| Citation: |

Yanwei Fan, Bukang Zhou, Junhua Wang, Zhaoyang Chen, Aimin Chang. Preparation and thermal-sensitive characteristic of copper doped n-type silicon material[J]. Journal of Semiconductors, 2015, 36(1): 013004. doi: 10.1088/1674-4926/36/1/013004

****

Y W Fan, B K Zhou, J H Wang, Z Y Chen, A M Chang. Preparation and thermal-sensitive characteristic of copper doped n-type silicon material[J]. J. Semicond., 2015, 36(1): 013004. doi: 10.1088/1674-4926/36/1/013004.

|

Preparation and thermal-sensitive characteristic of copper doped n-type silicon material

DOI: 10.1088/1674-4926/36/1/013004

More Information

-

Abstract

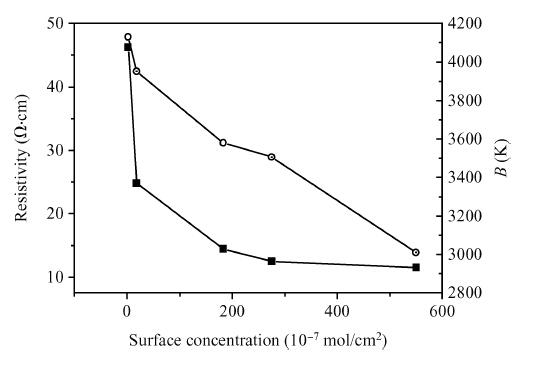

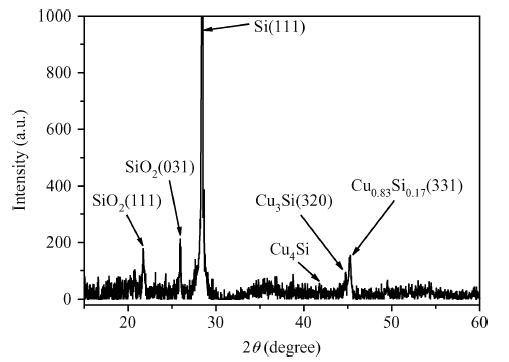

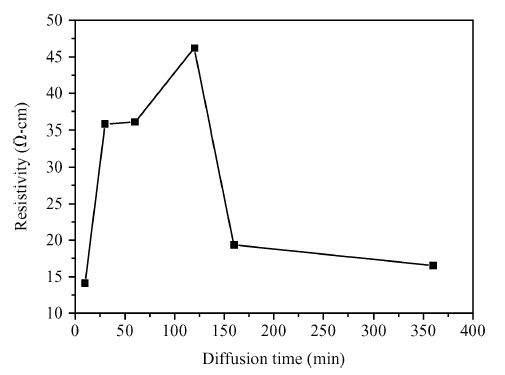

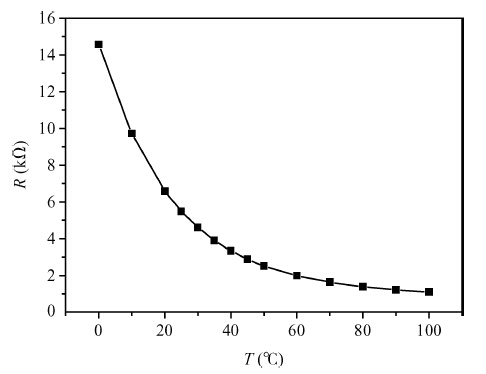

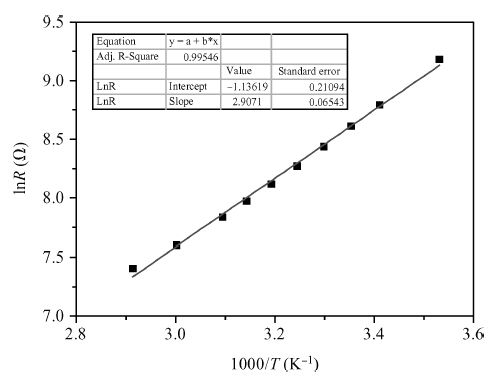

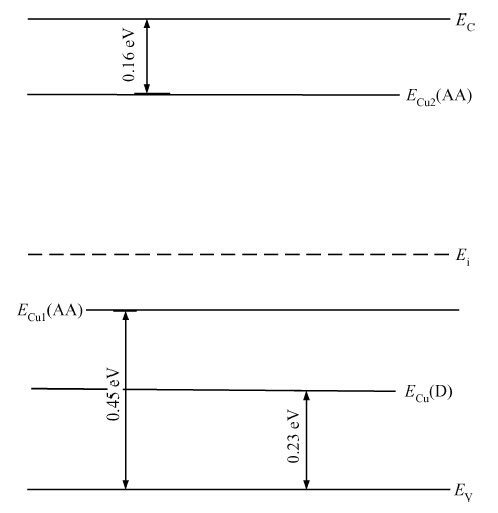

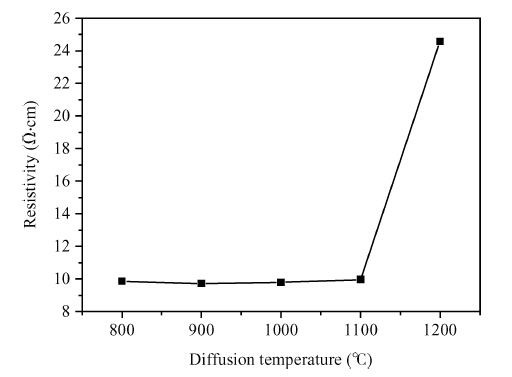

Copper doped n-type single-crystal silicon materials are prepared by a high temperature diffusion process. The electrical and thermal-sensitive characteristic of materials is investigated under different experimental conditions. The results show that the maximum resistivity of 46.2 Ω ·cm is obtained when the sample is treated at 1200 ℃ for 2 h with the surface concentration of the copper dopant source being 1.83 × 10-7 mol/cm2. The copper doped n-type silicon material presents a negative temperature-sensitive characteristic and the B values are about 3010-4130 K.-

Keywords:

- single-crystal silicon,

- deep level impurity,

- copper

-

References

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] -

Proportional views

DownLoad:

DownLoad: