| Citation: |

Lixia Zhao, Chao Yang, He Zhu, Jianjun Song. Scattering mechanism of hole in (001), (101), (111) biaxially-strained Si and Si1-xGex materials[J]. Journal of Semiconductors, 2015, 36(7): 072003. doi: 10.1088/1674-4926/36/7/072003

****

L X Zhao, C Yang, H Zhu, J J Song. Scattering mechanism of hole in (001), (101), (111) biaxially-strained Si and Si1-xGex materials[J]. J. Semicond., 2015, 36(7): 072003. doi: 10.1088/1674-4926/36/7/072003.

|

Scattering mechanism of hole in (001), (101), (111) biaxially-strained Si and Si1-xGex materials

DOI: 10.1088/1674-4926/36/7/072003

More Information

-

Abstract

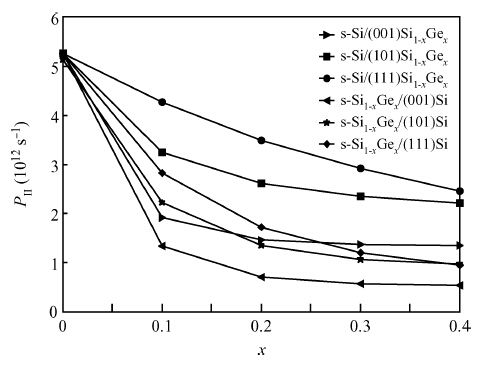

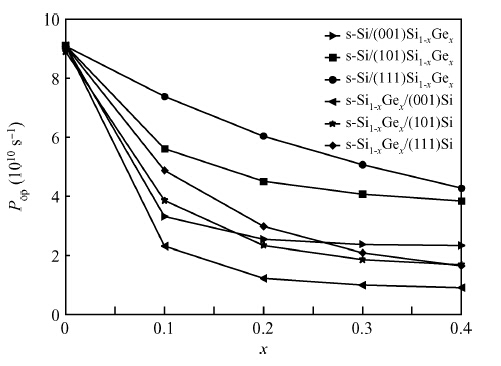

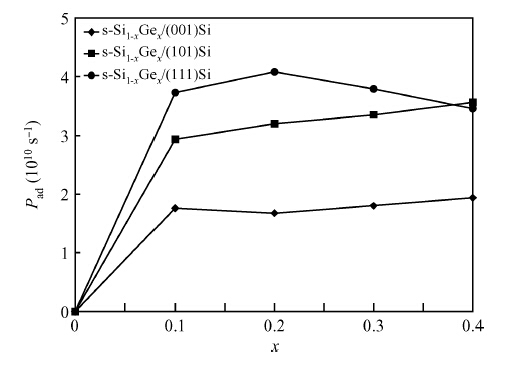

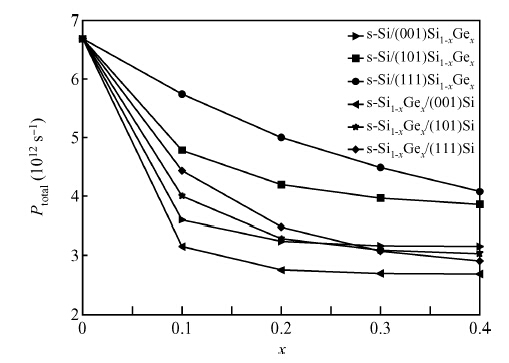

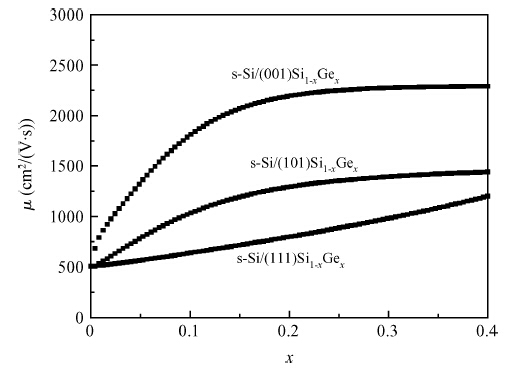

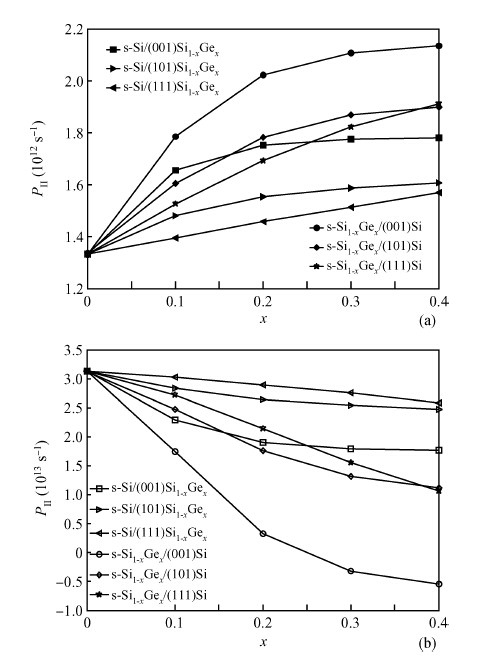

Based on Fermi's golden rule and the theory of Boltzmann collision term approximation, the hole scattering mechanism related to stress and orientation in Si-based strained materials was studied in-depth. The results show that: (1) the total hole scattering rates in Si-based strained materials decrease obviously under strain; (2) the turn is Si/(111)Si1-xGex > Si/(101)Si1-xGex > Si1-xGex/(111)Si > Si1-xGex/(101)Si > Si/(001)Si1-xGex > Si1-xGex/(001)Si when Ge fraction is about 0.2; (3) the decreasing total hole scattering rates of in strained materials with the increasing stress is mainly caused the decreasing acoustic phonon scattering rate under strain. The theoretical conclusions obtained could provide important references for researching the hole mobility and the understanding of Si-based materials or other physical strained materials.-

Keywords:

- strain,

- orientation,

- scattering,

- hole

-

References

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] -

Proportional views

DownLoad:

DownLoad: