| Citation: |

I. M. El Radaf, A. M. Mansour, G. B. Sakr. Fabrication, electrical and photovoltaic characteristics of CuInGeSe4/n-Si diode[J]. Journal of Semiconductors, 2018, 39(12): 124010. doi: 10.1088/1674-4926/39/12/124010

****

I M El Radaf, A M Mansour, G B Sakr, Fabrication, electrical and photovoltaic characteristics of CuInGeSe4/n-Si diode[J]. J. Semicond., 2018, 39(12): 124010. doi: 10.1088/1674-4926/39/12/124010.

|

Fabrication, electrical and photovoltaic characteristics of CuInGeSe4/n-Si diode

DOI: 10.1088/1674-4926/39/12/124010

More Information

-

Abstract

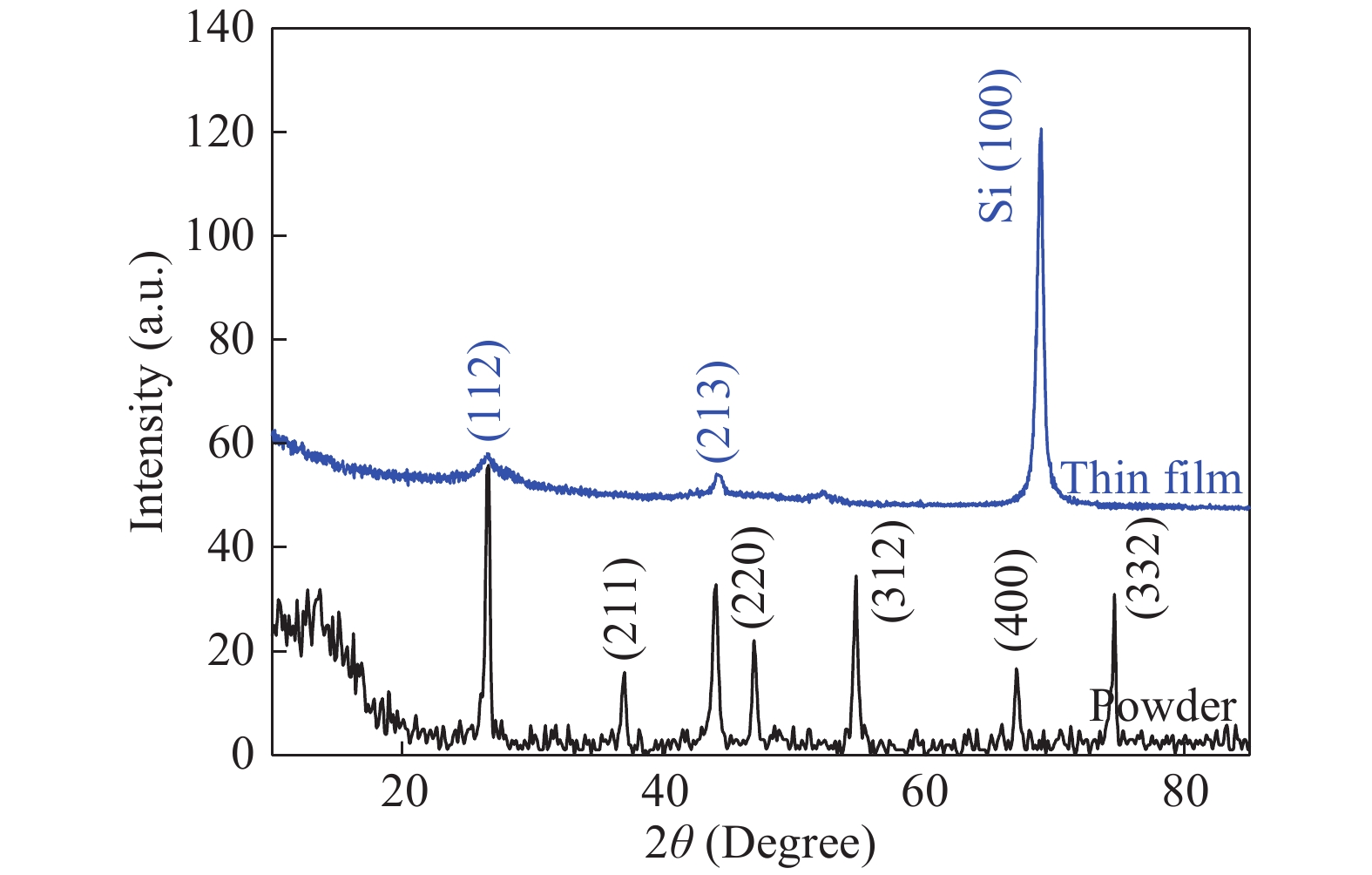

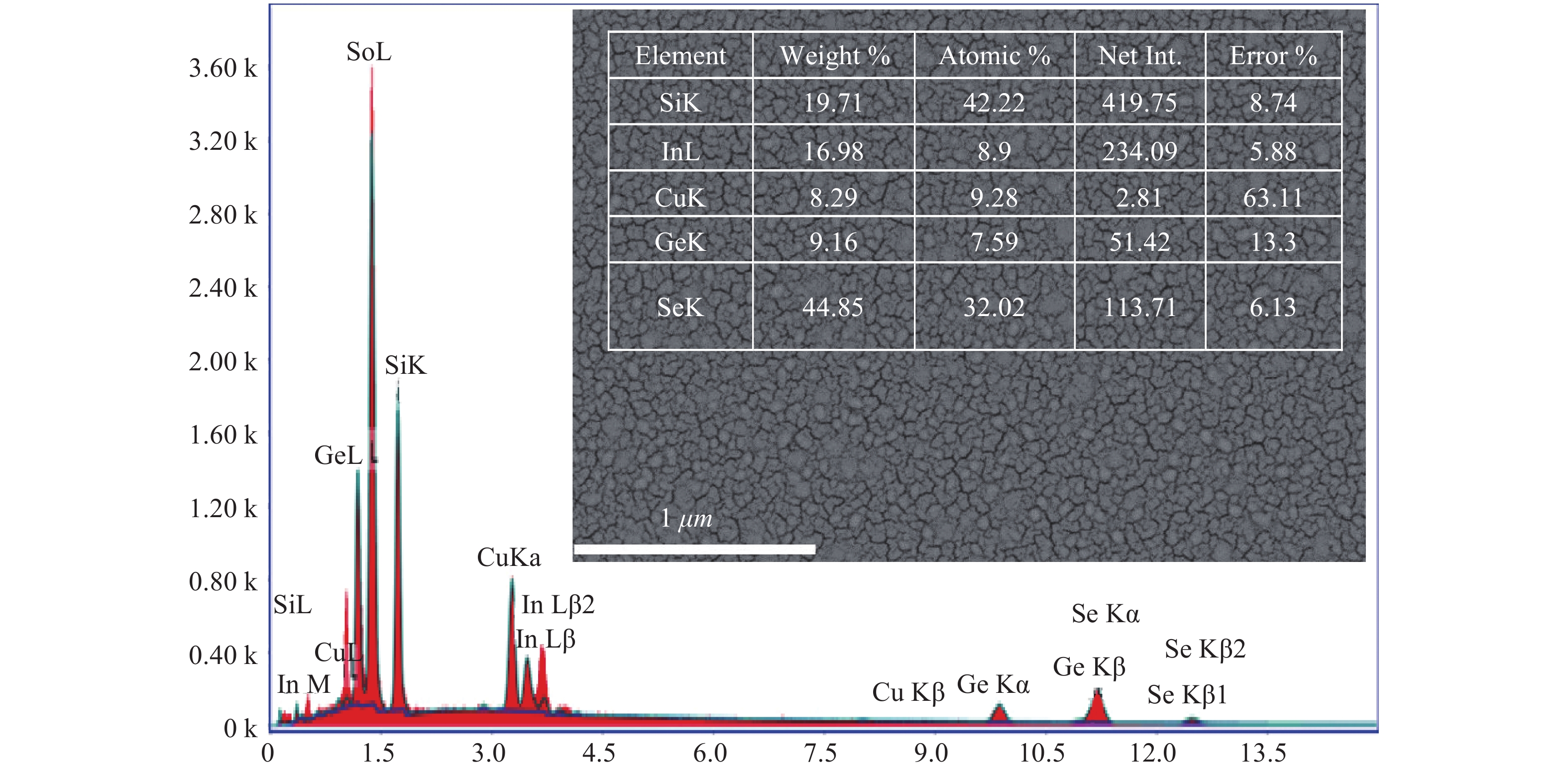

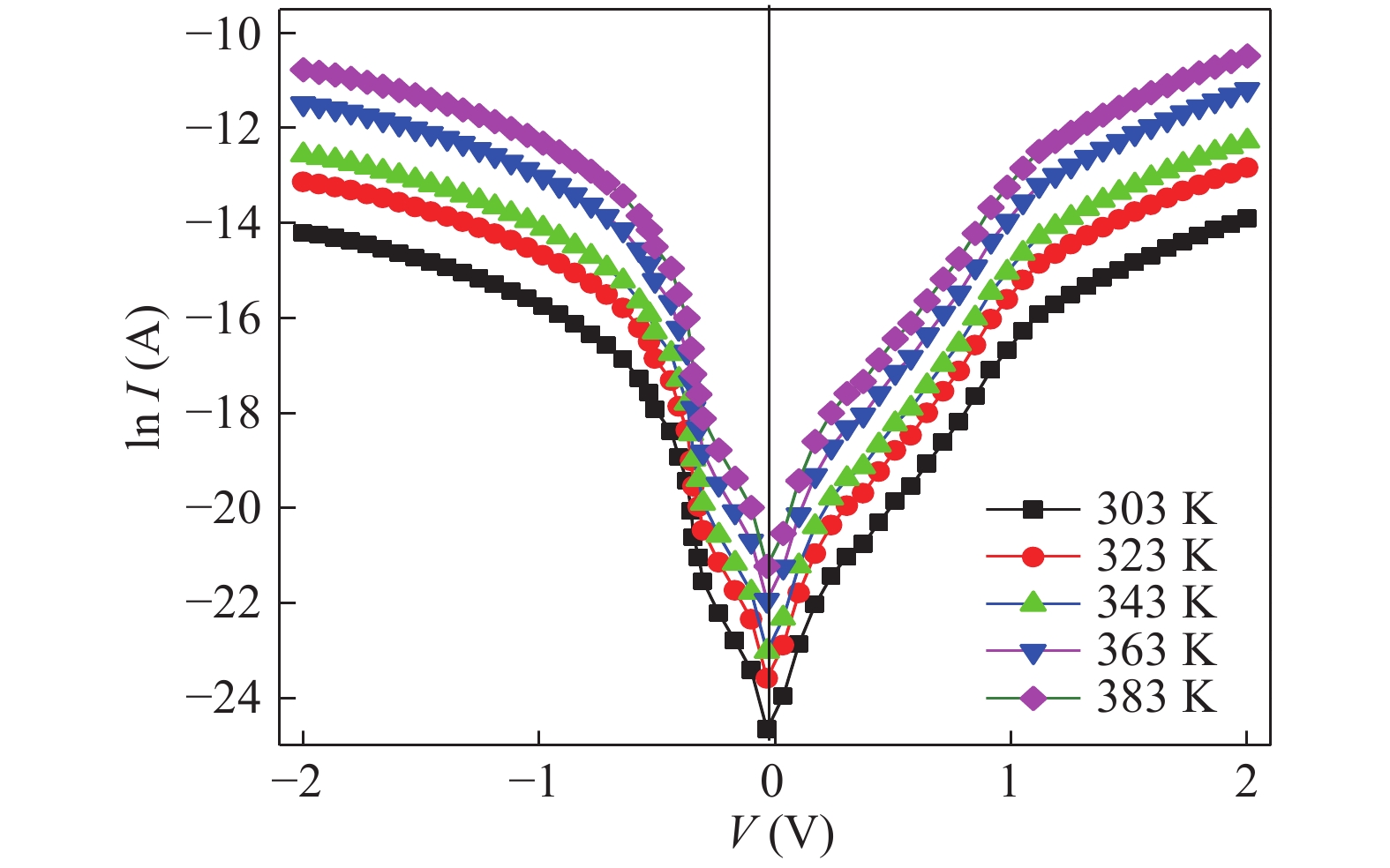

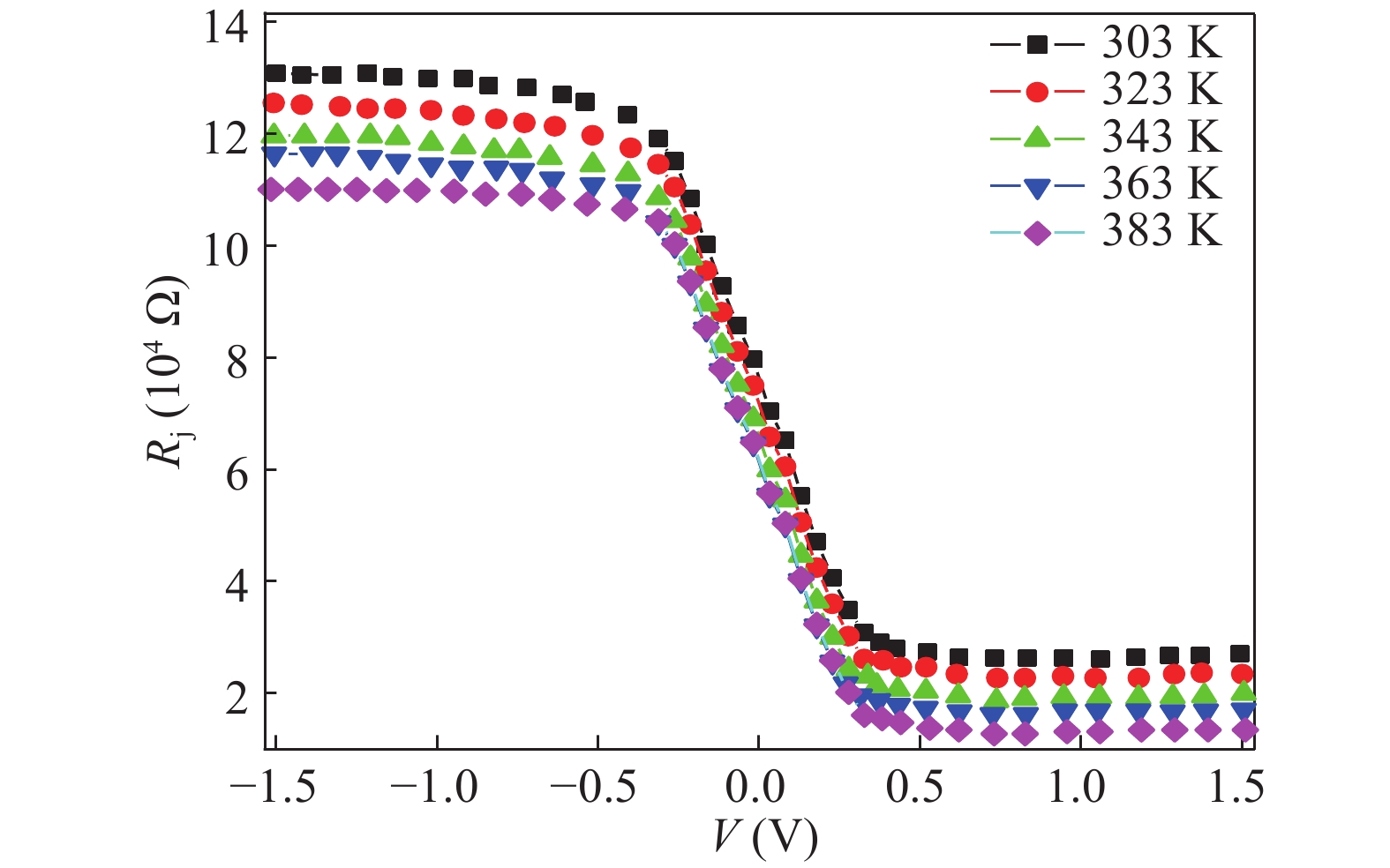

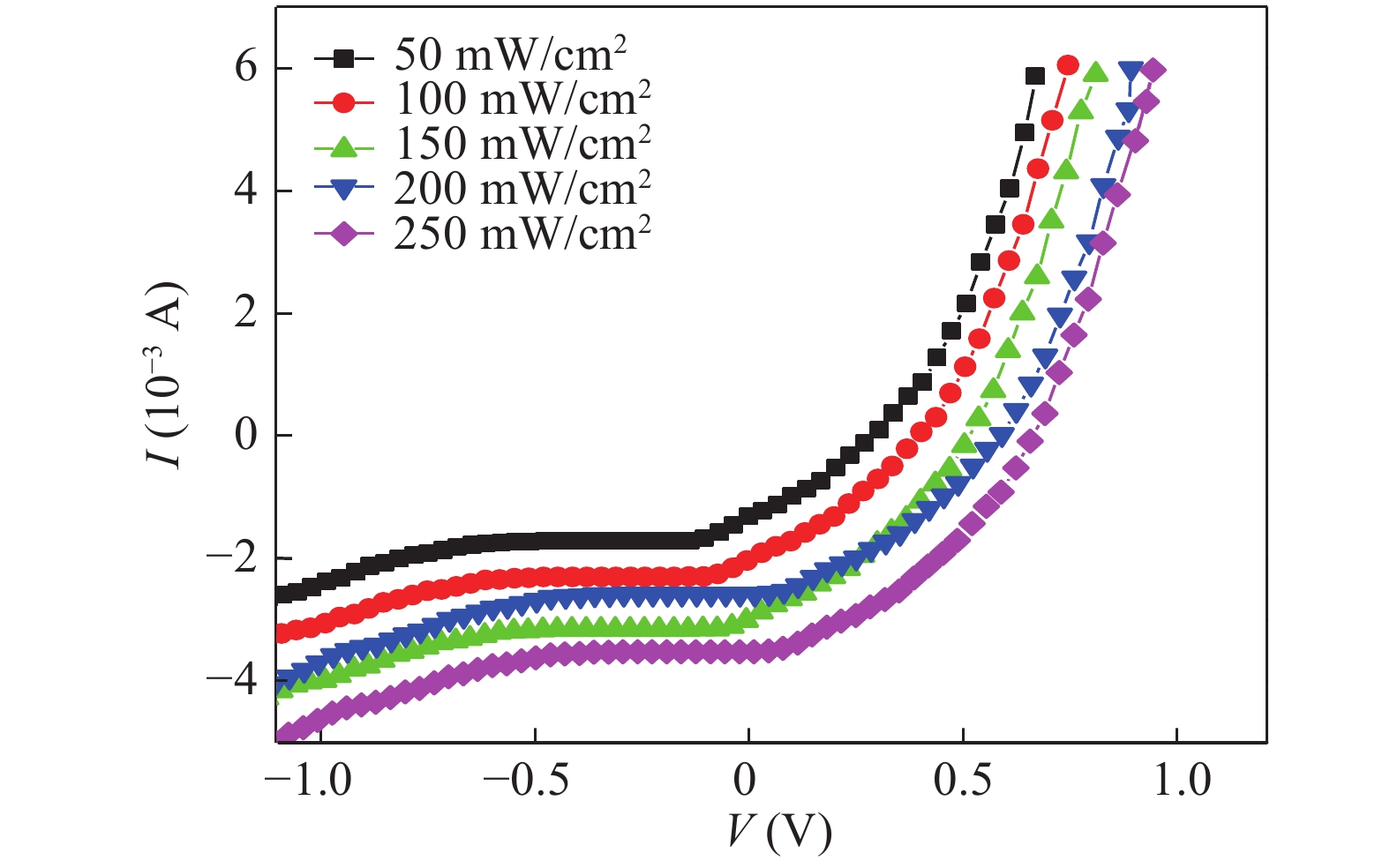

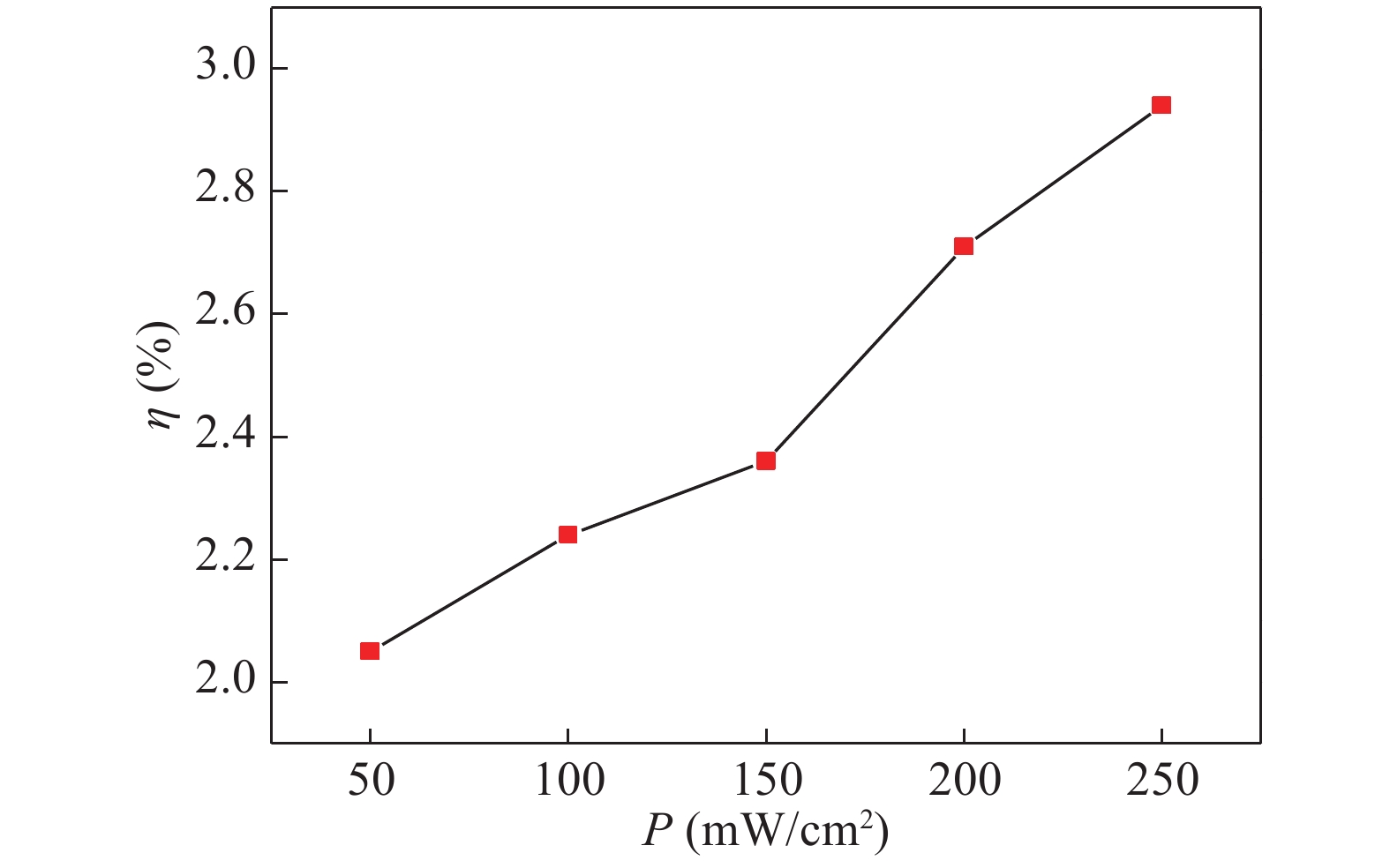

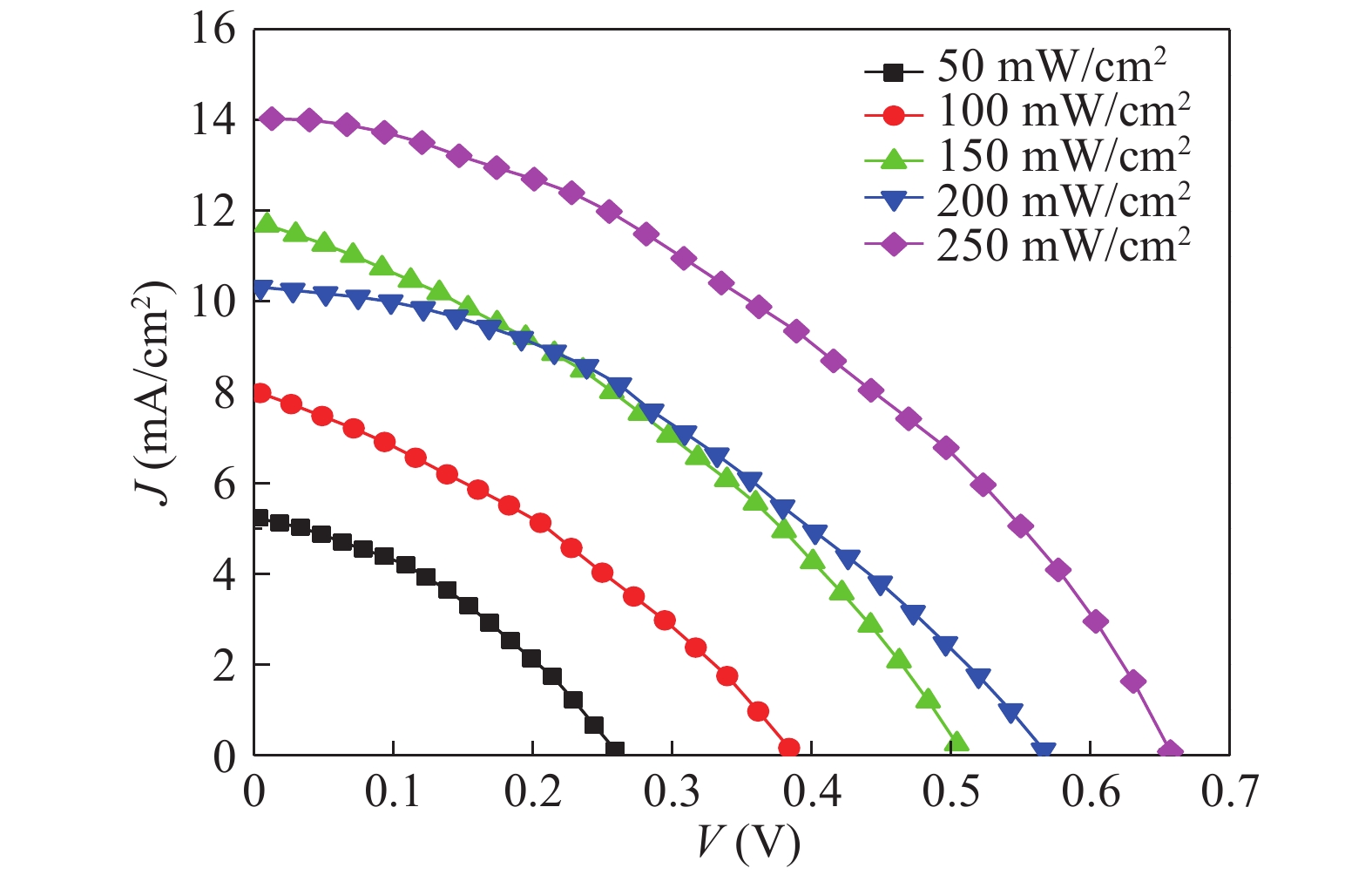

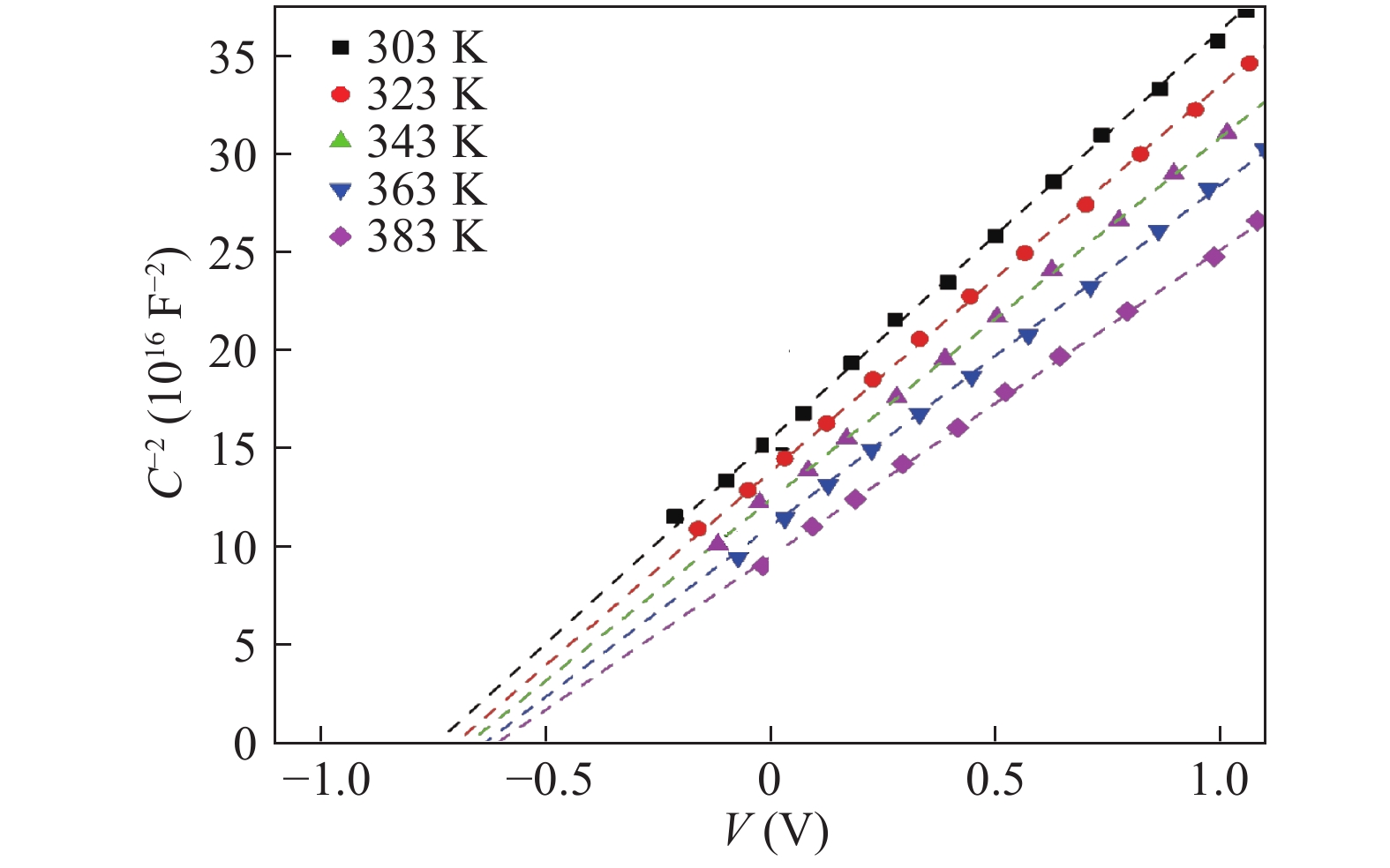

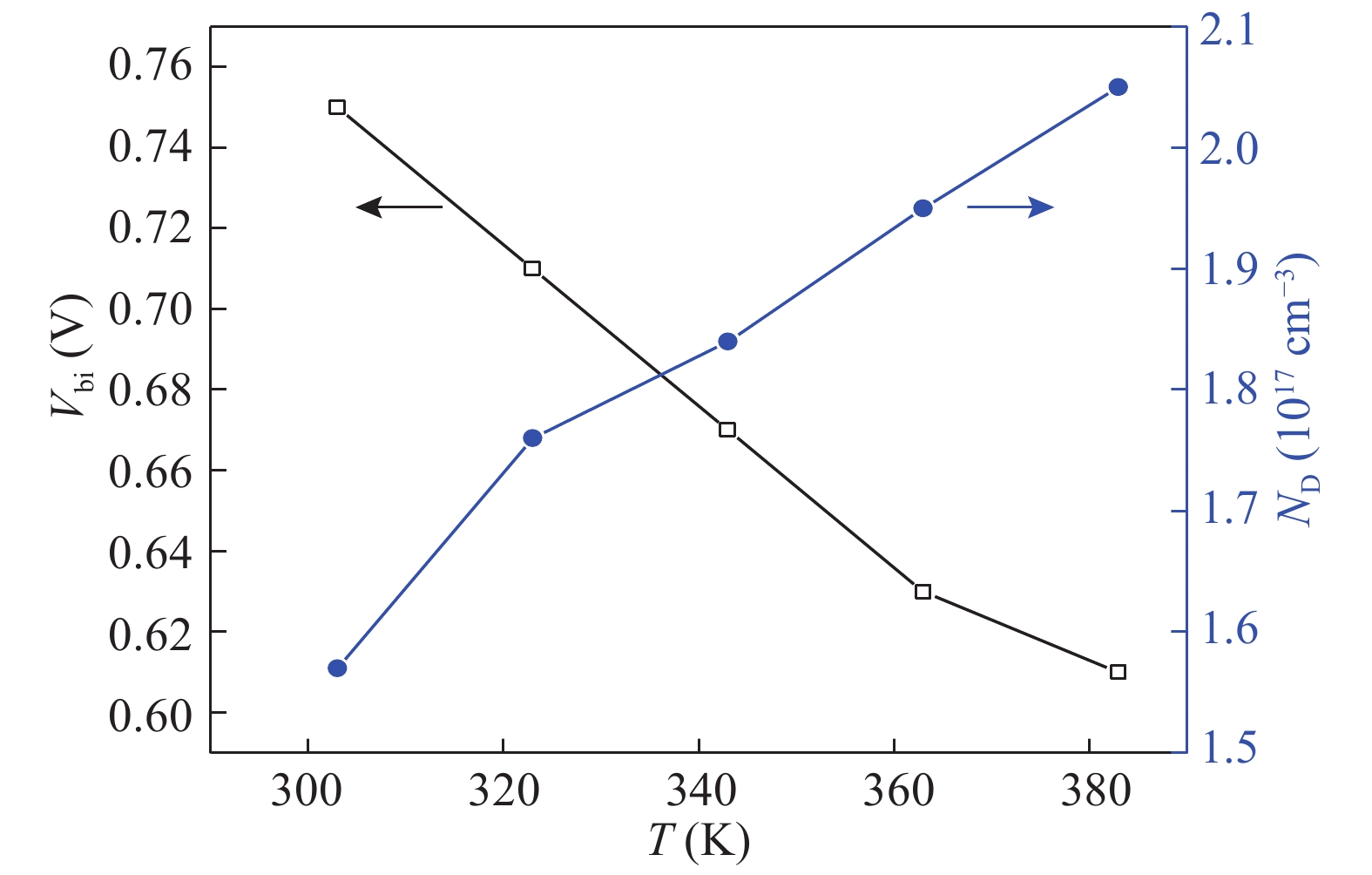

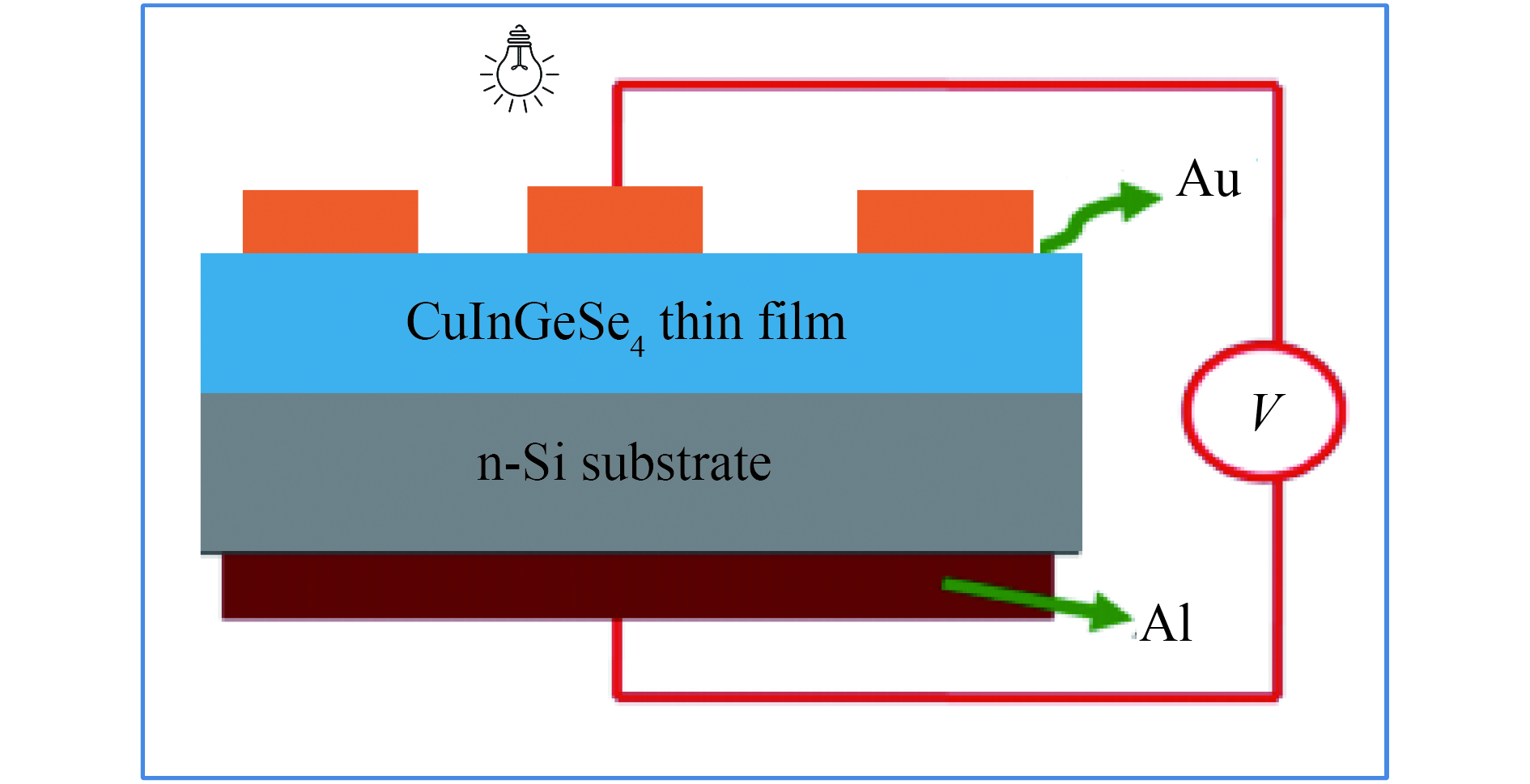

The CuInGeSe4 thin film was deposited onto n-type single crystal silicon wafers by the electron beam deposition technique. The Au/CuInGeSe4/n-Si/Al heterojunction device has been fabricated. The structure of the CuInGeSe4 thin film was characterized by X-ray diffraction (XRD), scanning electron microscope (SEM), and energy dispersive X-ray analysis (EDX). The dark current–voltage characteristics of the Au/CuInGeSe4/n-Si/Al heterojunction diode have been studied at a temperature range of 303–383 K. Also, the photovoltaic properties were examined at different illumination intensities. The capacitance–voltage characteristics of the CuInGeSe4/n-Si heterojunction were studied at different temperatures in the dark. -

References

[1] Matsushita H, Katsui A. Materials design for Cu-based quaternary compounds derived from chalcopyrite-rule. J Phys Chem Solids, 2005, 66: 1933 doi: 10.1016/j.jpcs.2005.09.028[2] Gorgut G P, Fedorchuk A O, Kityk I V, et al. Synthesis and structural properties of CuInGeS4. J Cryst Growth, 2011, 324: 212 doi: 10.1016/j.jcrysgro.2011.02.029[3] Li W, Yan X, Xu W L, et al. Efficiency improvement of CIGS solar cells by a modified rear contact. Sol Energy, 2017, 157: 486 doi: 10.1016/j.solener.2017.08.054[4] Shah A V, Schade H, Vanecek M, et al. Thin-film silicon solar cell technology. Prog Photovoltaics Res Appl, 2004, 12: 113 doi: 10.1002/pip.533[5] Matsushita H, Ochiai T, Mikajiri K, et al. Preparation of CuInGeSe4 thin films by selenization method using the Cu–In–Ge evaporated layer precursors. J Phys Chem Solids, 2005, 66: 1937 doi: 10.1016/j.jpcs.2005.09.031[6] Matsushita H, Maeda T, Katsui A, et al. Thermal analysis and synthesis from the melts of Cu-based quaternary compounds Cu–III–IV–VI4 and Cu2–II–IV–VI4(II = Zn, Cd; III = Ga, In; IV = Ge, Sn; VI = Se). J Cryst Growth, 2000, 208: 416 doi: 10.1016/S0022-0248(99)00468-6[7] Hughes O H, Woolley J C, Lopez-Rivera S A, et al. Quaternary adamantine selenides and tellurides of the form I III IV VI4. Solid State Commun, 1980, 35: 573 doi: 10.1016/0038-1098(80)90585-2[8] Contreras M A, Ramanathan K, Abushama J, et al. Diode characteristics in state-of-the-art ZnO/CdS/ Cu(In1-xGax)Se2 solar cells. Prog Photovolt Res Appl, 2005, 13: 209 doi: 10.1002/pip.626[9] Abd El-Rahman K F, Darwish A A A, El-Shazly E A A. Electrical and photovoltaic properties of SnSe/Si heterojunction. Mater Sci Semicond Process, 2014, 25: 123 doi: 10.1016/j.mssp.2013.10.003[10] Lin Y, Chen X. Advanced nano deposition methods. Weinheim: Wiley-VCH Verlag GmbH & Co. KGaA, 2016[11] Cuomo J J, Rossnagel S M, Haufman H R, et al. Handbook of ion beam processing technology: principles, deposition, film modification, and synthesis. Westwood: Noyes Publications, 1989[12] Cividjian N, Hagen C W. Electron-beam-induced nanometer-scale deposition. Adv Imaging Electron Phys, 2006, 143: 1 doi: 10.1016/S1076-5670(06)43001-9[13] Strehl P. Beam Instrumentation and Diagnostics. Berlin: Springer, 2006[14] El Radaf I M, Nasr M, Mansour A M. Structural, electrical and photovoltaic properties of CoS/Si heterojunction prepared by spray pyrolysis. Mater Res Express, 2018, 5: 015904 doi: 10.1088/2053-1591/aaa25e[15] Hassan N, Mansour A M, Roushdy N, et al. Optical sensing performance characteristics of Schottky devices diodes based nano-particle disodium 6-hydroxy-5-[(2-methoxy-5-methyl-4-sulfophenyl)azo]-2-naphthalenesulfonate thin films: A comparison study. Optik (Stuttg), 2018, 158: 1255 doi: 10.1016/j.ijleo.2017.12.203[16] Nasr M, El Radaf I M, Mansour A M. Current transport and capacitance–voltage characteristics of an n-PbTe/p-GaP heterojunction prepared using the electron beam deposition technique. J Phys Chem Solids, 2018, 115: 283 doi: 10.1016/j.jpcs.2017.12.029[17] Farag A A M, Terra F S, Mahmoud G M, et al. Study of Gaussian distribution of inhomogeneous barrier height for n-InSb/p-GaAs heterojunction prepared by flash evaporation. J Alloys Compd, 2009, 481: 427 doi: 10.1016/j.jallcom.2009.03.004[18] Farag A A M, Soliman H S, Atta A A. Analysis of dark and photovoltaic characteristics of Au/Pyronine G(Y)/p-Si/Al heterojunction. Synth Met, 2012, 161: 2759 doi: 10.1016/j.synthmet.2011.10.017[19] Farag A A M, Terra F S, Fahim G M M, et al. Current transport and capacitance-voltage characteristics of n-InSb/p-GaP prepared by flash evaporation and liquid phase epitaxy. Met Mater Int, 2012, 18: 509 doi: 10.1007/s12540-012-3020-4[20] Gupta R K, Aydın M E, Yakuphanoglu F. Photoconducting and electrical properties of Al/TIPS-pentacene/p-Si/Al hybrid diode for optical sensor applications. Synth Met, 2011, 161: 2355 doi: 10.1016/j.synthmet.2011.09.002[21] Yahia I S, Farag A A M, Yakuphanoglu F, et al. Temperature dependence of electronic parameters of organic Schottky diode based on fluorescein sodium salt. Synth Met, 2011, 161: 881 doi: 10.1016/j.synthmet.2011.02.016[22] Yahia I S, Fadel M, Sakr G B, et al. Analysis of current–voltage characteristics of Al/p-ZnGa2Se4/n-Si nanocrystalline heterojunction diode. J Alloys Compd, 2011, 509: 4414 doi: 10.1016/j.jallcom.2011.01.068[23] Soliman H S, Farag A A M, Khosifan N M, et al. Electronic and photovoltaic properties of Au/pyronine G(Y)/p-GaAs/Au:Zn heterojunction. J Alloys Compd, 2012, 530: 157 doi: 10.1016/j.jallcom.2012.03.053[24] Çetinkaya H G, Tecimer H, Uslu H, et al. Photovoltaic characteristics of Au/PVA (Bi-doped)/n-Si Schottky barrier diodes (SBDs) at various temperatures. Curr Appl Phys, 2013, 13: 1150 doi: 10.1016/j.cap.2013.03.010[25] Farag A A M, Terra F S, Ashery A, et al. Structural and electrical characteristics of n-InSb/p-GaAs heterojunction prepared by liquid phase epitaxy. J Alloys Compd, 2014, 615: 604 doi: 10.1016/j.jallcom.2014.06.058[26] Farag A A M, Terra F S, Ashery A, et al. Structural and electrical characterization of n-InAs/p-GaP heterojunctions prepared by vacuum flash evaporation and liquid phase epitaxy. Optoelectron. Adv Mater – RAPID Commun, 2017, 11: 82[27] Ahmad Z, Sayyad M H, Yaseen M, et al. Investigation of 5,10,15,20-Tetrakis(3-,5--Di-Tert-Butylphenyl)Porphyrinatocopper(II) for Electronics Applications. Int J Chem Mol Nucl Mater Metall Eng, 2011, 5: 380[28] Farag A A M, Terra F S, Ashery A, et al. Temperature dependence of J-V and C-V characteristics of n-InAs/p-GaAs heterojunctions prepared by flash evaporation technique and liquid phase epitaxy. Indian Pure Appl Phys, 2018, 56: 203[29] El-Nahass M M, Metwally H S, El-Sayed H E A , et al. Electrical and photovoltaic properties of FeTPPCl/p-Si heterojunction. Synth Met, 2011, 161: 2253 doi: 10.1016/j.synthmet.2011.08.030[30] Hameed T A, El Radaf I M, Elsayed-Ali H E. Characterization of CuInGeSe4 thin films and Al/n-Si/p-CuInGeSe4/Au heterojunction device. J Mater Sci Mater Electron, 2018, 29: 12584 doi: 10.1007/s10854-018-9375-7[31] Sze S M, Ng K K. Physics of semiconductor devices. New York: Wiley-Interscience, 2007 -

Proportional views

DownLoad:

DownLoad: