| Citation: |

Binglei Fu, Naixin Liu, Zhe Liu, Jinmin Li, Junxi Wang. Advantages of InGaN/GaN light emitting diodes with p-GaN grown under high pressure[J]. Journal of Semiconductors, 2014, 35(11): 114007. doi: 10.1088/1674-4926/35/11/114007

****

B L Fu, N X Liu, Z Liu, J M Li, J X Wang. Advantages of InGaN/GaN light emitting diodes with p-GaN grown under high pressure[J]. J. Semicond., 2014, 35(11): 114007. doi: 10.1088/1674-4926/35/11/114007.

|

Advantages of InGaN/GaN light emitting diodes with p-GaN grown under high pressure

DOI: 10.1088/1674-4926/35/11/114007

More Information

-

Abstract

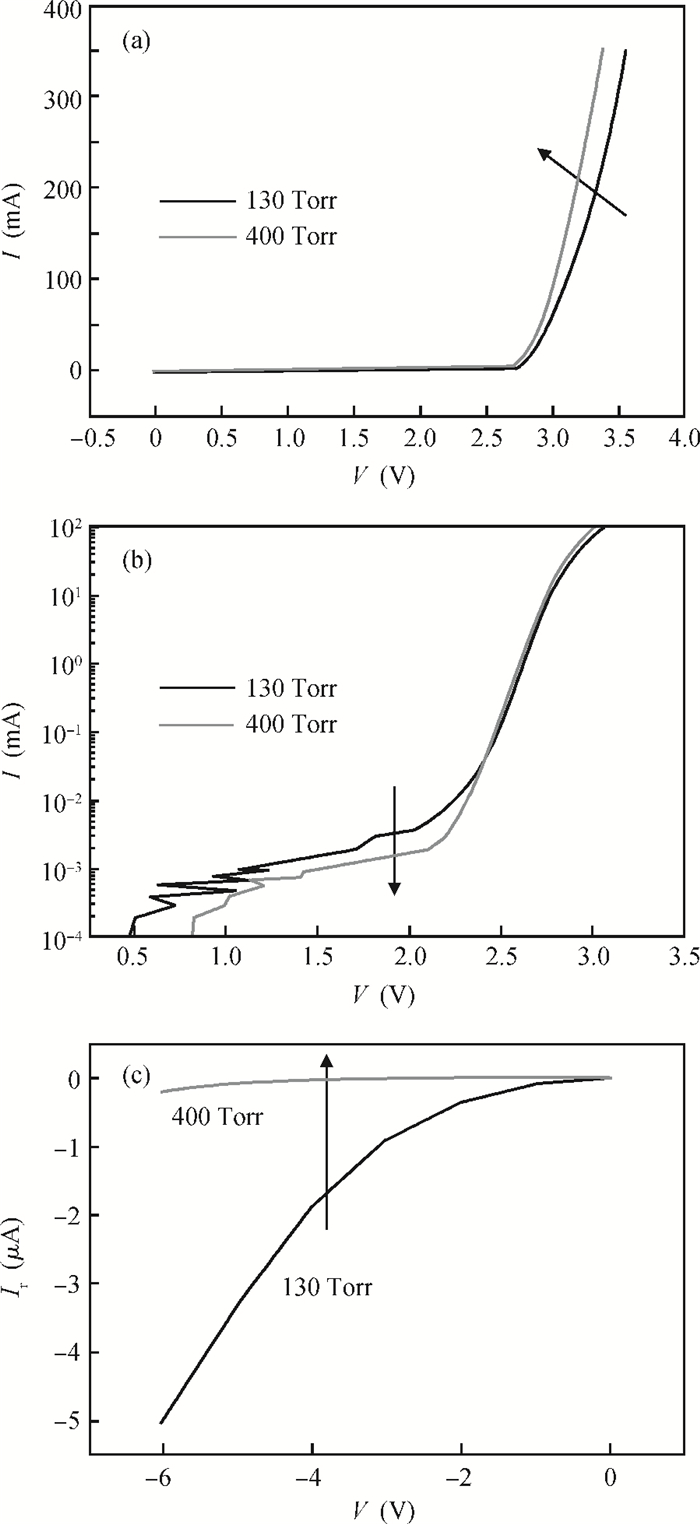

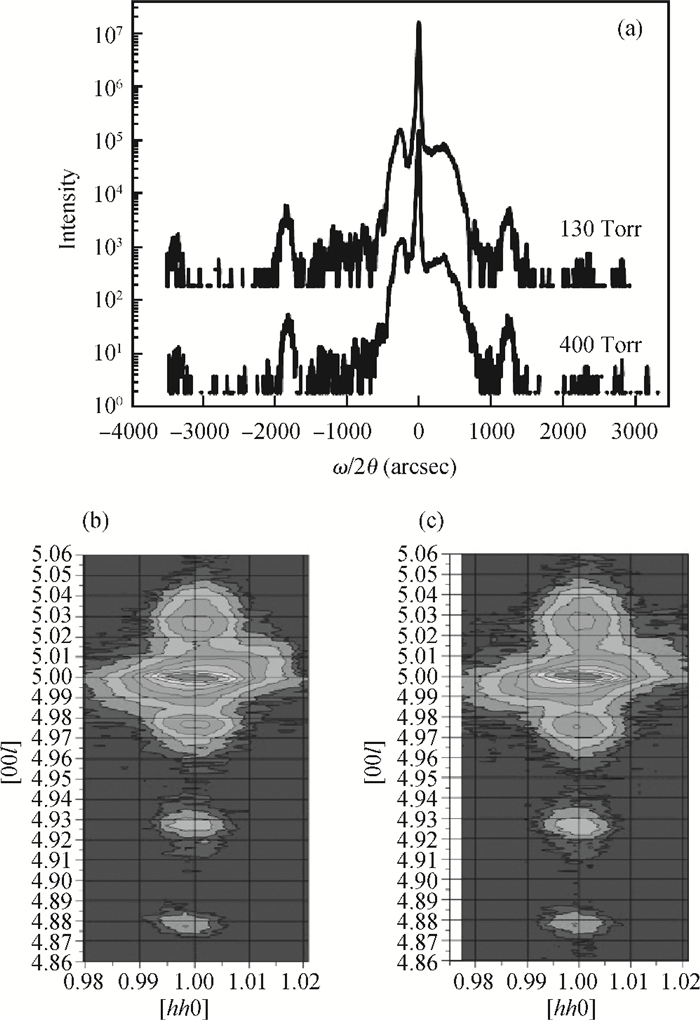

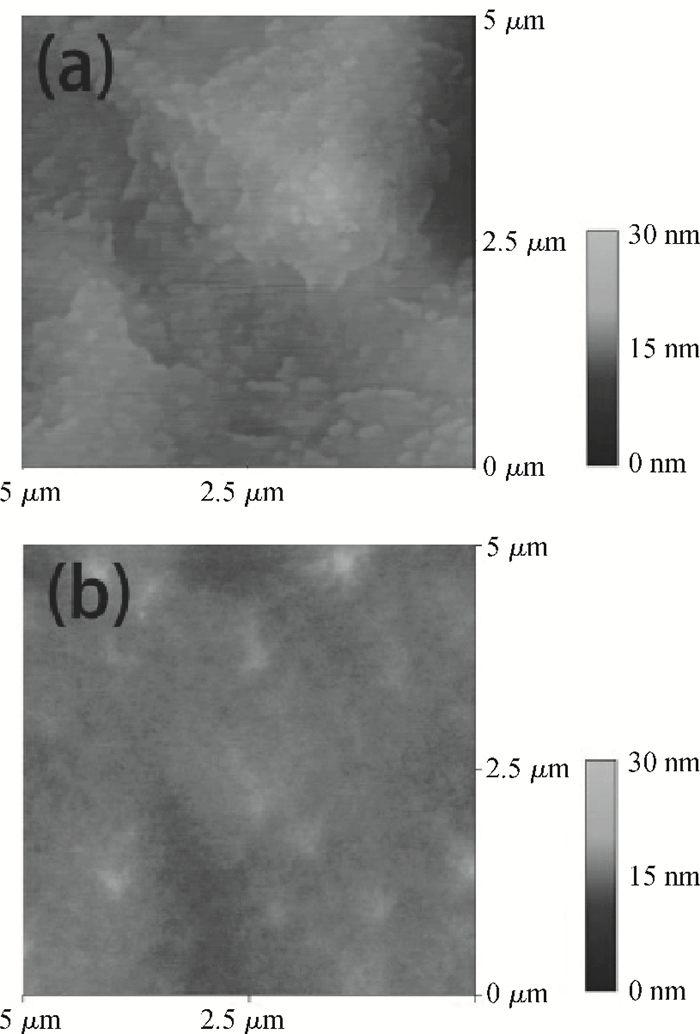

The advantages of InGaN/GaN light emitting diodes (LEDs) with p-GaN grown under high pressures are studied. It is shown that the high growth pressure could lead to better electronic properties of p-GaN layers due to the eliminated compensation effect. The contact resistivity of p-GaN layers are decreased due to the reduced donor-like defects on the p-GaN surface. The leakage current is also reduced, which may be induced by the better filling of V-defects with p-GaN layers grown under high pressures. The LED efficiency thus could be enhanced with high pressure grown p-GaN layers.-

Keywords:

- light emitting diodes,

- V-defects,

- growth pressure,

- p-GaN

-

References

[1] Meyaard D S, Lin G B, Shan Q, et al. Asymmetry of carrier transport leading to efficiency droop in GaInN based light-emitting diodes. Appl Phys Lett, 2011, 99(25):251115 doi: 10.1063/1.3671395[2] Le L C, Zhao D G, Jiang D S, et al. Carriers capturing of V-defect and its effect on leakage current and electroluminescence in InGaN-based light-emitting diodes. Appl Phys Lett, 2012, 101(25):252110 doi: 10.1063/1.4772548[3] Lee W, Limb J, Ryou J H, et al. Influence of growth temperature and growth rate of p-GaN layers on the characteristics of green light emitting diodes. J Electron Mater, 2006, 35(4):587 doi: 10.1007/s11664-006-0104-2[4] Fu B, Liu N, Zhang N, et al. The effect of growth pressure and growth rate on the properties of Mg-doped GaN. J Electron Mater, 2014, DOI: 10.1007/s11664-014-3005-9[5] Ratsch C, Garcia J, Caflisch R E. Influence of edge diffusion on the growth mode on vicinal surfaces. Appl Phys Lett, 2005, 87(14):141901 doi: 10.1063/1.2077851[6] Wang L C, Guo E Q, Liu Z Q, et al. Electrical characteristics of a vertical light emitting diode with n-type contacts on a selectively wet-etching roughened surface. Journal of Semiconductors, 2011, 32(2):024009 doi: 10.1088/1674-4926/32/2/024009[7] Liu L, Ling M, Yang J, et al. Efficiency degradation behaviors of current/thermal co-stressed GaN-based blue light emitting diodes with vertical-structure. J Appl Phys, 2012, 111(9):093110 doi: 10.1063/1.4712030[8] Oh M S, Kwon M K, Park I K, et al. Improvement of green LED by growing p-GaN on In0.25GaN/GaN MQWs at low temperature. J Cryst Growth, 2006, 289(1):107 doi: 10.1016/j.jcrysgro.2005.10.129[9] Ji Y, Zhang Z H, Kyaw Z, et al. Influence of n-type versus p-type AlGaN electron-blocking layer on InGaN/GaN multiple quantum wells light-emitting diodes. Appl Phys Lett, 2013, 103(5):053512 doi: 10.1063/1.4817381 -

Proportional views

DownLoad:

DownLoad: