| Citation: |

Danmei Zhao, Degang Zhao. Analysis of the growth of GaN epitaxy on silicon[J]. Journal of Semiconductors, 2018, 39(3): 033006. doi: 10.1088/1674-4926/39/3/033006

****

D M Zhao, D G Zhao. Analysis of the growth of GaN epitaxy on silicon[J]. J. Semicond., 2018, 39(3): 033006. doi: 10.1088/1674-4926/39/3/033006.

|

Analysis of the growth of GaN epitaxy on silicon

DOI: 10.1088/1674-4926/39/3/033006

More Information

-

Abstract

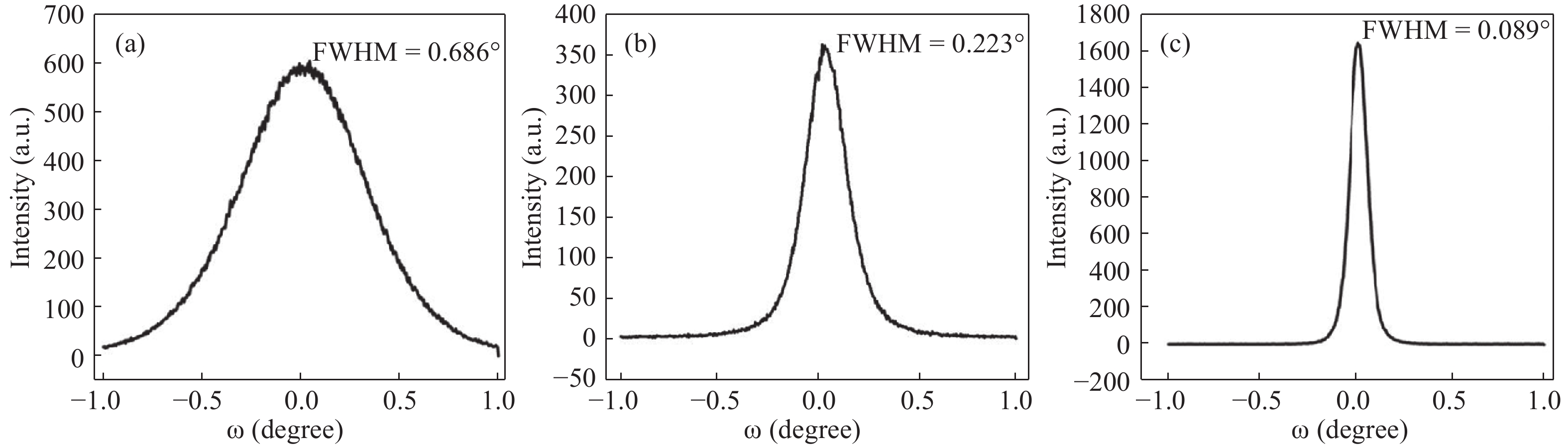

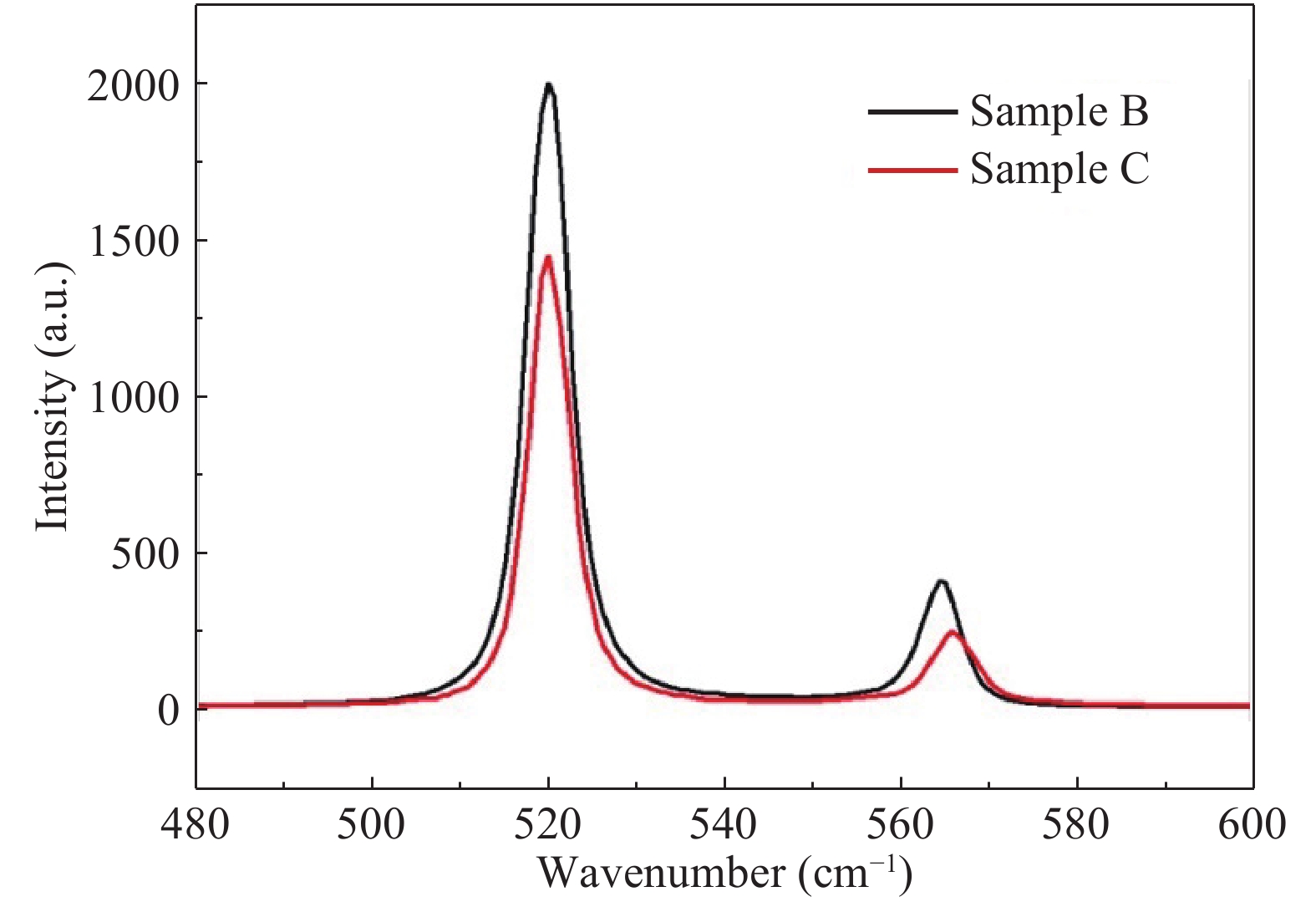

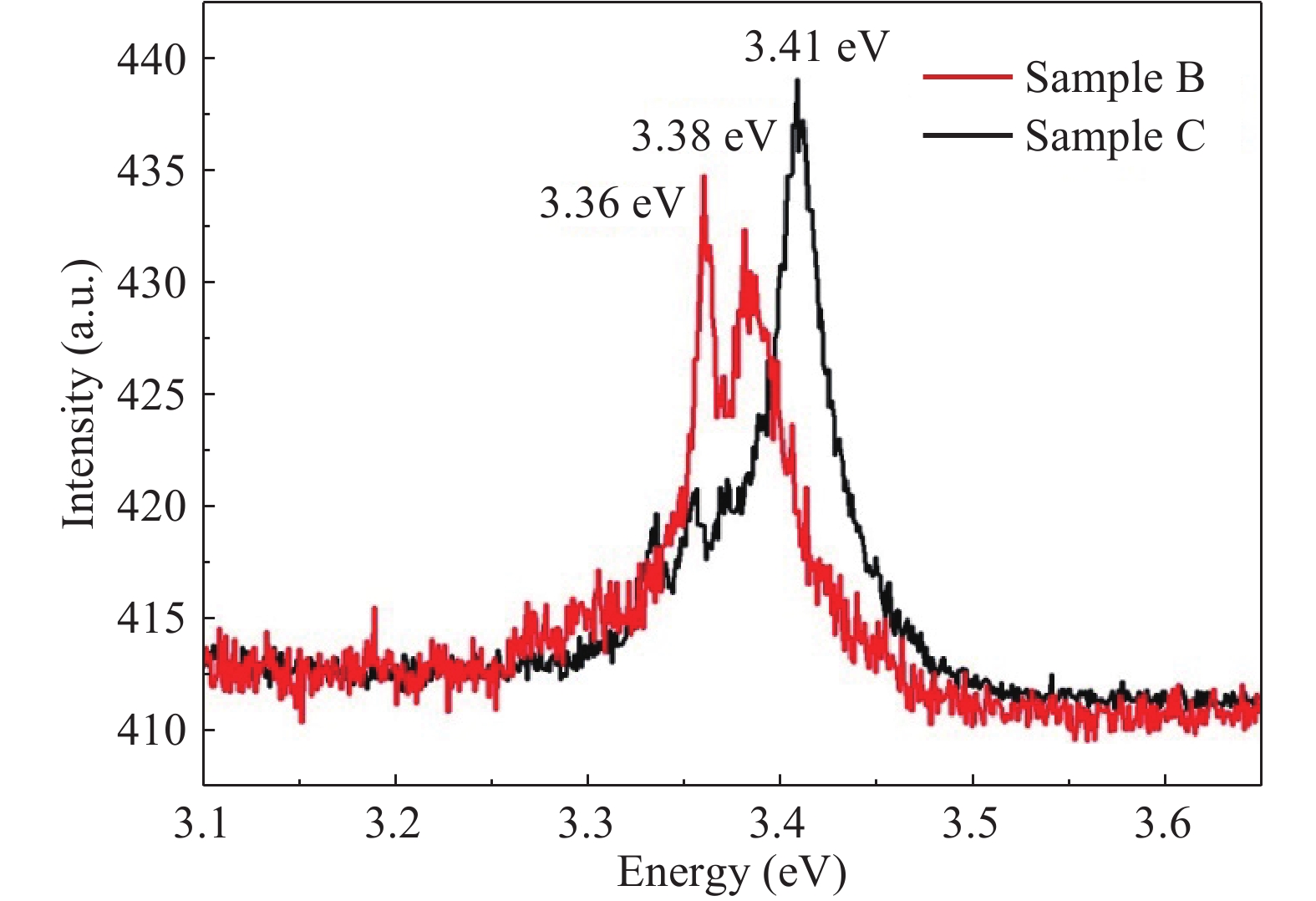

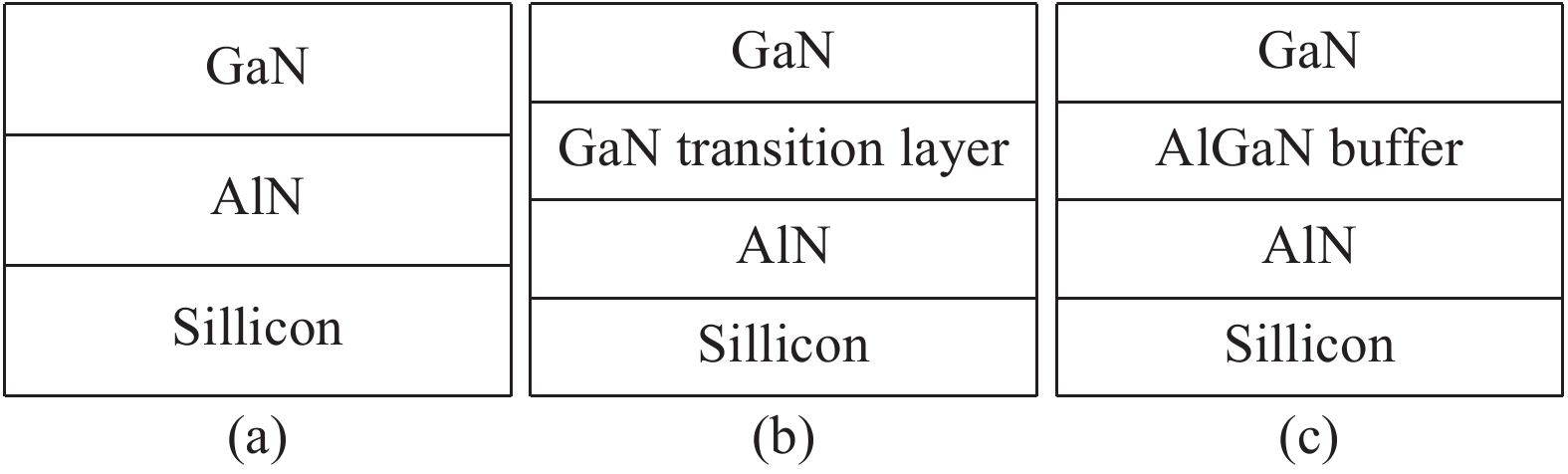

Due to the great potential of GaN based devices, the analysis of the growth of crack-free GaN with high quality has always been a research hotspot. In this paper, two methods for improving the property of the GaN epitaxial layer on Si (111) substrate are researched. Sample A, as a reference, only has an AlN buffer between the Si substrate and the epitaxy. In the following two samples, a GaN transition layer (sample B) and an AlGaN buffer (sample C) are grown on the AlN buffer separately. Both methods improve the quality of GaN. Meanwhile, using the second method, the residual tensile thermal stress decreases. To further study the impact of the two introduced layers, we investigate the stress condition of GaN epitaxial layer by Raman spectrum. According to the Raman spectrum, the calculated residual stress in the GaN epitaxial layer is approximately 0.72 GPa for sample B and 0.42 GPa for sample C. The photoluminescence property of GaN epitaxy is also investigated by room temperature PL spectrum. -

References

[1] Lenka H, Meersschaut J, Kandaswamy P K, et al. Dislocation density and tetragonal distortion of a GaN epilayer on Si (111): A comparative RBS/C and TEM study. Nucl Instrum Meth Phys Res B, 2014, 331: 69 doi: 10.1016/j.nimb.2014.02.014[2] Cong G W , Lu Y, Peng W Q, et al. Design of the low-temperature AlN interlayer for GaN grown on Si (111) substrate. J Cryst Growth, 2005, 276(3/4): 381 doi: 10.1016/j.jcrysgro[3] Mauder C, Booker I D, Fahle D, et al. On the anisotropic wafer curvature of GaN-based eterostructures on Si(110) substrates grown by MOVPE. J Cryst Growth, 2011, 315(1): 220 doi: 10.1016/j.jcrysgro.2010.08.049[4] Yoshida S, Li J, Ikeda N. AlGaN/GaN field effect Schottky barrier diode (FESBD). Phys Stat Sol C, 2005, 2(7): 2602 doi: 10.1002/(ISSN)1610-1642[5] Wang M Y, Zhang G A, Zhang Z J, et al. Study on GaN-based light emitting diodes grownon 4-in. Si(111) substrate. Opt Commun, 2014, 326: 20 doi: 10.1016/j.optcom.2014.04.002[6] Luo R H, Xiang P, Liu M G, et al. High quality GaN grown on Si(111) using fast coalescence growth. Jpn J Appl Phys, 2011, 50: 121001[7] Tungare M, Weng X J, Leathersich J M, et al. Modification of dislocation behavior in GaN overgrown on engineered AlN film-on-bulk Si substrate. J Appl Phys, 2013, 113(16): 3518 doi: 10.1063/1.4798598[8] Kim M H, Do Y G, Kang H C, et al. Effects of step-graded AlxGa1–xN interlayer on properties of GaN grown on Si(111) using ultrahigh vacuum chemical vapor deposition. Appl Phys Lett, 2001, 79(17): 2713 doi: 10.1063/1.1412824[9] Benjamin L, Han J, Sun Q. Strain relaxation and dislocation reduction in AlGaN step-graded buffer for crack-free GaN on Si (111). Phys Status Solidi C, 2004, 11(3/4): 437 doi: 10.1002/pssc.201300690[10] Ni Y Q, He Z Y, Zhong J, et al. Electrical properties of MOCVD-grown GaN on Si (111) substrates with low-temperature AlN interlayers. Chin Phys B, 2013, 22(8): 088104[11] Tung L T, Lin K L, Chang E Y, et al. Photoluminescence and Raman studies of GaN films grown by MOCVD. J Phys: Conf Ser, 2009, 187: 012021 doi: 10.1088/1742-6596/187/1/012021[12] Martínez O, Avella M, Jiménez J, et al. Optical properties of epitaxial lateral overgrowth GaN structures studied by Raman and cathode luminescence spectroscopies. J Appl Phys, 2004, 96: 3639 doi: 10.1063/1.1786670[13] Zhao D G, Xu S J, Xie M H, et al. Stress and its effect on optical properties of GaN epilayers grown on Si(111), 6H-SiC(0001), and c-plane sapphire. Appl Phys Lett, 2003, 83(4): 677 doi: 10.1063/1.1592306[14] Zhao D M, Zhao D G, Jiang D S, et al. Impact of GaN transition layers in the growth of GaN epitaxial layer on silicon. J Semicond, 2015, 36(6): 063003 doi: 10.1088/1674-4926/36/6/063003[15] Fritze S, Drechsel P, Stauss P, et al. A role of low-temperature AlGaN interlayers in thick GaN on silicon by metalorganic vapor phase epitaxy. J Appl Phys, 2012, 111: 124505[16] Able A, Wegscheider W, Engl K, et al. Growth of crack-free GaN on Si(111) with graded AlGaN buffer layers. J Cryst Growth, 2005, 276: 415[17] Zhao D M, Zhao D G, Jiang D S, et al. Temperature-dependent photoluminescence spectra of GaN epitaxial layer grown on Si (111) substrate. Chin Phys B, 2015, 24(10): 108101 doi: 10.1088/1674-1056/24/10/108101 -

Proportional views

DownLoad:

DownLoad: