| Citation: |

Jing Zhang, Ding Liu, Yani Pan. Suppression of oxygen and carbon impurity deposition in the thermal system of Czochralski monocrystalline silicon[J]. Journal of Semiconductors, 2020, 41(10): 102702. doi: 10.1088/1674-4926/41/10/102702

****

J Zhang, D Liu, Y N Pan, Suppression of oxygen and carbon impurity deposition in the thermal system of Czochralski monocrystalline silicon[J]. J. Semicond., 2020, 41(10): 102702. doi: 10.1088/1674-4926/41/10/102702.

|

Suppression of oxygen and carbon impurity deposition in the thermal system of Czochralski monocrystalline silicon

DOI: 10.1088/1674-4926/41/10/102702

More Information

-

Abstract

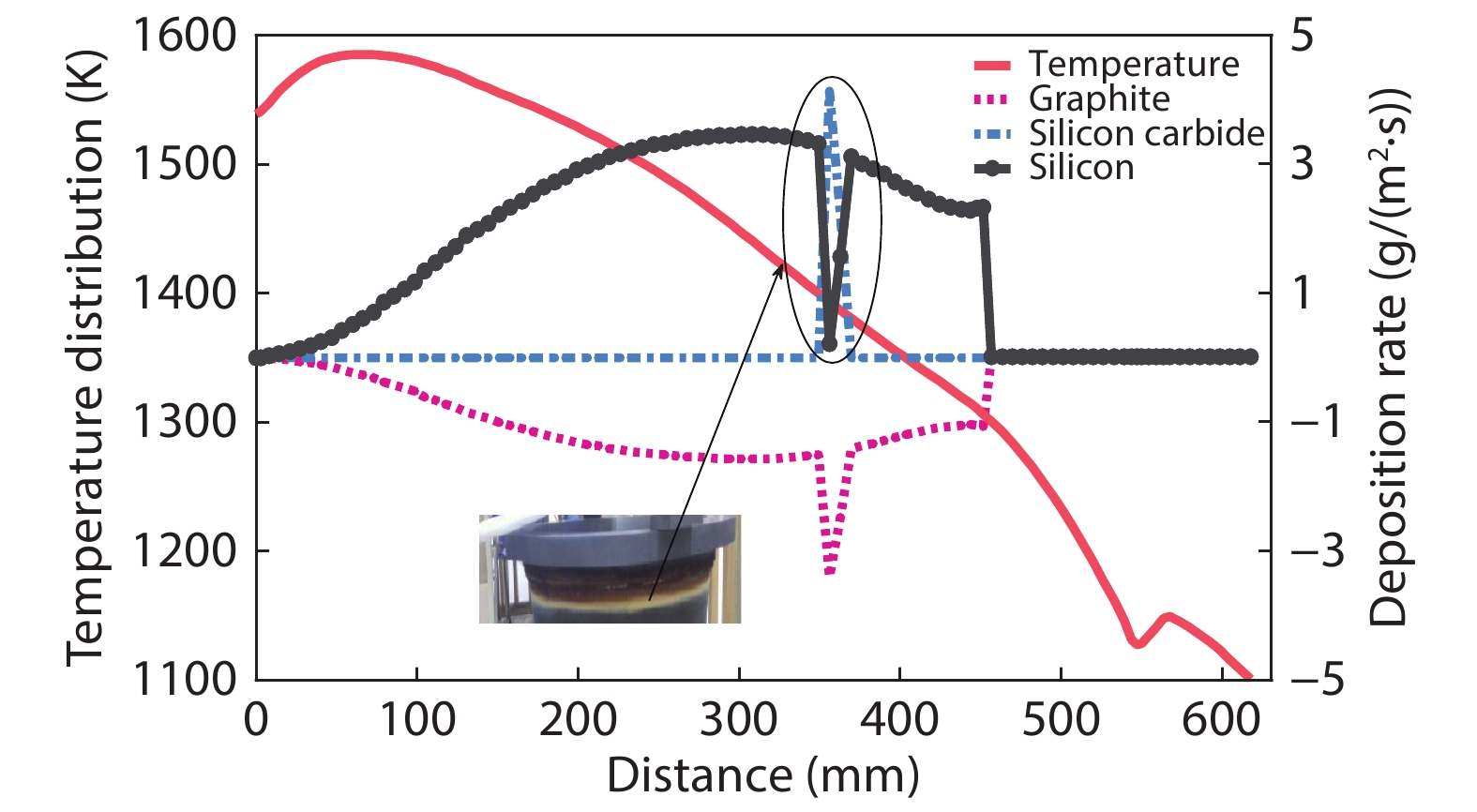

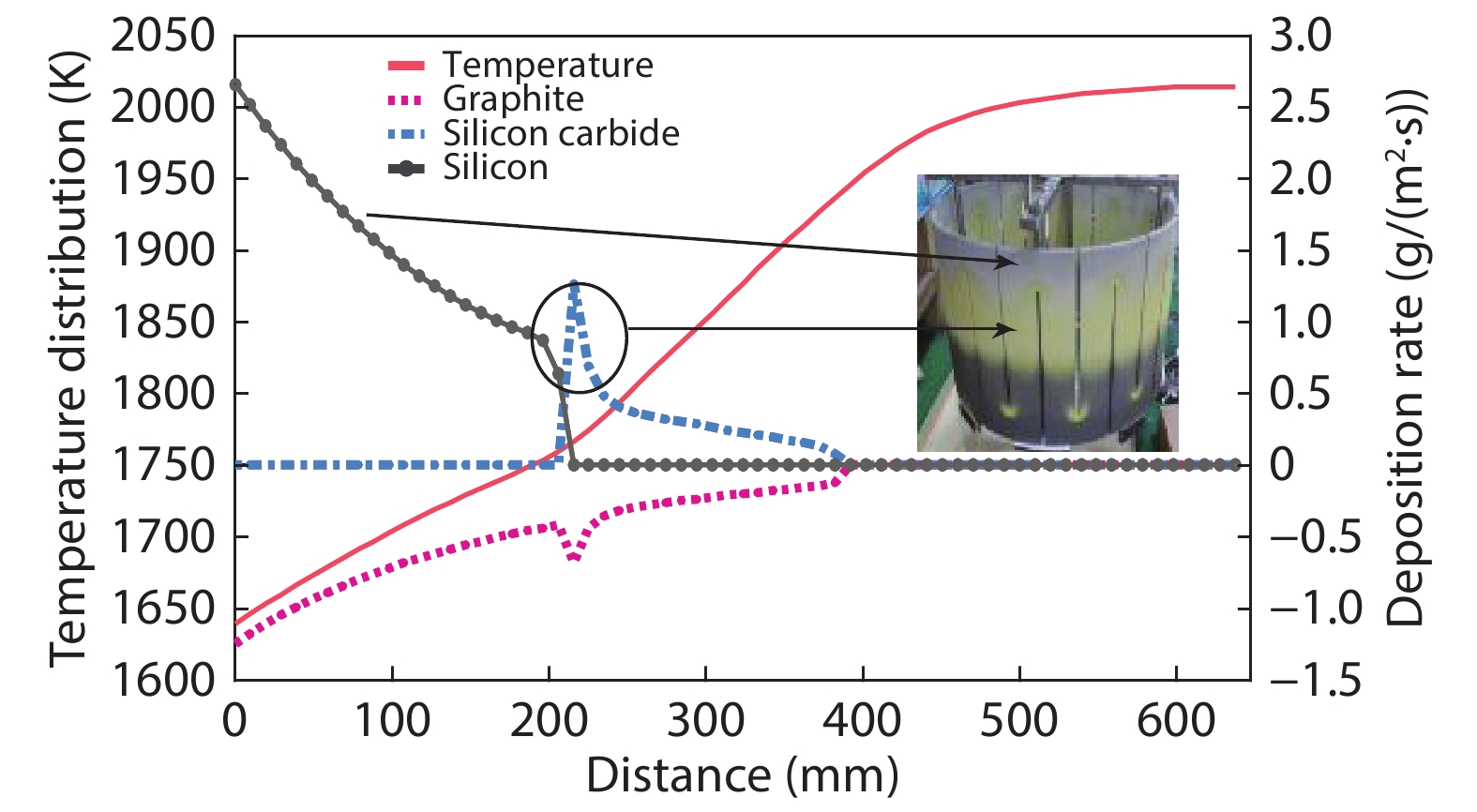

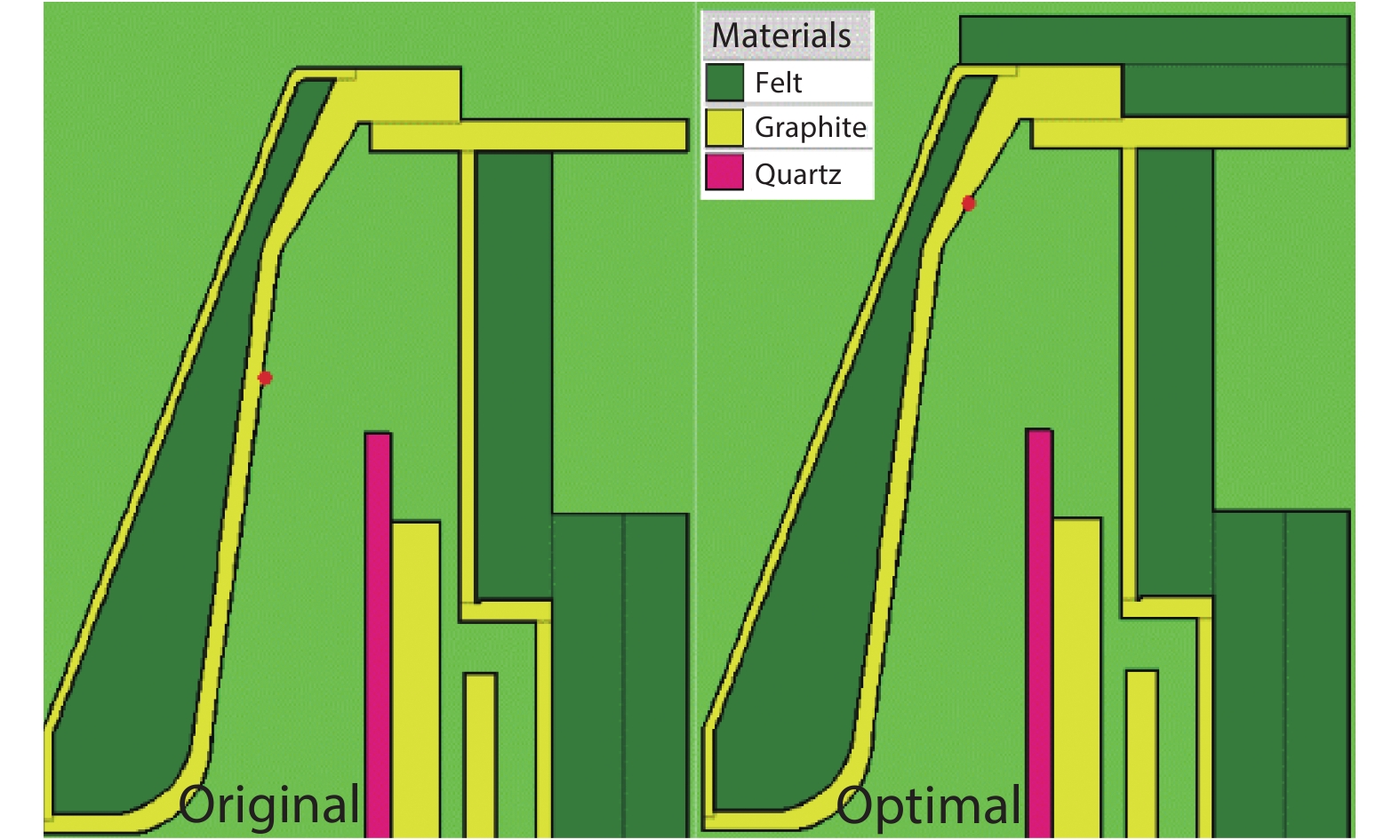

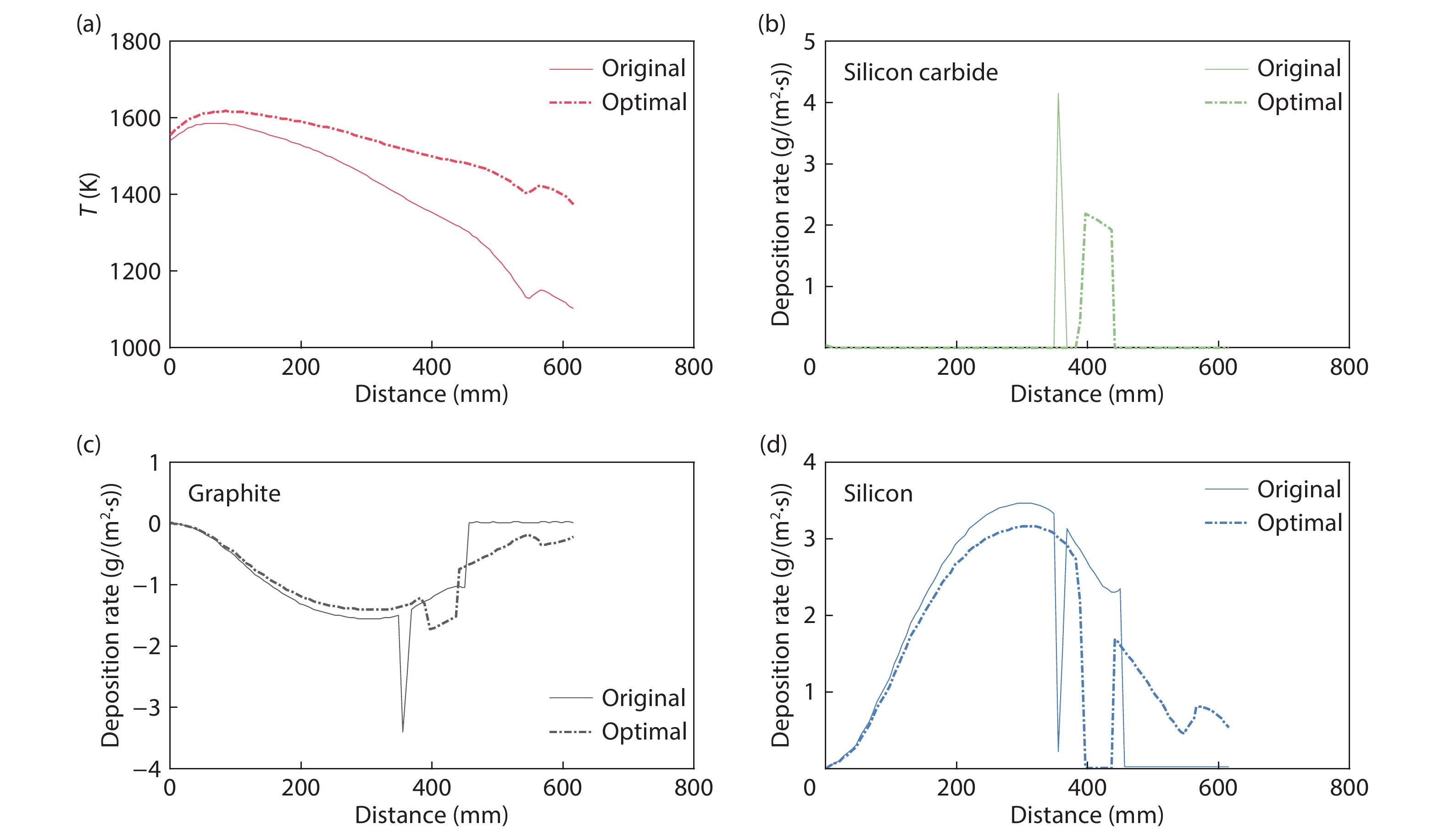

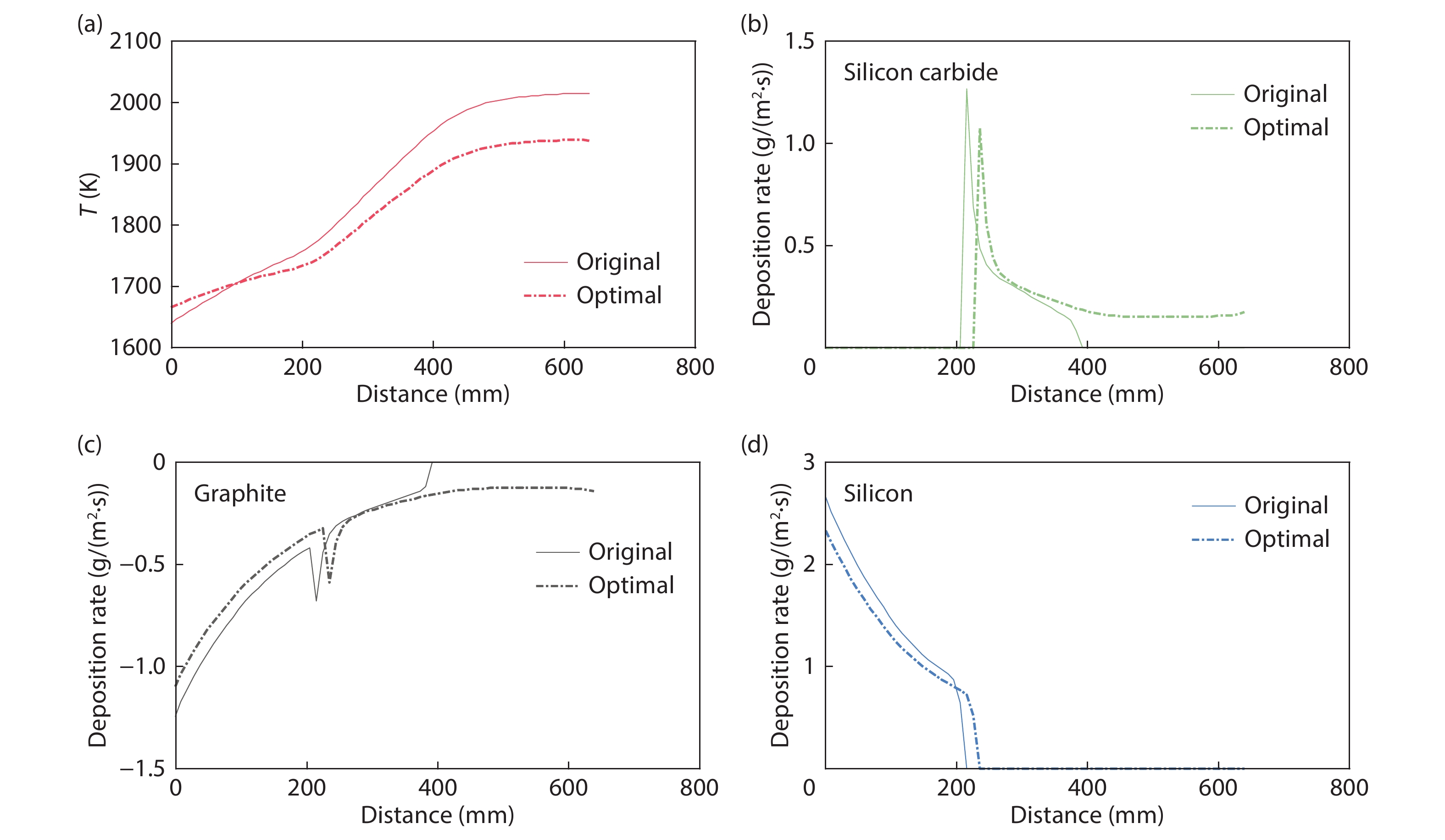

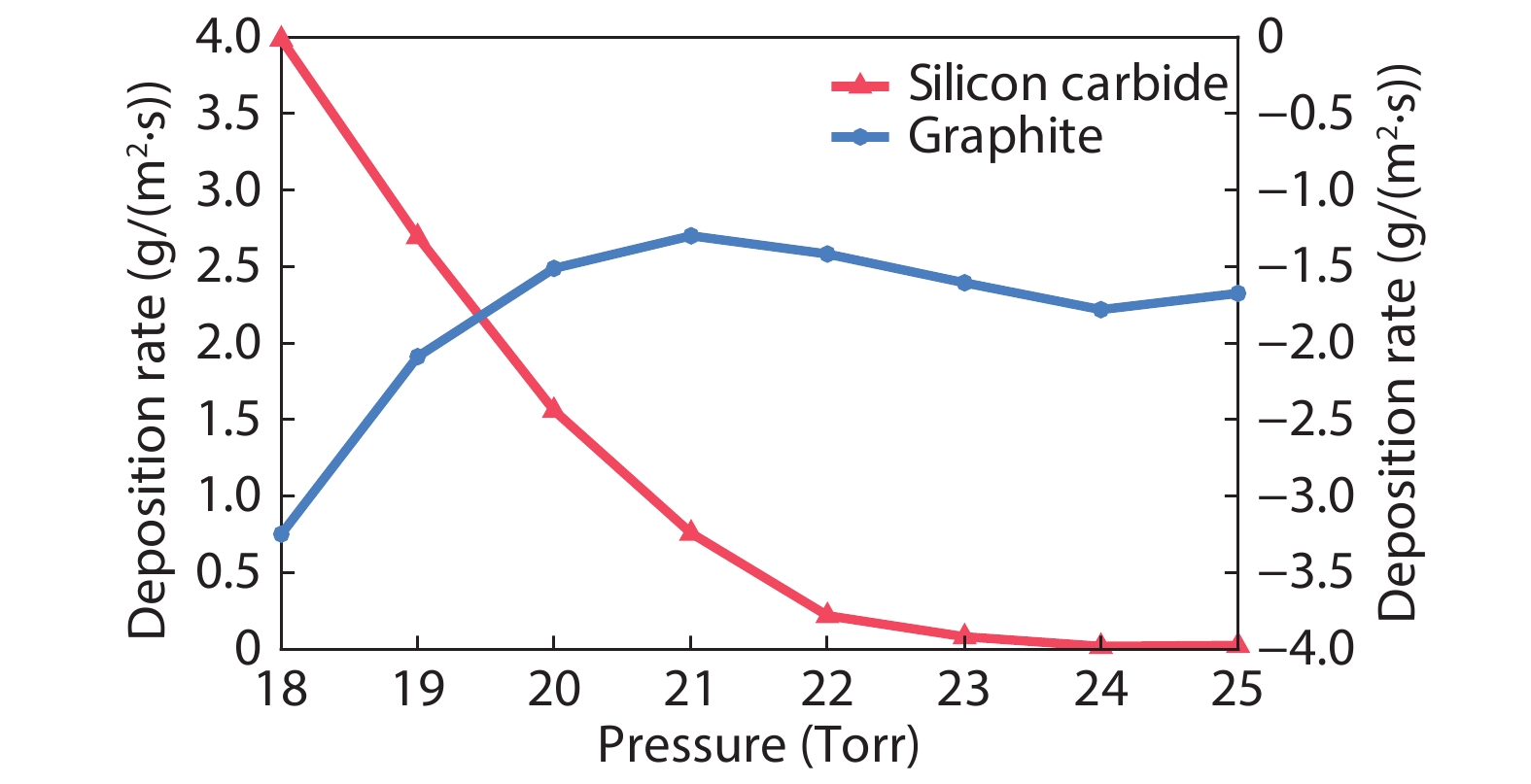

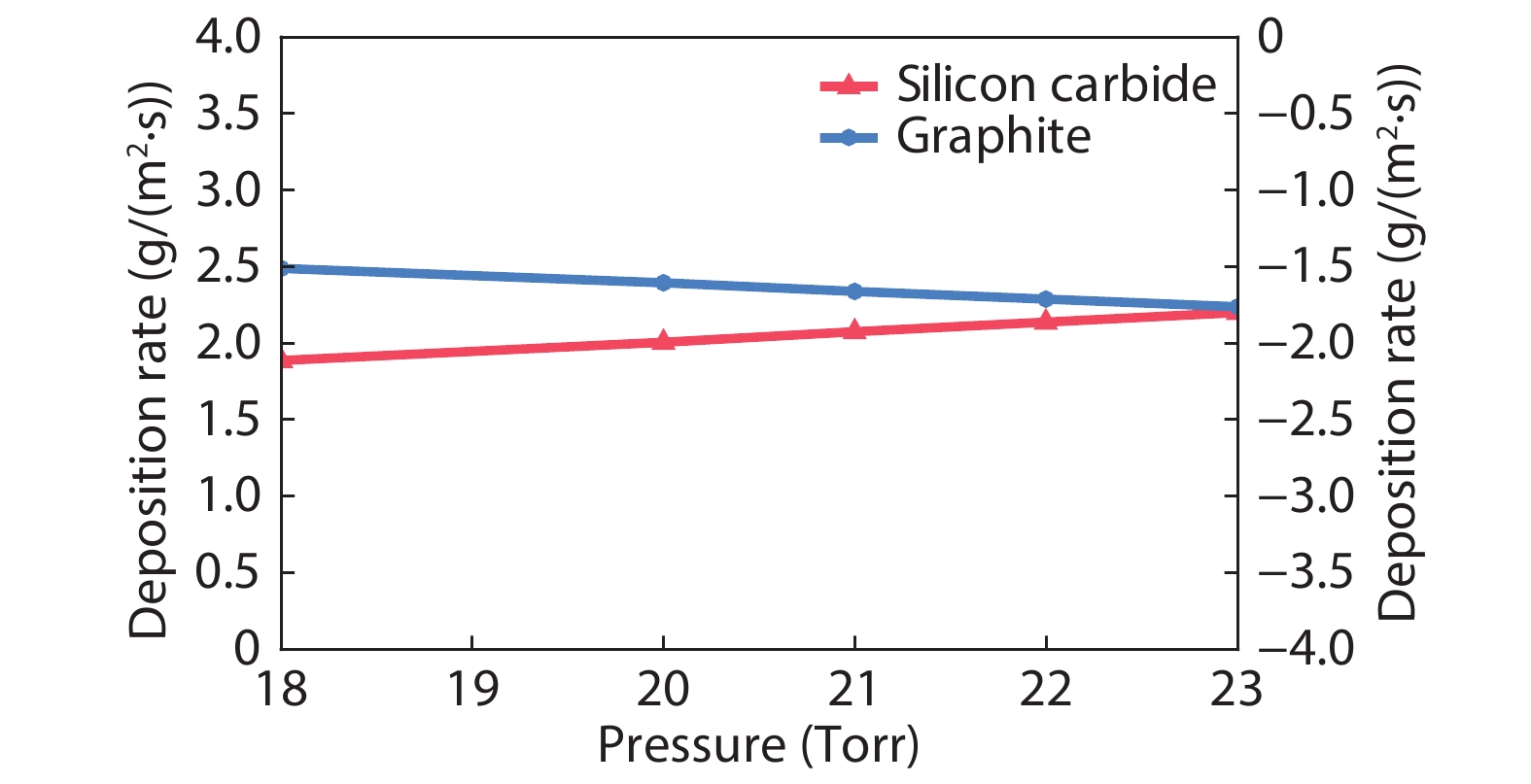

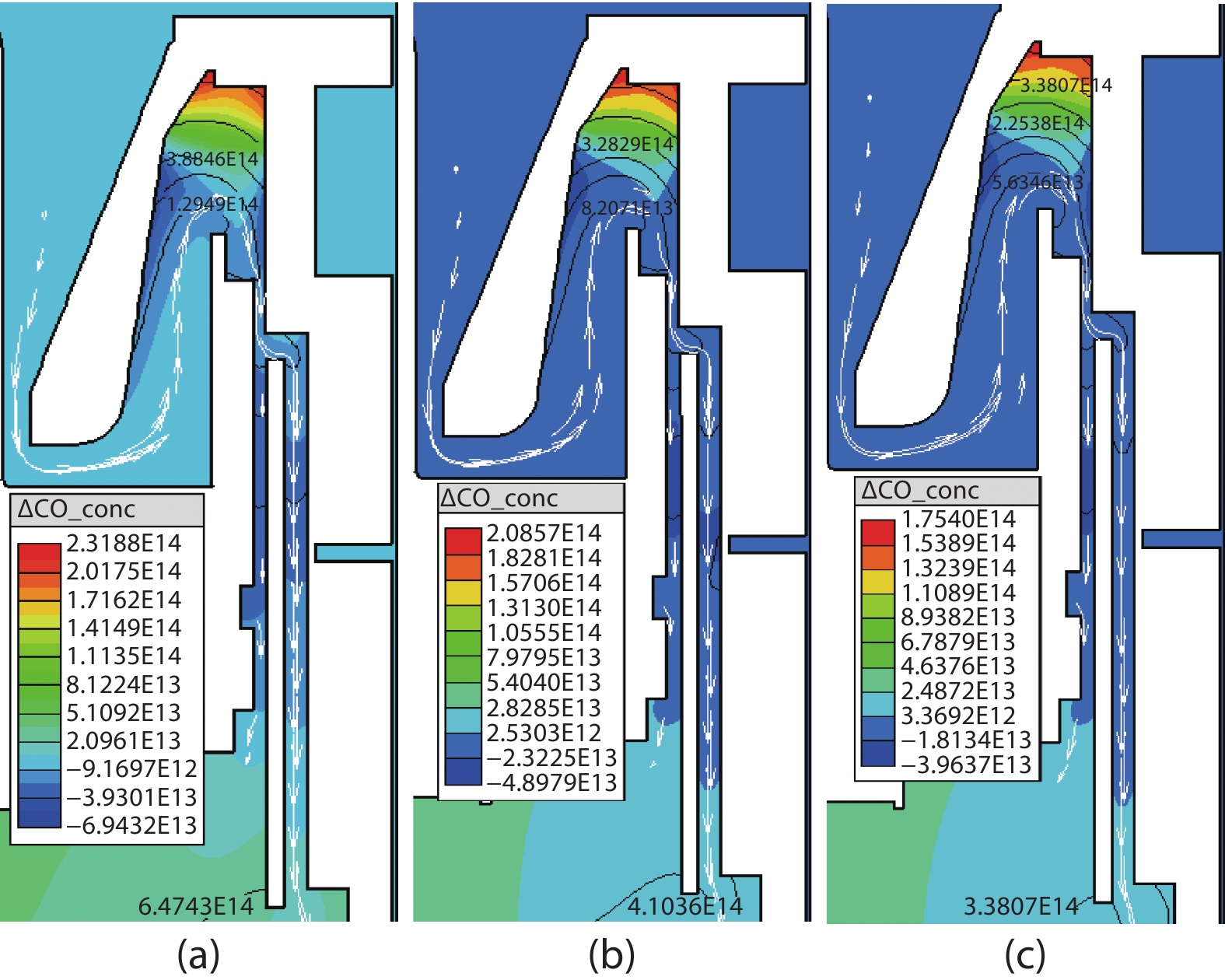

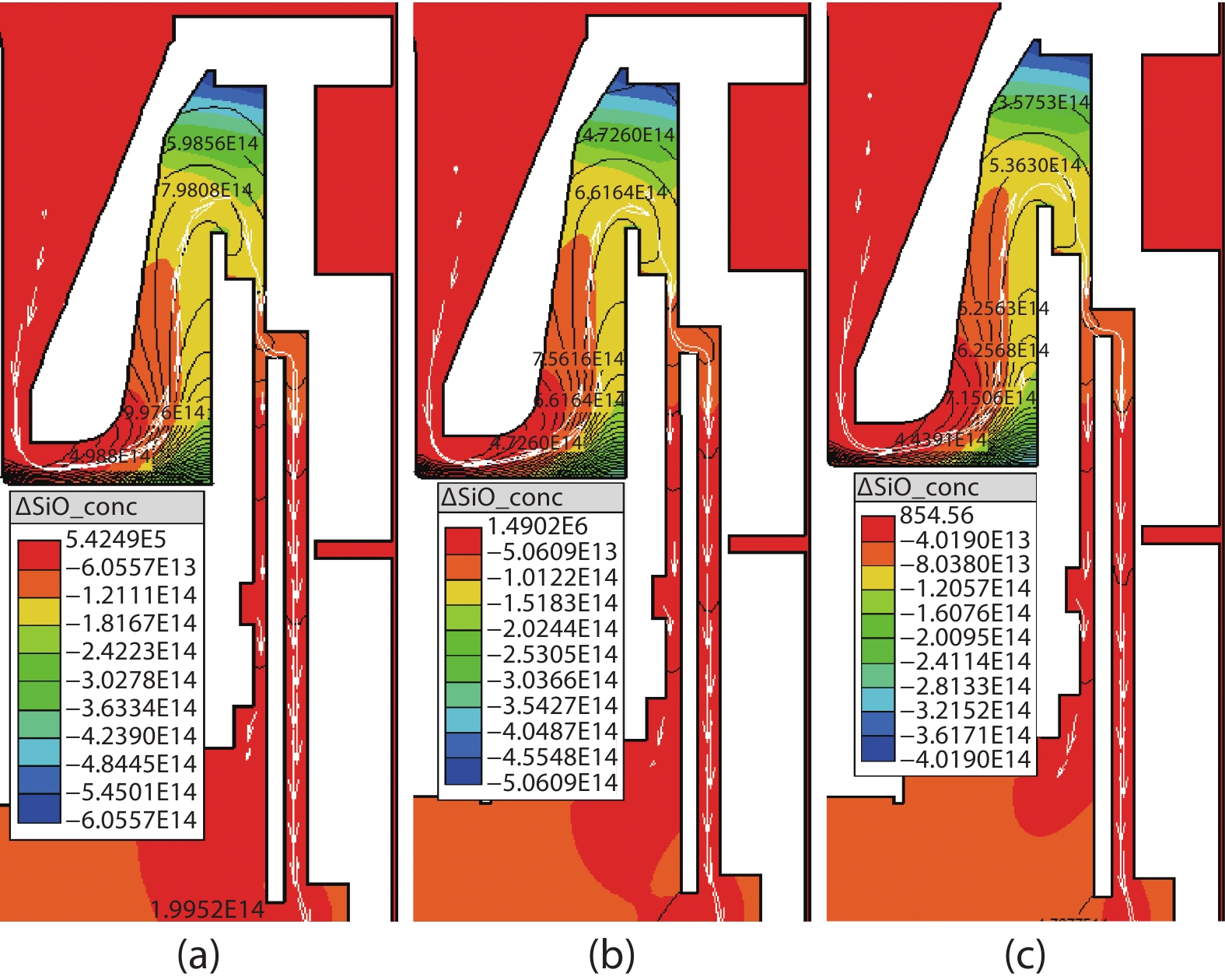

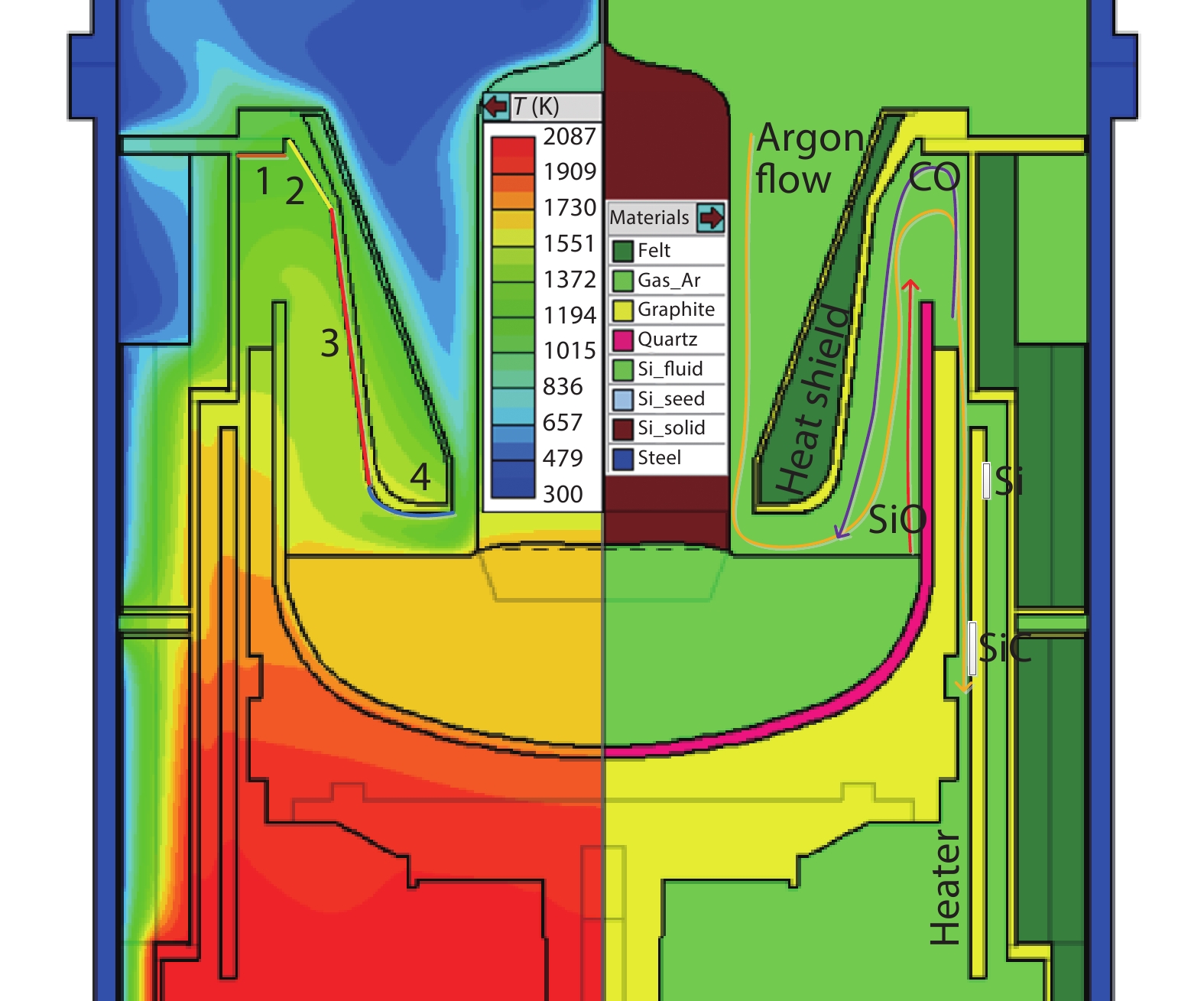

When preparing large monocrystalline silicon materials, severe carbon etching and silicide deposition often occur to the thermal system. Therefore, a suppression method that optimizes the upper insulation structure has been proposed. Assisted by the finite element method, we calculated temperature distribution and carbon deposition of heater and heat shield, made the rule of silicide and temperature distributing in the system, and we explained the formation of impurity deposition. Our results show that the optimized thermal system reduces carbon etching loss on heat components. The lowered pressure of the furnace brings a rapid decrease of silicide deposition. The increase of the argon flow rate effectively inhibits CO and back diffusion. The simulated results agree well with the experiment observations, validating the effectiveness of the proposed method.-

Keywords:

- monocrystalline silicon,

- carbon,

- silicide deposition,

- thermal system

-

References

[1] Tavakoli M H, Renani E K, Honarmandnia M, et al. Computational analysis of heat transfer, thermal stress and dislocation density during resistively Czochralski growth of germanium single crystal. J Cryst Growth, 2018, 483, 125 doi: 10.1016/j.jcrysgro.2017.11.021[2] Liu D, Zhao X G, Zhao Y. A review of growth process modeling and control of Czochralski silicon single crystal. Control Theory Appl, 2017, 34(1), 1 doi: 10.7641/CTA.2017.60247[3] Vegad M, Bhatt N M. Effect of location of zero gauss plane on oxygen concentration at crystal melt interface during growth of magnetic silicon single crystal using Czochralski technique. Proced Technol, 2016, 23, 480 doi: 10.1016/j.protcy.2016.03.053[4] Zhao D M, Zhao D G. Analysis of the growth of GaN epitaxy on silicon. J Semicond, 2018, 39(3), 033006 doi: 10.1088/1674-4926/39/3/033006[5] Zhang J, Ren J C, Liu D. Effect of crucible rotation and crystal rotation on the oxygen distribution at the solid-liquid interface during the growth of Czochralski monocrystalline silicon under superconducting horizontal magnetic field. Results Phys, 2019, 13, 1 doi: 10.1016/j.rinp.2019.02.063[6] Ni Z, Liu D. Numerical simulation of MHD oscillatory mixed convection in CZ crystal growth by lattice Boltzmann method. Results Phys, 2018(10), 882 doi: 10.1016/j.rinp.2018.08.002[7] Ran T, Li Y, Chang Q, et al. Experiment and numerical simulation of melt convection and oxygen distribution in 400 mm Czochralski silicon crystal growth. Rare Met, 2017, 36(2), 134 doi: 10.1007/s12598-016-0865-6[8] Liu X, Gao B, Kakimoto K. Numerical investigation of carbon contamination during the melting process of Czochralski silicon crystal growth. J Cryst Growth, 2015, 417, 58 doi: 10.1016/j.jcrysgro.2014.07.040[9] Lan C W. Recent progress of crystal growth modeling and growth control. Chem Eng Sci, 2004, 59(7), 1437 doi: 10.1016/j.ces.2004.01.010[10] Vorob’ev A N, Sid’ko A P, Kalaev V V. Advanced chemical model for analysis of Cz and DS Si-crystal growth. J Cryst Growth, 2014, 386, 226 doi: 10.1016/j.jcrysgro.2013.10.022[11] Chao H W, Ding L, Bin J S, et al. Thermo-fluid coupling of unsteady flow in Czochralski crystal growth. Acta Phys Sin, 2015, 64(20), 1 doi: 10.7498/aps.64.208102[12] Feng Q L, He Z Q, Chang Q, et al. Effect of rapid thermal annealing ambient on gettering efficiency and surface microstructure in 300 mm CZ silicon wafers. J Semicond, 2008, 29(5), 822[13] Liu X, Nakano S, Kakimoto K. Effect of the packing structure of silicon chunks on the melting process and carbon reduction in Czochralski silicon crystal growth. J Cryst Growth, 2017, 468, 595 doi: 10.1016/j.jcrysgro.2016.09.062[14] Wang L, Horiuchi T, Sekimoto A, et al. Numerical investigation of the effect of static magnetic field on the TSSG growth of SiC. J Cryst Growth, 2018, 5(498), 140 doi: 10.1016/j.jcrysgro.2018.06.017[15] Wang S F, Fan M H, He Y T, et al. Catalytic conversion of biomass-derived polyols into para-xylene over SiO2-modified zeolites. Chin J Chem Phys, 2019, 32, 513 doi: 10.1063/1674-0068/cjcp1901016[16] Guan X J, Zhang X Y. Simulation of V/G during Φ450 mm Czochralski grown silicon single crystal growth under the different crystal and crucible rotation rates. International Symposium on Materials Application and Engineering, 2016, 67, 02002 -

Proportional views

DownLoad:

DownLoad: