| Citation: |

Entao Zhang, Jianwei Ben, Zikai Nie, Shanli Zhang, Yang Chen, Ke Jiang, Xiaojuan Sun, Dabing Li. Compressive stress management for hillock-free AlGaN epitaxy on HTA-AlN templates using low-Al-content interlayer[J]. Journal of Semiconductors, 2026, In Press. doi: 10.1088/1674-4926/25080020

****

E T Zhang, J W Ben, Z K Nie, S L Zhang, Y Chen, K Jiang, X J Sun, and D B Li, Compressive stress management for hillock-free AlGaN epitaxy on HTA-AlN templates using low-Al-content interlayer[J]. J. Semicond., 2026, 47(2): 022502 doi: 10.1088/1674-4926/25080020

|

Compressive stress management for hillock-free AlGaN epitaxy on HTA-AlN templates using low-Al-content interlayer

DOI: 10.1088/1674-4926/25080020

CSTR: 32376.14.1674-4926.25080020

More Information-

Abstract

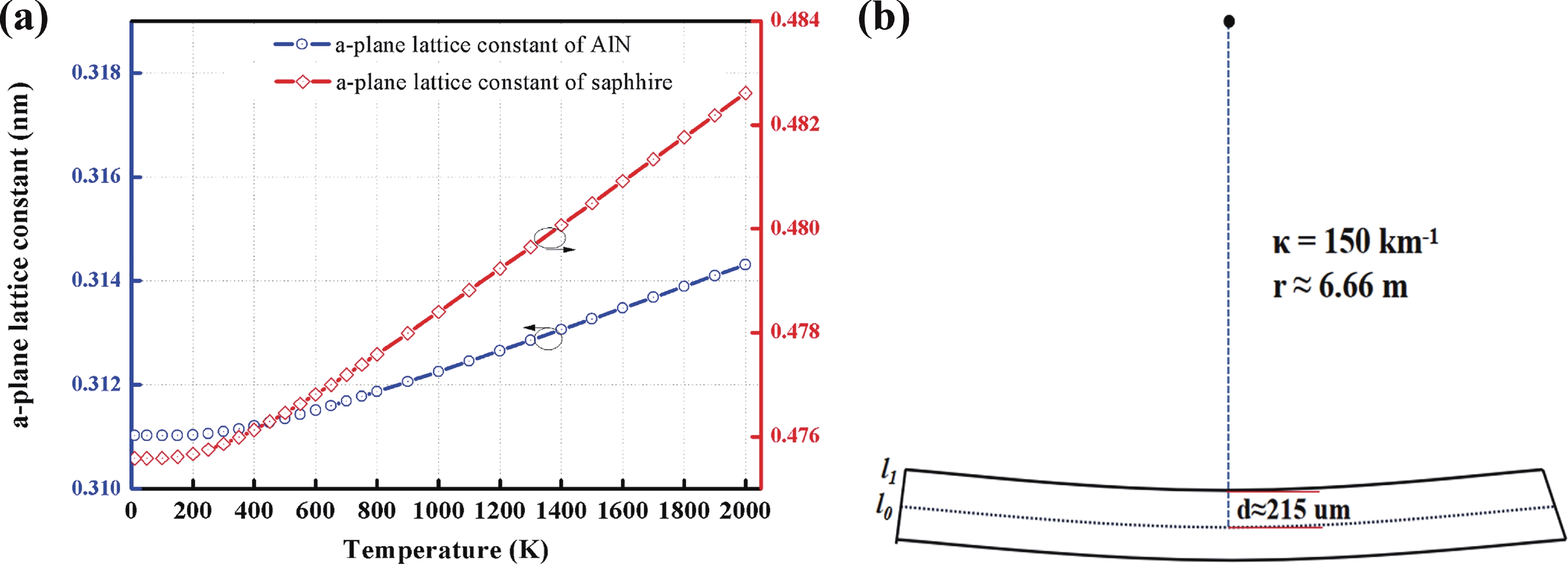

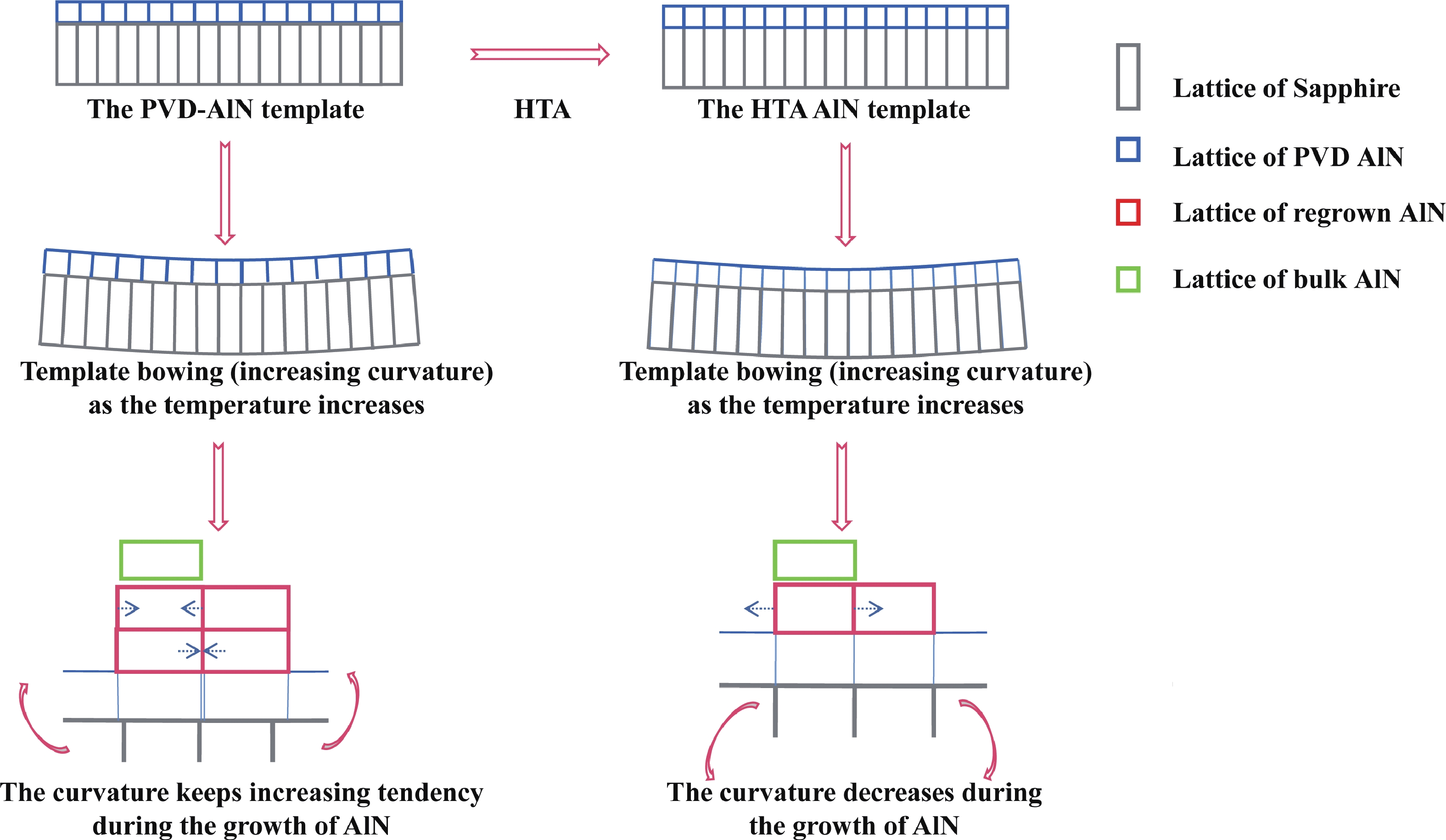

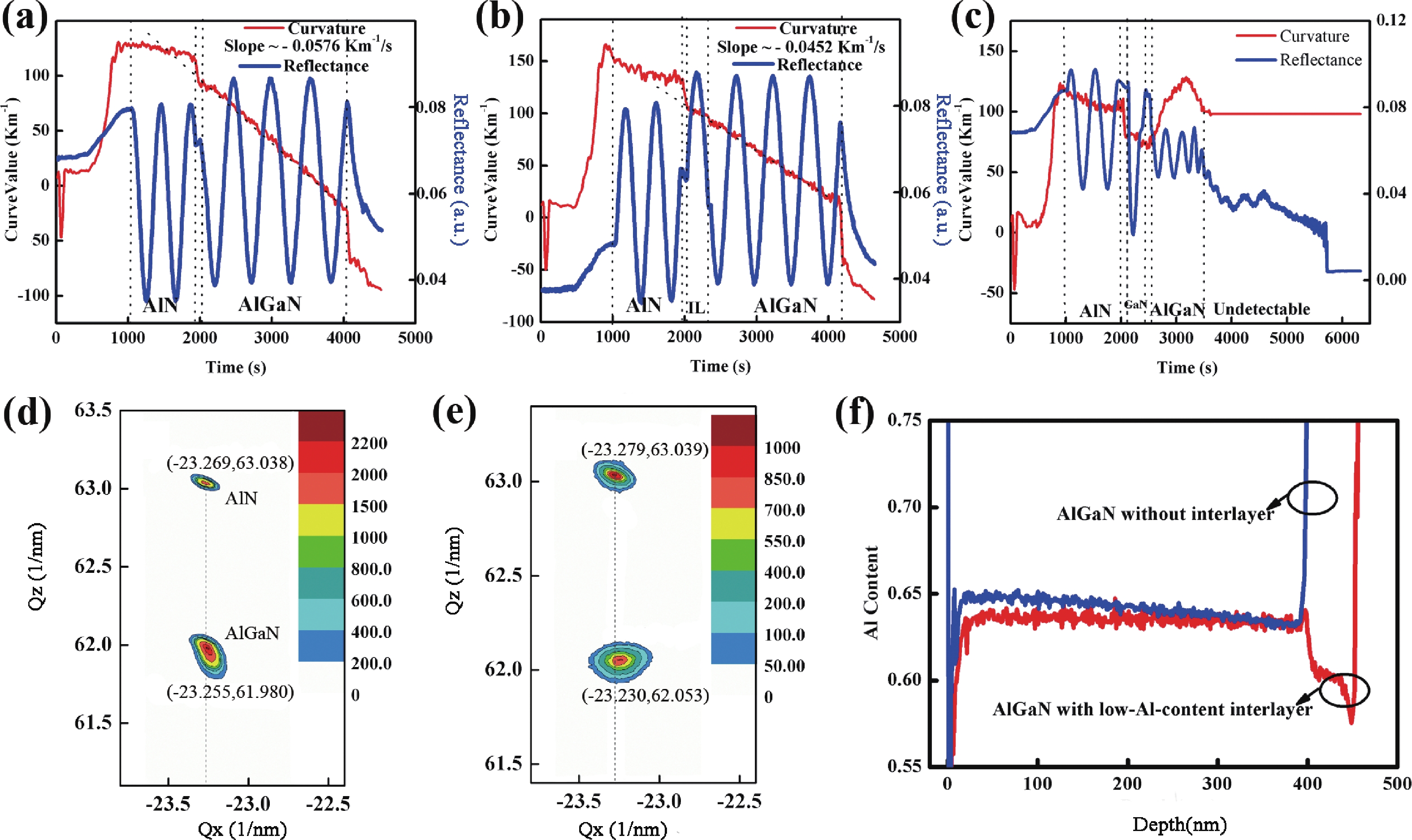

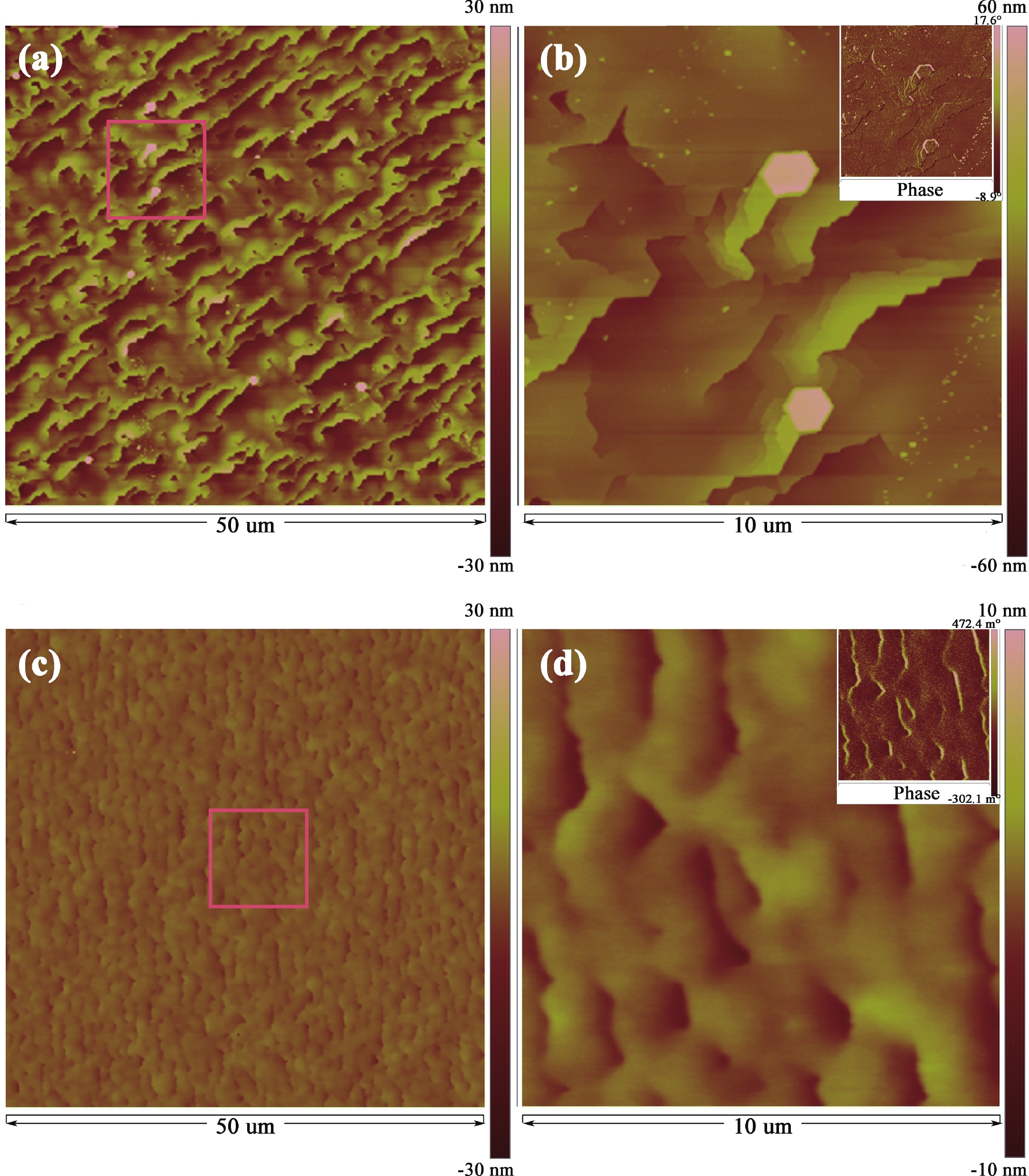

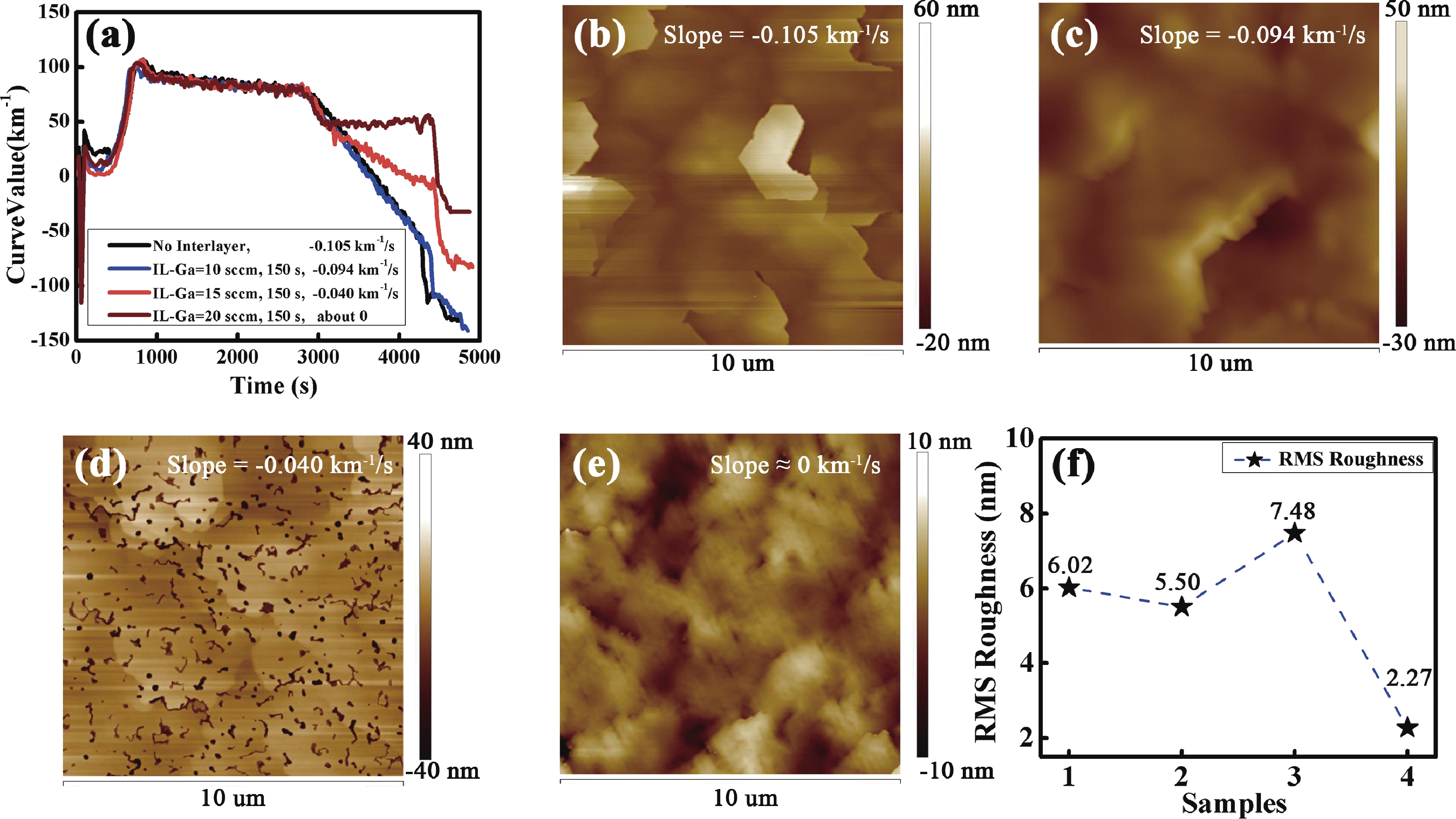

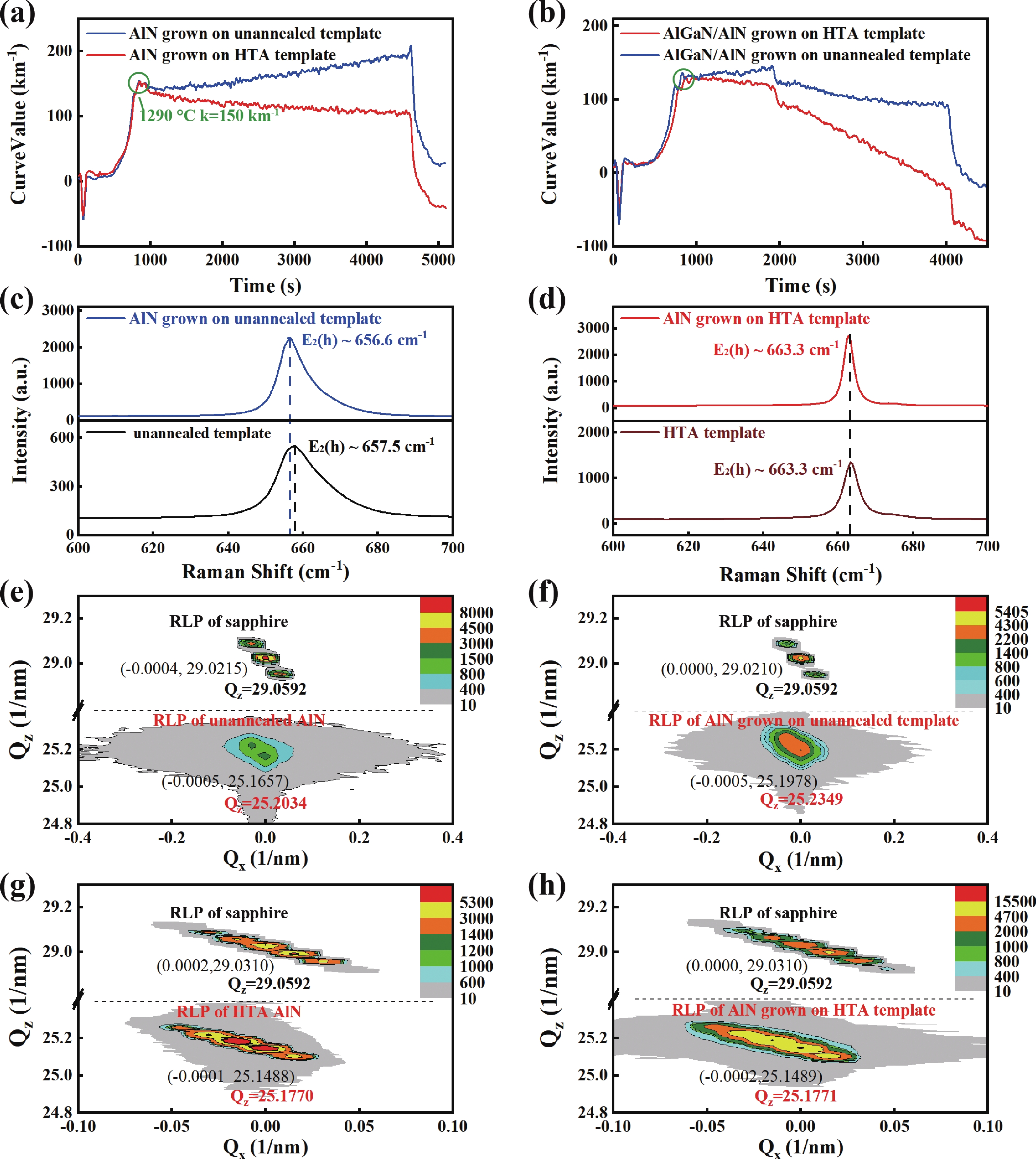

High-temperature-annealed AlN (HTA-AlN) templates provide ideal substrates for high-quality AlGaN epitaxy. However, the significant compressive stress accumulated within the AlGaN layer makes it challenging to achieve a smooth surface free of hexagonal hillocks on these templates. To address this issue, we investigate the mechanism of compressive stress accumulation during the growth of AlGaN-based epilayers on HTA-AlN templates using in-situ curvature analysis in this study. To verify the mechanism, a low-Al-content AlGaN interlayer is introduced between the AlN epilayer and the subsequent AlGaN epilayer. The larger a-plane lattice constant of this interlayer relative to the AlGaN epilayer slows the accumulation rate of compressive stress. The hexagonal hillock can be effectively suppressed and the surface of AlGaN epilayer can be significantly regulated by adopting various low-Al-content AlGaN interlayers. This work provides a comprehension on the stress accumulation mechanism in AlGaN epilayers and a feasible method to obtain hillock-free surface of AlGaN epilayers on HTA-AlN templates, which will be beneficial for fabricating AlGaN based devices.-

Keywords:

- surface,

- hillock,

- AlGaN,

- high temperature anneal,

- AlN template

-

References

[1] Jiang K, Sun X J, Chen Y X, et al. Three-dimensional metal−semiconductor−metal bipolar ultraviolet phototransistor based on GaN p-i-n epilayer. Appl Phys Lett, 2021, 119(16): 161105 doi: 10.1063/5.0064779[2] Zhang Y, Long H L, Zhang J, et al. Fast growth of high quality AlN films on sapphire using a dislocation filtering layer for ultraviolet light-emitting diodes. CrystEngComm, 2019, 21(27): 4072 doi: 10.1039/C9CE00589G[3] Jiang K, Sun X J, Shi Z M, et al. Quantum engineering of non-equilibrium efficient p-doping in ultra-wide band-gap nitrides. Light Sci Appl, 2021, 10(1): 69 doi: 10.1038/s41377-021-00503-y[4] Bi L, Yao Y X, Jiang Q M, et al. Instability of parasitic capacitance in T-shape-gate enhancement-mode AlGaN/GaN MIS-HEMTs. J Semicond, 2022, 43(3): 032801 doi: 10.1088/1674-4926/43/3/032801[5] Ben J W, Sun X J, Jia Y P, et al. Defect evolution in AlN templates on PVD-AlN/sapphire substrates by thermal annealing. CrystEngComm, 2018, 20(32): 4623 doi: 10.1039/C8CE00770E[6] Miyake H, Nishio G, Suzuki S, et al. Annealing of an AlN buffer layer in N2−CO for growth of a high-quality AlN film on sapphire. Appl Phys Express, 2016, 9(2): 025501 doi: 10.7567/APEX.9.025501[7] Ben J W, Luo J L, Lin Z C, et al. Introducing voids around the interlayer of AlN by high temperature annealing. Chin Phys B, 2022, 31(7): 076104 doi: 10.1088/1674-1056/ac3d7f[8] Wang J M, Xu F J, Liu B Y, et al. Control of dislocations in heteroepitaxial AlN films by extrinsic supersaturated vacancies introduced through thermal desorption of heteroatoms. Appl Phys Lett, 2021, 118(16): 162103 doi: 10.1063/5.0045552[9] Yue W K, Liu R X, Li P X, et al. Power enhancement of 265 nm DUV-LED flip-chip by HVPE-AlN high-temperature annealing. Micromachines, 2023, 14(2): 467 doi: 10.3390/mi14020467[10] Susilo N, Ziffer E, Hagedorn S, et al. Improved performance of UVC-LEDs by combination of high-temperature annealing and epitaxially laterally overgrown AlN/sapphire. Photon Res, 2020, 8(4): 589 doi: 10.1364/PRJ.385275[11] Mitrofanov O, Manfra M. Mechanisms of gate lag in GaN/AlGaN/GaN high electron mobility transistors. Superlattices Microstruct, 2003, 34(1/2): 33 doi: 10.1016/j.spmi.2003.12.002[12] Liu S F, Yuan Y, Sheng S S, et al. Four-inch high quality crack-free AlN layer grown on a high-temperature annealed AlN template by MOCVD. J Semicond, 2021, 42(12): 122804 doi: 10.1088/1674-4926/42/12/122804[13] Uesugi K, Shojiki K, Tezen Y, et al. Suppression of dislocation-induced spiral hillocks in MOVPE-grown AlGaN on face-to-face annealed sputter-deposited AlN template. Appl Phys Lett, 2020, 116(6): 062101 doi: 10.1063/1.5141825[14] Ni R X, Chuo C C, Yang K, et al. AlGaN-based ultraviolet light-emitting diode on high-temperature annealed sputtered AlN template. J Alloys Compd, 2019, 794: 8 doi: 10.1016/j.jallcom.2019.04.256[15] Hakamata J, Kawase Y, Dong L, et al. Growth of high-quality AlN and AlGaN films on sputtered AlN/sapphire templates via high-temperature annealing. Phys Status Solidi B, 2018, 255(5): 1700506 doi: 10.1002/pssb.201700506[16] Uesugi K, Kuboya S, Shojiki K, et al. 263 nm wavelength UV-C LED on face-to-face annealed sputter-deposited AlN with low screw- and mixed-type dislocation densities. Appl Phys Express, 2022, 15(5): 055501 doi: 10.35848/1882-0786/ac66c2[17] Chen J T, Liu J X, Huang Y N, et al. Hillock related degradation mechanism for AlGaN-based UVC LEDs. Nanomaterials, 2023, 13(9): 1562 doi: 10.3390/nano13091562[18] Peters L, Meyer T, Margenfeld C, et al. Parasitic AlxOyNz surface defects on high-temperature annealed AlN and their role in hillock formation. Appl Phys Lett, 2023, 123(11): 112104 doi: 10.1063/5.0170006[19] Teramura S, Kawase Y, Sakuragi Y, et al. High crystallinity and highly relaxed Al0.60Ga0.40N films using growth mode control fabricated on a sputtered AlN template with high-temperature annealing. Phys Status Solidi A, 2020, 217(14): 1900868 doi: 10.1002/pssa.201900868[20] Liu S F, Yuan Y, Huang L J, et al. Drive high power UVC-LED wafer into low-cost 4-inch era: Effect of strain modulation. Adv Funct Materials, 2022, 32(19): 2112111 doi: 10.1002/adfm.202112111[21] Fang X Z, Wang J M, Xu F J, et al. Elimination of spiral hillocks in AlGaN grown on high-temperature annealed AlN templates by adopting an AlN/AlGaN stress modulation multilayer. Appl Phys Lett, 2024, 124(6): 062103 doi: 10.1063/5.0184353[22] Mogilatenko A, Walde S, Hagedorn S, et al. Impact of Si doping on dislocation behavior in MOVPE-grown AlN on high-temperature annealed AlN buffer layers. J Appl Phys, 2022, 131(4): 045702 doi: 10.1063/5.0073076[23] Walde S, Huang C Y, Tsai C L, et al. High-quality AlGaN epitaxy on lattice-engineerable AlN template for high-power UVC light-emitting diodes. Acta Mater, 2022, 226: 117625 doi: 10.1016/j.actamat.2022.117625[24] Charles M, Mrad M, Kanyandekwe J, et al. Extraction of stress and dislocation density using in situ curvature measurements for AlGaN and GaN on silicon growth. J Cryst Growth, 2019, 517: 64 doi: 10.1016/j.jcrysgro.2019.04.014[25] Aida H, Lee D S, Belousov M, et al. Effect of initial bow of sapphire substrate on substrate curvature during InGaN growth stage of light emitting diode epitaxy. Jpn J Appl Phys, 2012, 51(1R): 012102 doi: 10.1143/JJAP.51.012102[26] Yang S B, Miyagawa R, Miyake H, et al. Raman scattering spectroscopy of residual stresses in epitaxial AlN films. Appl Phys Express, 2011, 4(3): 031001 doi: 10.1143/APEX.4.031001[27] Feng Y N, Saravade V, Chung T F, et al. Strain-stress study of AlxGa1-xN/AlN heterostructures on c-plane sapphire and related optical properties. Sci Rep, 2019, 9(1): 10172 doi: 10.1038/s41598-019-46628-4[28] Figge S, Kröncke H, Hommel D, et al. Temperature dependence of the thermal expansion of AlN. Appl Phys Lett, 2009, 94(10): 101915 doi: 10.1063/1.3089568[29] Wachtman J B JR, Scuderi T G, Cleek G W. Linear thermal expansion of aluminum oxide and thorium oxide from 100° to 1100°K. J Am Ceram Soc, 1962, 45(7): 319 doi: 10.1111/j.1151-2916.1962.tb11159.x[30] Harutyunyan V S, Aivazyan A P, Weber E R, et al. High-resolution X-ray diffraction strain-stress analysis of GaN/sapphire heterostructures. J Phys D: Appl Phys, 2001, 34(10A): A35 doi: 10.1088/0022-3727/34/10A/308[31] Morales F M, Mánuel J M, García R, et al. Evaluation of interpolations of InN, AlN and GaN lattice and elastic constants for their ternary and quaternary alloys. J Phys D: Appl Phys, 2013, 46(24): 245502 doi: 10.1088/0022-3727/46/24/245502[32] Nakajima K. Equilibrium phase diagrams for stranski-krastanov structure mode of III−V ternary quantum dots. Jpn J Appl Phys, 1999, 38(4R): 1875 doi: 10.1143/JJAP.38.1875[33] Wang W L, Li Y, Zheng Y L, et al. Performance-improved vertical GaN-based light-emitting diodes on Si substrates through designing the epitaxial structure. CrystEngComm, 2018, 20(32): 4685 doi: 10.1039/C8CE00826D[34] Vennéguès P, Beaumont B, Haffouz S, et al. Influence of in situ sapphire surface preparation and carrier gas on the growth mode of GaN in MOVPE. J Cryst Growth, 1998, 187(2): 167 doi: 10.1016/S0022-0248(97)00875-0[35] Ejder E. Refractive index of GaN. Phys Stat Sol (a), 1971, 6(2): 445 doi: 10.1002/pssa.2210060212[36] Lu S Q, Luo Z Y, Li J C, et al. Role of strain-induced microscale compositional pulling on optical properties of high Al content AlGaN quantum wells for deep-ultraviolet LED. Nanoscale Res Lett, 2022, 17(1): 13 doi: 10.1186/s11671-022-03652-0[37] He C G, Qin Z X, Xu F J, et al. Mechanism of stress-driven composition evolution during hetero-epitaxy in a ternary AlGaN system. Sci Rep, 2016, 6: 25124 doi: 10.1038/srep25124[38] Rössler U. New data and updates for IV-IV, III-V, II-VI and I-VII compounds, their mixed crystals and diluted magnetic semiconductors. Berlin, Heidelberg: Springer Berlin Heidelberg, 2011 doi: 10.1007/978-3-642-14148-5[39] Wang A J, Shang S L, Du Y, et al. Structural and elastic properties of cubic and hexagonal TiN and AlN from first-principles calculations. Comput Mater Sci, 2010, 48(3): 705 doi: 10.1016/j.commatsci.2010.03.014 -

Supplements

25080020Supporting_Information.pdf

25080020Supporting_Information.pdf

-

Proportional views

Entao Zhang received his BS degree from Huazhong University of Science and Technology in 2019. Currently, he is a PhD student at State Key Laboratory of Luminescence Science and Technology, Changchun Institute of Optics, Fine Mechanics and Physics (CIOMP), Chinese Academy of Sciences (CAS), under the supervision of Professor Dabing Li. His research focuses on AlGaN-based materials and devices.

Entao Zhang received his BS degree from Huazhong University of Science and Technology in 2019. Currently, he is a PhD student at State Key Laboratory of Luminescence Science and Technology, Changchun Institute of Optics, Fine Mechanics and Physics (CIOMP), Chinese Academy of Sciences (CAS), under the supervision of Professor Dabing Li. His research focuses on AlGaN-based materials and devices. Jianwei Ben received his PhD in 2019 from CIOMP, CAS. Currently, he is a Special Research Assistant at CIOMP. His research focuses on wide-bandgap nitride materials and devices.

Jianwei Ben received his PhD in 2019 from CIOMP, CAS. Currently, he is a Special Research Assistant at CIOMP. His research focuses on wide-bandgap nitride materials and devices. Dabing Li is a professor of Changchun Institute of Optics, Fine Mechanics and Physics, Chinese Academy of Science (CIOMP, CAS). He received the Ph.D. degree from the Institute of Semiconductors, CAS in 2004 and then he worked as a postdoctoral and visiting scholar in Mie University until 2008. His research interests include the physics, the Ⅲ-nitride materials and photoelectric devices.

Dabing Li is a professor of Changchun Institute of Optics, Fine Mechanics and Physics, Chinese Academy of Science (CIOMP, CAS). He received the Ph.D. degree from the Institute of Semiconductors, CAS in 2004 and then he worked as a postdoctoral and visiting scholar in Mie University until 2008. His research interests include the physics, the Ⅲ-nitride materials and photoelectric devices.

DownLoad:

DownLoad: