| Citation: |

Guoguo Yan, Feng Zhang, Yingxi Niu, Fei Yang, Lei Wang, Wanshun Zhao, Guosheng Sun, Yiping Zeng. Chloride-based fast homoepitaxial growth of 4H-SiC films in a vertical hot-wall CVD[J]. Journal of Semiconductors, 2016, 37(6): 063001. doi: 10.1088/1674-4926/37/6/063001

****

G G Yan, F Zhang, Y X Niu, F Yang, L Wang, W S Zhao, G S Sun, Y P Zeng. Chloride-based fast homoepitaxial growth of 4H-SiC films in a vertical hot-wall CVD[J]. J. Semicond., 2016, 37(6): 063001. doi: 10.1088/1674-4926/37/6/063001.

|

Chloride-based fast homoepitaxial growth of 4H-SiC films in a vertical hot-wall CVD

DOI: 10.1088/1674-4926/37/6/063001

More Information

-

Abstract

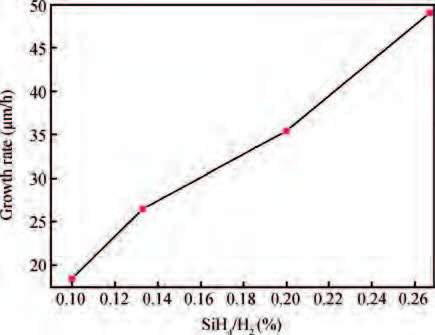

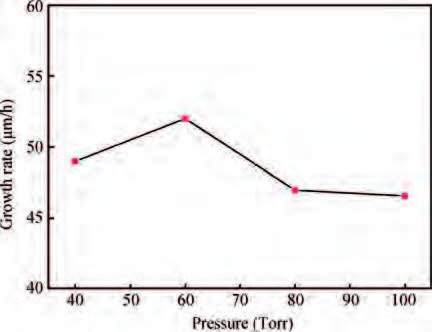

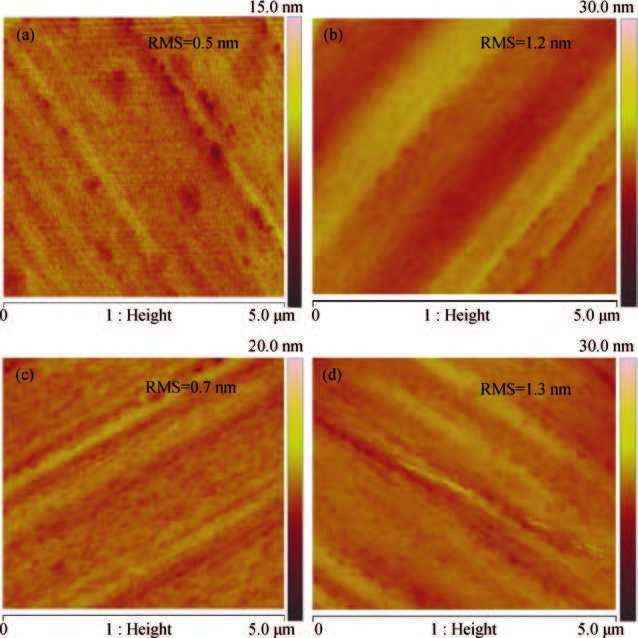

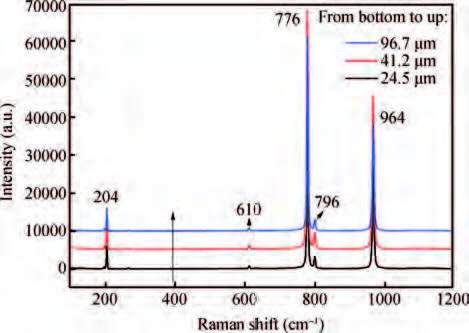

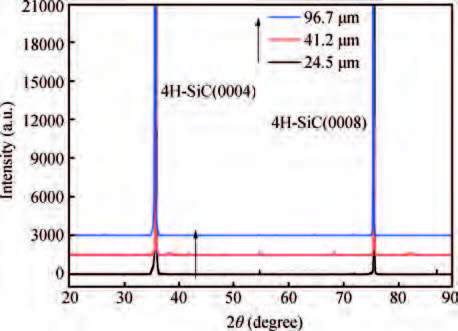

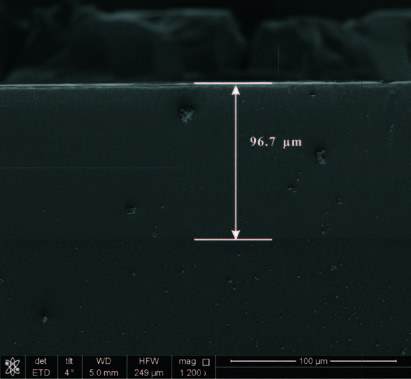

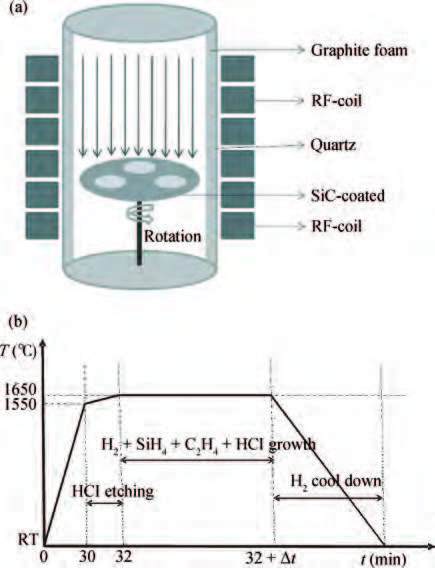

Chloride-based fast homoepitaxial growth of 4H-SiC epilayers was performed on 4° off-axis 4H-SiC substrates in a home-made vertical hot-wall chemical vapor deposition (CVD) system using H2-SiH4-C2H4-HCl. The effect of the SiH4/H2 ratio and reactor pressure on the growth rate of 4H-SiC epilayers has been studied successively. The growth rate increase in proportion to the SiH4/H2 ratio and the influence mechanism of chlorine has been investigated. With the reactor pressure increasing from 40 to 100 Torr, the growth rate increased to 52 μm/h and then decreased to 47 μm/h, which is due to the joint effect of H2 and HCl etching as well as the formation of Si clusters at higher reactor pressure. The surface root mean square (RMS) roughness keeps around 1 nm with the growth rate increasing to 49 μm/h. The scanning electron microscope (SEM), Raman spectroscopy and X-ray diffraction (XRD) demonstrate that 96.7 μm thick 4H-SiC layers of good uniformity in thickness and doping with high crystal quality can be achieved. These results prove that chloride-based fast epitaxy is an advanced growth technique for 4H-SiC homoepitaxy. -

References

[1] Zhao J H, Alexandrov P, Zhang J H, et al. Fabrication and characterization of 11-kV normally off 4H-SiC trenched-and-implanted vertical junction FET. IEEE Electron Device Lett, 2004, 25(7):474[2] Song Q W, Zhang Y M, Han J S, et al. The fabrication and characterization of 4H-SiC power UMOSFETs. Chin Phys B, 2013, 22(2):027302[3] Jantawongrit P, Sanorpim S, Yaguchi H, et al. Microstructures of InN film on 4H-SiC (0001) substrate grown by RF-MBE. Journal of Semiconductors, 2015, 36(8):083002[4] Rao M H L, Murty N V L N. An improved analytical model of 4H-SiC MESFET incorporating bulk and interface trapping effects. Journal of Semiconductors, 2015, 36(1):014004[5] Robert J L, Contreras S, Camassel J, et al. 4H-SiC material for Hall effect and high-temperature sensors working in harsh environments. Mater Sci Forum, 2002, 389-393:1435[6] Pedersen H, Leone S, Henry A, et al. Very high growth rate of 4H-SiC epilayers using the chlorinated precursor methyltrichlorosilane (MTS). J Cryst Growth, 2007, 307(2):334[7] Ishida Y, Takahashi T, Okumura H, et al. Origin of giant step bunching on 4H-SiC (0001) surfaces. Materials Science Forum, 2009:473[8] Tsuchida H, Ito M, Kamata I, et al. Low-pressure fast growth and characterization of 4H-SiC epilayers. Materials Science Forum, 2010:77[9] Thomas B, Hecht C, Stein R, et al. Challenges in large-area multi-wafer SiC epitaxy for production needs. Materials Science Forum, 2006:135[10] Burk A A, O'Loughlin M J, Sumakeris J J, et al. SiC epitaxial growth on multiple 100-mm wafers and its application to power-switching devices. Materials Science Forum, 2009:77[11] Li Yanyue, Deng Xiaochuan, Liu Yunfeng, et al. Effect of post oxidation annealing in nitric oxide on interface properties of 4H-SiC/SiO2 after high temperature oxidation. Journal of Semiconductors, 2015, 36(9):094003[12] Myers R L, Shishkin Y, Kordina O, et al. High growth rates (>30 mμm/h) of 4H-SiC epitaxial layers using a horizontal hot-wall CVD reactor. J Cryst Growth, 2005, 285(4):486[13] Vivona M, Greco G, Franco S D, et al. Comparative study of the current transport mechanisms in Ni2Si Ohmic contacts on n- and p-type implanted 4H-SiC. Materials Science Forum, 2014:665[14] Yan Guoguo, Sun Guosheng, Wu Hailei, et al. Multi-wafer 3C-SiC thin films grown on Si (100) in a vertical HWLPCVD reactor. Journal of Semiconductors, 2011, 32(6):063001[15] Guo Hui, Zhao Yaqiu, Zhang Yuming, et al. Influence of n-type doping on the oxidation rate in n-type 6H-SiC. Journal of Semiconductors, 2015, 36(1):013006[16] Henry A, Leone S, Beyer F C, et al. SiC epitaxy growth using chloride-based CVD. Physica B, 2012, 407(10):1467[17] Tanaka T, Kawabata N, Mitani Y, et al. Influence of growth pressure and addition of HCl gas on growth rate of 4H-SiC epitaxy. Materials Science Forum, 2015, 821-823:133[18] Sun G S, Liu X F, Wu H L, et al. Determination of the transport properties in 4H-SiC wafers by Raman scattering measurement, Chinese Phys B, 2011, 20(3):033301[19] Yan Guoguo, Sun Guosheng, Wu Hailei, et al. Multi-wafer 3C-SiC thin films grown on Si (100) in a vertical HWLPCVD reactor. Journal of Semiconductors, 2011, 32(6):063001[20] Liu B, Sun G S, Liu X F, et al. Fast homoepitaxial growth of 4H-SiC films on 4° off-axis substrates in a SiH4-C2H4-H2 system. Chin Phys Lett, 2013, 30(12):128101[21] Fujihira K, Kimoto T, Matsunami H. Growth and characterization of 4H-SiC in vertical hot-wall chemical vapor deposition. J Cryst Growth, 2003, 255(1/2):136[22] La Via F, Izzo G, Mauceri M, et al. 4H-SiC epitaxial layer growth by trichlorosilane (TCS). J Cryst Growth, 2008, 311(1):107[23] La Via F, Galvagno G, Foti G, et al. 4H SiC epitaxial growth with chlorine addition. Chem Vapor Depos, 2006, 12(8/9):509[24] Karhu I B R, Ul Hassan J, Ivanov I, et al. The role of chlorine during high growth rate epitaxy, Mater Sci Forum, 2015, 821-823:141[25] Rupp R, Makarov Y N, Behner H, et al. Silicon carbide epitaxy in a vertical CVD reactor:experimental results and numerical process simulation. Phys Status Solidi B, 1997, 202(1):281[26] Kordina O, Hallin C, Ellison A, et al. High temperature chemical vapor deposition of SiC. Appl Phys Lett, 1996, 69(10):1456[27] Li J P, Steckl A J. Nucleation and void formation mechanisms in SiC thin-film growth on Si by carbonization. J Electrochem Soc, 1995, 142(2):634[28] Kunstmann T, Angerer H, Knecht J, et al. Novel brominated carbosilane precursors for low-temperature heteroepitaxy of beta-SiC and their comparison with methyltrichlorosilane. Chem Mater, 1995, 7(9):1675[29] Kunstmann T, Veprek S, Schmidbaur H, et al. Chemical vapor deposition of 3C-SiC on Si (100) from methyltrichlorosilane and methyltribromosilane. Inst Phys Conf Ser, 1996, 142:213[30] La Via F, Leone S, Mauceri M, et al. Very high growth rate epitaxy processes with chlorine addition. Materials Science Forum, 2007, 556/557:157[31] Nakashima S, Harima H. Raman investigation of SiC polytypes. Phys Status Solidi A, 1997, 162(1):39[32] Wu Hailei, Sun Guosheng, Yang Ting, et al. High-quality homoepitaxial layers grown on 4H-SiC at high growth rate by vertical LPCVD. Journal of Semiconductors, 2011, 32(4):043005 -

Proportional views

DownLoad:

DownLoad: