| Citation: |

Ruifeng Li, Debo Wang. A distributed static model of capacitive MEMS microwave power detection chip[J]. Journal of Semiconductors, 2026, In Press. doi: 10.1088/1674-4926/25100007

****

R F Li and D B Wang, A distributed static model of capacitive MEMS microwave power detection chip[J]. J. Semicond., 2026, 47(3), 032302 doi: 10.1088/1674-4926/25100007

|

A distributed static model of capacitive MEMS microwave power detection chip

DOI: 10.1088/1674-4926/25100007

CSTR: 32376.14.1674-4926.25100007

More Information-

Abstract

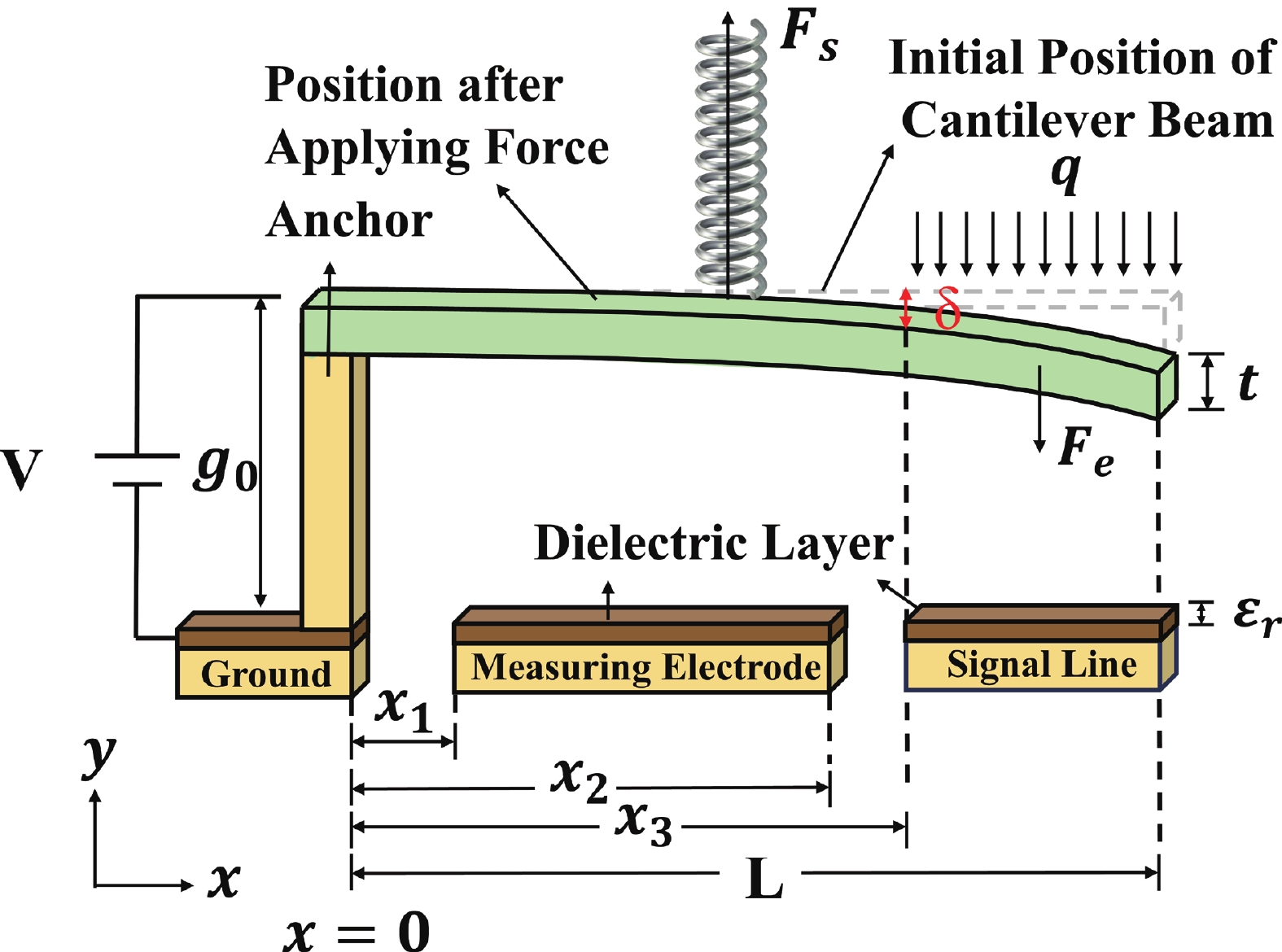

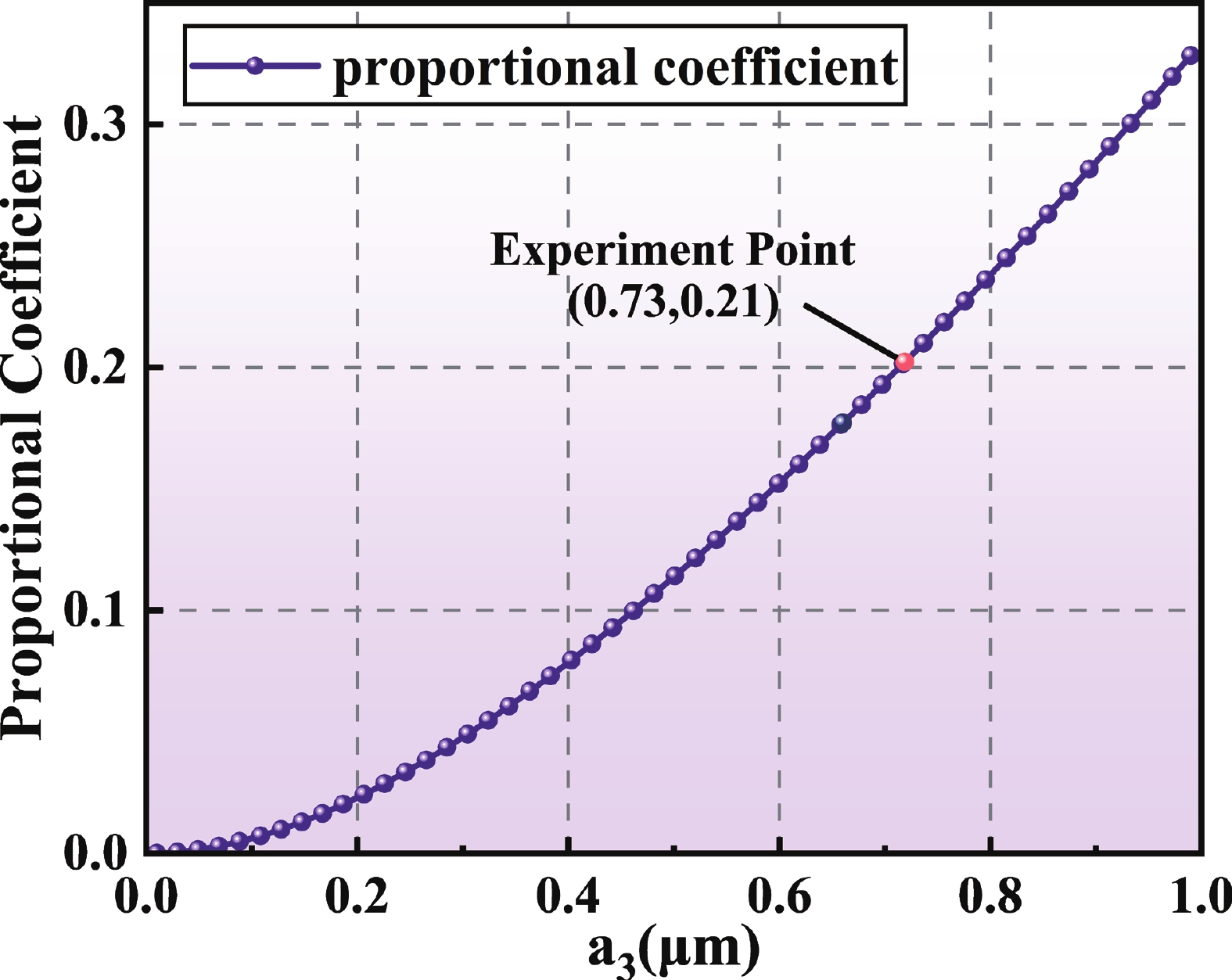

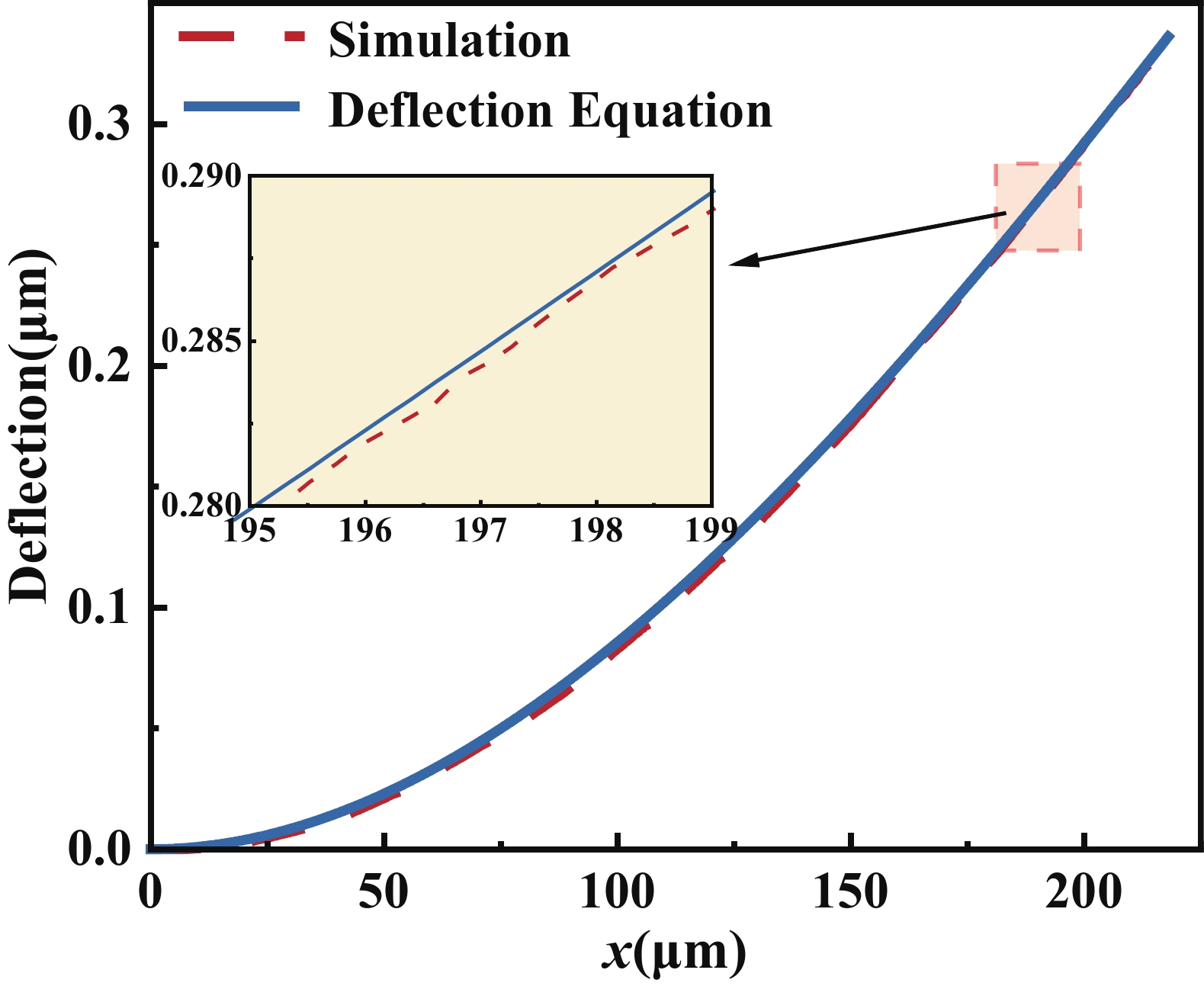

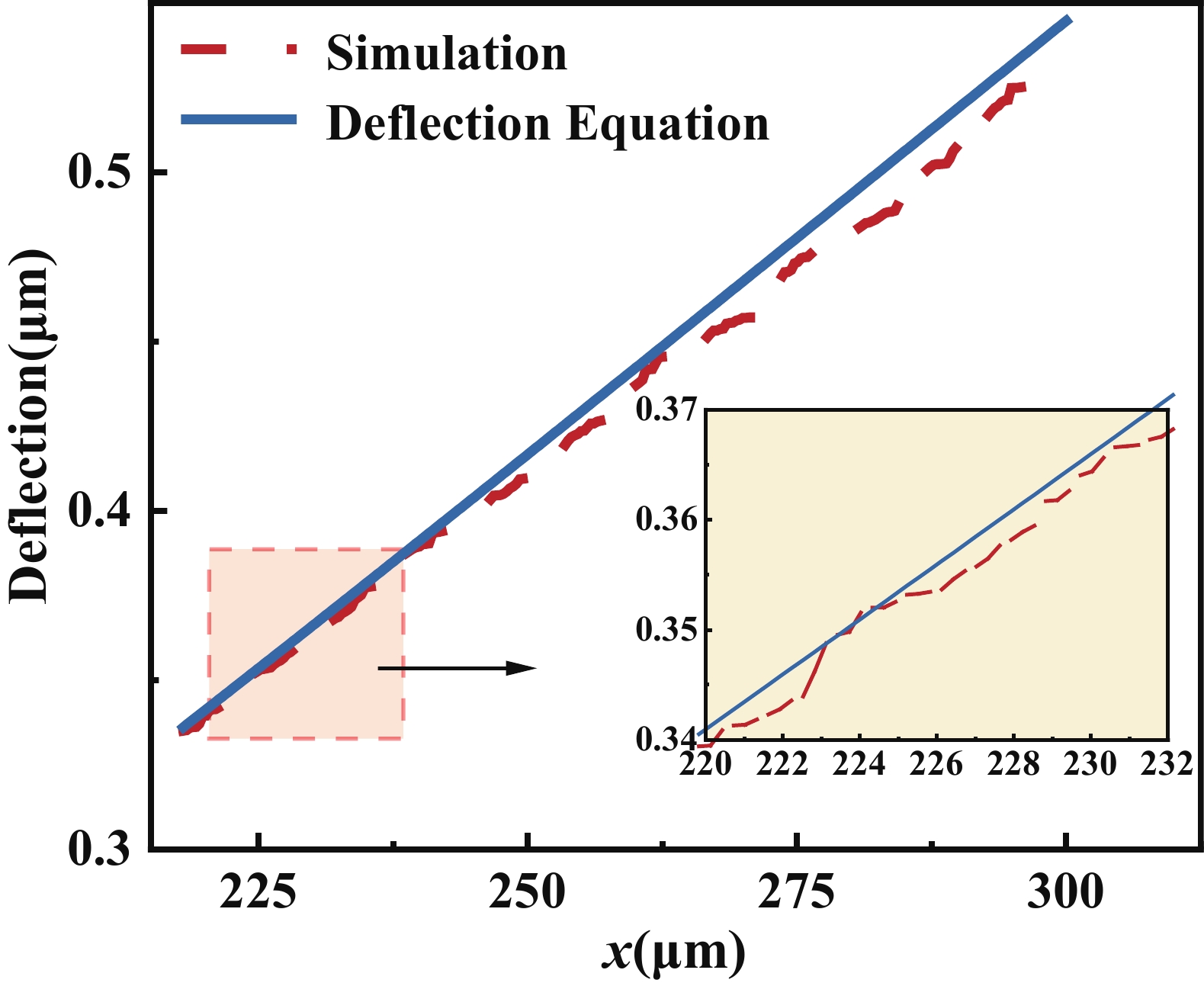

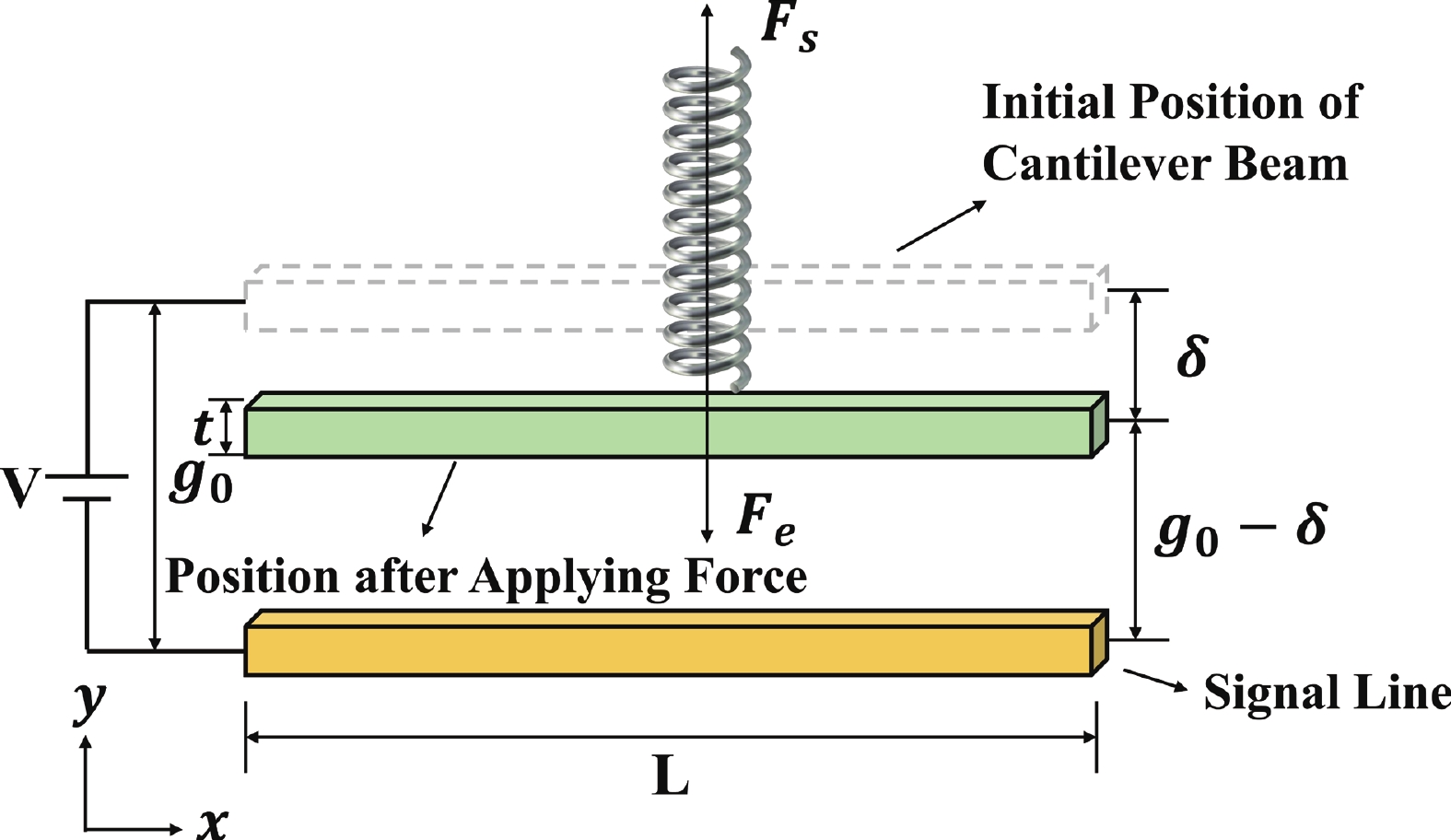

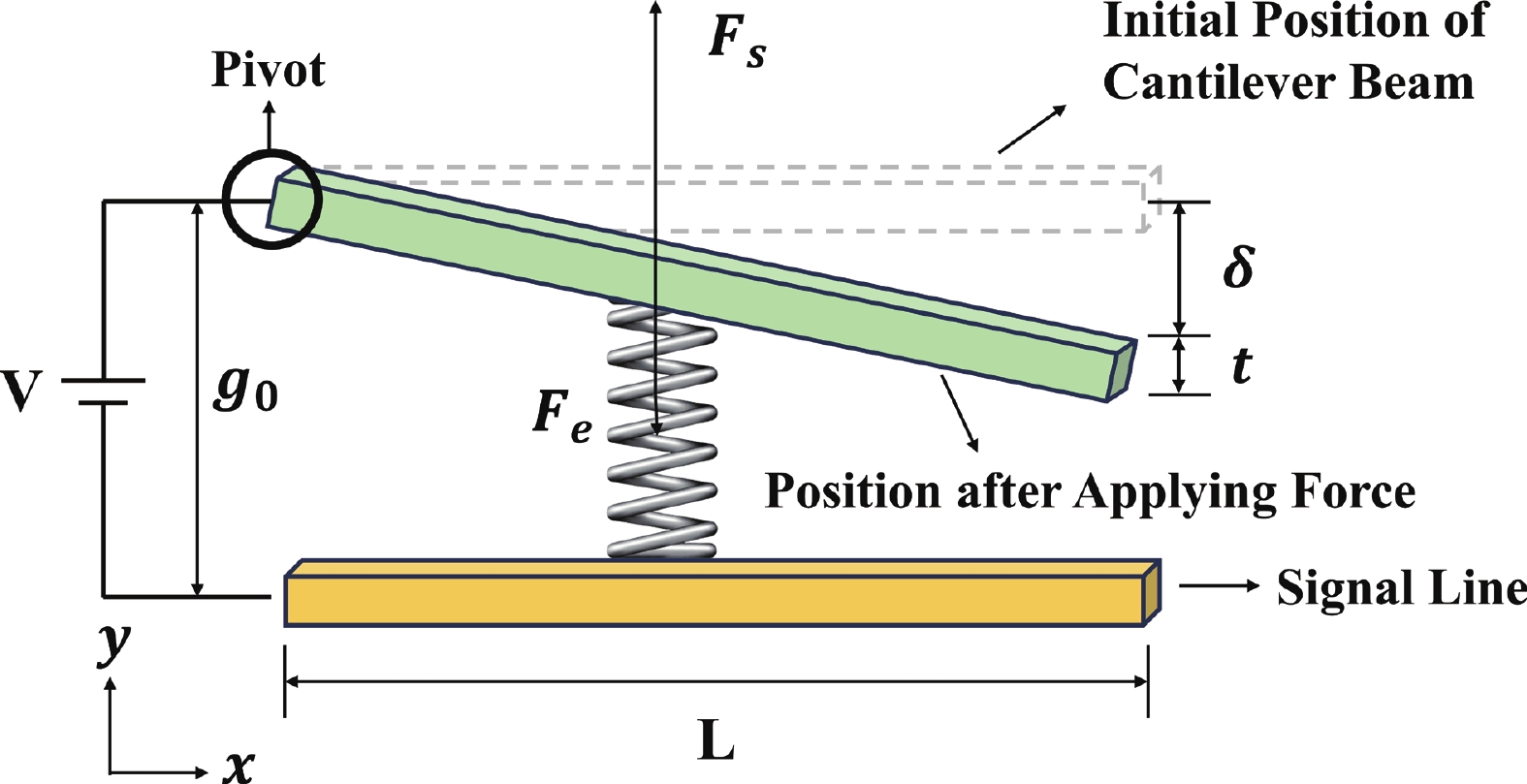

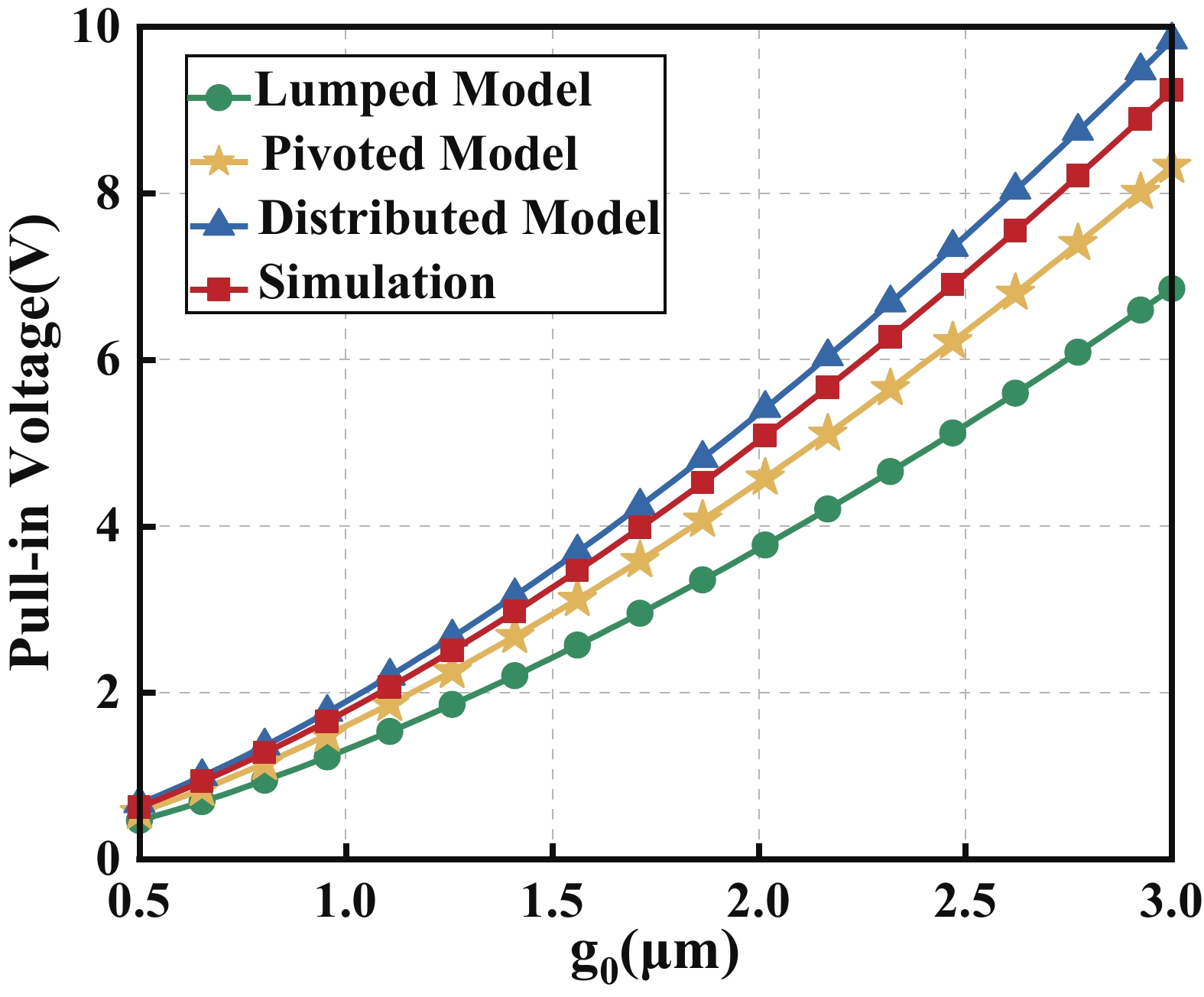

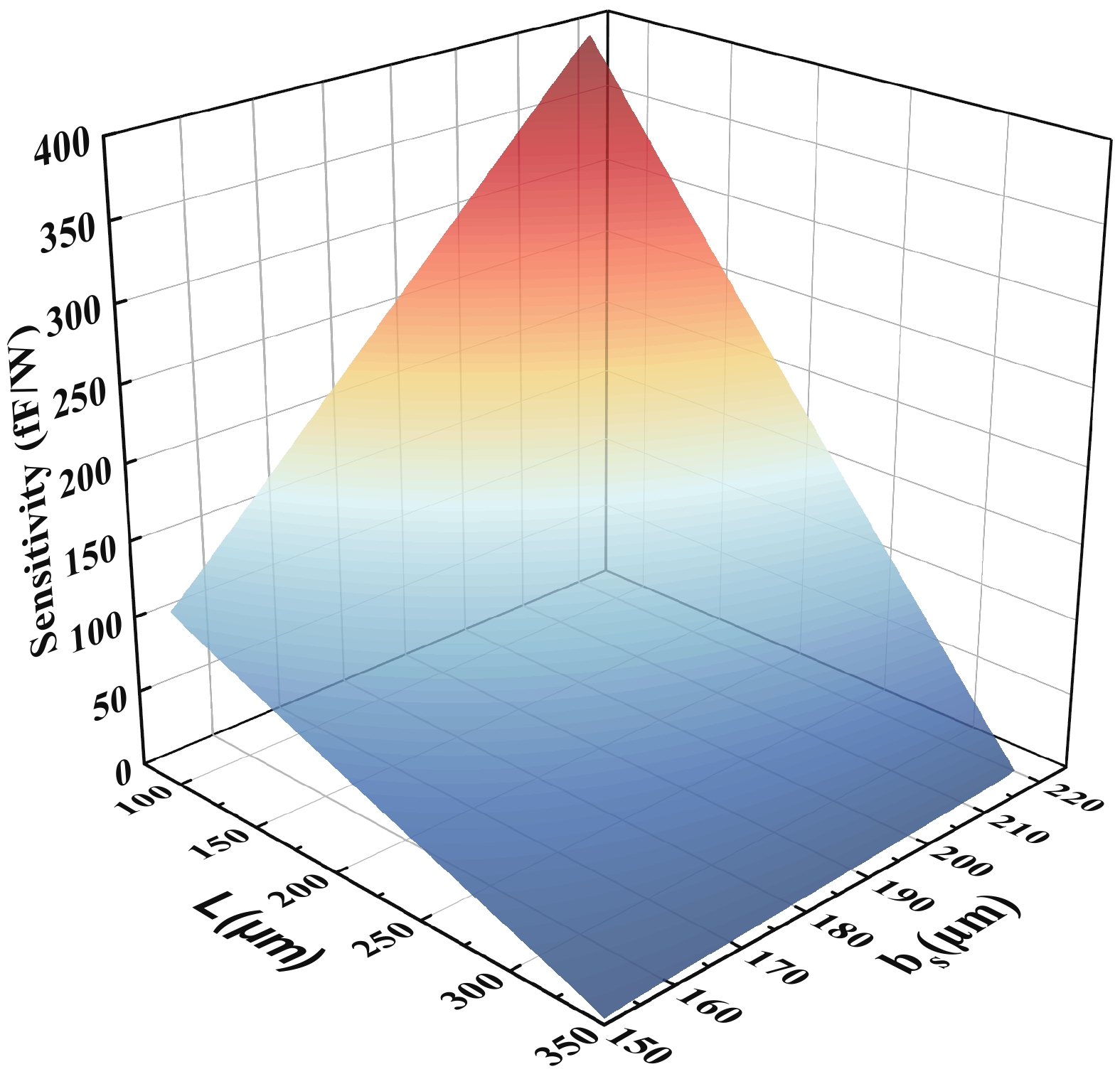

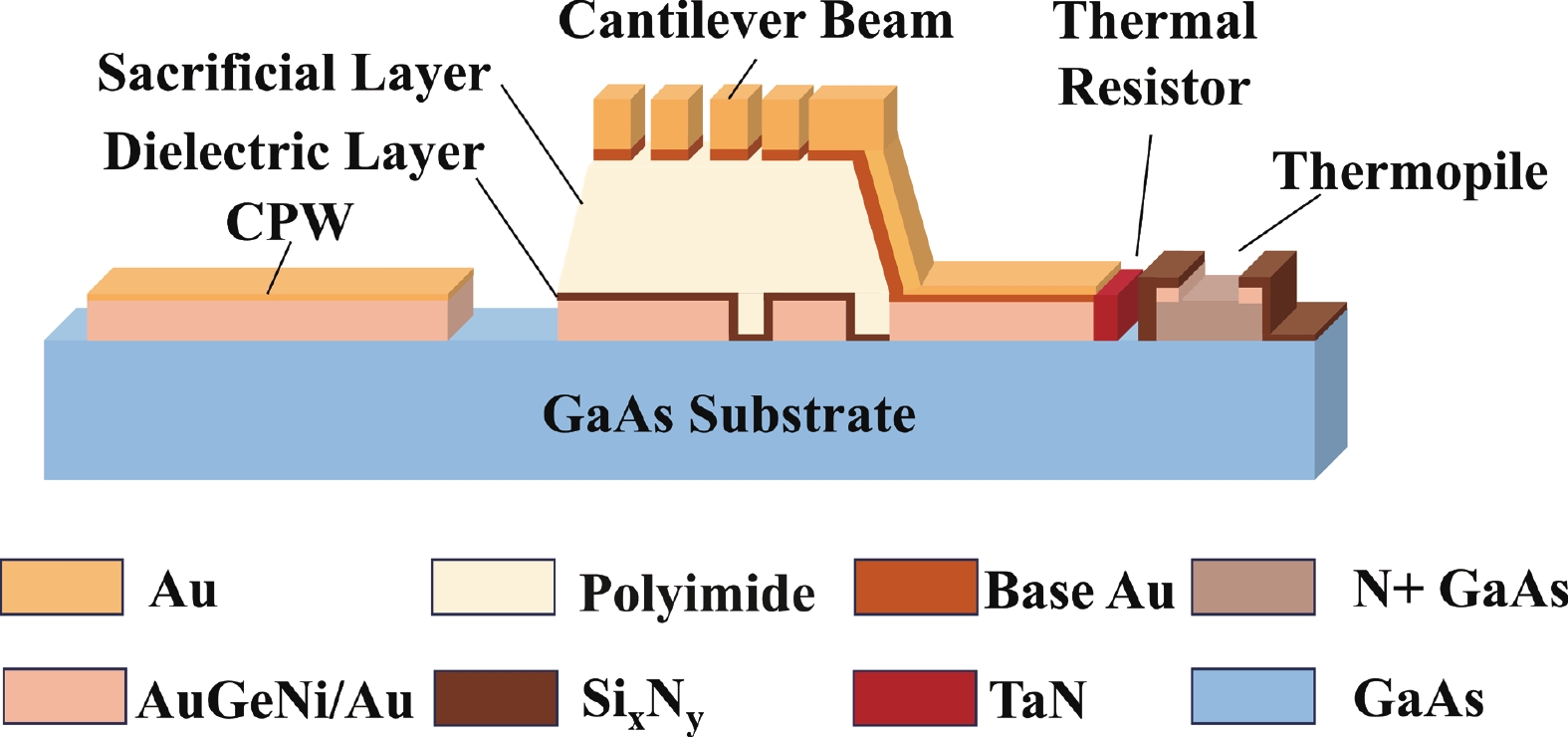

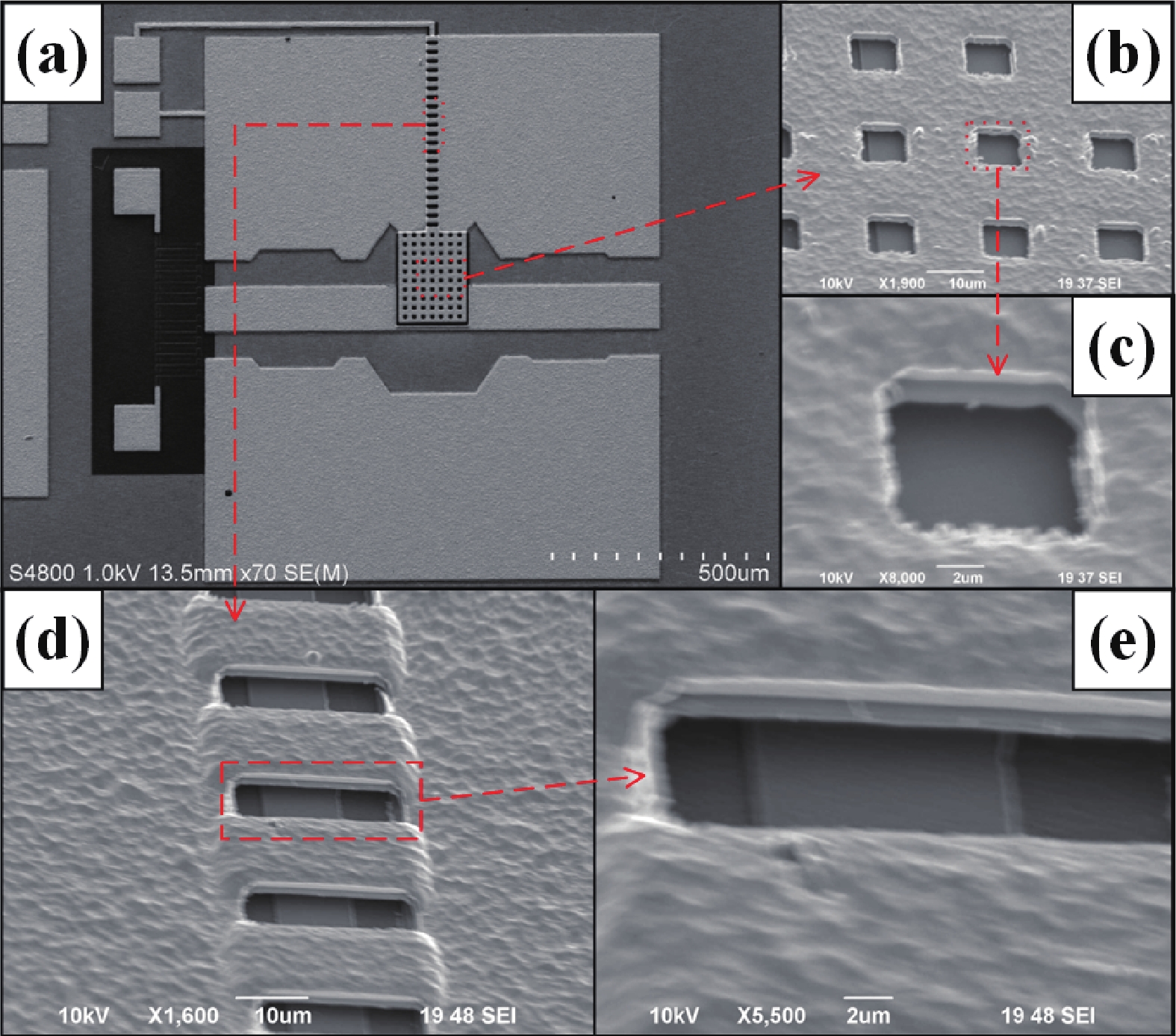

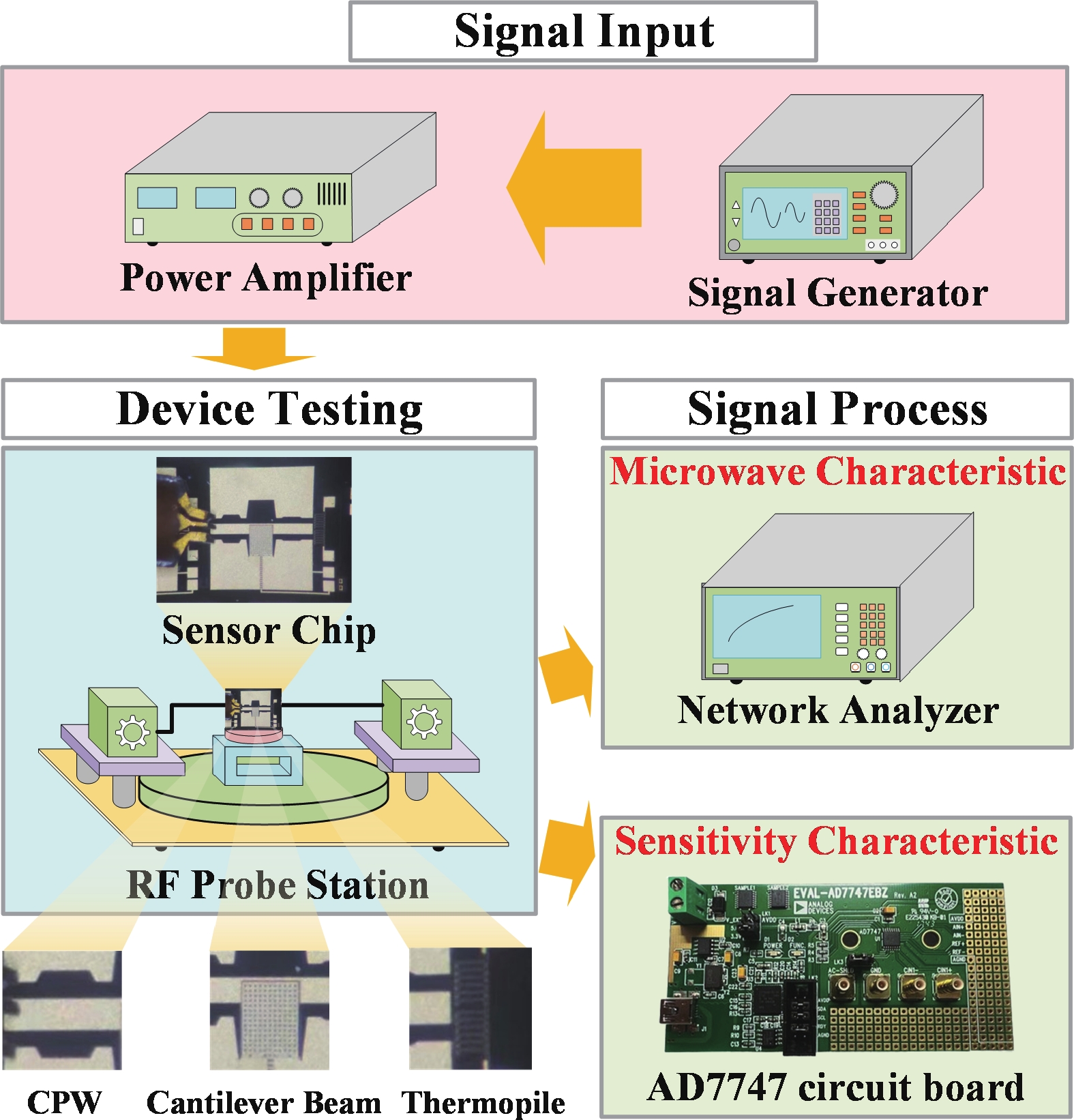

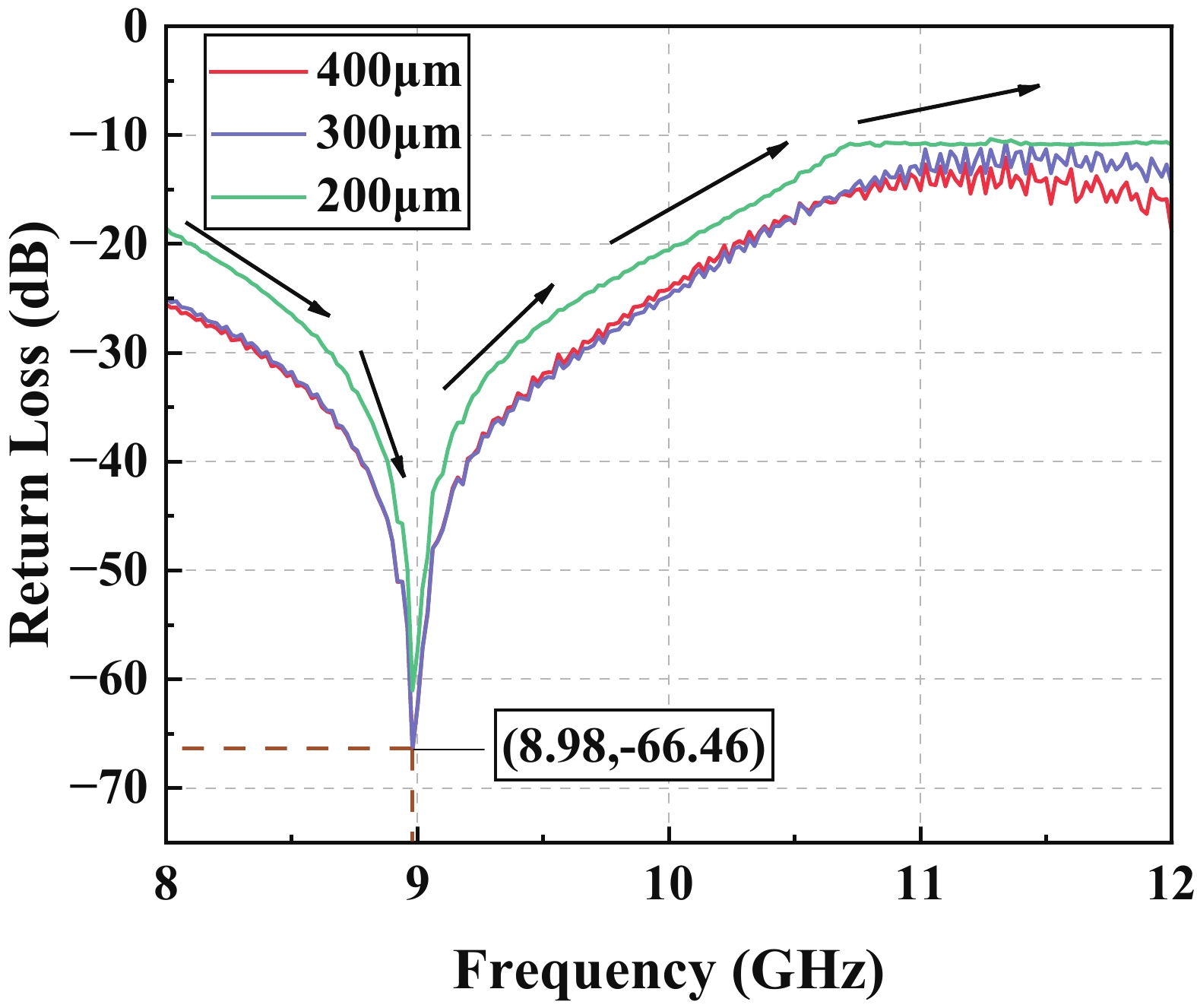

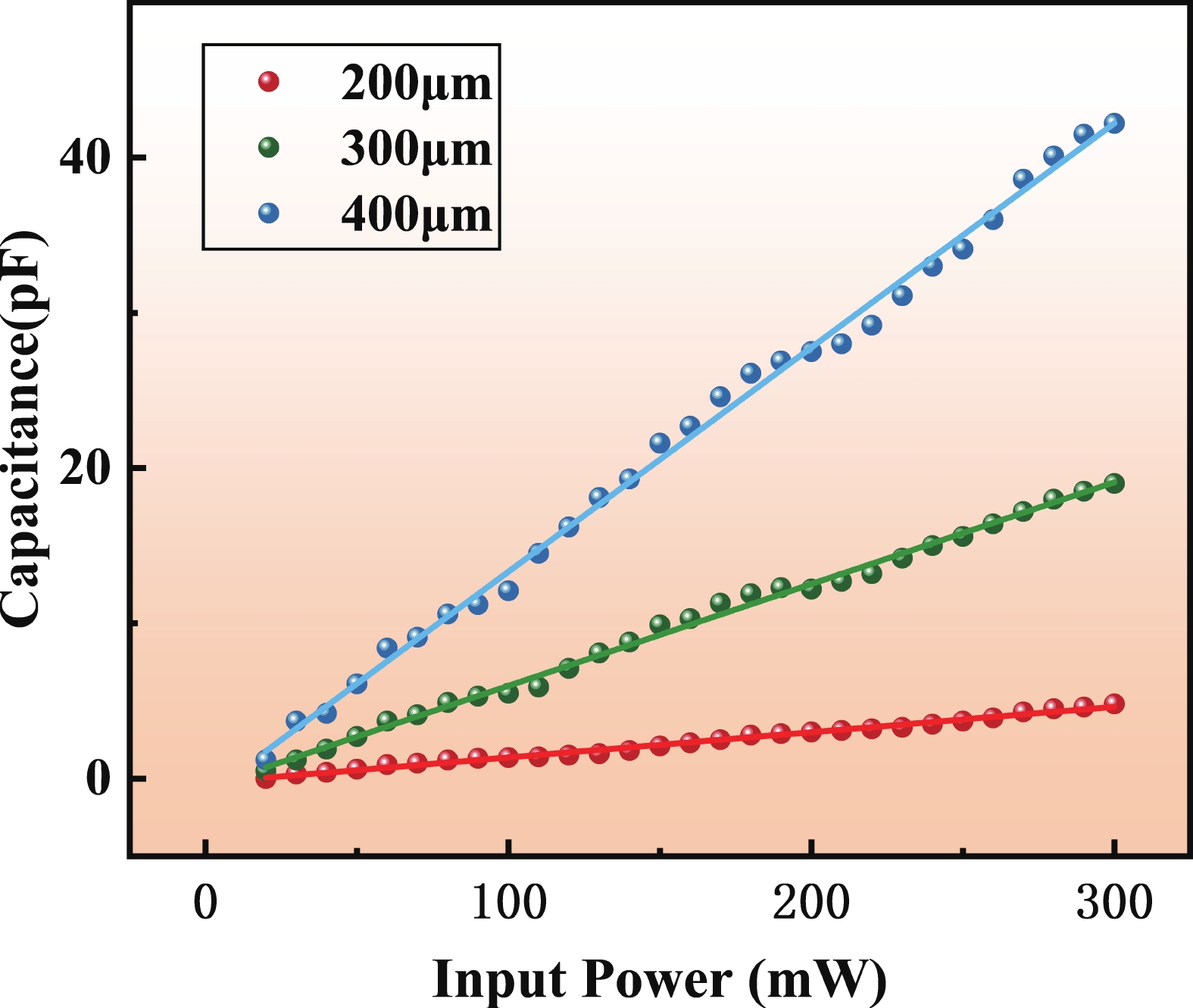

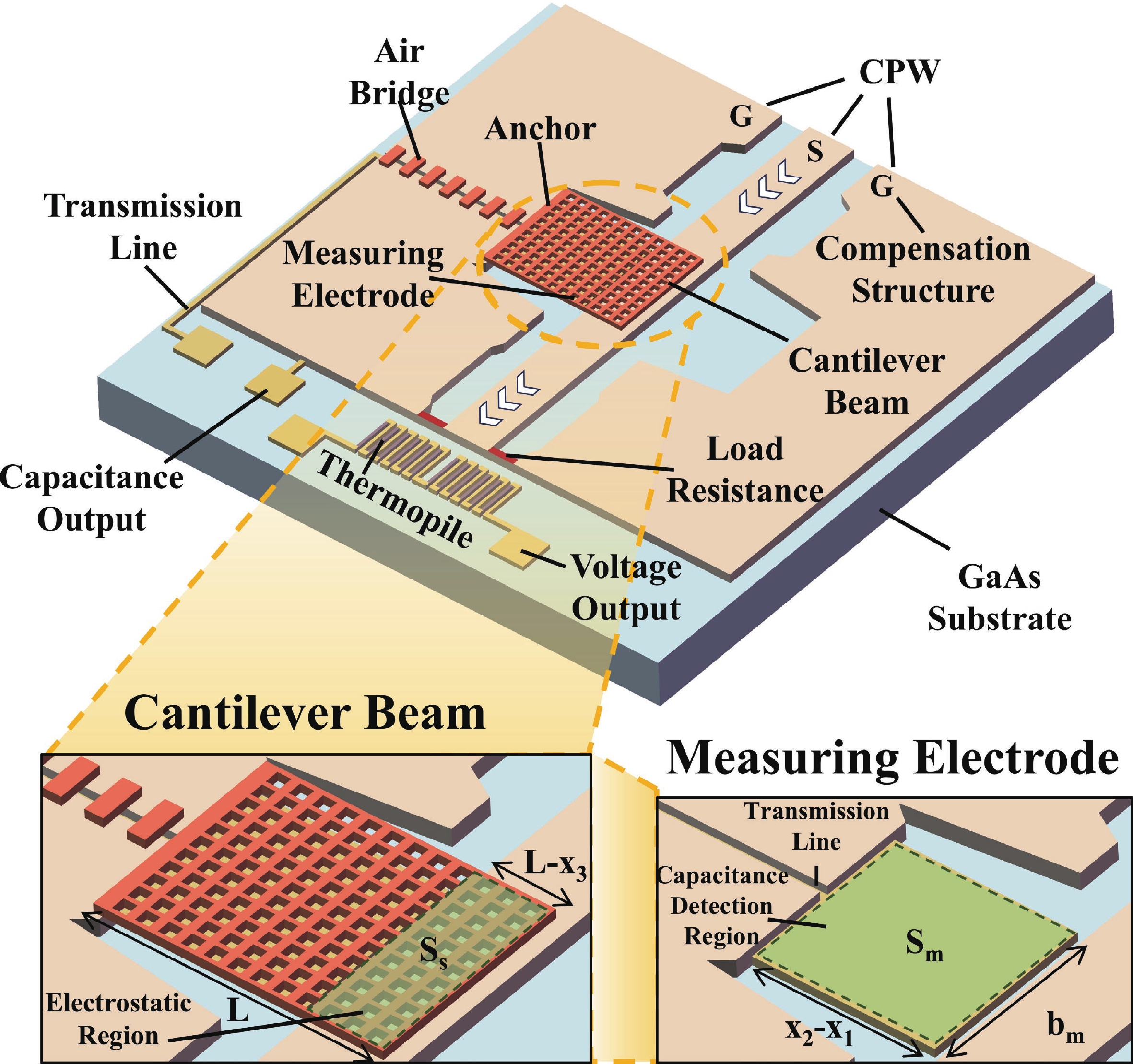

To improve the theoretical prediction accuracy of static mechanical quantities in MEMS cantilever beams for microwave power detection chips, a distributed static model is proposed based on the deflection equation. An analytical framework is established through the precise characterization of cantilever beam bending. The framework can accurately extract key electromechanical parameters, and the correlation between these parameters and geometric changes is systematically studied. Results show that the pull-in voltage increases with the gap but decreases with the length. The predicted pull-in voltage indicates a relative error of only 6.5% between the distributed static model and the simulation, which is significantly lower than that of the other two models. The overload power and sensitivity are also analyzed to facilitate performance trade-offs in chip design. The measured return loss varies between −66.46 and −10.56 dB over the 8−12 GHz frequency band, exhibiting a characteristic V-shaped trend. Moreover, the measured sensitivity of 66.5 fF/W closely matches the theoretical value of 69.3 fF/W, showing a relative error of 5.6%. These findings confirm that the distributed model outperforms the other two in terms of both accuracy and physical realism, thereby providing important reference for the design of microwave power detection chips.-

Keywords:

- MEMS,

- power detection,

- cantilever beam,

- static model,

- sensitivity

-

References

[1] Liu Y C, Su Y Q, Weng Z C, et al. A MEMS fast steering mirror with 10 mm aperture for free-space optical communication. 2024 IEEE 37th International Conference on Micro Electro Mechanical Systems (MEMS). Austin, 2024: 1011 doi: 10.1109/MEMS58180.2024.10439423[2] Rajalakshmi D, Roslin D K, Sravya M L, et al. Developing an Internet of Things (IoT) driven alert system for detecting and mitigating rash driving incidents. 2025 5th International Conference on Soft Computing for Security Applications (ICSCSA), 2025: 747 doi: 10.1109/ICSCSA66339.2025.11171108[3] Yi Z X, Liao X P. Measurements on intermodulation distortion of capacitive power sensor based on MEMS cantilever beam. IEEE Sens J, 2014, 14(3): 621 doi: 10.1109/JSEN.2013.2293147[4] Rotake D R, Darji A D. Stiffness and sensitivity analysis of microcantilever based piezoresistive sensor for bio-MEMS application. 2018 IEEE SENSORS, 2018: 1 doi: 10.1109/ICSENS.2018.8589732[5] Fernández L J, Wiegerink R J, Flokstra J, et al. A capacitive RF power sensor based on MEMS technology. J Micromech Microeng, 2006, 16(7): 1099 doi: 10.1088/0960-1317/16/7/001[6] Lin X Z, Ying J, Lin X Z. Analytical model of electrostatic fixed-fixed microbeam for pull-in voltage. 2008 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, 2008: 803 doi: 10.1109/AIM.2008.4601763[7] Shoaib M, Hamid N H B, Ali N B B Z, et al. Study of nonlinear pull-in voltage effects in electrostatic cantilever-based MEMS sensors. 2014 5th International Conference on Intelligent and Advanced Systems (ICIAS), 2014: 1 doi: 10.1109/ICIAS.2014.6869509[8] Zhang H Q, Li L F, Bai X J, et al. Mechanical model of MEMS cantilever beam of capacitive microwave power sensor. Microelectronics, 2019, 49(3): 373 doi: 10.13911/j.cnki.1004-3365.180304[9] Xie J C, Zuo W, Zhang C C, et al. Study on static mechanical model of MEMS cantilever beam. Microelectronics, 2020, 50(4): 543 doi: 10.13911/j.cnki.1004-3365.190561[10] Zhang C C, He Y, Xie J C, et al. Optimization of overload power of capacitive MEMS microwave power sensor. Microelectronics, 2021, 51(3): 434 doi: 10.13911/j.cnki.1004-3365.200406[11] Wang D B, Gu X F, Zhao J, et al. An in-line microwave power detection system based on double MEMS cantilever beams. IEEE Sens J, 2020, 20(18): 10476 doi: 10.1109/JSEN.2020.2994149[12] Xu Q R, Ding Z Y, Wang D B. Research on microwave power detection chips based on MEMS cantilever beams. Microelectronics, 2025, 55(2): 303 doi: 10.13911/j.cnki.1004-3365.240084[13] Xiong S L, Xu Q R, You A X, et al. Study on the second-order vibration model of dual-channel microwave power detection chip. IEEE Trans Electron Devices, 2025, 72(7): 3820 doi: 10.1109/TED.2025.3566358[14] Xu Q R, Chen X, Wang D B. A novel dual-channel MEMS microwave power detection chip with fixed beam. IEEE Trans Electron Devices, 2025, 72(8): 4385 doi: 10.1109/TED.2025.3584003[15] Xu L, Fang Y M, Qie J J. Analysis of dynamic pull-in phenomena for parallel-plate electrostatic micro-actuator. Semicond Technol, 2012, 37(3): 176 doi: 10.3969/j.issn.1003-353x.2012.03.003[16] Fu W W, Fang Y M, Liu T. Analysis of statical pull-in phenomena for perforated-plate electrostatic micro-actuator. Chin J Electron Devices, 2014, 37(3): 395 doi: 10.3969/j.issn.1005-9490.2014.03.004[17] Zuo W, Guo Q T, Ji X C, et al. Structural optimization of capacitive MEMS microwave power sensor. IEEE Sens J, 2020, 20(19): 11380 doi: 10.1109/JSEN.2020.2998075[18] Gere J M, Goodno B J. Mechanics of materials. Stamford: Cengage Learning, 2013[19] Liu C. Foundations of MEMS. Beijing: China Machine Press, 2007 (in Chinese)[20] Wei L C, Mohammad A B, Kassim N M. Analytical modeling for determination of pull-in voltage for an electrostatic actuated MEMS cantilever beam. ICONIP '02. Proceedings of the 9th International Conference on Neural Information Processing. Computational Intelligence for the E-Age, 2002: 233 doi: 10.1109/SMELEC.2002.1217814[21] Bansal D, Bajpai A, Kumar P, et al. Effect of stress on pull-in voltage of RF MEMS SPDT switch. IEEE Trans Electron Devices, 2020, 67(5): 2147 doi: 10.1109/TED.2020.2982667[22] Pamidighantam S, Puers R, Baert K, et al. Pull-in voltage analysis of electrostatically actuated beam structures with fixed-fixed and fixed-free end conditions. J Micromech Microeng, 2002, 12(4): 458 doi: 10.1088/0960-1317/12/4/319[23] Xin Z H, Sun H Y, Wang D B. A high-performance dual-channel MEMS microwave power sensor with cantilever beam. IEEE Sens J, 2023, 23(11): 11540 doi: 10.1109/JSEN.2023.3269035[24] Benfriha E, Adnane A, Cheriet M E, et al. Pyramidal Sun sensor calibration via dichotomy method. 2024 1st International Conference on Electrical, Computer, Telecommunication and Energy Technologies (ECTE-Tech), 2024: 1 doi: 10.1109/ECTE-Tech62477.2024.10851147[25] Yi Z X, Liao X P. A capacitive power sensor based on the MEMS cantilever beam fabricated by GaAs MMIC technology. J Micromech Microeng, 2013, 23(3): 035001 doi: 10.1088/0960-1317/23/3/035001[26] Xu Q R, Ding Z Y, Wang D B. MEMS microwave power detection chip based on fixed beams and its model. J Semicond, 2025, 46(6): 062301 doi: 10.1088/1674-4926/24100018[27] Li C, Xiong J J, Wang D B. A novel capacitive microwave power sensor based on double MEMS cantilever beams. IEEE Sens J, 2022, 22(12): 11803 doi: 10.1109/JSEN.2022.3174556[28] Zhang Z Q, Liao X P. Suspended thermopile for microwave power sensors based on bulk MEMS and GaAs MMIC technology. IEEE Sens J, 2015, 15(4): 2019 doi: 10.1109/JSEN.2014.2382719[29] Kasambe P V, Barwaniwala A, Sonawane B, et al. Mathematical modeling and numerical simulation of novel cantilever beam designs for ohmic RF MEMS switch application. 2019 International Conference on Advances in Computing. Communication and Control (ICAC3), 2019: 1 doi: 10.1109/ICAC347590.2019.9036830 -

Proportional views

Ruifeng Li was born in China in 2005. She studies at Nanjing University of Posts and Telecommunications for her undergraduate degree. Her interest is MEMS microwave power detection chip.

Ruifeng Li was born in China in 2005. She studies at Nanjing University of Posts and Telecommunications for her undergraduate degree. Her interest is MEMS microwave power detection chip. Debo Wang was born in China in 1983. He received the B.S. degree in electronic science and technology from the Hebei University of Science and technology, Shijiazhuang, China, in 2007, the M.S. degree and the PhD degree in Key Laboratory of MEMS of the Ministry of Education from the southeast university, Nanjing, China, in 2010 and 2012. He is now a post-doctor in Nanjing University and an associate professor of the Nanjing University of Posts and Telecommunication. The discipline of his research focuses on the RF MEMS devices, particularly on microwave power sensor and its package.

Debo Wang was born in China in 1983. He received the B.S. degree in electronic science and technology from the Hebei University of Science and technology, Shijiazhuang, China, in 2007, the M.S. degree and the PhD degree in Key Laboratory of MEMS of the Ministry of Education from the southeast university, Nanjing, China, in 2010 and 2012. He is now a post-doctor in Nanjing University and an associate professor of the Nanjing University of Posts and Telecommunication. The discipline of his research focuses on the RF MEMS devices, particularly on microwave power sensor and its package.

DownLoad:

DownLoad: