| Citation: |

Shufang Zhao, Wenhao Ran, Lili Wang, Guozhen Shen. Interlocked MXene/rGO aerogel with excellent mechanical stability for a health-monitoring device[J]. Journal of Semiconductors, 2022, 43(8): 082601. doi: 10.1088/1674-4926/43/8/082601

****

S F Zhao, W H Ran, L L Wang, G Z Shen. Interlocked MXene/rGO aerogel with excellent mechanical stability for a health-monitoring device[J]. J. Semicond, 2022, 43(8): 082601. doi: 10.1088/1674-4926/43/8/082601

|

Interlocked MXene/rGO aerogel with excellent mechanical stability for a health-monitoring device

DOI: 10.1088/1674-4926/43/8/082601

More Information

-

Abstract

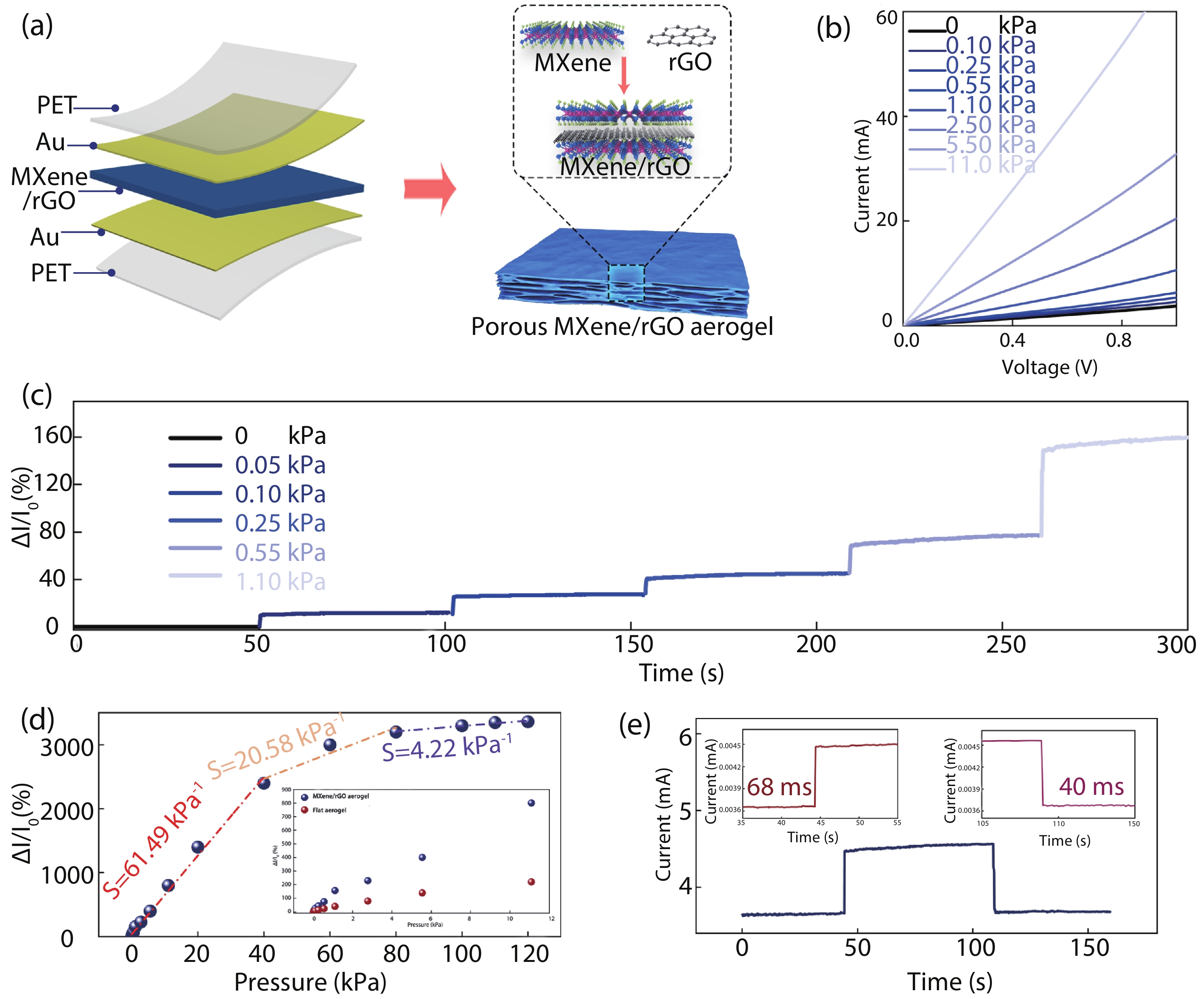

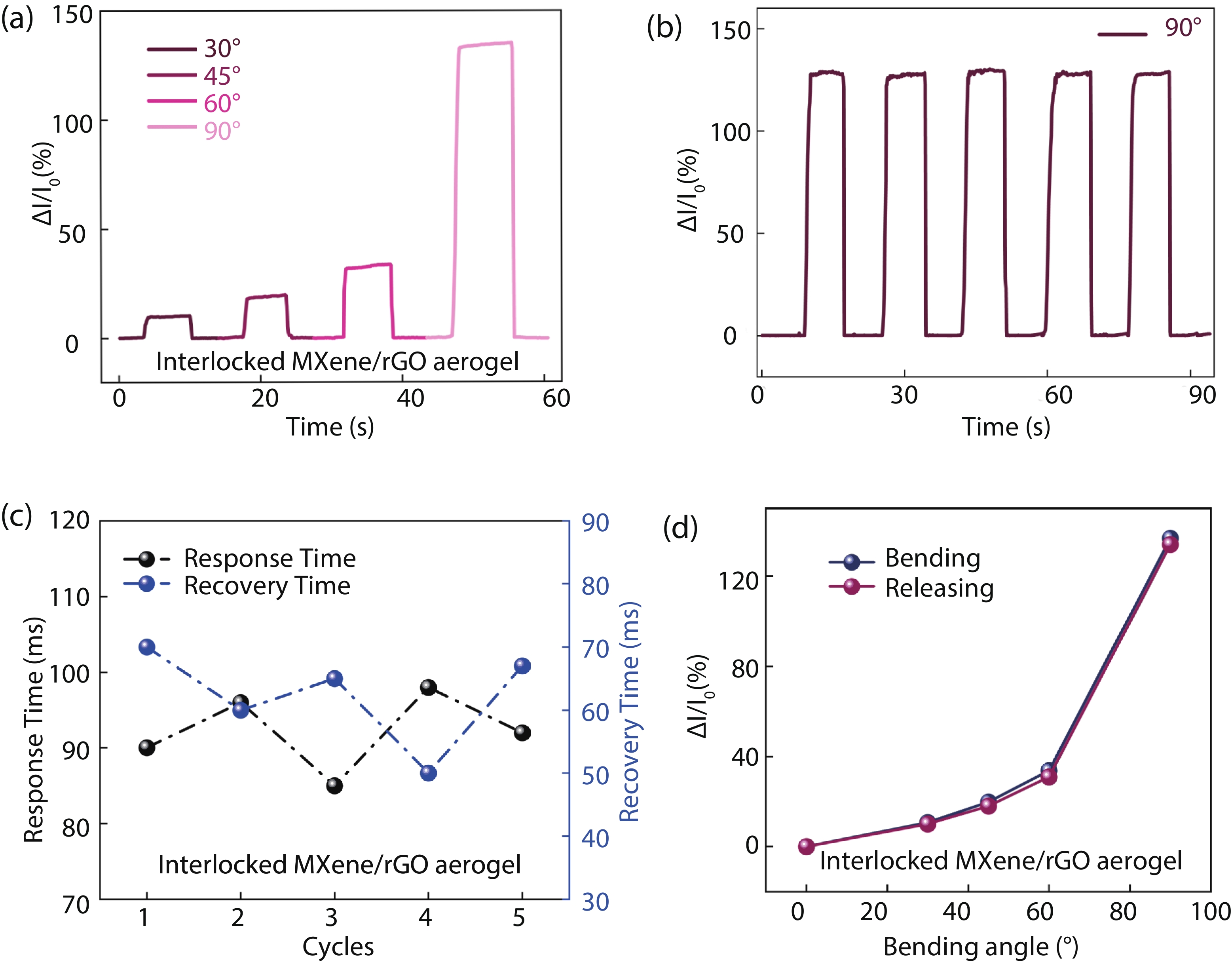

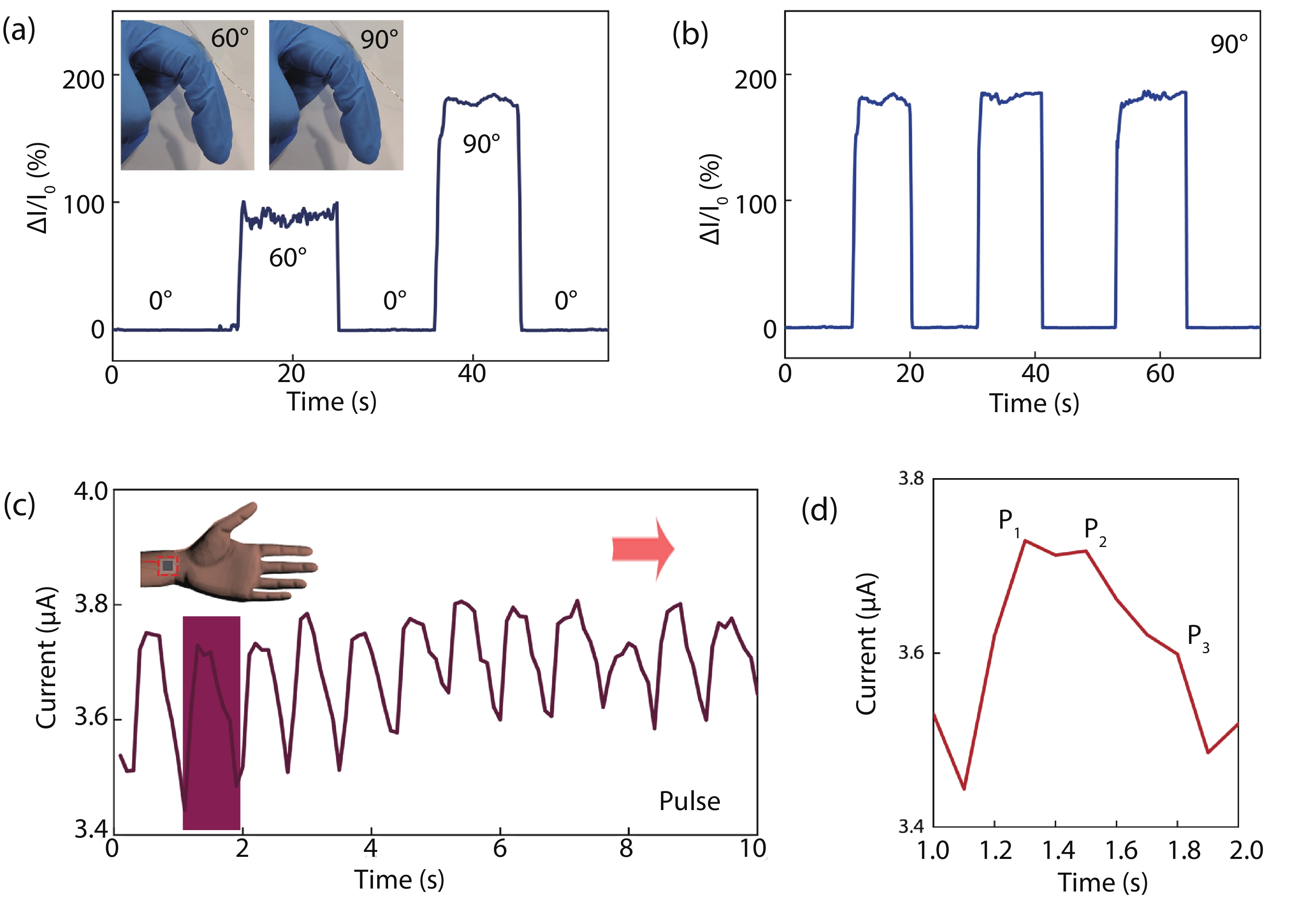

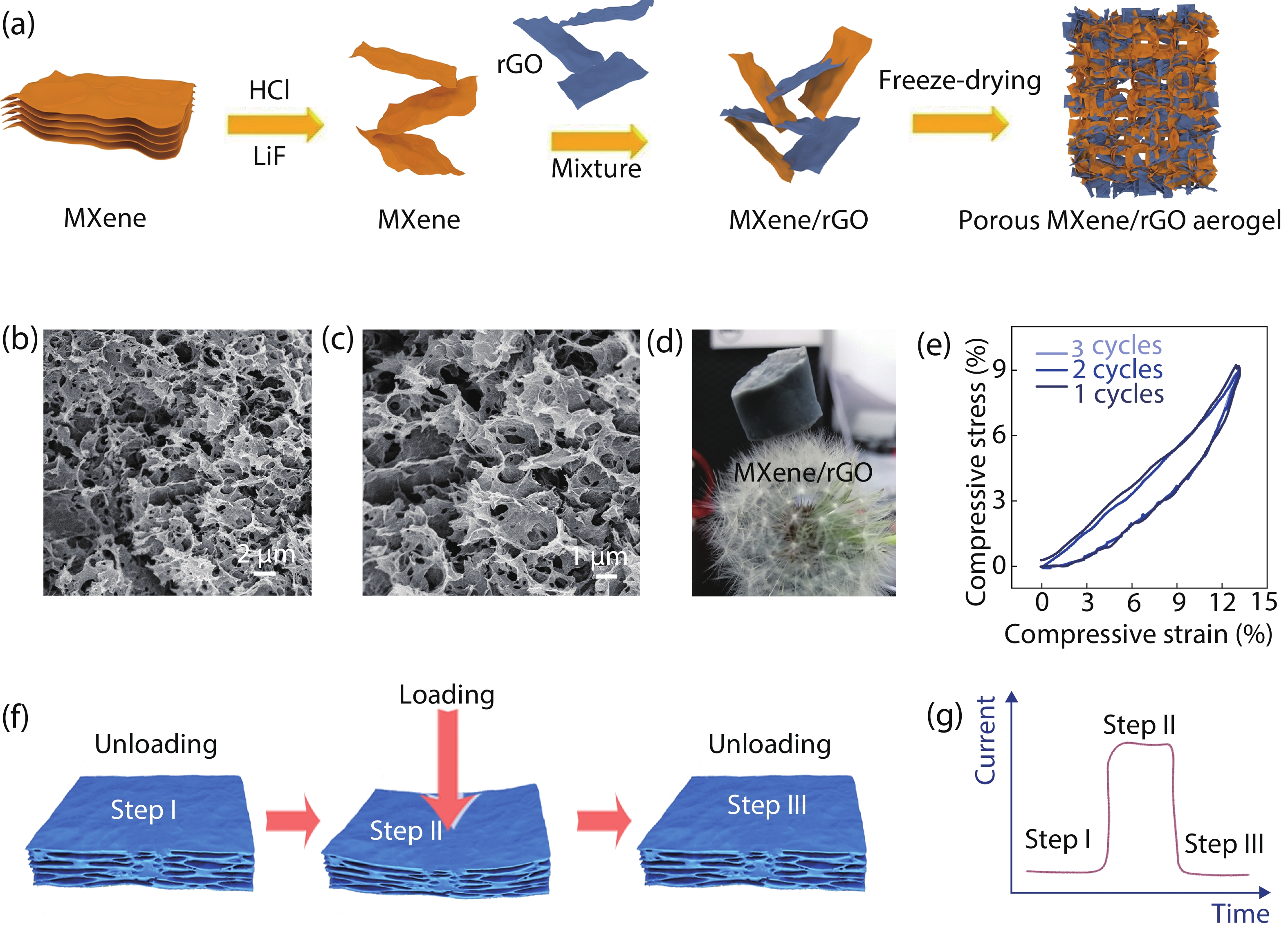

Two-dimensional (2D) materials have attracted considerable interest thanks to their unique electronic/physical–chemical characteristics and their potential for use in a large variety of sensing applications. However, few-layered nanosheets tend to agglomerate owing to van der Waals forces, which obstruct internal nanoscale transport channels, resulting in low electrochemical activity and restricting their use for sensing purposes. Here, a hybrid MXene/rGO aerogel with a three-dimensional (3D) interlocked network was fabricated via a freeze-drying method. The porous MXene/rGO aerogel has a lightweight and hierarchical porous architecture, which can be compressed and expanded several times without breaking. Additionally, a flexible pressure sensor that uses the aerogel as the sensitive layer has a wide response range of approximately 0–40 kPa and a considerable response within this range, averaging approximately 61.49 kPa–1. The excellent sensing performance endows it with a broad range of applications, including human-computer interfaces and human health monitoring. -

References

[1] Cao M, Su J, Fan S, et al. Wearable piezoresistive pressure sensors based on 3D graphene. Chem Eng J, 2021, 406, 126777 doi: 10.1016/j.cej.2020.126777[2] Jin X, Li L, Zhao S, et al. Assessment of occlusal force and local gas release using degradable bacterial cellulose/Ti3C2T x MXene bioaerogel for oral healthcare. ACS Nano, 2021, 15, 18385 doi: 10.1021/acsnano.1c07891[3] Wang L, Chen S, Li W, et al. Grain-boundary-induced drastic sensing performance enhancement of polycrystalline-microwire printed gas sensors. Adv Mater, 2019, 31, 1804583 doi: 10.1002/adma.201804583[4] Wu J, Huang D, Ye Y, et al. Theoretical study of a group IV p–i–n photodetector with a flat and broad response for visible and infrared detection. J Semicond, 2020, 41, 122402 doi: 10.1088/1674-4926/41/12/122402[5] Zhong B, Jiang K, Wang L, et al. Wearable sweat loss measuring devices: From the role of sweat loss to advanced mechanisms and designs. Adv Sci, 2022, 9, 2103257 doi: 10.1002/advs.202103257[6] Geng R, Gong Y. High performance active image sensor pixel design with circular structure oxide TFT. J Semicond, 2019, 40, 022402 doi: 10.1088/1674-4926/40/2/022402[7] Zhao S, Ran W, Wang D, et al. 3D dielectric layer enabled highly sensitive capacitive pressure sensors for wearable electronics. ACS Appl Mater Interfaces, 2020, 12, 32023 doi: 10.1021/acsami.0c09893[8] Mak P I. Lab-on-COS-an in-vitro diagnostic (IVD) tool for a healthier society. J Semicond, 2020, 41, 110301 doi: 10.1088/1674-4926/41/11/110301[9] Zhang Z, Chen C, Fei T, et al. Wireless communication and wireless power transfer system for implantable medical device. J Semicond, 2020, 41, 102403 doi: 10.1088/1674-4926/41/10/102403[10] Chen T, Zhang S H, Lin Q H, et al. Highly sensitive and wide-detection range pressure sensor constructed on a hierarchical-structured conductive fabric as a human-machine interface. Nanoscale, 2020, 12, 21271 doi: 10.1039/D0NR05976E[11] Wang L, Jiang K, Shen G. A perspective on flexible sensors in developing diagnostic devices. Appl Phys Lett, 2022, 119, 150501 doi: 10.1063/5.0057020[12] Li L, Wang D, Zhang D, et al. Near-infrared light triggered self-powered mechano-optical communication system using wearable photodetector textile. Adv Funct Mater, 2021, 31, 2104782 doi: 10.1002/adfm.202104782[13] Kang K, Jung H, An S, et al. Skin-like transparent polymer-hydrogel hybrid pressure sensor with pyramid microstructures. Polymers, 2021, 13, 3272 doi: 10.3390/polym13193272[14] Qi K, Zhou Y, Ou K, et al. Weavable and stretchable piezoresistive carbon nanotubes-embedded nanofiber sensing yarns for highly sensitive and multimodal wearable textile sensor. Carbon, 2020, 170, 464 doi: 10.1016/j.carbon.2020.07.042[15] Wang G, Wang Z, Wu Y, et al. A robust stretchable pressure sensor for electronic skins. Org Electron, 2020, 86, 105926 doi: 10.1016/j.orgel.2020.105926[16] Torad N L, Ding B, El-Said WA, et al. Mof-derived hybrid nanoarchitectured carbons for gas discrimination of volatile aromatic hydrocarbons. Carbon, 2020, 168, 55 doi: 10.1016/j.carbon.2020.05.013[17] Bai H, Li C, Shi G. Functional composite materials based on chemically converted graphene. Adv Mater, 2011, 23, 1089 doi: 10.1002/adma.201003753[18] Sun J, Du S. Application of graphene derivatives and their nanocomposites in tribology and lubrication: A review. RSC Adv, 2019, 9, 40642 doi: 10.1039/C9RA05679C[19] Pan H. Ultra-high electrochemical catalytic activity of MXenes. Sci Rep, 2016, 6, 32531 doi: 10.1038/srep32531[20] Zhao L, Wang Z, Li Y, et al. Designed synthesis of chlorine and nitrogen co-doped Ti3C2 MXene quantum dots and their outstanding hydroxyl radical scavenging properties. J Mater Sci Technol, 2021, 78, 30 doi: 10.1016/j.jmst.2020.10.048[21] Kamath K, Adepu V, Mattela V, et al. Development of Ti3C2Tx/MoS2 xSe2(1– x) nanohybrid multilayer structures for piezoresistive mechanical transduction. ACS Appl Electron Mater, 2021, 3, 4091 doi: 10.1021/acsaelm.1c00583[22] Sun J, Du H, Chen Z, et al. MXene quantum dot within natural 3D watermelon peel matrix for biocompatible flexible sensing platform. Nano Res, 2022, 15, 3653 doi: 10.1007/s12274-021-3967-x[23] Gong S, Schwalb W, Wang Y, et al. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat Commun, 2014, 5, 3132 doi: 10.1038/ncomms4132[24] Ma Y, Yue Y, Zhang H, et al. 3D synergistical MXene/reduced graphene oxide aerogel for a piezoresistive sensor. ACS Nano, 2018, 12, 3209 doi: 10.1021/acsnano.7b06909[25] Tian Y, Han J, Yang J, et al. A highly sensitive graphene aerogel pressure sensor inspired by fluffy spider leg. Adv Mater Interfaces, 2021, 8, 2100511 doi: 10.1002/admi.202100511[26] Wang L, Zhang M, Yang B, et al. Thermally stable, light-weight, and robust aramid nanofibers/Ti3AlC2 MXene composite aerogel for sensitive pressure sensor. ACS Nano, 2020, 8, 10633 doi: 10.1021/acsnano.0c04888[27] Zhai J, Zhang Y, Cui C, et al. Flexible waterborne polyurethane/cellulose nanocrystal composite aerogels by integrating graphene and carbon nanotubes for a highly sensitive pressure sensor. ACS Sustain Chem Eng, 2021, 9, 14029 doi: 10.1021/acssuschemeng.1c03068[28] Wei S, Qiu X, An J, et al. Highly sensitive, flexible, green synthesized graphene/biomass aerogels for pressure sensing application. Compos Sci Technol, 2021, 7, 20,108730 doi: 10.1016/j.compscitech.2021.108730[29] Xu Q, X Chang, Zhu Z, et al. Flexible pressure sensors with high pressure sensitivity and low detection limit using a unique honeycomb-designed polyimide/reduced graphene oxide composite aerogel. RSC Adv, 2021, 11, 11760 doi: 10.1039/D0RA10929K[30] Wang D, Wang L, Shen G. Nanofiber/nanowires-based flexible and stretchable sensors. J Semicond, 2020, 41, 041605 doi: 10.1088/1674-4926/41/4/041605[31] Wei S J. Reconfigurable computing: a promising microchip architecture for artificial intelligence. J Semicond, 2020, 41, 020301 doi: 10.1088/1674-4926/41/2/020301[32] Wang K, Lou Z, Wang L, et al. Bioinspired interlocked structure-induced high deformability for two-dimensional titanium carbide (MXene)/natural microcapsule-based flexible pressure sensors. ACS Nano, 2019, 13, 9139 doi: 10.1021/acsnano.9b03454[33] Dong K, Wang Z L. Self-charging power textiles integrating energy harvesting triboelectric nanogenerators with energy storage batteries/supercapacitors. J Semicond, 2021, 42, 101601 doi: 10.1088/1674-4926/42/10/101601 -

Proportional views

DownLoad:

DownLoad: