| Citation: |

Xutang Tao. Bulk gallium oxide single crystal growth[J]. Journal of Semiconductors, 2019, 40(1): 010401. doi: 10.1088/1674-4926/40/1/010401

****

X T Tao, Bulk gallium oxide single crystal growth[J]. J. Semicond., 2019, 40(1): 010401. doi: 10.1088/1674-4926/40/1/010401.

|

-

References

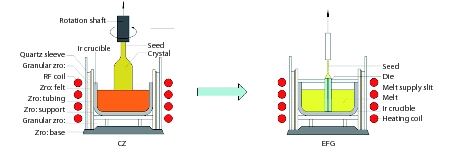

[1] Higashiwaki M, Jessen G H. Guest Editorial: the dawn of gallium oxide microelectronics. Appl Phys Lett, 2018, 112, 060401 doi: 10.1063/1.5017845[2] Baldini M, Galazka Z, Wagner G. Recent progress in the growth of β-Ga2O3 for power electronics applications. Materials Science in Semiconductor Processing, 2018, 78, 132−146 doi: 10.1016/j.mssp.2017.10.040[3] Aida H, Nishiguchi K, Takeda H, et al. Growth of β-Ga2O3 single crystals by the edge-defined, film fed growth method. Jpn J Appl Phys, 2008, 47(11), 8506−8509 doi: 10.1143/JJAP.47.8506[4] Tomm Y, Reiche P, Klimm D, et al. Czochralski grown Ga2O3 crystals. J Cryst Growth, 2000, 220(4), 510 doi: 10.1016/S0022-0248(00)00851-4[5] Mastro M A, Kuramata A, Calkins J, et al. Opportunities and future directions for Ga2O3. ECS Journal of Solid State Science and Technology, 2017, 6(5), 356−359 doi: 10.1149/2.0031707jss -

Proportional views

DownLoad:

DownLoad: