| Citation: |

Wen Gu, Zhibin Liu, Yanan Guo, Xiaodong Wang, Xiaolong Jia, Xingfang Liu, Yiping Zeng, Junxi Wang, Jinmin Li, Jianchang Yan. Comprehensive study of crystalline AlN/sapphire templates after high-temperature annealing with various sputtering conditions[J]. Journal of Semiconductors, 2020, 41(12): 122802. doi: 10.1088/1674-4926/41/12/122802

****

W Gu, Z B Liu, Y N Guo, X D Wang, X L Jia, X F Liu, Y P Zeng, J X Wang, J M Li, J C Yan, Comprehensive study of crystalline AlN/sapphire templates after high-temperature annealing with various sputtering conditions[J]. J. Semicond., 2020, 41(12): 122802. doi: 10.1088/1674-4926/41/12/122802.

|

Comprehensive study of crystalline AlN/sapphire templates after high-temperature annealing with various sputtering conditions

DOI: 10.1088/1674-4926/41/12/122802

More Information

-

Abstract

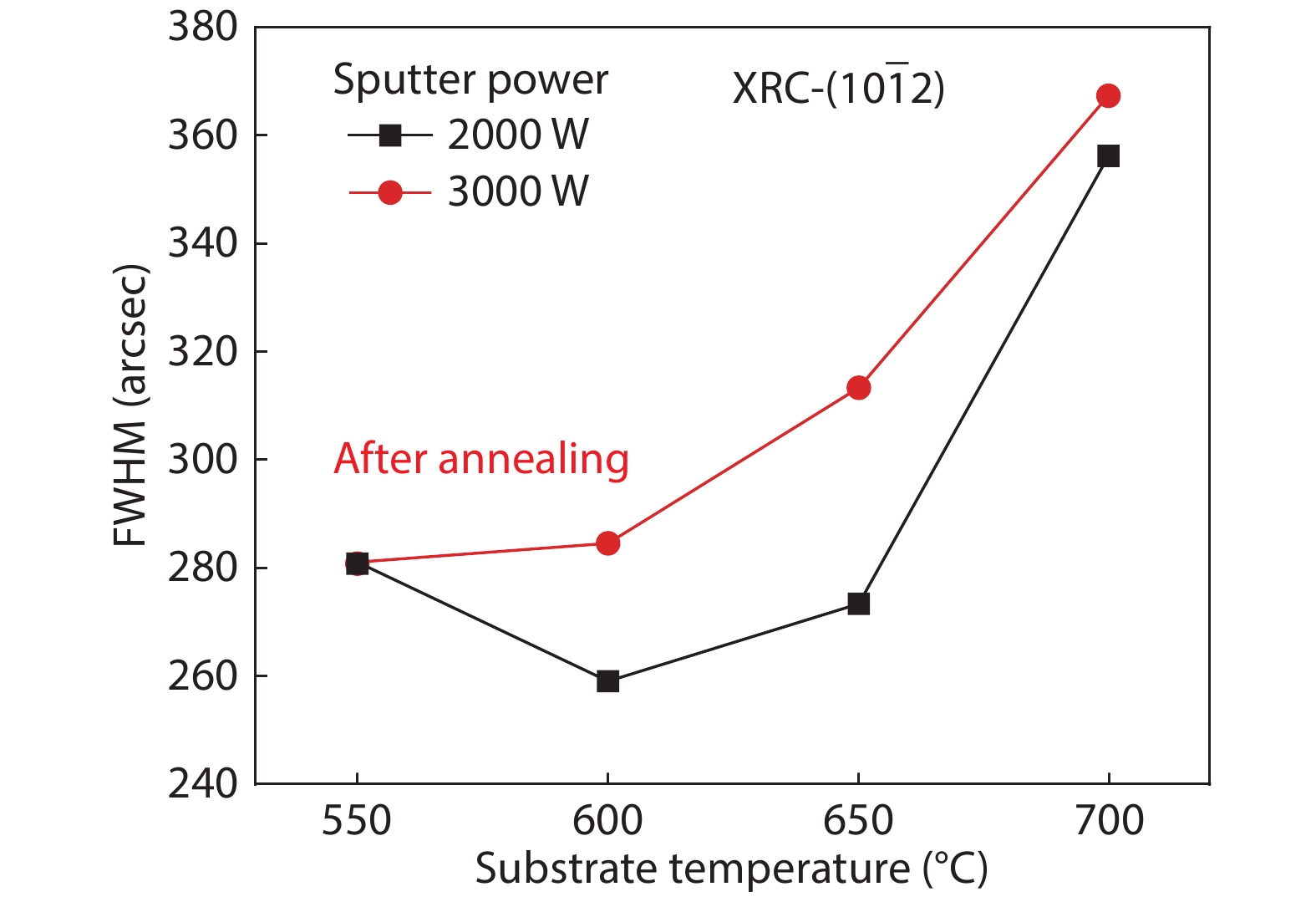

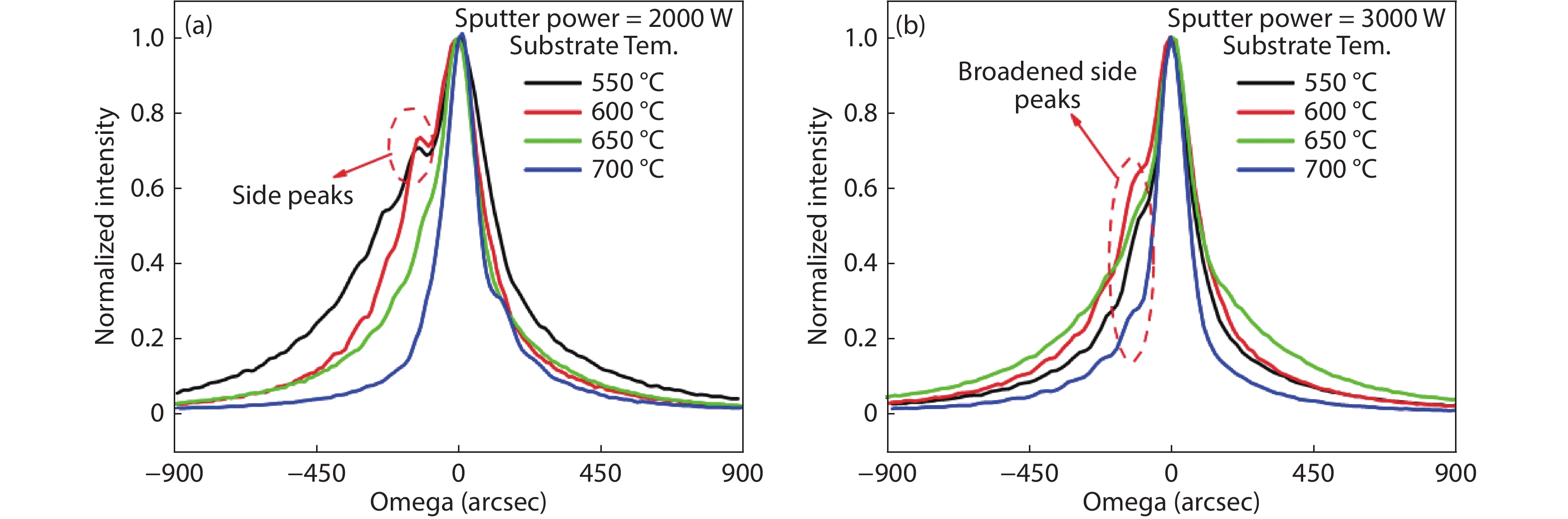

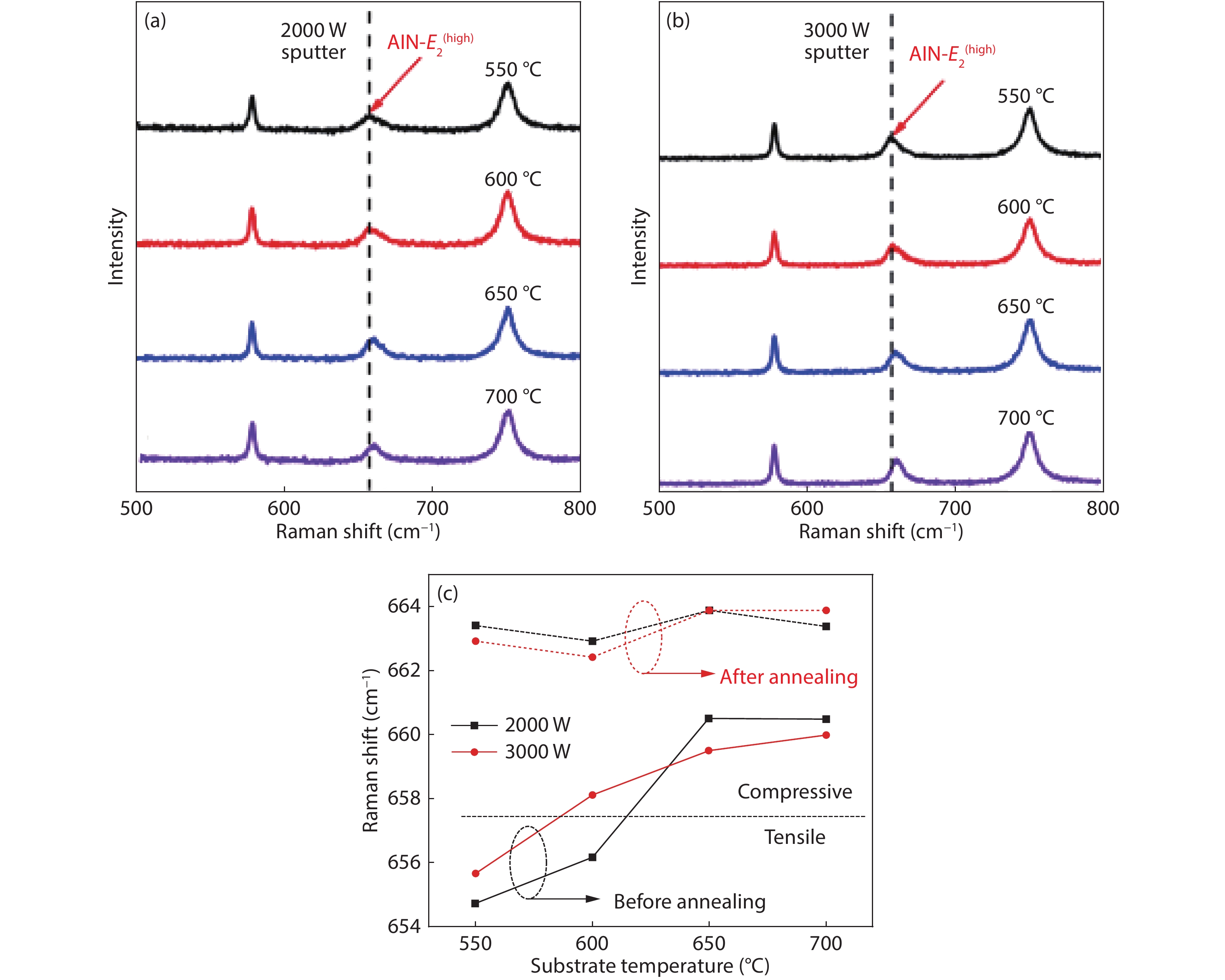

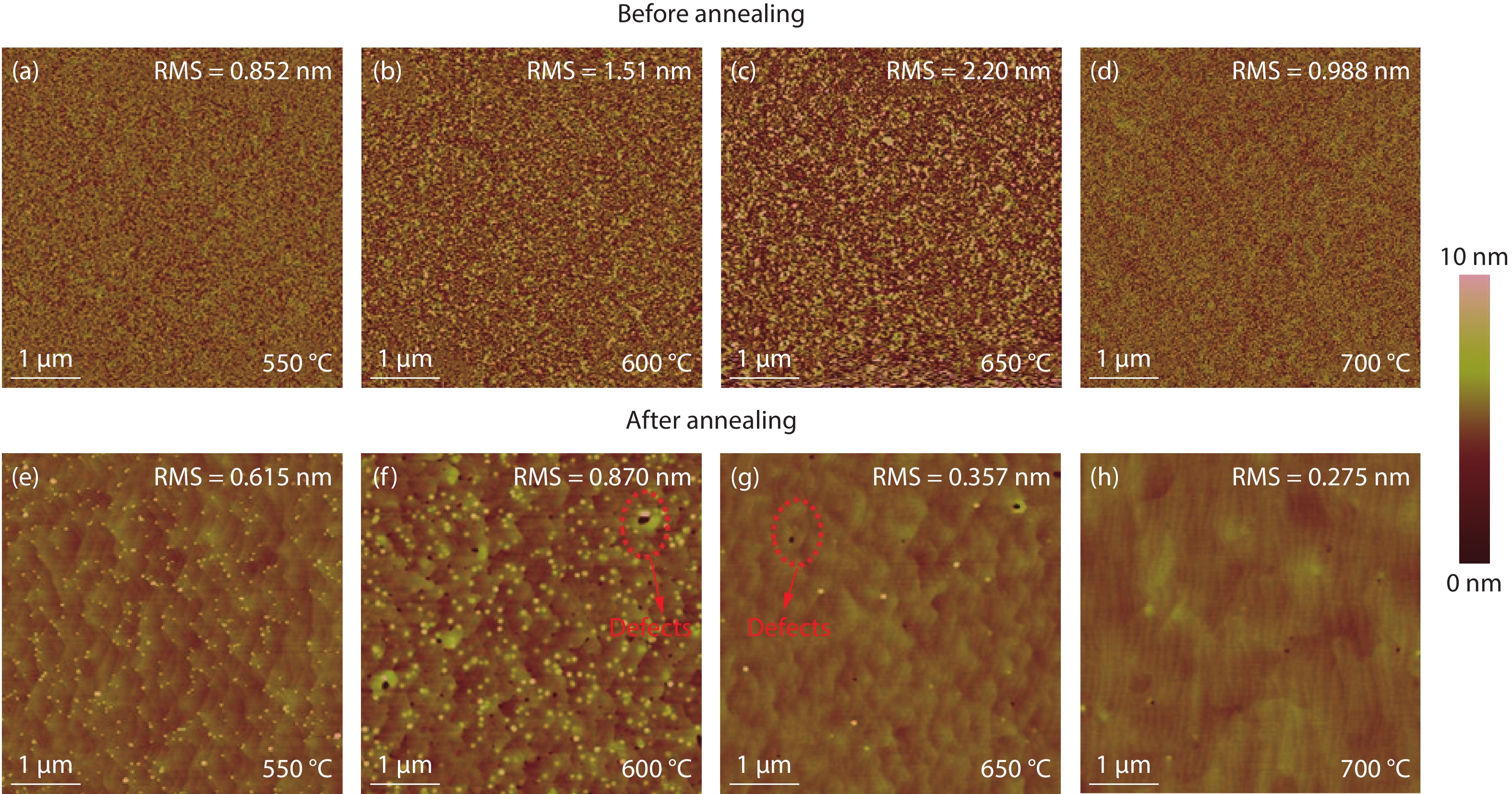

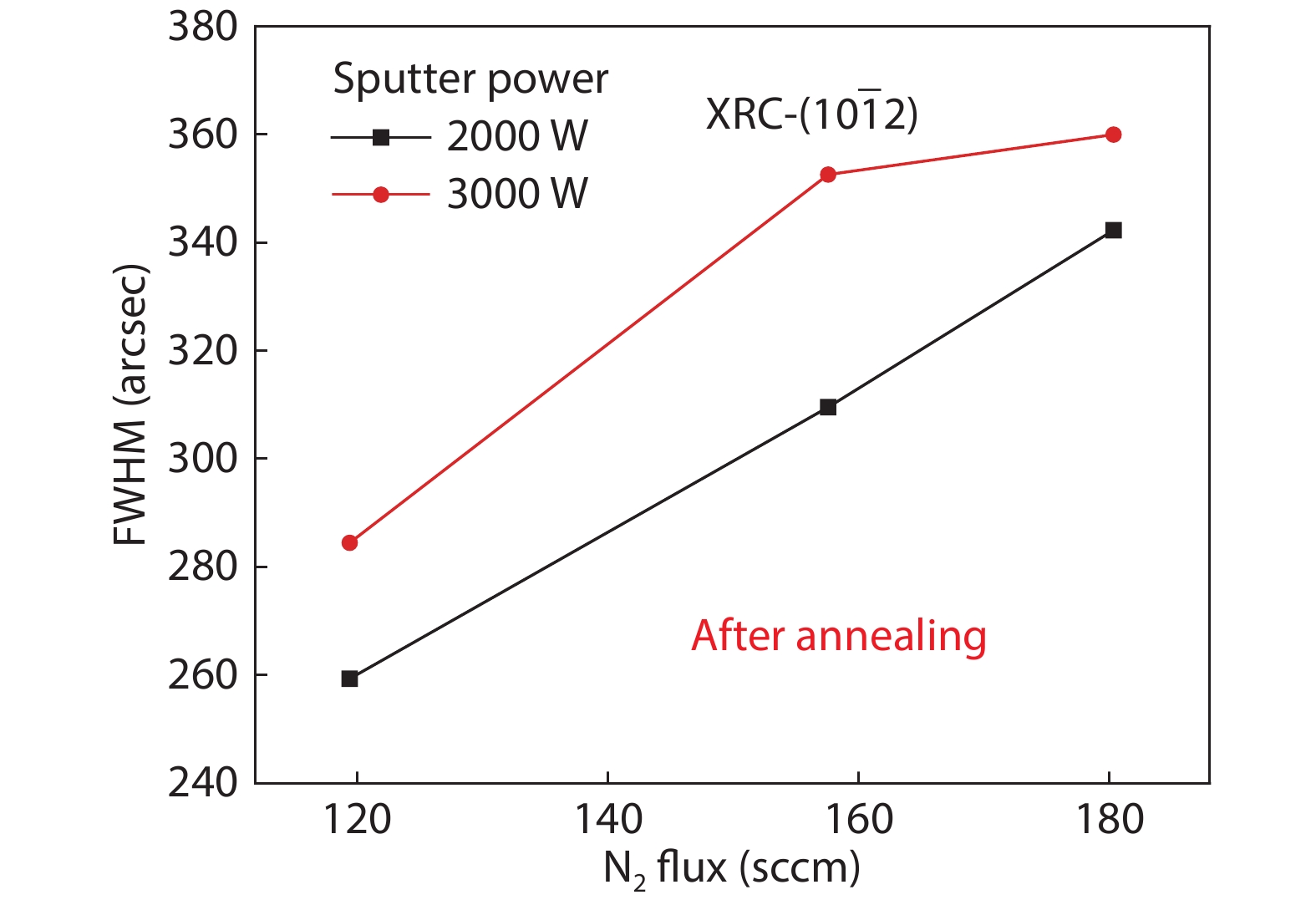

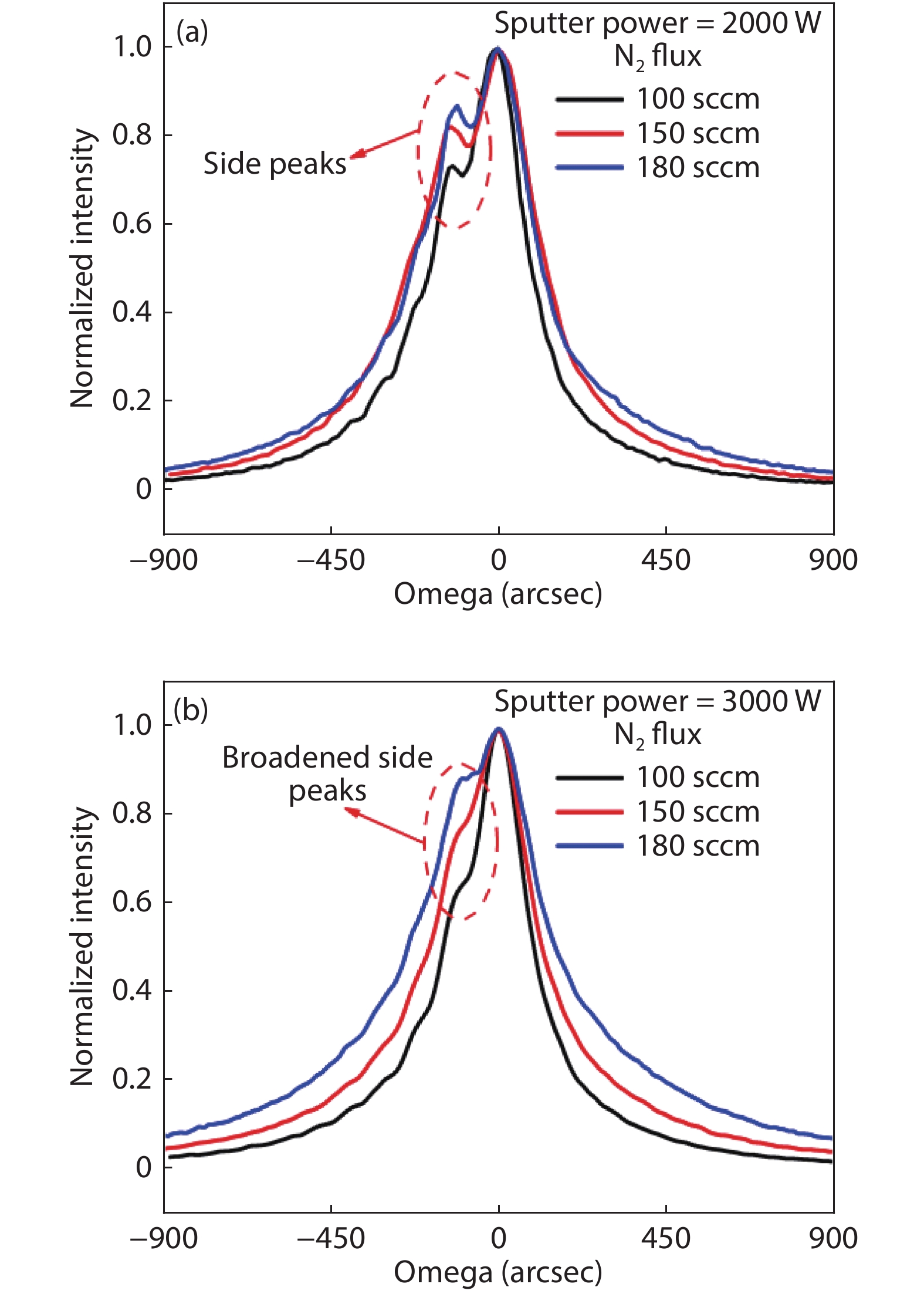

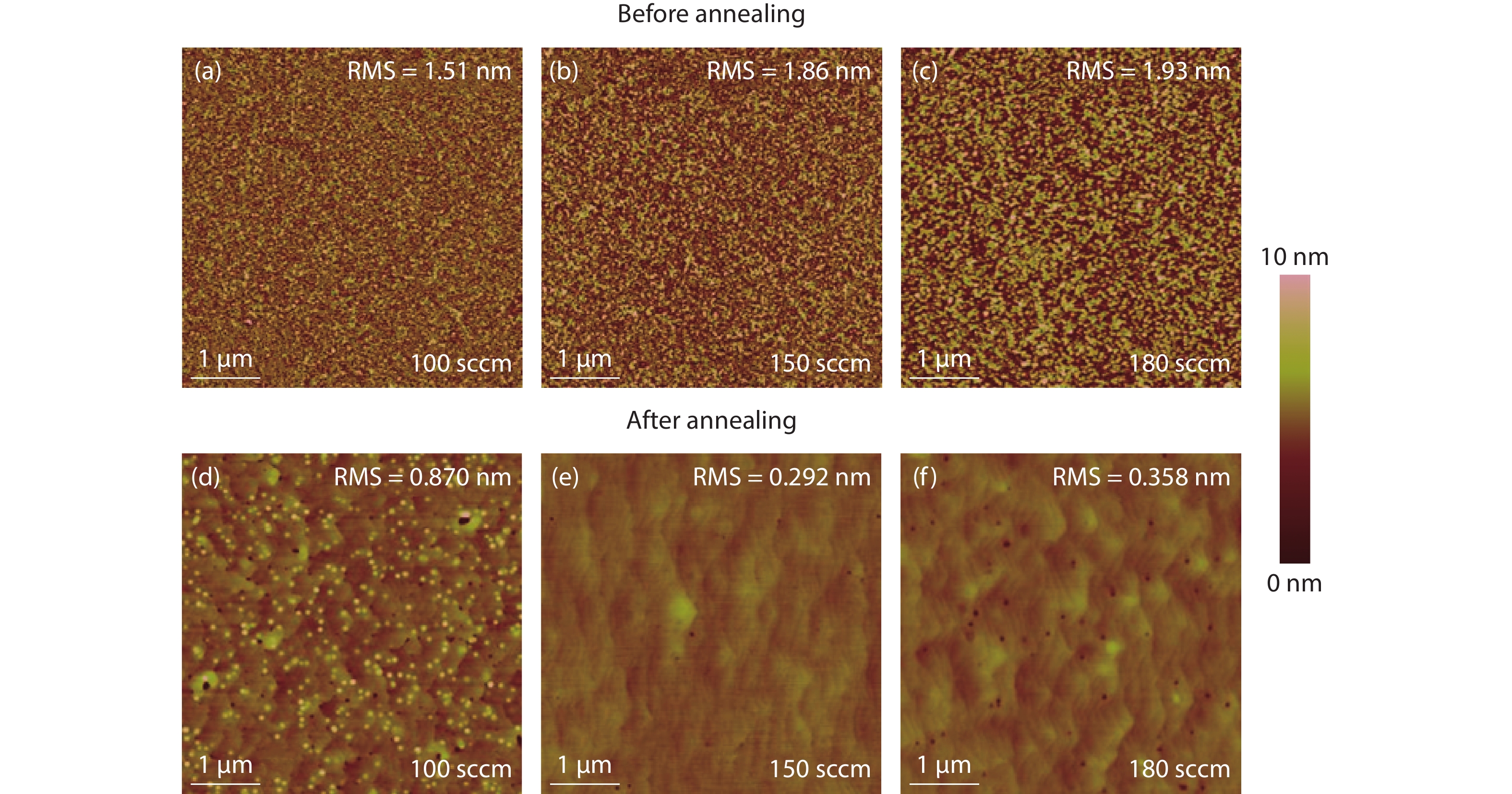

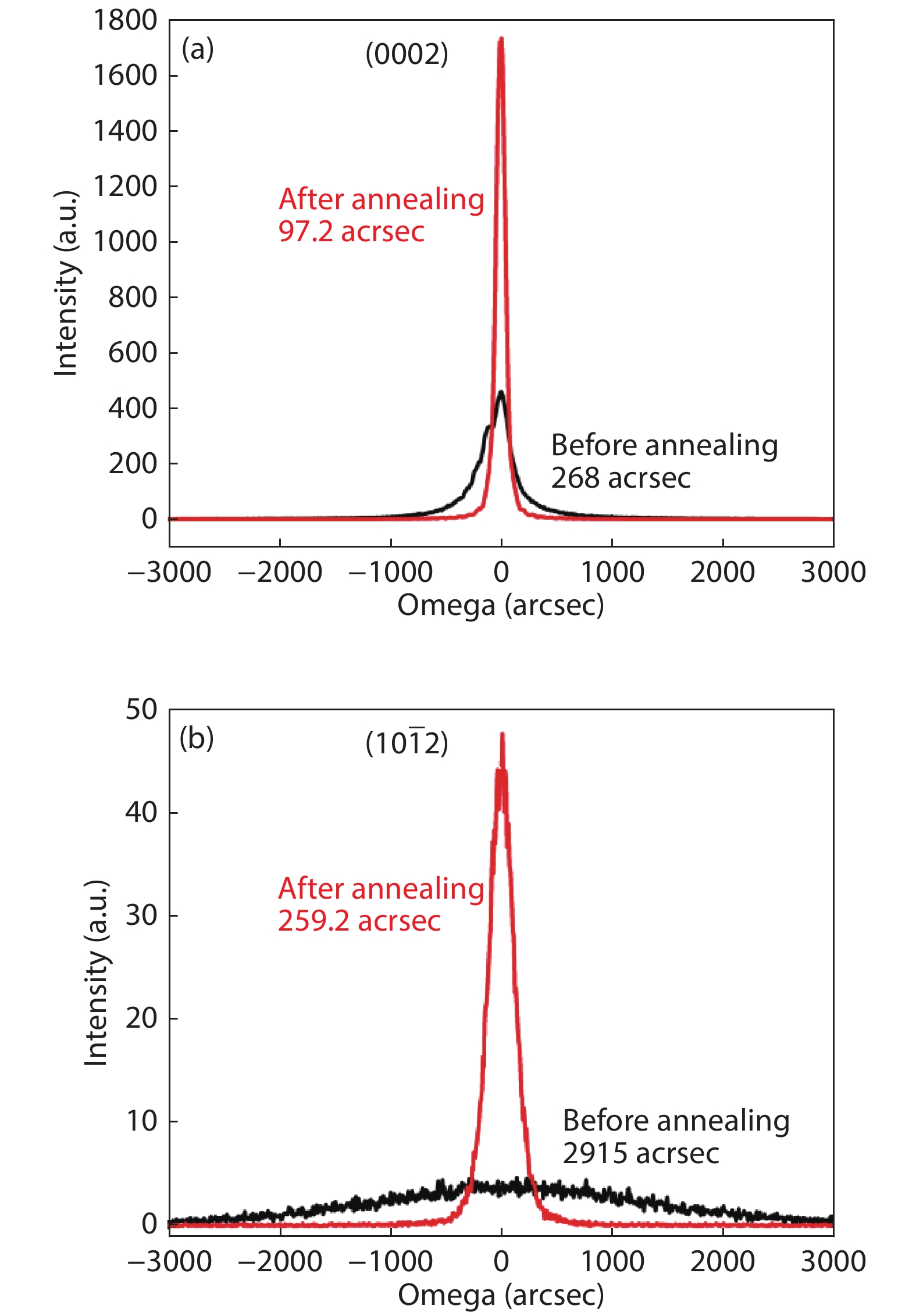

High-quality AlN/sapphire templates were fabricated by the combination of sputtering and high-temperature (HT) annealing. The influence of sputtering parameters including nitrogen flux, radio frequency power, and substrate temperature on the crystalline quality and surface morphology of annealed AlN films were investigated. With lower substrate temperature, lower power, and lower N2 flux, the full width at half maximum of the X-ray rocking curve for AlN (0002) and (10$ \bar {1} $ 2) were improved to 97.2 and 259.2 arcsec after high-temperature annealing. This happens because the increased vacancy concentration of sputtered AlN films can facilitate the annihilation of dislocations by increasing the recovery rate during HT annealing. Step and step-bunching morphologies were clearly observed with optimized sputtering conditions.-

Keywords:

- sputter,

- annealing,

- AlN,

- dislocation density

-

References

[1] Li J M, Liu Z, Liu Z Q, et al. Advances and prospects in nitrides based light-emitting-diodes. J Semicond, 2016, 37, 061001 doi: 10.1088/1674-4926/37/6/061001[2] Wu Z H, Yan J C, Guo Y N, et al. Study of the morphology evolution of AlN grown on nano-patterned sapphire substrate. J Semicond, 2019, 40, 122803 doi: 10.1088/1674-4926/40/12/122803[3] Dong P, Yan J C, Zhang Y, et al. AlGaN-based deep ultraviolet light-emitting diodes grown on nano-patterned sapphire substrates with significant improvement in internal quantum efficiency. J Cryst Growth, 2014, 395, 9 doi: 10.1016/j.jcrysgro.2014.02.039[4] Ehrentraut D, Sitar Z. Advances in bulk crystal growth of AlN and GaN. MRS Bull, 2009, 34, 259 doi: 10.1557/mrs2009.76[5] Dalmau R, Moody B, Schlesser R, et al. Growth and characterization of AlN and AlGaN epitaxial films on AlN single crystal substrates. J Electrochem Soc, 2011, 158, H530 doi: 10.1149/1.3560527[6] Xu F J, Zhang L S, Xie N, et al. Realization of low dislocation density AlN on a small-coalescence-area nano-patterned sapphire substrate. CrystEngComm, 2019, 21, 2490 doi: 10.1039/C8CE01788C[7] Yan J C, Wang J X, Liu N X, et al. High quality AlGaN grown on a high temperature AIN template by MOCVD. J Semicond, 2009, 30, 103001 doi: 10.1088/1674-4926/30/10/103001[8] Yan J C, Wang J X, Zhang Y, et al. AlGaN-based deep-ultraviolet light-emitting diodes grown on High-quality AlN template using MOVPE. J Cryst Growth, 2015, 414, 254 doi: 10.1016/j.jcrysgro.2014.10.015[9] Chen X, Zhang Y, Yan J C, et al. Deep-ultraviolet stimulated emission from AlGaN/AlN multiple-quantum-wells on nano-patterned AlN/sapphire templates with reduced threshold power density. J Alloy Compd, 2017, 723, 192 doi: 10.1016/j.jallcom.2017.06.240[10] Dong P, Yan J C, Wang J X, et al. 282-nm AlGaN-based deep ultraviolet light-emitting diodes with improved performance on nano-patterned sapphire substrates. Appl Phys Lett, 2013, 102, 241113 doi: 10.1063/1.4812237[11] Chen X, Yan J C, Zhang Y, et al. Improved crystalline quality of AlN by epitaxial lateral overgrowth using two-phase growth method for deep-ultraviolet stimulated emission. IEEE Photonics J, 2016, 8, 1 doi: 10.1109/JPHOT.2016.2614102[12] Du Z J, Duan R F, Wei T B, et al. Producing deep UV-LEDs in high-yield MOVPE by improving AlN crystal quality with sputtered AlN nucleation layer. J Semicond, 2017, 38, 113003 doi: 10.1088/1674-4926/38/11/113003[13] Huang C, Wu P, Chang K, et al. High-quality and highly-transparent AlN template on annealed sputter-deposited AlN buffer layer for deep ultra-violet light-emitting diodes. AIP Adv, 2017, 7, 055110 doi: 10.1063/1.4983708[14] Susilo N, Hagedorn S, Jaeger D, et al. AlGaN-based deep UV LEDs grown on sputtered and high temperature annealed AlN/sapphire. Appl Phys Lett, 2018, 112, 041110 doi: 10.1063/1.5010265[15] Wang M X, Xu F J, Xie N, et al. Crystal quality evolution of AlN films via high-temperature annealing under ambient N2 conditions. CrystEngComm, 2018, 20, 6613 doi: 10.1039/C8CE00967H[16] Tanaka S, Shojiki K, Uesugi K, et al. Quantitative evaluation of strain relaxation in annealed sputter-deposited AlN film. J Cryst Growth, 2019, 512, 16 doi: 10.1016/j.jcrysgro.2019.02.001[17] Xiao S Y, Suzuki R, Miyake H, et al. Improvement mechanism of sputtered AlN films by high-temperature annealing. J Cryst Growth, 2018, 502, 41 doi: 10.1016/j.jcrysgro.2018.09.002[18] Kumada T, Ohtsuka M, Takada K, et al. Influence of sputter power and N2 gas flow ratio on crystalline quality of AlN layers deposited at 823 K by RF reactive sputtering. Phys Status Solidi C, 2012, 9, 515 doi: 10.1002/pssc.201100489[19] Miyake H, Lin C H, Tokoro K, et al. Preparation of high-quality AlN on sapphire by high-temperature face-to-face annealing. J Cryst Growth, 2016, 456, 155 doi: 10.1016/j.jcrysgro.2016.08.028[20] Fukuyama H, Miyake H, Nishio G, et al. Impact of high-temperature annealing of AlN layer on sapphire and its thermodynamic principle. Jpn J Appl Phys, 2016, 55, 05FL02 doi: 10.7567/JJAP.55.05FL02[21] Washiyama S, Guan Y, Mita S, et al. Recovery kinetics in high temperature annealed AlN heteroepitaxial films. J Appl Phys, 2020, 127, 115301 doi: 10.1063/5.0002891[22] Kumada T, Ohtsuka M, Fukuyama H. Influence of substrate temperature on the crystalline quality of AlN layers deposited by RF reactive magnetron sputtering. AIP Adv, 2015, 5, 017136 doi: 10.1063/1.4906796[23] Medjani F, Sanjinés R, Allidi G, et al. Effect of substrate temperature and bias voltage on the crystallite orientation in RF magnetron sputtered AlN thin films. Thin Solid Films, 2006, 515, 260 doi: 10.1016/j.tsf.2005.12.145[24] Yang S B, Miyagawa R, Miyake H, et al. Raman scattering spectroscopy of residual stresses in epitaxial AlN films. Appl Phys Express, 2011, 4, 031001 doi: 10.1143/APEX.4.031001[25] Guo Q X, Yahata K, Tanaka T, et al. Low-temperature growth of aluminum nitride on sapphire substrates. J Cryst Growth, 2003, 257, 123 doi: 10.1016/S0022-0248(03)01565-3[26] Zhao L, Yang K, Ai Y J, et al. Crystal quality improvement of sputtered AlN film on sapphire substrate by high-temperature annealing. J Mater Sci: Mater Electron, 2018, 29, 13766 doi: 10.1007/s10854-018-9507-0 -

Proportional views

DownLoad:

DownLoad: