| Citation: |

Xiaoguang Guo, Xiaoji Zhang, Xianzhao Tang, Dongming Guo, Hang Gao, Xiaoji Teng. Nanoindentation on the doubler plane of KDP single crystal[J]. Journal of Semiconductors, 2013, 34(3): 034001. doi: 10.1088/1674-4926/34/3/034001

****

X G Guo, X J Zhang, X Z Tang, D M Guo, H Gao, X J Teng. Nanoindentation on the doubler plane of KDP single crystal[J]. J. Semicond., 2013, 34(3): 034001. doi: 10.1088/1674-4926/34/3/034001.

|

Nanoindentation on the doubler plane of KDP single crystal

DOI: 10.1088/1674-4926/34/3/034001

More Information

-

Abstract

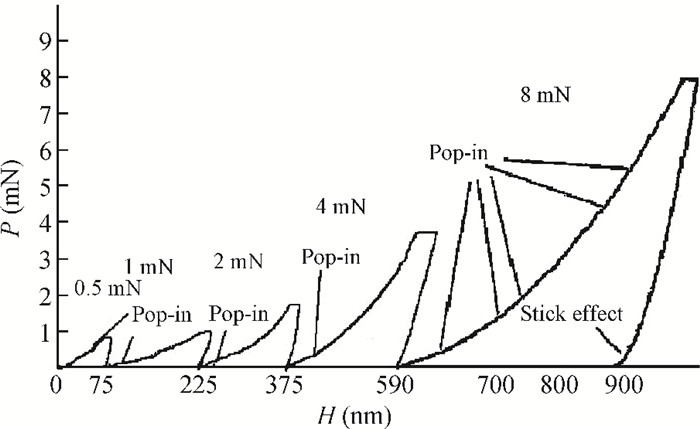

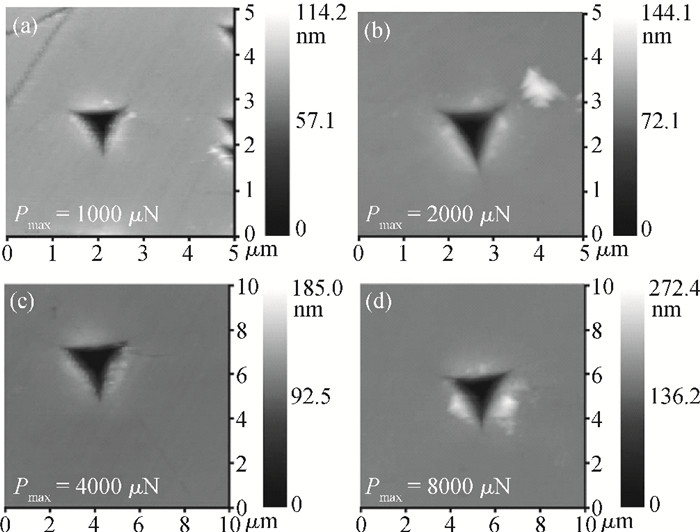

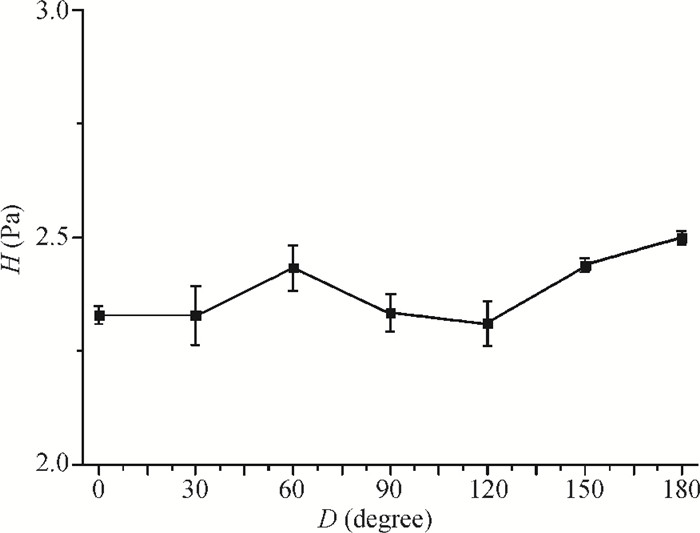

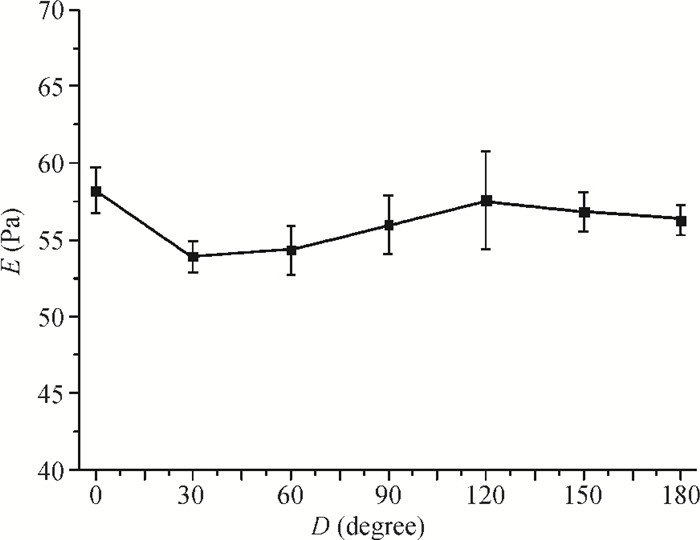

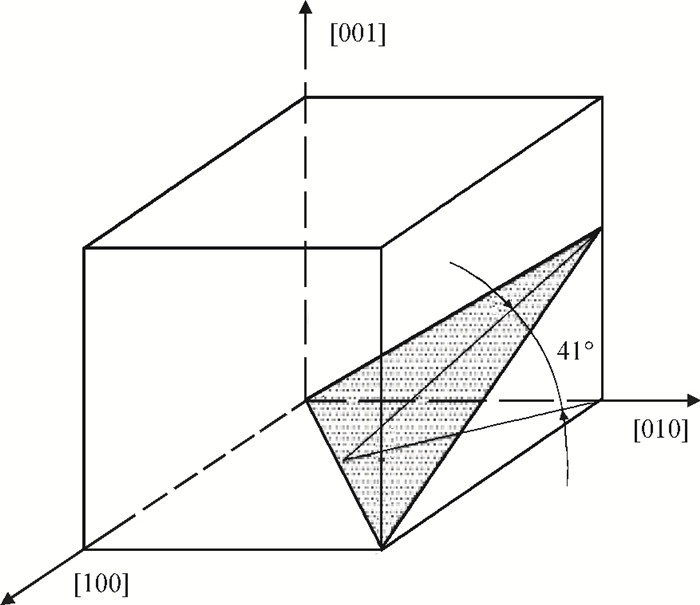

The nanohardness is from 1.44 to 2.61 GPa, the Vickers hardness is from 127 to 252 Vickers, and elastic modulus is from 52 to 123 GPa by the nanoindentation experiments on the doubler plane of KDP crystal. An indentation size effect is observed on the doubler plane in the test as the nanohardness and elastic modulus decreases with the increase of the maximum load. Slippage is identified as the major mode of plastic deformation, and pop-in events are attributed to the initiation of slippage. And the variation of unloading curve end is the result of stick effects between the indenter and the contact surface. The depth of the elastic deformation, which is between 40 and 75 nm, is responsible for the elastic deformation. The doubler plane of KDP crystal has anisotropy, and the relative anisotropy of nanohardness is 8.2% and the relative anisotropy of elastic modulus is 8.0%.-

Keywords:

- KDP crystal,

- the doubler plane,

- nanoindentation,

- size effect,

- anisotropy

-

References

[1] Kucheyey S O, Siekhaus W J, Land T A, et al. Mechanical response of KD2xH2(1-x)PO4 crystals during nanoindentation. Appl Phys Lett, 2004, 84(13):2274 doi: 10.1063/1.1690867[2] Zhang Q. Nano-indentation of cubic and tetragonal single crystals. New York:University of Rochester, 2008 https://search.proquest.com/docview/304533490[3] Wang J H. Research on effects of mechanical properties of KDP crystal on super-smooth surface formation. Harbin:Harbin Institute of Technology, 2006 http://www.sciencedirect.com/science/article/pii/S0025540815002196[4] Lu C P, Gao H, Teng X J, et al. Mechanical response of KDPsingle crystal using nanoindentation technique. J Mechan Eng, 2010, 46(17):192 doi: 10.3901/JME.2010.17.192[5] Lu C P. Ductile machining of KDP crystal materials oriented mechanical behaviors. Dalian:Dalian University of Technology, 2010 http://www.sciencedirect.com/science/article/pii/S0890695516300347[6] Lin Y H, Chen T C, Yang P F, et al. Atomic-level simulations of nanoindentation-induced phase transformation in mono-crystalline silicon. Appl Surf Sci, 2007, 254(5):1415 doi: 10.1016/j.apsusc.2007.06.071[7] Page T F, Oliver W C, Mchargue C J. The deformation-behavior of ceramic crystals subjected to very low load (nano) indentations. J Mater Research, 1992, 7(2):450 doi: 10.1557/JMR.1992.0450 -

Proportional views

DownLoad:

DownLoad: