| Citation: |

Xiaoyu Liang, Xiaoman Cheng, Boqun Du, Xiao Bai, Jianfeng Fan. Enhanced performance of C60 N-type organic field-effect transistors using a pentacene passivation layer[J]. Journal of Semiconductors, 2013, 34(8): 084002. doi: 10.1088/1674-4926/34/8/084002

****

X Y Liang, X M Cheng, B Q Du, X Bai, J F Fan. Enhanced performance of C60 N-type organic field-effect transistors using a pentacene passivation layer[J]. J. Semicond., 2013, 34(8): 084002. doi: 10.1088/1674-4926/34/8/084002.

|

Enhanced performance of C60 N-type organic field-effect transistors using a pentacene passivation layer

DOI: 10.1088/1674-4926/34/8/084002

More Information

-

Abstract

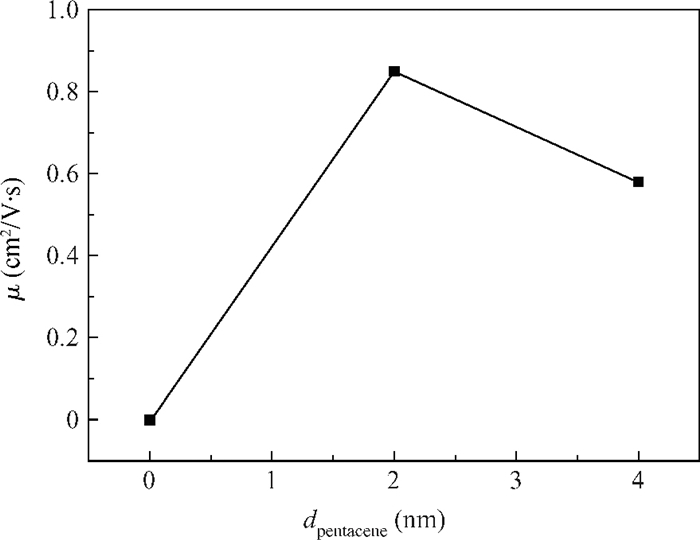

We investigated the properties of C60-based organic field-effect transistors (OFETs) with a pentacene passivation layer inserted between the C60 active layer and the gate dielectric. After modification of the pentacene passivation layer, the performance of the devices was considerably improved compared to C60-based OFETs with only a PMMA dielectric. The peak field-effect mobility was up to 1.01 cm2/(V·s) and the on/off ratio shifted to 104. This result indicates that using a pentacene passivation layer is an effective way to improve the performance of N-type OFETs.-

Keywords:

- organic field-effect transistors,

- passivation layer,

- C60,

- pentacene

-

References

[1] Tsumura A, Koezuka H, Ando T. Macromolecular electronic device:field-effect transistor with a polythiophene thin film. Appl Phys Lett, 1986, 49(18):1210 doi: 10.1063/1.97417[2] Zhao G, Cheng X M, Tian H J, et al. Improved performance of pentacene organic field-effect transistors by inserting a V2O5 metal oxide layer. Chin Phys Lett, 2011, 28(12):127203 doi: 10.1088/0256-307X/28/12/127203[3] Akimichi H, Waragai K, Hotta S, et al. Field-effect transistors using alkyl substituted oligothiophenes. Appl Phys Lett, 1991, 58(14):1500 doi: 10.1063/1.105158[4] Minagawa M, Higashikawa T, Nakai K, et al. Fabrication and evaluation of poly (3-hexylthiophene) field-effect transistor with V2O5 layer. Molecular Crystals and Liquid Crystals, 2010, 519(1):213 doi: 10.1080/15421401003597977[5] Yadav S, Kumar P, Ghosh S. Optimization of surface morphology to reduce the effect of grain boundaries and contact resistance in small molecule based thin film transistors. Appl Phys Lett, 2012, 101(19):193307 doi: 10.1063/1.4766913[6] Dimitrakopoulos C D, Malenfant P R L. Organic thin film transistors for large area electronics. Adv Mater, 2002, 14(2):99 doi: 10.1002/(ISSN)1521-4095[7] Newman C R, Frisbie C D, da Silva Filho D A, et al. Introduction to organic thin film transistors and design of n-channel organic semiconductors. Chem Mater, 2004, 16(23):4436 doi: 10.1021/cm049391x[8] Chua L L, Zaumseil J, Chang J F, et al. General observation of n-type field-effect behaviour in organic semiconductors. Nature, 2005, 434(7030):194 doi: 10.1038/nature03376[9] Zheng Hong, Cheng Xiaoman, Tian Haijun, et al. Enhanced performance of C60 organic field effect transistors using a tris (8-hydroxyquinoline) aluminum buffer layer. Journal of Semiconductors, 2011, 32(9):094005 doi: 10.1088/1674-4926/32/9/094005[10] Kao C C, Lin P, Lee C C, et al. High-performance bottom-contact devices based on an air-stable n-type organic semiconductor N, N-bis (4-trifluoromethoxybenzyl)-1, 4, 5, 8-naphthalene-tetracarboxylic di-imide. Appl Phys Lett, 2007, 90:212101 doi: 10.1063/1.2741414[11] Wang S, Minari T, Miyadera T, et al. Contact-metal dependent current injection in pentacene thin-film transistors. Appl Phys Lett, 2007, 91(20):203508 doi: 10.1063/1.2813640[12] Zhou Jianlin, Niu Qiaoli. Properties of C60 thin film transistor based on polystyrene. Chin Phys B, 2010, 19(7):077305 doi: 10.1088/1674-1056/19/7/077305[13] Haddon R, Perel A, Morris R, et al. C60 thin film transistors. Appl Phys Lett, 1995, 67(1):121 doi: 10.1063/1.115503[14] Anthopoulos T D, Singh B, Marjanovic N, et al. High performance n-channel organic field-effect transistors and ring oscillators based on C60 fullerene films. Appl Phys Lett, 2006, 89(21):213504 doi: 10.1063/1.2387892[15] Itaka K, Yamashiro M, Yamaguchi J, et al. High-mobility C60 field-effect transistors fabricated on molecular-wetting controlled substrates. Adv Mater, 2006, 18(13):1713 doi: 10.1002/(ISSN)1521-4095[16] Lee H N, Lee Y G, Ko I H, et al. Organic passivation layers for pentacene organic thin-film transistors. Current Appl Phys, 2008, 8(5):626 doi: 10.1016/j.cap.2007.11.003[17] Zhou Jianlin, Yu Junsheng, Yu Xinge, et al. A high mobility C60 field-effect transistor with an ultrathin pentacene passivation layer and bathophenanthroline/metal bilayer electrodes. Chin Phys B, 2012, 21(2):027305 doi: 10.1088/1674-1056/21/2/027305 -

Proportional views

DownLoad:

DownLoad: