| Citation: |

Yongai Zhang, Tihang Lin, Xiangyao Zeng, Xiongtu Zhou, Tailiang Guo. Fabrication and field emission characteristics of a novel planar-gate electron source with patterned carbon nanotubes for backlight units[J]. Journal of Semiconductors, 2013, 34(6): 064005. doi: 10.1088/1674-4926/34/6/064005

****

Y N G Zhang, T H Lin, X Y Zeng, X T Zhou, T L Guo. Fabrication and field emission characteristics of a novel planar-gate electron source with patterned carbon nanotubes for backlight units[J]. J. Semicond., 2013, 34(6): 064005. doi: 10.1088/1674-4926/34/6/064005.

|

Fabrication and field emission characteristics of a novel planar-gate electron source with patterned carbon nanotubes for backlight units

DOI: 10.1088/1674-4926/34/6/064005

More Information

-

Abstract

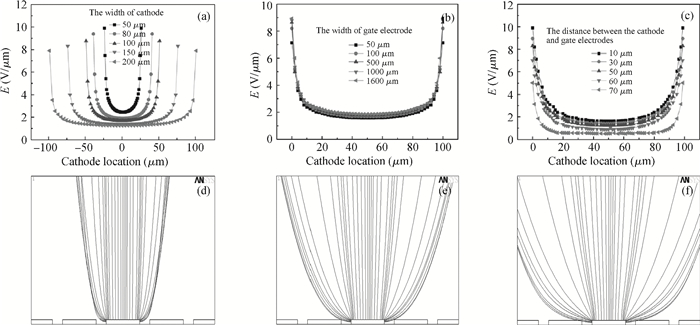

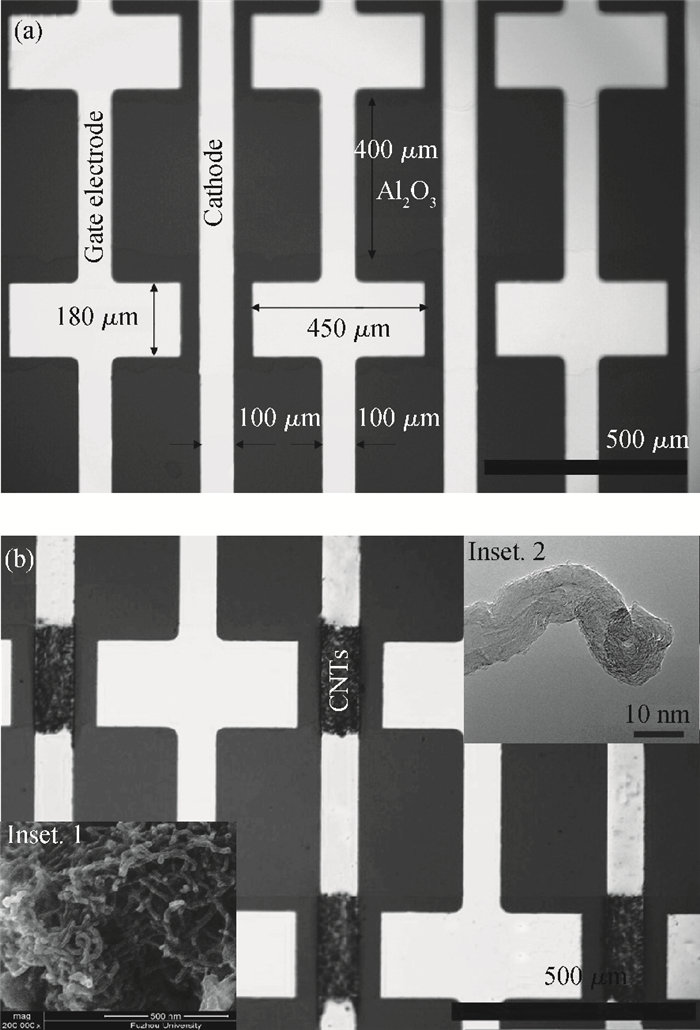

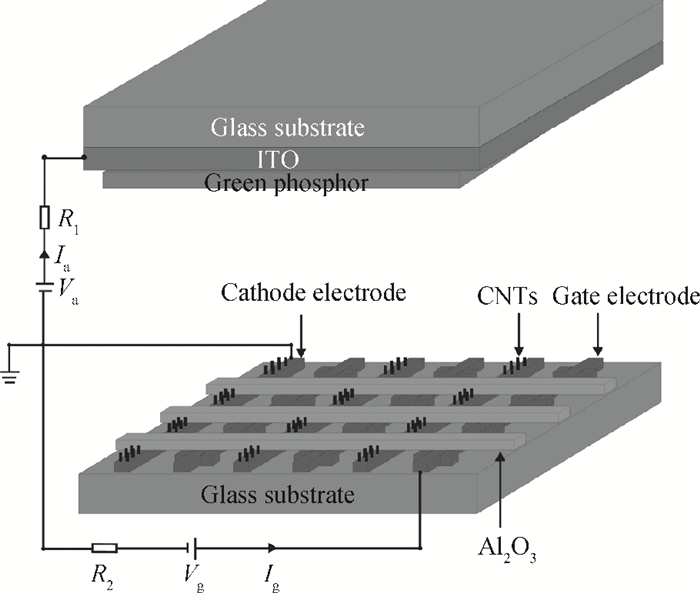

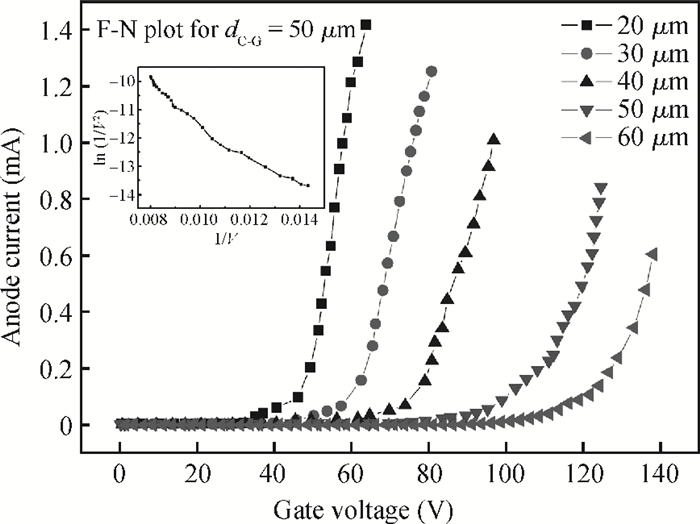

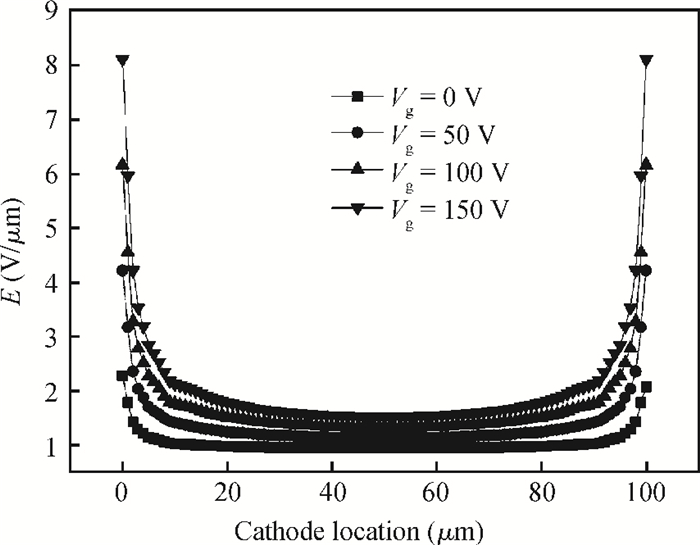

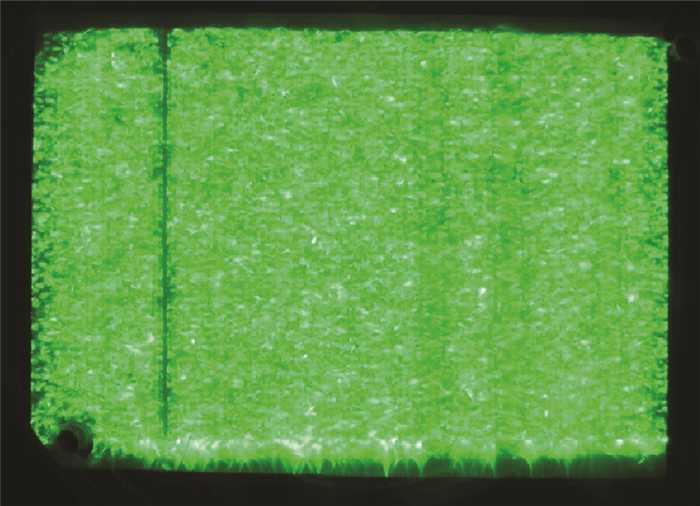

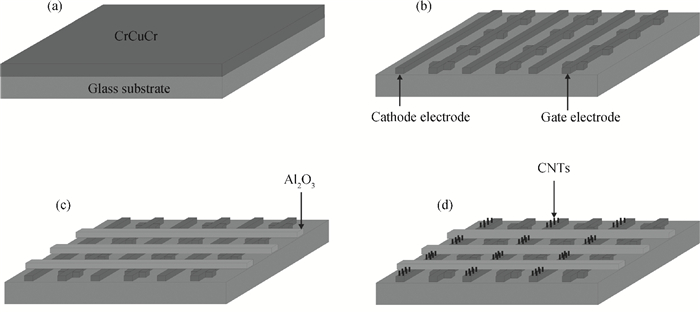

This paper describes the fabrication of backlight units (BLUs) for a liquid crystal display (LCD) based on a novel planar-gate electron source with patterned carbon nanotubes (CNTs) formed by electrophoretic deposition. The electric field distributions and electron trajectories of this triode structure are simulated according to Ansys software. The device structure is optimized by supporting numerical simulation. The field emission results show that the emission current depends strongly on the cathode-gate gap and the gate voltage. Direct observation of the luminous images on a phosphor screen reveals that the electron beams undergo a noticeable expansion along the lateral direction with increasing gate voltage, which is in good agreement with the simulation results. The luminous efficiency and luminance of the fabricated device reaches 49.1 lm/W and 5500 cd/m2, respectively. All results indicate that the novel planar-gate electron source with patterned CNTs may lead to practical applications for an electron source based on a flat lamp for BLUs in LCD.-

Keywords:

- planar-gate triode,

- patterned CNTs,

- simulation,

- field emission,

- BLUs

-

References

[1] De Heer W A, Chatelain A, Ugarte D. A carbon nanotube field-emission electron source. Science, 1995, 270(5239):1179 doi: 10.1126/science.270.5239.1179[2] Iijima S. Helical microtubules of graphitic carbon. Nature, 1991, 354:56 doi: 10.1038/354056a0[3] Xiao X J, Ye Y, Guo T L, et al. Improved filed emission properties of carbon nanotubes by nickel electroplating and corrosion. Journal of Semiconductors, 2012, 33(5):053004 doi: 10.1088/1674-4926/33/5/053004[4] Zhang Y A, Lin J Y, Guo T L, et al. Stable field emission from planar-gate electron source with CNTs by electrophoretic deposition. Solid-State Electron, 2012, 67(1):6 doi: 10.1016/j.sse.2011.08.005[5] Zheng L W, Hu L Q, Guo T L, et al. Improved of the field emission properties carbon nanotubes by CNT/Fe3O4 composite electrophoretic deposition. Journal of Semiconductors, 2012, 32(12):0126001 http://www.jos.ac.cn/bdtxbcn/ch/reader/view_abstract.aspx?file_no=11060101&flag=1[6] Choi W B, Chung D S, Kang J H, et al. Fully sealed, high-brightness carbon-nanotube field-emission display. Appl Phys Lett, 1999, 75(20):3129 doi: 10.1063/1.125253[7] Guo P S, Chen T, Chen Y W, et al. Fabrication of field emission display prototype utilizing printed carbon nanotubes/nanofibers emitters. Solid-State Electron, 2008, 52(6):877 doi: 10.1016/j.sse.2008.01.023[8] Lee S H, Ma C M, Teng C C, et al. The effect of a magnetic field on the graphitization of carbon nanotubes and its application in field emission. Diamond Relat Mater, 2012, 25:111 doi: 10.1016/j.diamond.2012.02.019[9] Choi H Y, Chang W S, Kim H S, et al. Acquisition of X-ray images by using a CNT cold emitter. Phys Lett A, 2006, 357:36 doi: 10.1016/j.physleta.2006.04.015[10] Silan J L, Niemann D L, Ribaya B P, et al. Investigation of carbon nanotube field emitter geometry for increased current density. Solid-State Electron, 2010, 54(12):1543 doi: 10.1016/j.sse.2010.07.004[11] Jung Y J, Son G H, Park J H, et al. Fabrication and properties of under-gated triode with CNT emitter for flat lamp. Diamond Relat Mater, 2005, 14(11/12):2112 http://www.sciencedirect.com/science/article/pii/S0925963505002761[12] Lee J, Jung Y, Song J Y, et al. High-performance field emission from a carbon nanotube carpet. Carbon, 2012, 50(12):3889 http://www.sciencedirect.com/science/article/pii/S0008622312003478[13] Jang E S, Goak J C, Lee H S, et al. Light radiation through a transparent cathode plate with single-walled carbon nanotube field emitters. Appl Surf Sci, 2010, 256(22):6838 doi: 10.1016/j.apsusc.2010.04.098[14] Choi Y C, Lee J W, Lee S K, et al. The high contrast ratio and fast response time of a liquid crystal display lit by a carbon nanotube field emission backlight unit. Nanotechnology, 2008, 19(23):235306 doi: 10.1088/0957-4484/19/23/235306[15] Song M S, Park Y K, Yun J J, et al. Distributed circuit model for cold cathode fluorescent lamps in back-light unit of liquid crystal display. Display, 2010, 31(2):104 doi: 10.1016/j.displa.2010.02.006[16] Huang W, Li J M, Yang L M, et al. Local dimming algorithm and color gamut calibration for RGB LED backlight LCD display. Optics & Laser Technology, 2011, 43(1):214 http://www.sciencedirect.com/science/article/pii/S0030399210001611?via%3Dihub[17] Kim Y C, Kang H S, Cho E, et al. Building a backlight unit with lateral gate structure based on carbon nanotube field emitters. Nanotechnology, 2009, 20(9):095204 doi: 10.1088/0957-4484/20/9/095204[18] Wang F H, Lin T C, Tzeng S D, et al. Field emission properties of carbon nanotube cathodes produced using composite plating. Appl Surf Sci, 2010, 256(24):7600 doi: 10.1016/j.apsusc.2010.06.010[19] Park J H, Son G H, Moon J S, et al. Screen printed carbon nanotube field emitter array for lighting source application. J Vac Sci Technol B, 2005, 23(2):749 doi: 10.1116/1.1851535[20] Cao Y B, Lei W, Liu M, et al. Ion bombardment in a normal-gate FED. Appl Surf Sci, 2005, 243(1-4):19 doi: 10.1016/j.apsusc.2004.06.097[21] Choi Y S, Kang J H, Kim H Y, et al. A simple structure and fabrication of carbon-nanotube field emission display. Appl Surf Sci, 2004, 221(1-4):370 doi: 10.1016/S0169-4332(03)00935-8[22] Zhang Y A, Wu C X, Guo T L, et al. An improved planar-gate triode with CNTs field emitters by electrophoretic deposition. Appl Surf Sci, 2011, 257(8):3259 doi: 10.1016/j.apsusc.2010.10.153[23] Lu W H, Song H, Jin Y X, et al. Electrophoresis deposition and field emission characteristics of planar-gate-type electron source with carbon nanotubes. Physica B, 2008, 403(10/11):1796 http://www.sciencedirect.com/science/article/pii/S0921452607008897[24] Su S H, Chiang W T, Lin C C, et al. Multi-wall carbon nanotubes:purification, morphology and field emission performance. Physica E, 2008, 40(7):2322 doi: 10.1016/j.physe.2007.09.087[25] Fowler R H, Nordheim L W. Electron emission in intense electric field. Proc R Soc Lond A, 1999, 173:1928 -

Proportional views

DownLoad:

DownLoad: