, 2024, 132, 110372 doi: 10.1016/j.nanoen.2024.110372[41] Zhang J H, Li Z T, Xu J, et al. Versatile self-assembled electrospun micropyramid arrays for high-performance on-skin devices with minimal sensory interference. Nat Commun, 2022, 13(1), 5839 doi: 10.1038/s41467-022-33454-y[42] Wu P Q, Gu J F, Liu X, et al. A robust core-shell nanofabric with personal protection, health monitoring and physical comfort for smart sportswear. Adv Mater, 2024, 36(47), e2411131 doi: 10.1002/adma.202411131[43] Wang S, Tian M H, Hu S Y, et al. Hierarchical nanofibrous mat via water-assisted electrospinning for self-powered ultrasensitive vibration sensors. Nano Energy, 2022, 97, 107149 doi: 10.1016/j.nanoen.2022.107149[44] Li Y H, Huang Y, Zhao N. Low-intensity sensitive and high stability flexible heart sound sensor enabled by hybrid near-field/far-field electrospinning. Adv Funct Materials, 2023, 33(29), 2300666 doi: 10.1002/adfm.202300666[45] Wang S G, Fan P, Liu W B, et al. Research progress of flexible electronic devices based on electrospun nanofibers. ACS Nano, 2024, 18(46), 31737 doi: 10.1021/acsnano.4c13106[46] Yin J, Reddy V S, Chinnappan A, et al. Electrospun micro/nanofiber with various structures and functions for wearable physical sensors. Polym Rev, 2023, 63(3), 715 doi: 10.1080/15583724.2022.2158467[47] Gao Z Y, Xiao X, Di Carlo A, et al. Advances in wearable strain sensors based on electrospun fibers. Adv Funct Materials, 2023, 33(18), 2214265 doi: 10.1002/adfm.202214265[48] Ghosh S, Khastgir D, Bhowmick A K, et al. Thermal degradation and ageing of segmented polyamides. Polym Degrad Stab, 2000, 67(3), 427 doi: 10.1016/S0141-3910(99)00141-X[49] Needleman A, Borders T L, Brinson L C, et al. Effect of an interphase region on debonding of a CNT reinforced polymer composite. Compos Sci Technol, 2010, 70(15), 2207 doi: 10.1016/j.compscitech.2010.09.002[50] Fu Y, Wang S K, Tian Y, et al. A high-sensitivity and multi-response magnetic nanofiber-aerogel sensor with directionally aligned porous structure based on triple network for interactive human−machine interfaces. Chem Eng J, 2024, 497, 154441 doi: 10.1016/j.cej.2024.154441[51] Shrestha K, Pradhan G B, Bhatta T, et al. Intermediate nanofibrous charge trapping layer-based wearable triboelectric self-powered sensor for human activity recognition and user identification. Nano Energy, 2023, 108, 108180 doi: 10.1016/j.nanoen.2023.108180 -

Supplements

25020031Supplemental_Material.pdf

25020031Supplemental_Material.pdf

-

Proportional views

Hao Zhu is a Ph.D. Student in the School of Mechanical Engineering at Jiangsu University, under the supervision of Prof. Guanggui Cheng. His research interests focus on the design and fabrication of flexible, wearable, and multifunctional electronic skin.

Hao Zhu is a Ph.D. Student in the School of Mechanical Engineering at Jiangsu University, under the supervision of Prof. Guanggui Cheng. His research interests focus on the design and fabrication of flexible, wearable, and multifunctional electronic skin. Zhelin Jin is a Ph.D. Student in the School of Mechanical Engineering at Jiangsu University, under the supervision of Prof. Guanggui Cheng. His research interests focus on micro-nano energy harvesting, self-powered sensors/systems and intelligent electronic device.

Zhelin Jin is a Ph.D. Student in the School of Mechanical Engineering at Jiangsu University, under the supervision of Prof. Guanggui Cheng. His research interests focus on micro-nano energy harvesting, self-powered sensors/systems and intelligent electronic device. Tie Li received his Ph.D. degree in Materials Physics and Chemistry from Fudan University in 2014, and then he was a Postdoctor at Suzhou Institute of Nano-Tech and Nano-Bionics (SINANO), Chinese Academy of Sciences (CAS) from 2014 to 2017, where he is now a Professor. His current research area includes programmable functional nanocomposite and devisable flexible sensors for energy conversion and wearable/portal electronics.

Tie Li received his Ph.D. degree in Materials Physics and Chemistry from Fudan University in 2014, and then he was a Postdoctor at Suzhou Institute of Nano-Tech and Nano-Bionics (SINANO), Chinese Academy of Sciences (CAS) from 2014 to 2017, where he is now a Professor. His current research area includes programmable functional nanocomposite and devisable flexible sensors for energy conversion and wearable/portal electronics. Guanggui Cheng received his Ph.D. degree from Jiangsu University in 2010. After graduation, he worked at Tulane University, America as a visiting scholar. Now he is professor in Jiangsu University, cultivated by the second level of "333" talents in Jiangsu Province. His research interests are surface/interface science and technology, triboelectric nanogenerator and self-powered sensors/systems.

Guanggui Cheng received his Ph.D. degree from Jiangsu University in 2010. After graduation, he worked at Tulane University, America as a visiting scholar. Now he is professor in Jiangsu University, cultivated by the second level of "333" talents in Jiangsu Province. His research interests are surface/interface science and technology, triboelectric nanogenerator and self-powered sensors/systems. Jianning Ding got his Ph.D. degree from Tsinghua University of Mechanical Design and Theory and is now doing research in Yangzhou University as a Professor. His research interests focus on flexible mechatronics, new energy technology and equipment functional devices, including solar cell, flexible sensors, soft robotics, and so on.

Jianning Ding got his Ph.D. degree from Tsinghua University of Mechanical Design and Theory and is now doing research in Yangzhou University as a Professor. His research interests focus on flexible mechatronics, new energy technology and equipment functional devices, including solar cell, flexible sensors, soft robotics, and so on.

DownLoad:

DownLoad: