| Citation: |

Yuehao Li, Chao Shen, Wenkang Zhan, Bo Xu, Yazhou Yang, Xu Zhang, Hongchang Wang, Chao Zhao, Haifang Jian. Contrastive learning for data-efficient substrate deoxidation monitoring in edge-side adaptive molecular beam epitaxy systems[J]. Journal of Semiconductors, 2026, In Press. doi: 10.1088/1674-4926/25070029

****

Y H Li, C Shen, W K Zhan, B Xu, Y Z Yang, X Zhang, H C Wang, C Zhao, and H F Jian, Contrastive learning for data-efficient substrate deoxidation monitoring in edge-side adaptive molecular beam epitaxy systems[J]. J. Semicond., 2026, 47(3): 032101 doi: 10.1088/1674-4926/25070029

|

Contrastive learning for data-efficient substrate deoxidation monitoring in edge-side adaptive molecular beam epitaxy systems

DOI: 10.1088/1674-4926/25070029

CSTR: 32376.14.1674-4926.25070029

More Information-

Abstract

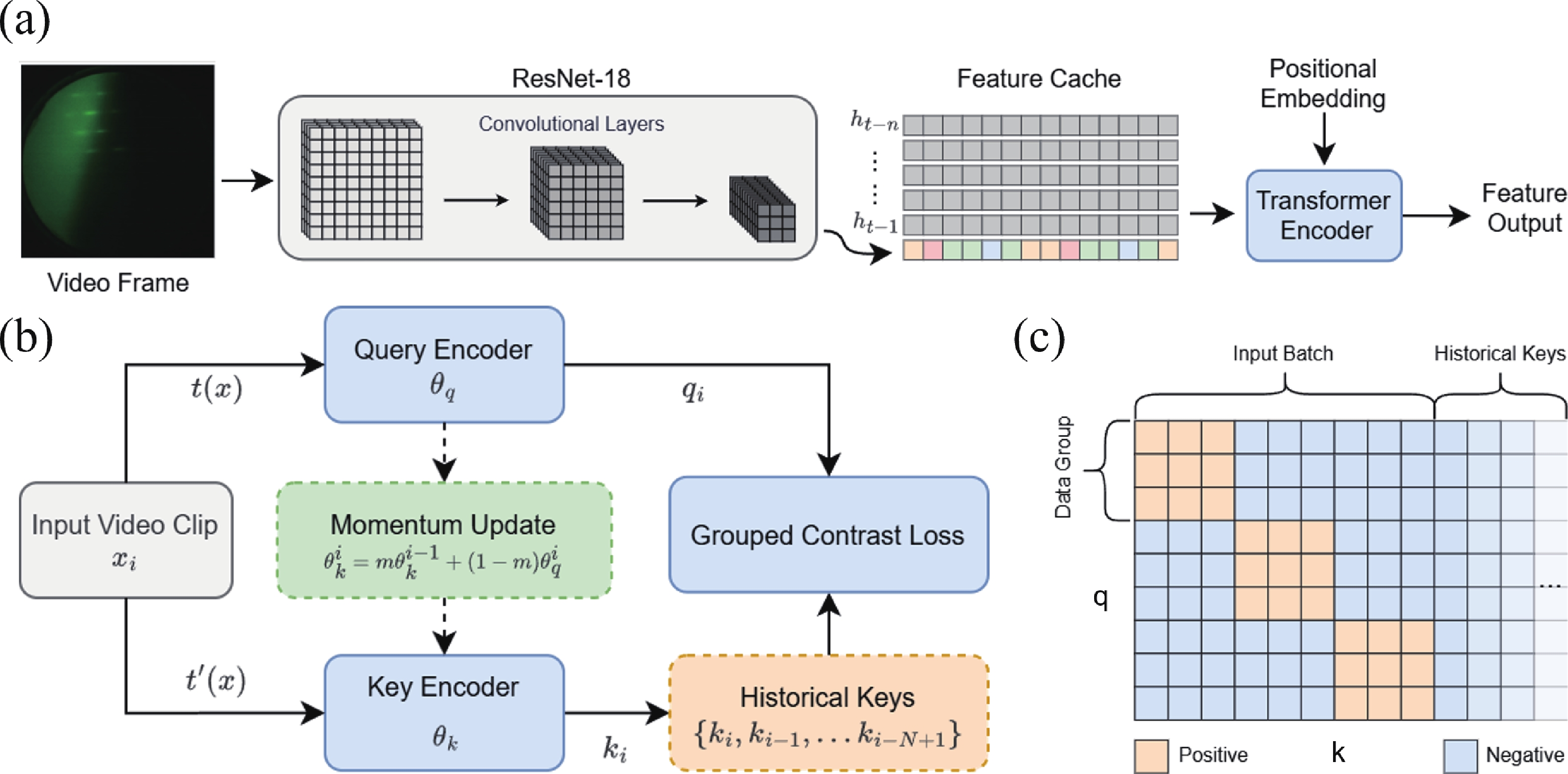

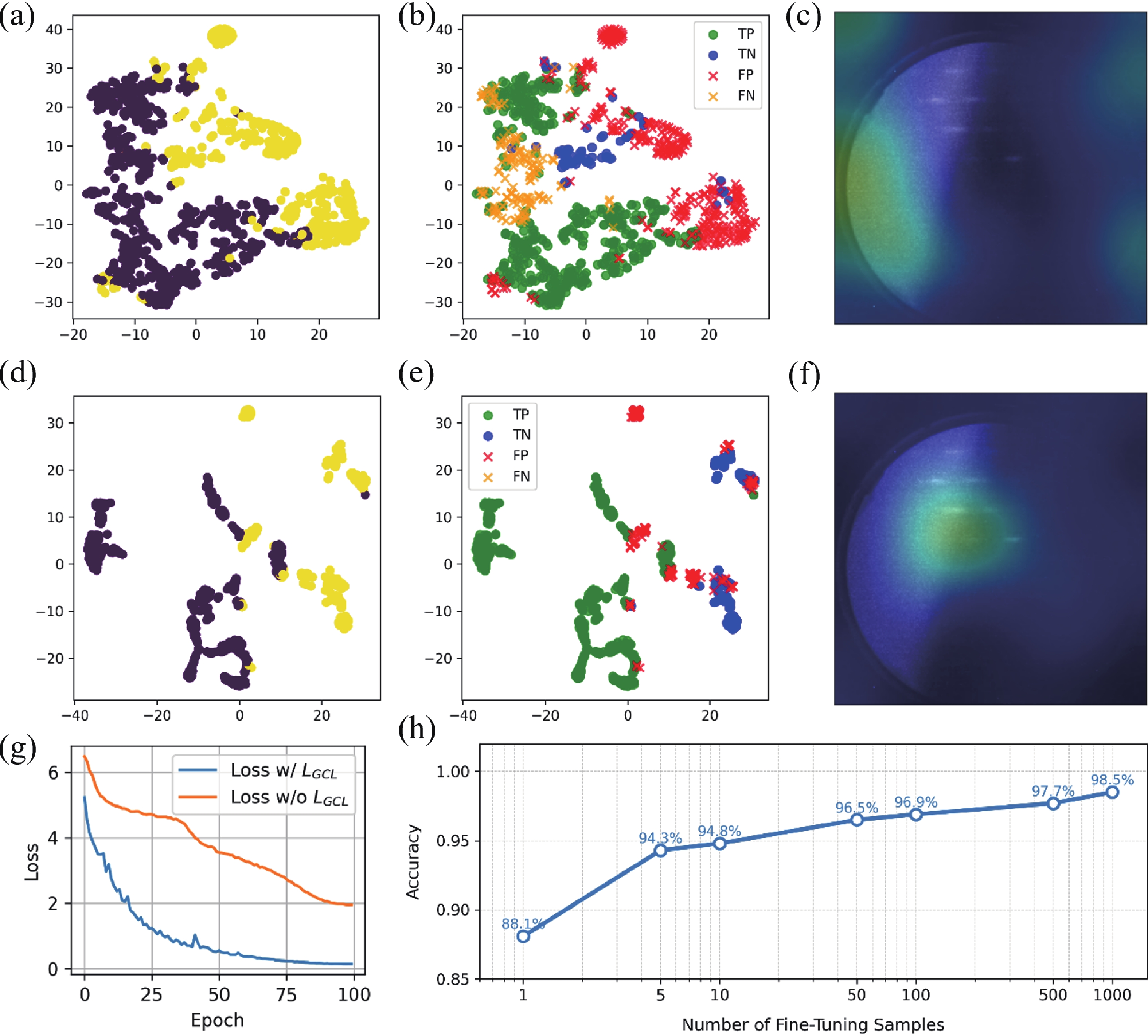

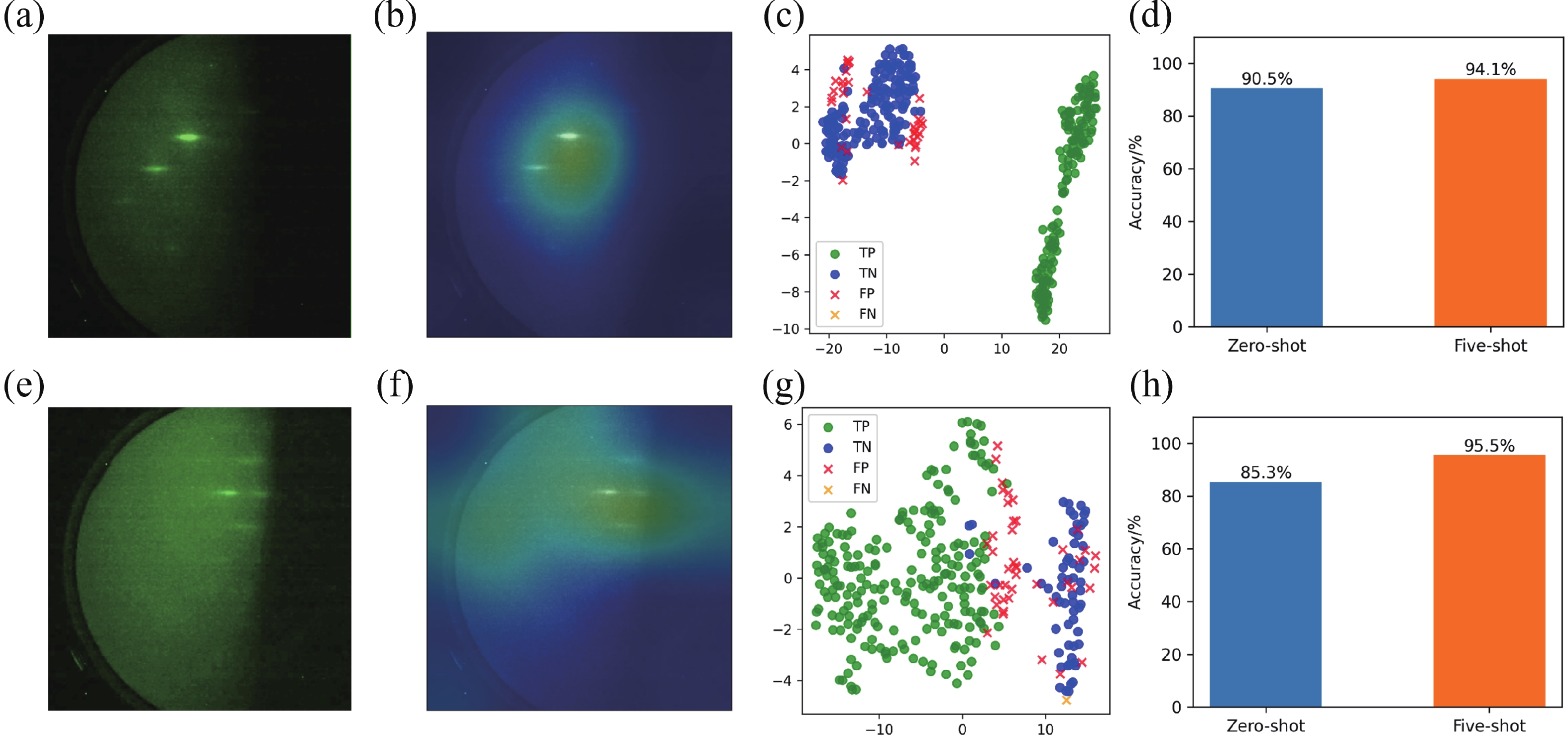

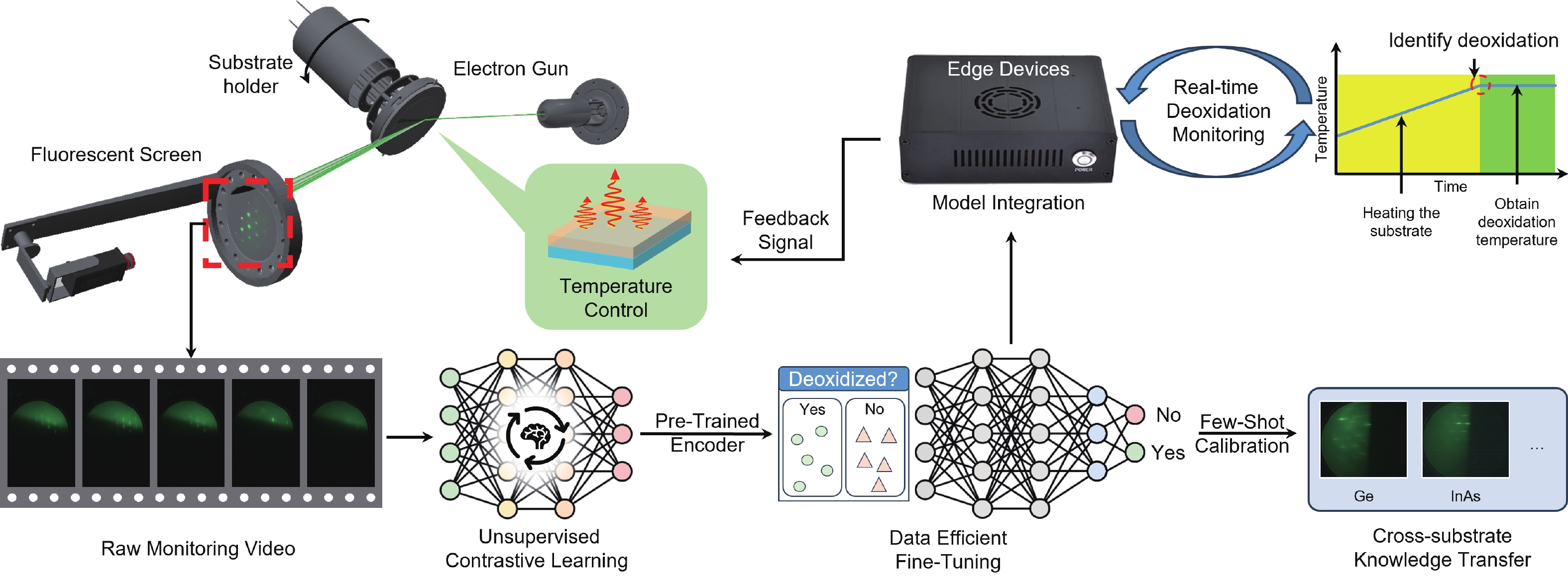

Accurate temperature control and effective oxide removal are essential for achieving high-quality epitaxial growth in molecular beam epitaxy (MBE). However, traditional methods often rely on manual identification of reflection high-energy electron diffraction (RHEED) patterns. This process is heavily influenced by the grower’s experience, leading to issues with reproducibility and limiting the potential for automation. In this report, we propose an unsupervised learning framework for real-time RHEED analysis during the deoxidation process. By incorporating temporal similarity constraints into contrastive learning, our model generates smooth and interpretable feature trajectories that illustrate transitions in the deoxidation state, thus eliminating the need for manual labeling. The model, pre-trained using grouped contrastive loss, shows significant improvement in RHEED feature boundary discrimination and localization of critical regions. We evaluated its generalizability through two transfer learning strategies: calibration-free clustering and few-shot fine-tuning. The pre-trained model achieved a clustering accuracy of 88.1% for GaAs deoxidation samples without additional labels and reached an accuracy of 94.3% to 95.5% after fine-tuning with just five sample pairs across GaAs, Ge, and InAs substrates. This framework is optimized for resource-constrained edge devices, allowing for real-time, plug-and-play integration with existing MBE systems and swift adaptation across various materials and equipment. This work paves the way for greater automation and improved reproducibility in semiconductor manufacturing. -

References

[1] Jain P, Honnungar R V. A review on materials for integrated optical waveguides. Proceedings of Fourth International Conference on Inventive Material Science Applications. Singapore: Springer Singapore, 2021: 55 doi: 10.1007/978-981-16-4321-7_5[2] Vyas K, Espinosa D H, Hutama D, et al. Group Ⅲ−Ⅴ semiconductors as promising nonlinear integrated photonic platforms. Adv Phys X, 2022, 7(1): 2097020 doi: 10.1080/23746149.2022.2097020[3] Kum H, Lee D, Kong W, et al. Epitaxial growth and layer−transfer techniques for heterogeneous integration of materials for electronic and photonic devices. Nat Electron, 2019, 2: 439 doi: 10.1038/s41928-019-0314-2[4] Lee Y, Choi S H, Kim H, et al. Epitaxy of emerging materials and advanced heterostructures for microelectronics and quantum sciences. Small Methods, 2025, 9(8): e2401815 doi: 10.1002/smtd.202401815[5] Tan C L, Chen J Z, Wu X J, et al. Epitaxial growth of hybrid nanostructures. Nat Rev Mater, 2018, 3(2): 17089 doi: 10.1038/natrevmats.2017.89[6] Solomon G S, Trezza J A, Harris J S Jr. Substrate temperature and monolayer coverage effects on epitaxial ordering of InAs and InGaAs islands on GaAs. Appl Phys Lett, 1995, 66(8): 991 doi: 10.1063/1.113822[7] Sfaxi L, Bouzaiene L, Sghaier H, et al. Effect of growth temperature on InAs wetting layer grown on (113)a GaAs by molecular beam epitaxy. J Cryst Growth, 2006, 293(2): 330 doi: 10.1016/j.jcrysgro.2006.05.042[8] Shen C, Zhan W K, Xin K Y, et al. Machine-learning-assisted and real−time−feedback−controlled growth of InAs/GaAs quantum dots. Nat Commun, 2024, 15: 2724 doi: 10.1038/s41467-024-47087-w[9] O’Steen M, Readinger E, Farrell S, et al. Systems and technology for production-scale molecular beam epitaxy. Molecular Beam Epitaxy. Amsterdam: Elsevier, 2018: 649 doi: 10.1016/B978-0-12-812136-8.00031-1[10] Arthur J R. Molecular beam epitaxy. Surf Sci, 2002, 500(1/2/3): 189 doi: 10.1016/S0039-6028(01)01525-4[11] Richter R, Hartnagel H L. Kinetics of oxidation on differently treated GaAs (100) surfaces studied by XPS and STM. J Electrochem Soc, 1990, 137(9): 2879 doi: 10.1149/1.2087092[12] Shen C, Zhan W K, Tang J, et al. Universal deoxidation of semiconductor substrates assisted by machine learning and real-time feedback control. ACS Appl Mater Interfaces, 2024, 16(14): 18213 doi: 10.1021/acsami.4c01765[13] Khaireh−Walieh A, Arnoult A, Plissard S, et al. Monitoring MBE substrate deoxidation via RHEED image-sequence analysis by deep learning. Cryst Growth Des, 2023, 23(2): 892 doi: 10.1021/acs.cgd.2c01132[14] Ritchie S, Johnson S R, Lavoie C, et al. Semiconductor substrate cleaning and surface morphology in molecular beam epitaxy. Surf Sci, 1997, 374(1/2/3): 418 doi: 10.1016/S0039-6028(96)00808-4[15] Feng L, Zhang L, Liu H, et al. Characterization study of native oxides on GaAs (100) surface by XPS. International Symposium on Photoelectronic Detection and Imaging 2013: Low-Light-Level Technology and Applications, 2013: 89120N. doi: 10.1117/12.2033679[16] Chin A, Chen W J, Chang T, et al. Thin oxides with in situ native oxide removal [n-MOSFETs]. IEEE Electron Device Lett, 1997, 18(9): 417 doi: 10.1109/55.622515[17] Chin A, Lin B C, Chen W J, et al. The effect of native oxide on thin gate oxide integrity. IEEE Electron Device Lett, 1998, 19(11): 426 doi: 10.1109/55.728901[18] Cho A Y, Arthur J R. Molecular beam epitaxy. Prog Solid State Chem, 1975, 10: 157 doi: 10.1016/0079-6786(75)90005-9[19] Xu P C, Ji X B, Li M J, et al. Small data machine learning in materials science. NPJ Comput Mater, 2023, 9: 42 doi: 10.1038/s41524-023-01000-z[20] Chong S S, Ng Y S, Wang H Q, et al. Advances of machine learning in materials science: Ideas and techniques. Front Phys, 2023, 19(1): 13501 doi: 10.1007/s11467-023-1325-z#[21] Kwoen J, Arakawa Y. Classification of reflection high-energy electron diffraction pattern using machine learning. Cryst Growth Des, 2020, 20(8): 5289 doi: 10.1021/acs.cgd.0c00506[22] Kwoen J, Arakawa Y. Classification of in situ reflection high energy electron diffraction images by principal component analysis. Jpn J Appl Phys, 2021, 60: SBBK03 doi: 10.35848/1347-4065/abdad5[23] Kwoen J, Arakawa Y. Multiclass classification of reflection high−energy electron diffraction patterns using deep learning. J Cryst Growth, 2022, 593: 126780 doi: 10.1016/j.jcrysgro.2022.126780[24] Liang H T, Stanev V, Kusne A G, et al. Application of machine learning to reflection high-energy electron diffraction images for automated structural phase mapping. Phys Rev Materials, 2022, 6(6): 063805 doi: 10.1103/PhysRevMaterials.6.063805[25] Kim H J, Chong M S, Rhee T G, et al. Machine-learning-assisted analysis of transition metal dichalcogenide thin−film growth. Nano Convergence, 2023, 10(1): 10 doi: 10.1186/s40580-023-00359-5[26] Provence S R, Thapa S, Paudel R, et al. Machine learning analysis of perovskite oxides grown by molecular beam epitaxy. Phys Rev Materials, 2020, 4(8): 083807 doi: 10.1103/PhysRevMaterials.4.083807[27] Morgan D, Jacobs R. Opportunities and challenges for machine learning in materials science. Annu Rev Mater Res, 2020, 50: 71 doi: 10.1146/annurev-matsci-070218-010015[28] Zhu L G, Zhou J, Sun Z M. Materials data toward machine learning: Advances and challenges. J Phys Chem Lett, 2022, 13(18): 3965 doi: 10.1021/acs.jpclett.2c00576[29] Limanond S, Si J, Tsakalis K. Monitoring and control of semiconductor manufacturing processes. IEEE Contr Syst Mag, 1998, 18(6): 46 doi: 10.1109/37.736011[30] Wang F X, Zhang M, Wang X X, et al. Deep learning for edge computing applications: A state-of-the-art survey. IEEE Access, 2020, 8: 58322 doi: 10.1109/ACCESS.2020.2982411[31] Shuvo M M H, Islam S K, Cheng J L, et al. Efficient acceleration of deep learning inference on resource-constrained edge devices: A review. Proc IEEE, 2023, 111(1): 42 doi: 10.1109/JPROC.2022.3226481[32] Gui J, Chen T, Zhang J, et al. A survey on self−supervised learning: Algorithms, applications, and future trends. IEEE Trans Pattern Anal Mach Intell, 2024, 46(12): 9052 doi: 10.1109/TPAMI.2024.3415112[33] Jaiswal A, Babu A R, Zadeh M Z, et al. A survey on contrastive self−supervised learning. Technologies, 2021, 9(1): 2 doi: 10.48550/arXiv.2011.00362[34] Le−Khac P H, Healy G, Smeaton A F. Contrastive representation learning: A framework and review. IEEE Access, 2020, 8: 193907 doi: 10.1109/ACCESS.2020.3031549[35] Chen T, Kornblith S, Norouzi M, et al. A simple framework for contrastive learning of visual representations. International Conference on Machine Learning, 2020: 1597[36] Zhang H J, Qiang W W, Zhang J X, et al. Unified feature extraction framework based on contrastive learning. Knowl Based Syst, 2022, 258: 110028 doi: 10.1016/j.knosys.2022.110028[37] Kaur K, Garg S, Aujla G S, et al. Edge computing in the industrial Internet of Things environment: Software-defined-networks−based edge−cloud interplay. IEEE Commun Mag, 2018, 56(2): 44 doi: 10.1109/MCOM.2018.1700622[38] Chalapathi G S S, Chamola V, Vaish A, et al. Industrial Internet of Things (IIoT) applications of edge and fog computing: A review and future directions. Fog/Edge Computing For Security, Privacy, and Applications. Cham: Springer International Publishing, 2021: 293 doi: 10.1007/978-3-030-57328-7_12[39] Kumar R, Sharma A. Edge AI: a review of machine learning models for resource−constrained devices. Artificial Intelligence and Machine Learning Review, 2024, 5(3): 1[40] He K M, Fan H Q, Wu Y X, et al. Momentum contrast for unsupervised visual representation learning. 2020 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), 2020: 9729 doi: 10.1109/CVPR42600.2020.00975[41] Asaoka Y. Desorption process of GaAs surface native oxide controlled by direct Ga-beam irradiation. J Cryst Growth, 2003, 251(1/2/3/4): 40 doi: 10.1016/S0022-0248(02)02492-2[42] Bruni M R, Gambacorti N, Kačiulis S, et al. Role of the substrate deoxidation process in the growth of strained InAs/InP heterostructures. J Cryst Growth, 1995, 150: 123 doi: 10.1016/0022-0248(95)80193-G[43] Oh J, Campbell J C. Thermal desorption of Ge native oxides and loss of Ge from the surface. Mater Sci Semicond Process, 2010, 13(3): 185 doi: 10.1016/j.mssp.2010.10.009[44] Shorten C, Khoshgoftaar T M. A survey on image data augmentation for deep learning. J Big Data, 2019, 6(1): 60 doi: 10.1186/s40537-019-0197-0[45] Vindas Y, Guépié B K, Almar M, et al. An hybrid CNN-Transformer model based on multi-feature extraction and attention fusion mechanism for cerebral emboli classification. Machine Learning in Health Care, 2022[46] He K M, Zhang X Y, Ren S Q, et al. Deep residual learning for image recognition. 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), 2016: 770 doi: 10.1109/CVPR.2016.90[47] Vaswani A, Shazeer N, Parmar N, et al. Attention is all you need. Advances in Neural Information Processing Systems, 2017, 30: 5998[48] Wang F, Liu H P. Understanding the behaviour of contrastive loss. 2021 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), 2021: 2495 doi: 10.1109/CVPR46437.2021.00252[49] Chen C, Zhang J, Xu Y, et al. Why do we need large batchsizes in contrastive learning? A gradient-bias perspective. Advances in Neural Information Processing Systems, 2022, 35: 33860[50] Wu Z R, Xiong Y J, Yu S X, et al. Unsupervised feature learning via non-parametric instance discrimination. 2018 IEEE/CVF Conference on Computer Vision and Pattern Recognition, 2018: 3733 doi: 10.1109/CVPR.2018.00393[51] van den Oord A, Li Y, Vinyals O. Representation learning with contrastive predictive coding. arXiv: 1807.03748, 2018[52] Zhang X, Zhao Z, Tsiligkaridis T, et al. Self-supervised contrastive pre-training for time series via time-frequency consistency, Advances in Neural Information Processing Systems, 2022, 35, 3988[53] McCullagh P, Nelder J A. Generalized linear models. London: Routledge, 2019 doi: 10.1016/0377-2217(84)90282-0[54] Ikotun A M, Ezugwu A E, Abualigah L, et al. K-means clustering algorithms: A comprehensive review, variants analysis, and advances in the era of big data. Inf Sci, 2023, 622: 178 doi: 10.1016/j.ins.2022.11.139[55] Maaten L. Accelerating t-SNE using tree-based algorithms. J Mach Learn Res, 2023, 15: 3221[56] Arora S, Hu W, Kothari P K. An analysis of the t-SNE algorithm for data visualization. Conference on Learning Theory, 2018: 1455[57] Selvaraju R R, Cogswell M, Das A, et al. Grad-CAM: Visual explanations from deep networks via gradient-based localization. 2017 IEEE International Conference on Computer Vision (ICCV), 2017: 618 doi: 10.1109/ICCV.2017.74[58] Wei X X, Zhang Z H, Huang H J, et al. An overview on deep clustering. Neurocomputing, 2024, 590: 127761 doi: 10.1016/j.neucom.2024.127761[59] Zheng Y, Chen Y H, Qian B, et al. A review on edge large language models: Design, execution, and applications. ACM Comput Surv, 2025, 57(8): 1 doi: 10.1145/3719664[60] Alam S, Yakopcic C, Wu Q, et al. Survey of deep learning accelerators for edge and emerging computing. Electronics, 2024, 13(15): 2988 doi: 10.3390/electronics13152988[61] Barnell M, Raymond C, Smiley S, et al. Ultra low-power deep learning applications at the edge with jetson orin AGX hardware. 2022 IEEE High Performance Extreme Computing Conference (HPEC), 2022: 1 doi: 10.1109/HPEC55821.2022.9926369 -

Supplements

supp-vid(0).mp4

supp-vid(0).mp4

25070029_supplementary.pdf

25070029_supplementary.pdf

-

Proportional views

Supplementary materials to this article can be found online at https://doi.org/10.1088/1674-4926/25070029.

§Yuehao Li and Chao Shen contributed equally to this work and should be considered as co-first authors.

Yuehao Li got his BS from Chongqing University of Posts and Telecommunications in 2022. Now he is a PhD student at Institute of Semiconductors, Chinese Academy of Sciences under the supervision of Prof. Haifang Jian. His research focuses on intelligent information processing.

Yuehao Li got his BS from Chongqing University of Posts and Telecommunications in 2022. Now he is a PhD student at Institute of Semiconductors, Chinese Academy of Sciences under the supervision of Prof. Haifang Jian. His research focuses on intelligent information processing. Chao Shen got his BS from Yancheng Teachers University in 2020 and MS from Xinjiang University in 2024. Now he is a PhD student at Institute of Semiconductors, Chinese Academy of Sciences under the supervision of Prof. Chao Zhao. His research focuses on heteroepitaxy of Ⅲ−Ⅴ semiconductor materials.

Chao Shen got his BS from Yancheng Teachers University in 2020 and MS from Xinjiang University in 2024. Now he is a PhD student at Institute of Semiconductors, Chinese Academy of Sciences under the supervision of Prof. Chao Zhao. His research focuses on heteroepitaxy of Ⅲ−Ⅴ semiconductor materials. Chao Zhao got his BS from Tianjin University in 2004 and PhD from Institute of Semiconductors, Chinese Academy of Sciences in 2009. Now he is a full professor at Institute of Semiconductors. His research focuses on heteroepitaxy of Ⅲ−Ⅴ semiconductor materials and device fabrication.

Chao Zhao got his BS from Tianjin University in 2004 and PhD from Institute of Semiconductors, Chinese Academy of Sciences in 2009. Now he is a full professor at Institute of Semiconductors. His research focuses on heteroepitaxy of Ⅲ−Ⅴ semiconductor materials and device fabrication. Haifang Jian got his BS from Shandong University in 2000, Ms from Beijing Institute of Technology in 2005, and PhD from Institute of Semiconductors, Chinese Academy of Sciences in 2010. Now he is a full professor at Institute of Semiconductors, Chinese Academy of Science. His research focuses on design of high-performance integrated circuits and intelligent information processing algorithms and systems.

Haifang Jian got his BS from Shandong University in 2000, Ms from Beijing Institute of Technology in 2005, and PhD from Institute of Semiconductors, Chinese Academy of Sciences in 2010. Now he is a full professor at Institute of Semiconductors, Chinese Academy of Science. His research focuses on design of high-performance integrated circuits and intelligent information processing algorithms and systems.

DownLoad:

DownLoad: