| Citation: |

Linsong Zhou, Haibo Rao, Wei Wang, Xianlong Wan, Junyuan Liao, Xuemei Wang, Da Zhou, Qiaolin Lei. Self-adaptive phosphor coating technology for wafer-level scale chip packaging[J]. Journal of Semiconductors, 2013, 34(5): 054010. doi: 10.1088/1674-4926/34/5/054010

****

L S Zhou, H B Rao, W Wang, X L Wan, J Y Liao, X M Wang, D Zhou, Q L Lei. Self-adaptive phosphor coating technology for wafer-level scale chip packaging[J]. J. Semicond., 2013, 34(5): 054010. doi: 10.1088/1674-4926/34/5/054010.

|

Self-adaptive phosphor coating technology for wafer-level scale chip packaging

DOI: 10.1088/1674-4926/34/5/054010

More Information

-

Abstract

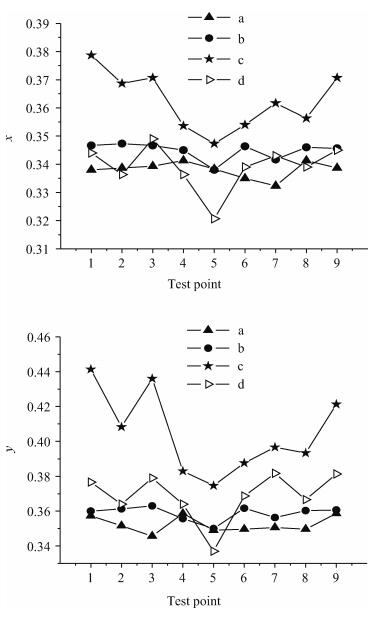

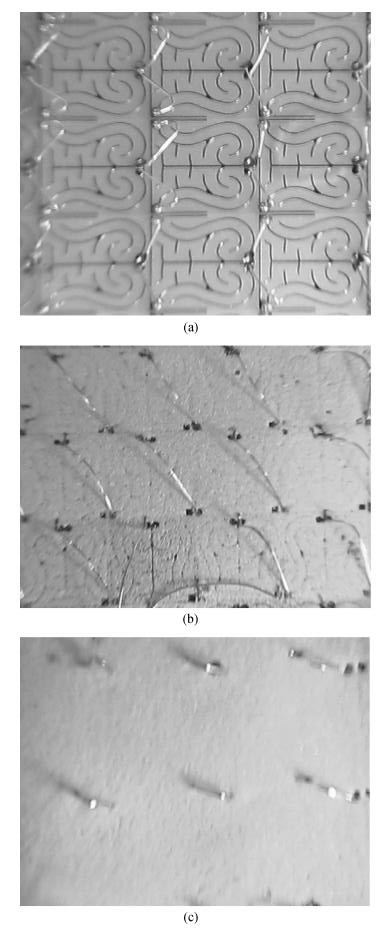

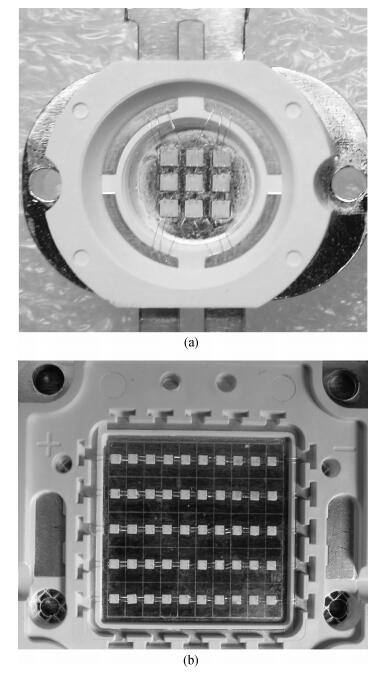

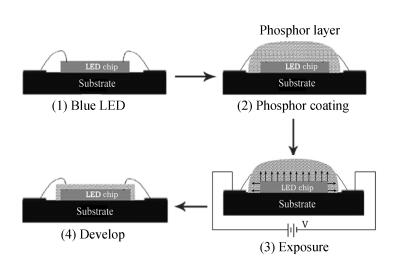

A new self-adaptive phosphor coating technology has been successfully developed, which adopted a slurry method combined with a self-exposure process. A phosphor suspension in the water-soluble photoresist was applied and exposed to LED blue light itself and developed to form a conformal phosphor coating with self-adaptability to the angular distribution of intensity of blue light and better-performing spatial color uniformity. The self-adaptive phosphor coating technology had been successfully adopted in the wafer surface to realize a wafer-level scale phosphor conformal coating. The first-stage experiments show satisfying results and give an adequate demonstration of the flexibility of self-adaptive coating technology on application of WLSCP. -

References

[1] Taguchi T. The light for the 21st century national project based on white light emitting diode (LED) lighting technology. Tran Inst Elec Info Comm Eng C, 2001, J84-C(11):1040 http://apps1.eere.energy.gov/buildings/publications/pdfs/ssl/report_led_november_2002a_1.pdf[2] Chen K, Zhang R, Lee S W R. Integration of phosphor printing and encapsulant dispensing processes for wafer level LED array packaging. IEEE 11th International Conference on Electronic Packaging Technology & High Density Packaging, 2010:1386 https://core.ac.uk/display/34050936[3] Braune B, Petersen K, Strauss J, et al. A new wafer level coating technique to reduce the color distribution of LEDs. Proc SPIE, 2007, 6486:64860X-1 doi: 10.1117/12.727556[4] Hou B, Rao H, Li J. Methods of increasing luminous deficiency of phosphor-converted LED realized by conformal phosphor coating. IEEE Journal of Display Technology, 2009, 5(2):57 doi: 10.1109/JDT.2008.2005272[5] Sommer C, Wenzl F P, Reil F, et al. A comprehensive study on the parameters effecting color conversion in phosphor converted white light-emitting diodes. Proc SPIE, 2010, 7784:77840D-1 doi: 10.1117/12.878987[6] Hou B, Rao H, Li J, et al. Phosphor coating technique with slurry method in application of white LED. SPIE, 2007, 6841:684106 http://proceedings.spiedigitallibrary.org/pdfaccess.ashx?url=/data/conferences/spiep/18628/684106_1.pdf[7] Rao H, Ding K, Song J, et al. Self-adaptive phosphor coating technology for white LED packaging. Frontiers of Optoelectron, 2012, 5(2):147 doi: 10.1007/s12200-012-0236-3[8] Zhu Y, Narendran N. Optimizing the performance of remote phosphor LEDs. J Light & Vis Env, 2008, 32(2):115[9] Narendran N, Gu Y, Freyssinier-Nova J P, et al. Extracting phosphor-scattered photons to improve white LED efficiency. Phys Status Solidi A, 2005, 202(6):R60 doi: 10.1002/pssa.v202:6[10] Fujita S, Yoshihara S, Sakamotoa A, et al. YAG glass-ceramic phosphor for white LED (Ⅰ, Ⅱ). Proc SPIE, 2005, 5941:594111, 594112 doi: 10.1117/12.614668 -

Proportional views

DownLoad:

DownLoad: