| Citation: |

Yufeng Zhao, Xinhua Li, Wenbo Wang, Bukang Zhou, Huahua Duan, Tongfei Shi, Xuesong Zeng, Ning Li, Yuqi Wang. Growth and properties of GaAs nanowires on fused quartz substrate[J]. Journal of Semiconductors, 2014, 35(9): 093002. doi: 10.1088/1674-4926/35/9/093002

****

Y F Zhao, X H Li, W B Wang, B K Zhou, H H Duan, T F Shi, X S Zeng, N Li, Y Q Wang. Growth and properties of GaAs nanowires on fused quartz substrate[J]. J. Semicond., 2014, 35(9): 093002. doi: 10.1088/1674-4926/35/9/093002.

|

Growth and properties of GaAs nanowires on fused quartz substrate

DOI: 10.1088/1674-4926/35/9/093002

More Information

-

Abstract

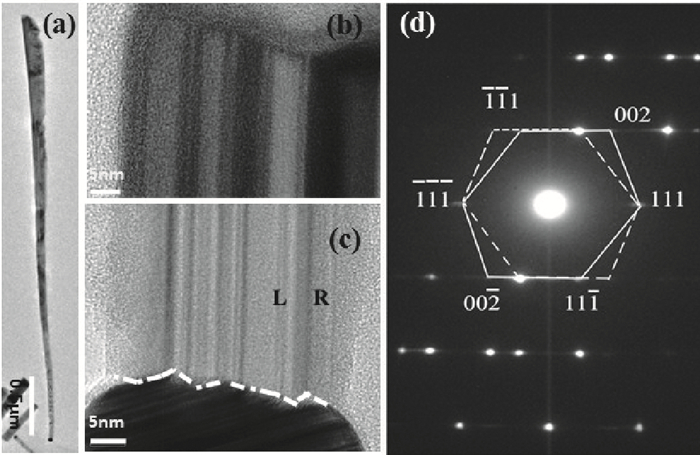

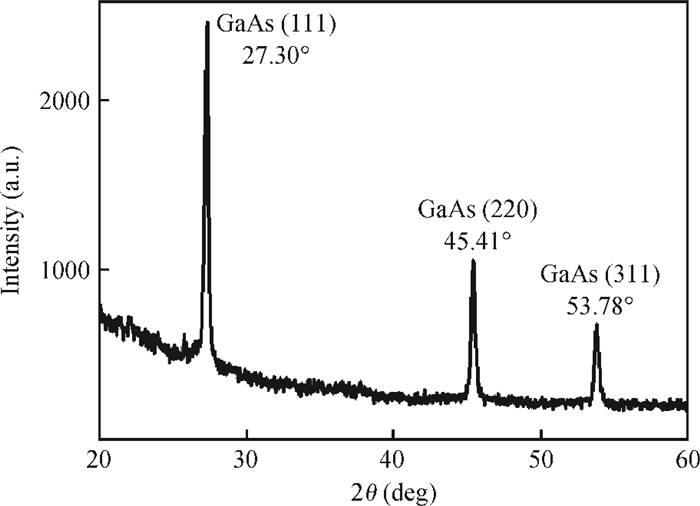

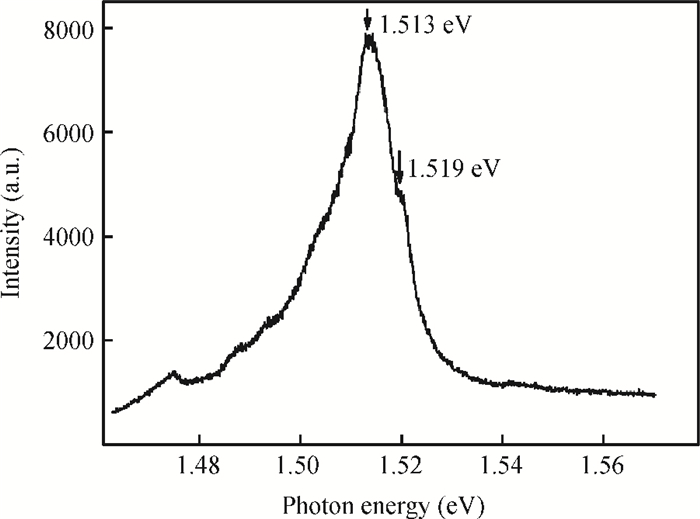

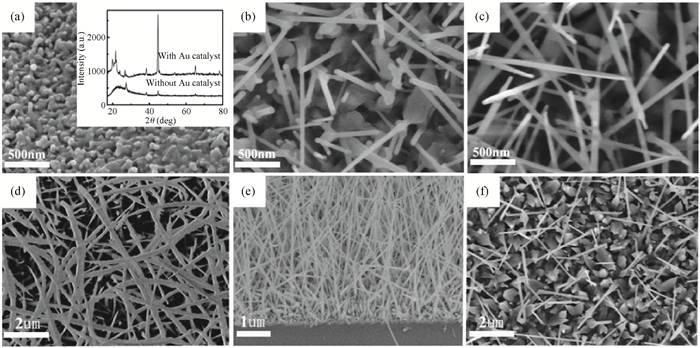

The growth of GaAs nanowires directly on fused quartz substrates using molecular beam epitaxy via a vapor-liquid-solid mechanism with gold as catalyst is reported. Unlike conventional Au-catalyst MBE growth of nanowires (NWs) on GaAs substrates, zinc blende is found to be the dominant crystal structure for NWs grown on fused-quartz substrates by MBE. Further transmission electron microscopy measurements show that the prepared ZB NWs have the growth direction of $[11\overline 2]$ and lamellar {111} twins extend through the length of NWs. Although there are longitudinal planar defects that extend through NWs, the narrow full width at half maximum of PL implies high crystal quality of NWs grown on fused-quartz substrates. -

References

[1] Doh Y J, van Dam J A, Roest A L, et al. Tunable supercurrent through semiconductor nanowires. Science, 2005, 309(5732):272 doi: 10.1126/science.1113523[2] Glas F, Harmand J C, Patriarche G. Why does wurtzite form in nanowires of Ⅲ-Ⅴ zinc blende semiconductors. Phys Rev Lett, 2007, 99(14):146101 doi: 10.1103/PhysRevLett.99.146101[3] Lu W, Lieber C M. Nanoelectronics from the bottom up. Nat Mater, 2007, 6(11):841 doi: 10.1038/nmat2028[4] Qian F, Gradecak S, Li Y, et al. Core/multishell nanowire heterostructures as multicolor, high-efficiency light-emitting diodes. Nano Lett, 2005, 5(11):2287 doi: 10.1021/nl051689e[5] Raj G, Pardeshi H, Pati K, et al. 2DEG charge density based drain current model for nano-scale AlInGaN/AlN/GaN HEMT devices. Journal of Semiconductors, 2013, 34(4):044002 doi: 10.1088/1674-4926/34/4/044002[6] Bao X Y, Soci C, Susac D, et al. Heteroepitaxial growth of vertical GaAs nanowires on Si (111) substrates by metal-organic chemical vapor deposition. Nano Lett, 2008, 8(11):3755 doi: 10.1021/nl802062y[7] Xu H Y, Guo Y N, Sun W, et al. Quantitative study of GaAs nanowires catalyzed by Au film of different thicknesses. Nanoscale Res Lett, 2012, 7(1):1 doi: 10.1186/1556-276X-7-1[8] Joyce H J, Gao Q, Tan H H, et al. High purity GaAs nanowires free of planar defects:growth and characterization. Adv Funct Mater, 2008, 18(23):3794 doi: 10.1002/adfm.v18:23[9] Lugani L, Ercolani D, Sorba L, et al. Modeling of InAs-InSb nanowires grown by Au-assisted chemical beam epitaxy. Nanotechnology, 2012, 23(9):095602 doi: 10.1088/0957-4484/23/9/095602[10] Ercolani D, Rossi F, Li A, et al. InAs/InSb nanowire heterostructures grown by chemical beam epitaxy. Nanotechnology, 2009, 20(50):505605 doi: 10.1088/0957-4484/20/50/505605[11] Plissard S, Dick K A, Larrieu G, et al. Gold-free growth of GaAs nanowires on silicon:arrays and polytypism. Nanotechnology, 2010, 21(38):385602 doi: 10.1088/0957-4484/21/38/385602[12] Tchernycheva M, Harmand J C, Patriarche G, et al. Temperature conditions for GaAs nanowire formation by Au-assisted molecular beam epitaxy. Nanotechnology, 2006, 17(16):4025 doi: 10.1088/0957-4484/17/16/005[13] Duan X, Lieber C M. General synthesis of compound semiconductor nanowires. Adv Mater, 2000, 12(4):298 doi: 10.1002/(ISSN)1521-4095[14] Shao Y, Nie T, Jiang Z, et al. Behavior of Au-Si droplets in Si (001) at high temperatures. Appl Phys Lett, 2012, 101(5):053104 doi: 10.1063/1.4739413[15] Wagner R, Ellis W. Vapor-liquid-solid mechanism of single crystal growth. Appl Phys Lett, 1964, 4(5):89 doi: 10.1063/1.1753975[16] Kayes B M, Atwater H A, Lewis N S. Comparison of the device physics principles of planar and radial p-n junction nanorod solar cells. J Appl Phys, 2005, 97(11):114302 doi: 10.1063/1.1901835[17] Plante M C, Lapierre R R. Control of GaAs nanowire morphology and crystal structure. Nanotechnology, 2008, 9(49):495603[18] Kang J H, Gao Q, Joyce H J, et al. Novel growth and properties of GaAs nanowires on Si substrates. Nanotechnology, 2010, 21(3):035604 doi: 10.1088/0957-4484/21/3/035604[19] Akinlami J O, Ashamu A O. Optical properties of gallium arsenide GaAs. Journal of Semiconductors, 2013, 34(3):032002 doi: 10.1088/1674-4926/34/3/032002[20] Wen L, Li X, Zhao Z, et al. Theoretical consideration of Ⅲ-Ⅴ nanowire/Si triple-junction solar cells. Nanotechnology, 2012, 23(50):505202 doi: 10.1088/0957-4484/23/50/505202[21] Dhaka V, Haggren T, Jussila H, et al. High quality GaAs nanowires grown on glass substrates. Nano Lett, 2012, 12(4):1912 doi: 10.1021/nl204314z[22] Geaney H, Dickinson C, Weng W, et al. Role of defects and growth directions in the formation of periodically twinned and kinked unseeded germanium nanowires. Cryst Growth Des, 2011, 11(7):3266 doi: 10.1021/cg200510y[23] Davidson F M, Lee D C, Fanfair D D, et al. Lamellar twinning in semiconductor nanowires. J Phys Chem C, 2007, 111(7):2929 doi: 10.1021/jp0672205[24] Nitta Y, Ohta J, Mitsunaga K, et al. GaAs/AlGaAs optical interconnection chip for neural network. Jpn J Appl Phys Lett, 1989, 28(11):L2101 https://confit.atlas.jp/guide/organizer/ssdm/ssdm1989/subject/S-C-1/search;jsessionid=76DDD57608627B90100FAFF5D46460D9?eventCode=ssdm1989&code=S-C-1[25] Dubrovskii V, Sibirev N, Cirlin G, et al. Theoretical analysis of the vapor-liquid-solid mechanism of nanowire growth during molecular beam epitaxy. Phys Rev E, 2006, 73(2):021603 https://www.ncbi.nlm.nih.gov/pubmed/16605346[26] Dubrovskii V, Cirlin G, Soshnikov I, et al. Diffusion-induced growth of GaAs nanowhiskers during molecular beam epitaxy:theory and experiment. Phys Rev B, 2005, 71(20):205325 doi: 10.1103/PhysRevB.71.205325[27] Glas F, Harmand J C, Patriarche G. Why does wurtzite form in nanowires of Ⅲ-Ⅴ zinc blende semiconductors. Phys Rev Lett, 2007, 99(14):146101 doi: 10.1103/PhysRevLett.99.146101[28] Shtrikman H, Popovitz-Biro R, Kretinin A, et al. Stacking-faults-free zinc blende GaAs nanowires. Nano Lett, 2008, 9(1):215 https://www.ncbi.nlm.nih.gov/pubmed/19093840[29] Cirlin G, Dubrovskii V, Samsonenko Y B, et al. Self-catalyzed, pure zinc-blende GaAs nanowires grown on Si (111) by molecular beam epitaxy. Phys Rev B, 2010, 82(3):035302 doi: 10.1103/PhysRevB.82.035302[30] Li C P, Lee C S, Ma X L, et al. Growth direction and cross-sectional study of silicon nanowires. Adv Mater, 2003, 15(7/8):607 http://repository.ust.hk/ir/Record/1783.1-22648 -

Proportional views

DownLoad:

DownLoad: