| Citation: |

Lixia Li, Dong Pan, Xuezhe Yu, Hyok So, Jianhua Zhao. Manipulation of morphology and structure of the top of GaAs nanowires grown by molecular-beam epitaxy[J]. Journal of Semiconductors, 2017, 38(10): 103001. doi: 10.1088/1674-4926/38/10/103001

****

L X Li, D Pan, X Z Yu, H So, J H Zhao. Manipulation of morphology and structure of the top of GaAs nanowires grown by molecular-beam epitaxy[J]. J. Semicond., 2017, 38(10): 103001. doi: 10.1088/1674-4926/38/10/103001.

|

Manipulation of morphology and structure of the top of GaAs nanowires grown by molecular-beam epitaxy

DOI: 10.1088/1674-4926/38/10/103001

More Information

-

Abstract

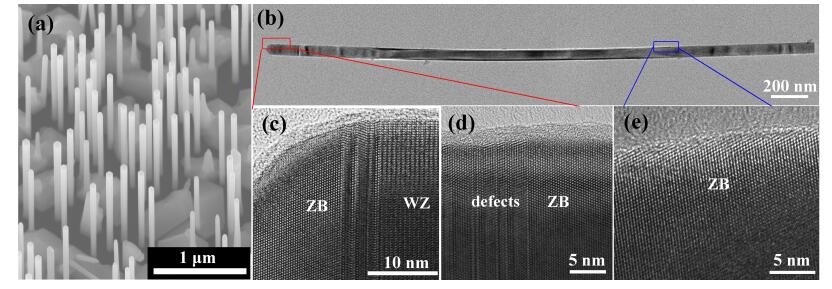

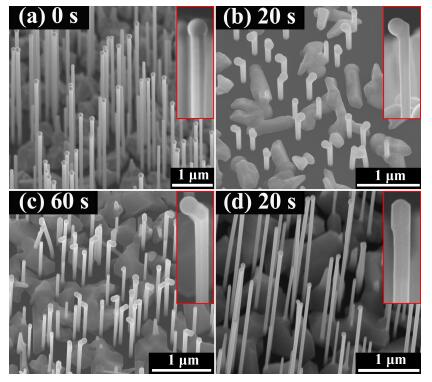

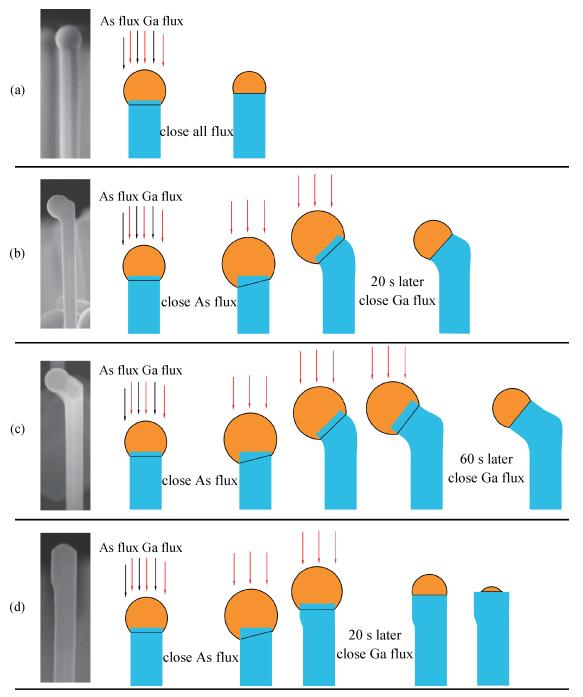

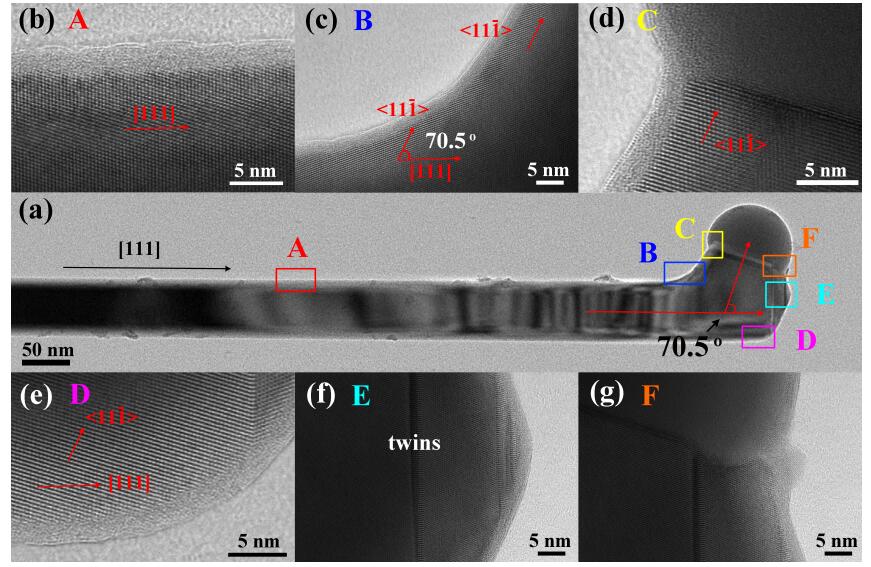

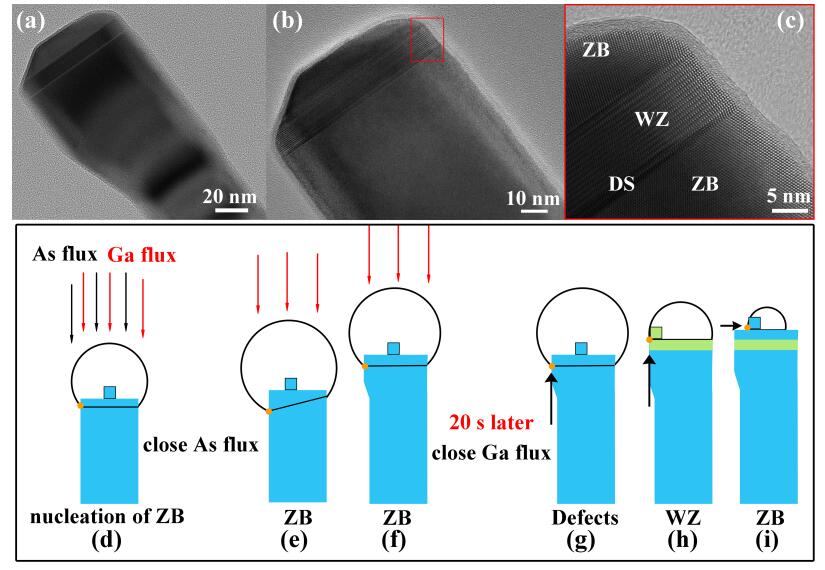

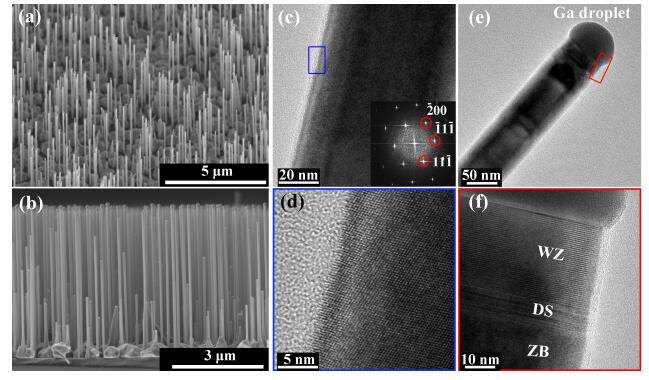

Self-catalyzed GaAs nanowires (NWs) are grown on Si (111) substrates by molecular-beam epitaxy. The effect of different closing sequences of the Ga and As cell shutters on the morphology and structural phase of GaAs NWs is investigated. For the sequences of closing the Ga and As cell shutters simultaneously or closing the As cell shutter 1 min after closing the Ga cell shutter, the NWs grow vertically to the substrate surface. In contrast, when the As cell shutter is closed first, maintaining the Ga flux is found to be critical for the following growth of GaAs NWs, which can change the growth direction from[111] to 〈111〉. The evolution of the morphology and structural phase transition at the tips of these GaAs NWs confirm that the triple-phase-line shift mode is at work even for the growth with different cell shutter closing sequences. Our work will provide new insights for better understanding of the growth mechanism and realizing of the morphology and structure control of the GaAs NWs.-

Keywords:

- GaAs,

- nanowire,

- molecular-beam epitaxy

-

References

[1] Borg B M, Dick K A, Ganjipour B, et al. InAs/GaSb heterostructure nanowires for tunnel field-effect transistors. Nano Lett, 2010, 10(10):4080 doi: 10.1021/nl102145h[2] Tatebayashi J, Kako S, Ho J, et al. Room-temperature lasing in a single nanowire with quantum dots. Nat Photon, 2015, 9(8):501 doi: 10.1038/nphoton.2015.111[3] Pan D, Fu M, Yu X, et al. Controlled synthesis of phase-pure InAs nanowires on Si(111) by diminishing the diameter to 10 nm. Nano Lett, 2014, 14(3):1214 doi: 10.1021/nl4040847[4] Pan D, Fan D X, Kang N, et al. Free-standing two-dimensional single-crystalline InSb nanosheets. Nano Lett, 2016, 16(2):834 doi: 10.1021/acs.nanolett.5b04845[5] Li L X, Pan D, Xue Y Z, et al. Near full-composition-range highquality GaAs1-xSbx nanowires grown by molecular-beam epitaxy. Nano Lett, 2017, 17(2):622 doi: 10.1021/acs.nanolett.6b03326[6] Joyce H J, Parkinson P, Jiang N, et al. Electron mobilities approaching bulk limits in "surface-free" GaAs nanowires. Nano Lett, 2014, 14(10):5989 doi: 10.1021/nl503043p[7] Yao M, Huang N, Cong S, et al. GaAs nanowire array solar cells with axial p-i-n junctions. Nano Lett, 2014, 14(6):3293 doi: 10.1021/nl500704r[8] Wang H. High gain single GaAs nanowire photodetector. Appl Phys Lett, 2013, 103(9):093101 doi: 10.1063/1.4816246[9] Tomioka K, Motohisa J, Hara S, et al. GaAs/AlGaAs core multishell nanowire-based light-emitting diodes on Si. Nano Lett, 2010, 10(5):1639 doi: 10.1021/nl9041774[10] Krogstrup P, Jørgensen H I, Heiss M, et al. Single-nanowire solar cells beyond the Shockley-Queisser limit. Nat Photon, 2013, 7(4):306 doi: 10.1038/nphoton.2013.32[11] Harmand J C, Patriarche G, Péré-Laperne N, et al. Analysis of vapor-liquid-solid mechanism in Au-assisted GaAs nanowire growth. Appl Phys Lett, 2005, 87(20):203101 doi: 10.1063/1.2128487[12] Wu Z H, Mei X Y, Kim D, et al. Growth of Au-catalyzed sequenceed GaAs nanowire arrays by molecular-beam epitaxy. Appl Phys Lett, 2002, 81(27):5177 doi: 10.1063/1.1532772[13] Persson A I, Larsson M W, Stenstrom S, et al. Solid-phase diffusion mechanism for GaAs nanowire growth. Nat Mater, 2004, 3(10):677 doi: 10.1038/nmat1220[14] Tchernycheva M, Harmand J C, Patriarche G, et al. Temperature conditions for GaAs nanowire formation by Au-assisted molecular beam epitaxy. Nanotechnology, 2006, 17(16):4025 doi: 10.1088/0957-4484/17/16/005[15] Zhao Y, Li X, Wang W, et al. Growth and properties of GaAs nanowires on fused quartz substrate. J Semicond, 2014, 35(9):093002 doi: 10.1088/1674-4926/35/9/093002[16] Li R, Huang H, Ren X, et al. Growth of pure zinc blende p-type GaAs nanowires by metal-organic chemical vapor deposition. J Semicond, 2011, 32(5):053003 doi: 10.1088/1674-4926/32/5/053003[17] Zhou C, Zheng K, Lu Z Y, et al. Quality control of GaAs nanowire structures by limiting As flux in molecular beam epitaxy. J Phys Chem C, 2015, 119, 20721 doi: 10.1021/acs.jpcc.5b05606[18] Paek J H, Nishiwaki T, Yamaguchi M, et al. Catalyst free MBEVLS growth of GaAs nanowires on (111) Si substrate. Phys Status Solidi C, 2009, 6(6):1436 doi: 10.1002/pssc.v6:6[19] Krogstrup P, Popovitz-Biro R, Johnson E, et al. Structural phase control in self-catalyzed growth of GaAs nanowires on silicon (111). Nano Lett, 2010, 10(11):4475 doi: 10.1021/nl102308k[20] Ramdani M R, Harmand J C, Glas F, et al. Arsenic pathways in self-catalyzed growth of GaAs nanowires. Cryst Growth Des, 2013, 13(1):91 doi: 10.1021/cg301167g[21] Spirkoska D, Arbiol J, Gustafsson A, et al. Structural and optical properties of high quality zinc-blende/wurtzite GaAs nanowire heterostructures. Phys Rev B, 2009, 80(24):245325 doi: 10.1103/PhysRevB.80.245325[22] Yamaguchi M, Paek J H, Amano H. Probability of twin formation on self-catalyzed GaAs nanowires on Si substrate. Nanoscale Res Lett, 2012, 7(1):558 doi: 10.1186/1556-276X-7-558[23] Plissard S, Dick K A, Larrieu G, et al. Gold-free growth of GaAs nanowires on silicon:arrays and polytypism. Nanotechnology, 2010, 21(38):385602 doi: 10.1088/0957-4484/21/38/385602[24] Yu X, Wang H, Lu J, et al. Evidence for structural phase transitions induced by the triple phase line shift in self-catalyzed GaAs nanowires. Nano Lett, 2012, 12(10):5436 doi: 10.1021/nl303323t[25] Bauer B, Rudolph A, Soda M, et al. Position controlled selfcatalyzed growth of GaAs nanowires by molecular beam epitaxy. Nanotechnology, 2010, 21(43):435601 doi: 10.1088/0957-4484/21/43/435601[26] Tchernycheva M, Harmand J C, Patriarche G, et al. Temperature conditions for GaAs nanowire formation by Au-assisted molecular beam epitaxy. Nanotechnology, 2006, 17(16):4025 doi: 10.1088/0957-4484/17/16/005[27] Yu X, Li L, Wang H, et al. Two-step fabrication of self-catalyzed Ga-based semiconductor nanowires on Si by molecular-beam epitaxy. Nanoscale, 2016, 8(20):10615 doi: 10.1039/C5NR07830J[28] Wang Y, Zhang X, Sun X, et al. Enhanced optical properties in inclined GaAs nanowire arrays for high-efficiency solar cells. Opt Laser Technol, 2016, 85:85 doi: 10.1016/j.optlastec.2016.05.022[29] Morral A F I, Colombo C, Abstreiter G, et al. Nucleation mechanism of gallium-assisted molecular beam epitaxy growth of gallium arsenide nanowires. Appl Phys Lett, 2008, 92(6):063112 doi: 10.1063/1.2837191[30] Wu Z H, Mei X, Kim D, et al. Growth, branching, and kinking of molecular-beam epitaxial 〈111〉 GaAs nanowires. Appl Phys Lett, 2003, 83(16):3368 doi: 10.1063/1.1618018[31] Han N, Yang Z X, Wang F, et al. Crystal Orientation controlled photovoltaic properties of multilayer GaAs nanowire arrays. ACS Nano, 2016, 10(6):6283 doi: 10.1021/acsnano.6b02473[32] Ren D, Dheeraj D L, Jin C, et al. New Insights into the origins of Sb-induced effects on self-catalyzed GaAsSb nanowire arrays. Nano Lett, 2016, 16(2):1201 doi: 10.1021/acs.nanolett.5b04503[33] Krogstrup P, Curiotto S, Johnson E, et al. Impact of the liquid phase shape on the structure of Ⅲ-V nanowires. Phys Rev Lett, 2011, 106(12):125505 doi: 10.1103/PhysRevLett.106.125505[34] Munshi A M, Dheeraj D L, Todorovic J, et al. Crystal phase engineering in self-catalyzed GaAs and GaAs/GaAsSb nanowires grown on Si(111). J Cryst Growth, 2013, 372:163 doi: 10.1016/j.jcrysgro.2013.03.004[35] Glas F, Harmand J C, Patriarche G. Why does wurtzite form in nanowires of Ⅲ-V zinc-blende semiconductors. Phys Rev Lett, 2007, 99:146101 doi: 10.1103/PhysRevLett.99.146101[36] Cirlin G E, Dubrovskii V G, Samsonenko Y B, et al. Selfcatalyzed, pure zincblende GaAs nanowires grown on Si(111) by molecular beam epitaxy. Phys Rev B, 2010, 82(3):035302 doi: 10.1103/PhysRevB.82.035302[37] Dubrovskii V G, Cirlin G E, Sibirev N V, et al. New mode of vapor-liquid-solid nanowire growth. Nano Lett, 2011, 11(3):1247 doi: 10.1021/nl104238d -

Proportional views

DownLoad:

DownLoad: