| Citation: |

Xudong Chen, Jianbing Cheng, Guobing Teng, Houdong Guo. Novel trench gate field stop IGBT with trench shorted anode[J]. Journal of Semiconductors, 2016, 37(5): 054008. doi: 10.1088/1674-4926/37/5/054008

****

X D Chen, J B Cheng, G B Teng, H D Guo. Novel trench gate field stop IGBT with trench shorted anode[J]. J. Semicond., 2016, 37(5): 054008. doi: 10.1088/1674-4926/37/5/054008.

|

Novel trench gate field stop IGBT with trench shorted anode

DOI: 10.1088/1674-4926/37/5/054008

More Information

-

Abstract

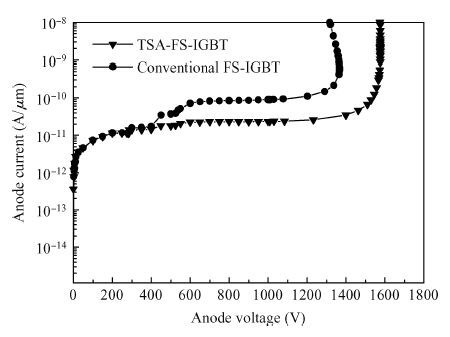

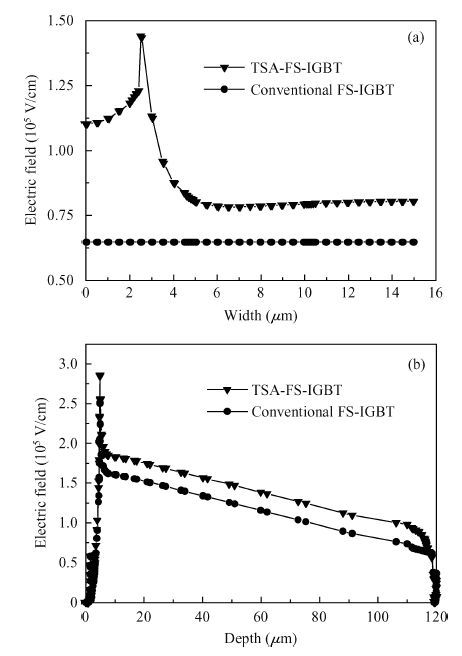

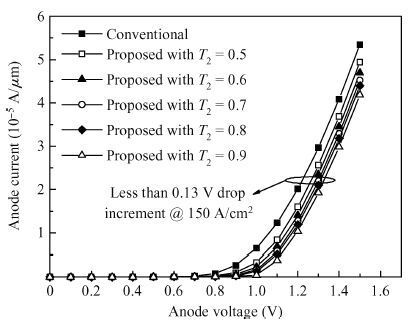

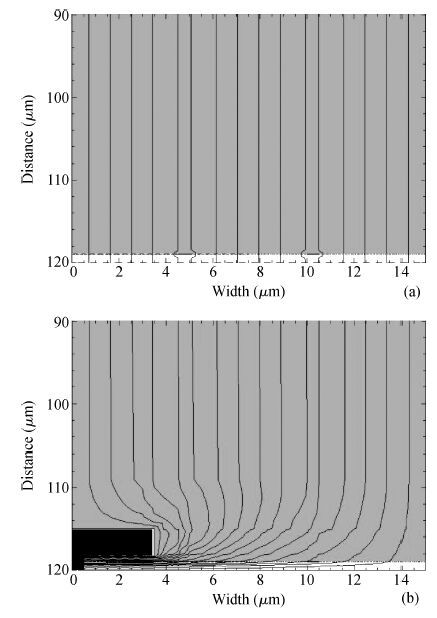

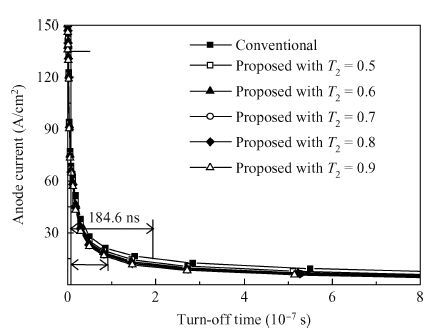

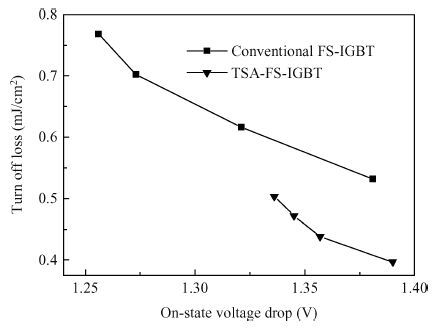

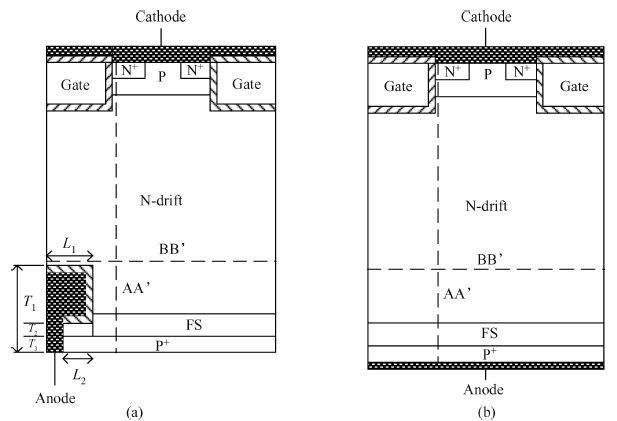

A novel trench field stop (FS) insulated gate bipolar transistor (IGBT) with a trench shorted anode (TSA) is proposed. By introducing a trench shorted anode, the TSA-FS-IGBT can obviously improve the breakdown voltage. As the simulation results show, the breakdown voltage is improved by a factor of 19.5% with a lower leakage current compared with the conventional FS-IGBT. The turn off time of the proposed structure is 50% lower than the conventional one with less than 9% voltage drop increased at a current density of 150 A/cm2. Additionally, there is no snapback observed. As a result, the TSA-FS-IGBT has a better trade-off relationship between the turn off loss and forward drop.-

Keywords:

- FS-IGBT,

- trench shorted anode,

- breakdown voltage,

- turn off loss,

- tradeoff

-

References

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] -

Proportional views

DownLoad:

DownLoad: