| Citation: |

Ye Wei, Shengbo Sang, Bing Zhou, Xiao Deng, Jing Chai, Jianlong Ji, Yang Ge, Yuanliang Huo, Wendong Zhang. Effects of incident energy and angle on carbon cluster ions implantation on silicon substrate:a molecular dynamics study[J]. Journal of Semiconductors, 2017, 38(9): 092002. doi: 10.1088/1674-4926/38/9/092002

****

Y Wei, S B Sang, B Zhou, X Deng, J Chai, J L Ji, Y Ge, Y L Huo, W D Zhang. Effects of incident energy and angle on carbon cluster ions implantation on silicon substrate:a molecular dynamics study[J]. J. Semicond., 2017, 38(9): 092002. doi: 10.1088/1674-4926/38/9/092002.

|

Effects of incident energy and angle on carbon cluster ions implantation on silicon substrate:a molecular dynamics study

DOI: 10.1088/1674-4926/38/9/092002

More Information

-

Abstract

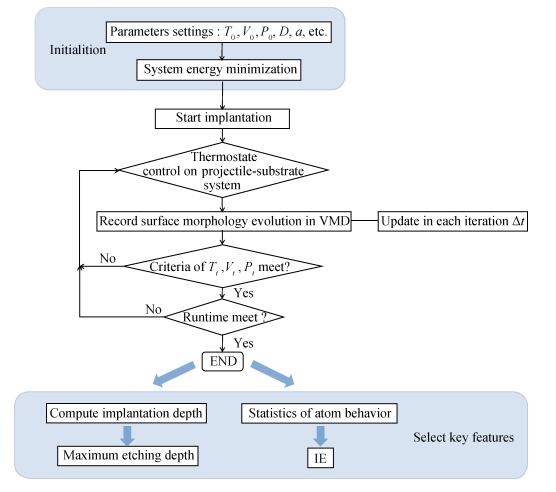

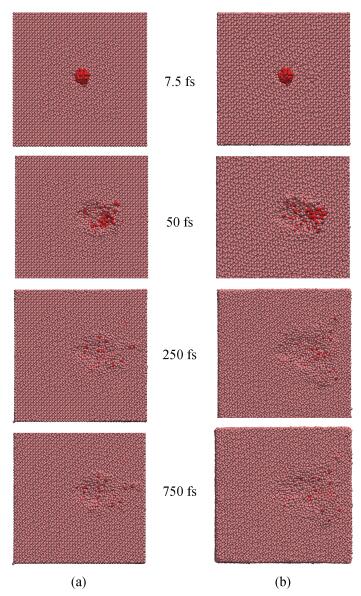

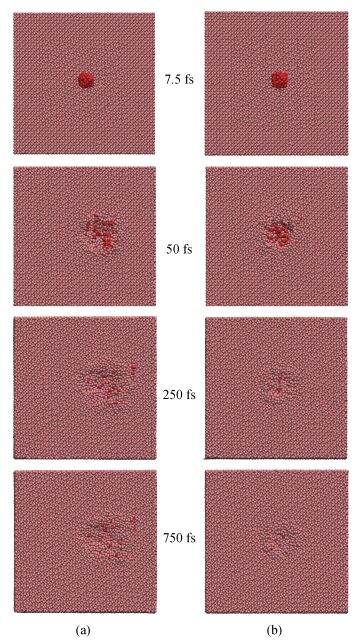

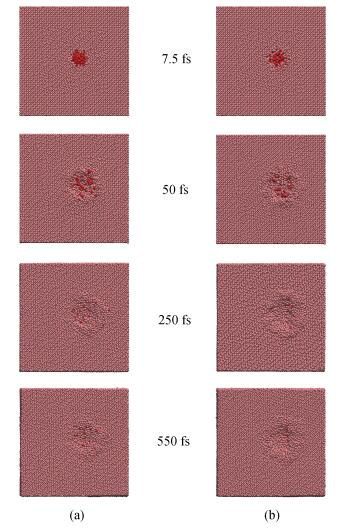

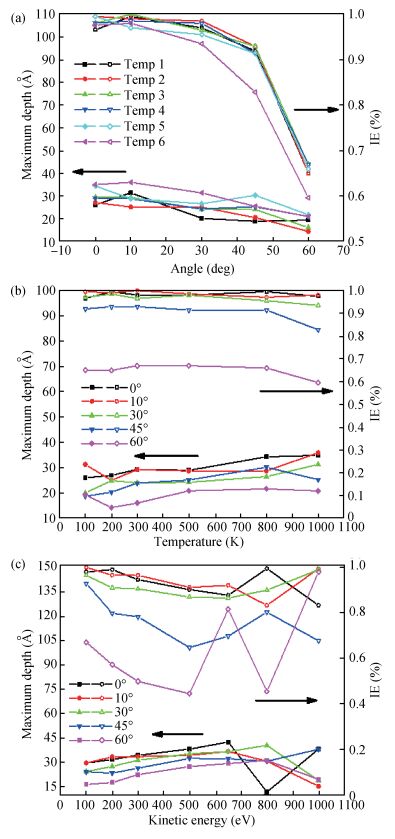

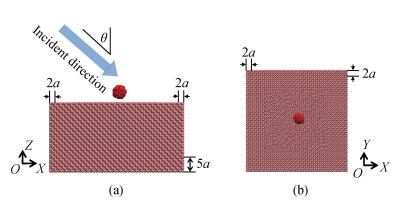

Carbon cluster ion implantation is an important technique in fabricating functional devices at micro/nanoscale. In this work, a numerical model is constructed for implantation and implemented with a cutting-edge molecular dynamics method. A series of simulations with varying incident energies and incident angles is performed for incidence on silicon substrate and correlated effects are compared in detail. Meanwhile, the behavior of the cluster during implantation is also examined under elevated temperatures. By mapping the nanoscopic morphology with variable parameters, numerical formalism is proposed to explain the different impacts on phrase transition and surface pattern formation. Particularly, implantation efficiency (IE) is computed and further used to evaluate the performance of the overall process. The calculated results could be properly adopted as the theoretical basis for designing nano-structures and adjusting devices' properties.-

Keywords:

- implantation,

- low incident energies,

- irradiation,

- molecular dynamics

-

References

[1] Garg S K, Datta D P, Kumar M, et al. 60 keV ArC-ion induced pattern formation on Si surface:roles of sputter erosion and atomic redistribution. Appl Surf Sci, 2014, 310:147 doi: 10.1016/j.apsusc.2014.03.115[2] Hofsäss H, Zhang K, Bobes O. Self-organized surface ripple pattern formation by ion implantation. J Appl Phys, 2016, 120(13):135308 doi: 10.1063/1.4964113[3] Zhang C Z, Bhattacharya S, Li Y S, et al. Effect of ion energy on microstructure and adhesion of diamond-like carbon on Ti6Al4V by ion beam deposition. Diamond Relat Mater, 2016, 70:12 doi: 10.1016/j.diamond.2016.09.013[4] de Fátim S, Mariano M, Ued M, et al. Magnetic-field enhanced plasma immersion ion implantation and deposition (PⅢ&D) of diamond-like carbon films inside tubes. Surf Coat Technol, 2017, 312:47 doi: 10.1016/j.surfcoat.2016.08.077[5] Li L L, Zhou X J, Yu Z G, et al. Effect of phosphorus ion implan-tation on back gate effect of partially depleted SOI NMOS under total dose radiation. J Semicond, 2015, 36(1):014006 doi: 10.1088/1674-4926/36/1/014006[6] He B P, Wang Z J, Sheng J K, et al. Total ionizing dose radiation effects on NMOS parasitic transistors in advanced bulk CMOS technology devices. J Semicond, 2016, 37(12):124003 doi: 10.1088/1674-4926/37/12/124003[7] Luo B R, Gao E L, Geng D C, et al. Etching-controlled growth of graphene by chemical vapor deposition. Chem Mater, 2017, 29(3):1022 doi: 10.1021/acs.chemmater.6b03672[8] Heviaa S A, Guzmán-Olivos F, Muñoz I, et al. Nanostructured substrate effects on diamond-like carbon films properties grown by pulsed laser deposition. Surf Coat Technol, 2017, 312:55 doi: 10.1016/j.surfcoat.2016.08.083[9] Borschel C, Ronning C. Ion beam irradiation of nanostructure-a 3D Monte Carlo simulation code. Nucl Instrum Methods Phys Res B, 2011, 269: 2133 doi: 10.1016/j.nimb.2011.07.004[10] Delcorte A, Debongnie M. Macromolecular sample sputtering by large Ar and CH4 clusters:elucidating chain size and projectile effects with molecular dynamics. J Phys Chem C, 2015, 119:25868 doi: 10.1021/acs.jpcc.5b07007[11] Wei Y, Zhan H F, Xia K, et al. Resonance of graphene nanoribbons doped with nitrogen and boron:a molecular dynamics study. Beilstein J Nanotechnol, 2014, 5:717 doi: 10.3762/bjnano.5.84[12] Kunal K, Aluru N. Intrinsic dissipation in a nano-mechanical resonator. J Appl Phys, 2014, 116(9):094304 doi: 10.1063/1.4894282[13] Czerwinski B, Rzeznik L, Paruch R, et al. Molecular dynamics computer simulations of 5 keV C60 bombardment of benzene crystal. Vacuum, 2009, 83:S95 doi: 10.1016/j.vacuum.2009.01.034[14] Norris S A, Samela J, Bukonte L, et al. Molecular dynamics of single-particle impacts predicts phase diagrams for large scale pattern formation. Nat Commun, 2011, 2:276 doi: 10.1038/ncomms1280[15] Zhang J, Liu C, Fan J. Comparison of Cu thin films deposited on Si substrates with different surfaces and temperatures. Appl Surf Sci, 2013, 276:417 doi: 10.1016/j.apsusc.2013.03.109[16] Wu B, Zhou J Q, Xue C, et al. Molecular dynamics simulation of the deposition and annealing of NiAl film on Ni substrate. Appl Surf Sci, 2015, 355:1145 doi: 10.1016/j.apsusc.2015.07.208[17] Lv Y N, Hodgson P, Kong L X, et al. Study of growth mechanism of TiC cluster in ferrite via molecular dynamics simulation. Mater Lett, 2015, 159:389 doi: 10.1016/j.matlet.2015.07.039[18] Wiatrowski A, Kijaszek W, Posadowski W M, et al. Deposition of diamond-like carbon thin films by the high power impulse magnetron sputtering method. Diamond Relat Mater, 2017, 72:71 doi: 10.1016/j.diamond.2017.01.007[19] Tsuchiya M, Murakami K, Magara K, et al. Structural and electrical properties and current-voltage characteristics of nitrogendoped diamond-like carbon films on Si substrates by plasmaenhanced chemical vapor deposition. Jpn J Appl Phys, 2016, 55(6):065502 doi: 10.7567/JJAP.55.065502[20] Zhao J F, Lemoine P, Liu Z H, et al. A study of microstructure and nanomechanical properties of silicon incorporated DLC films deposited on silicon substrates. Diamond Relat Materi, 2001, 10(3-7):1070 doi: 10.1016/S0925-9635(00)00544-6[21] Postawa Z, Paruch R, Rzeznik L, et al. Dynamics of large Ar cluster bombardment of organic solids. Surf Interface Anal, 2013, 45(1):35 doi: 10.1002/sia.4927[22] Garrison B J, Postawa Z. Computational view of surface based organic mass spectrometry. Mass Spectrom Rev, 2008, 27(4):289 doi: 10.1002/mas.v27:4[23] Humphrey W, Dalke A, Schulten K. VMD:visual molecular dynamics. J Molecul Graph, 1996, 14(1):33 doi: 10.1016/0263-7855(96)00018-5[24] Plimpton S. Fast parallel algorithms for short-range molecular dynamics. J Comput Phys, 1995, 117(1):1 doi: 10.1006/jcph.1995.1039[25] Berendsen H J C, Postma J P M, van Gunsteren W F, et al. Molecular dynamics with coupling to an external bath. J Chem Phys, 1984, 81(8):3684 doi: 10.1063/1.448118[26] Joseph S, Aluru N R. Why are carbon nanotubes fast transporters of water. Nano Lett, 2008, 8(2):452 doi: 10.1021/nl072385q[27] Wang Y, Scheerschmidt K, Gösele U. Theoretical investigations of bond properties in graphite and graphitic silicon. Phys Rev B, 2000, 61(19):12864 doi: 10.1103/PhysRevB.61.12864[28] Hwang S F, Li Y H, Hong Z H. Molecular dynamic simulation for Cu cluster deposition on Si substrate. Comput Mater Sci, 2012, 56:85 doi: 10.1016/j.commatsci.2012.01.010[29] Czerwinski B, Rzeznik L, Paruch R, et al. Effect of impact angle and projectile size on sputtering efficiency of solid benzene investigated by molecular dynamics simulations. Nucl Instrum Methods Phys Res B, 2014, 269:1578[30] Ju S P, Weng C I, Chang J G, et al. Topographic study of sputterdeposited film with different process parameters. J Appl Phys, 2001, 89(12):7825 doi: 10.1063/1.1371007 -

Proportional views

DownLoad:

DownLoad: