| Citation: |

Aodong He, Bo Liu, Zhitang Song, Yegang Lü, Juntao Li, Weili Liu, Songlin Feng, Guanping Wu. Chemical mechanical planarization of amorphous Ge2Sb2Te5 with a soft pad[J]. Journal of Semiconductors, 2013, 34(7): 076002. doi: 10.1088/1674-4926/34/7/076002

****

A D He, B Liu, Z T Song, Y G Lü, J T Li, W L Liu, S L Feng, G P Wu. Chemical mechanical planarization of amorphous Ge2Sb2Te5 with a soft pad[J]. J. Semicond., 2013, 34(7): 076002. doi: 10.1088/1674-4926/34/7/076002.

|

Chemical mechanical planarization of amorphous Ge2Sb2Te5 with a soft pad

DOI: 10.1088/1674-4926/34/7/076002

More Information

-

Abstract

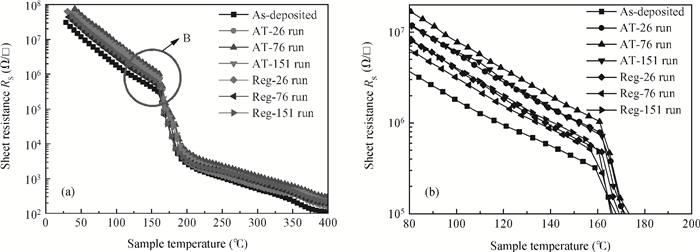

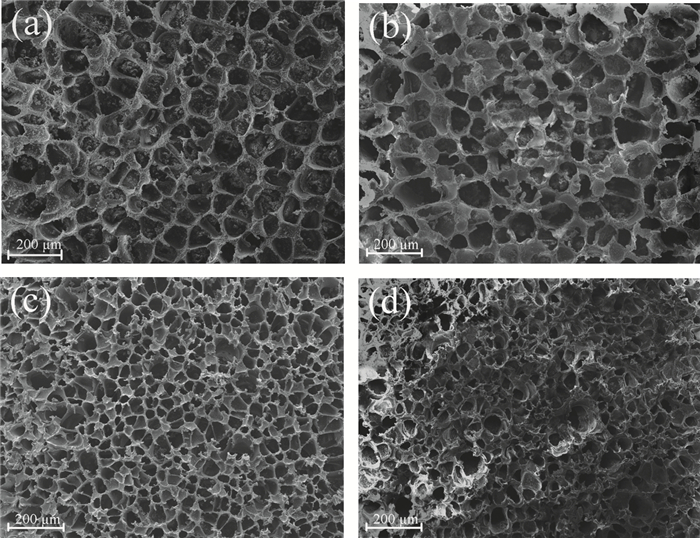

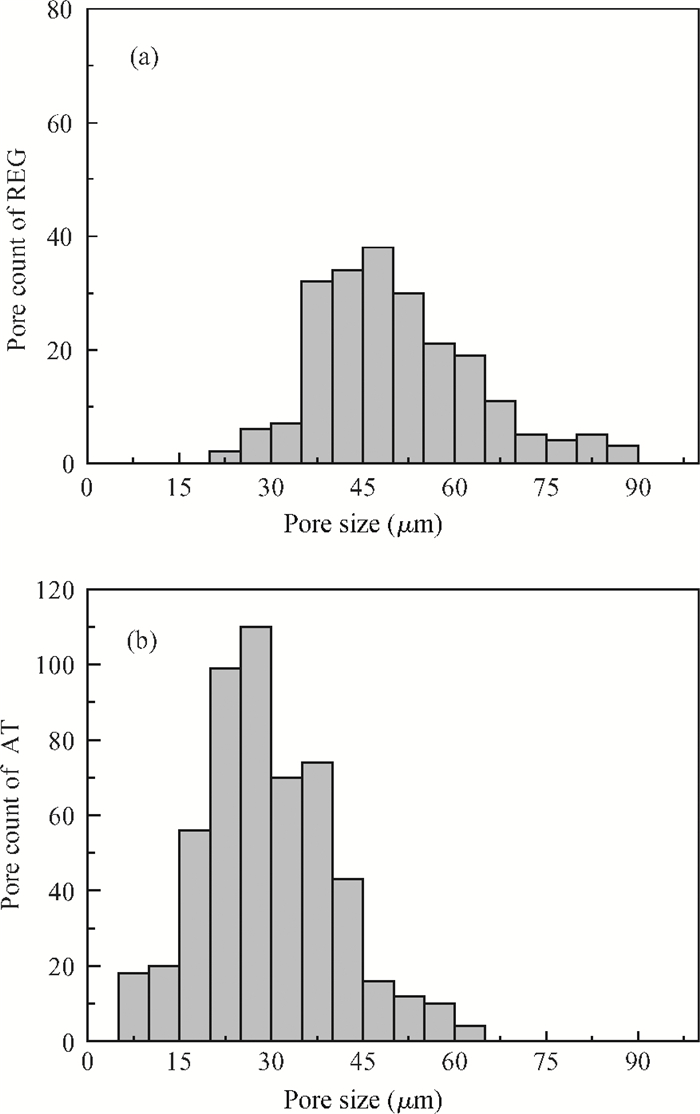

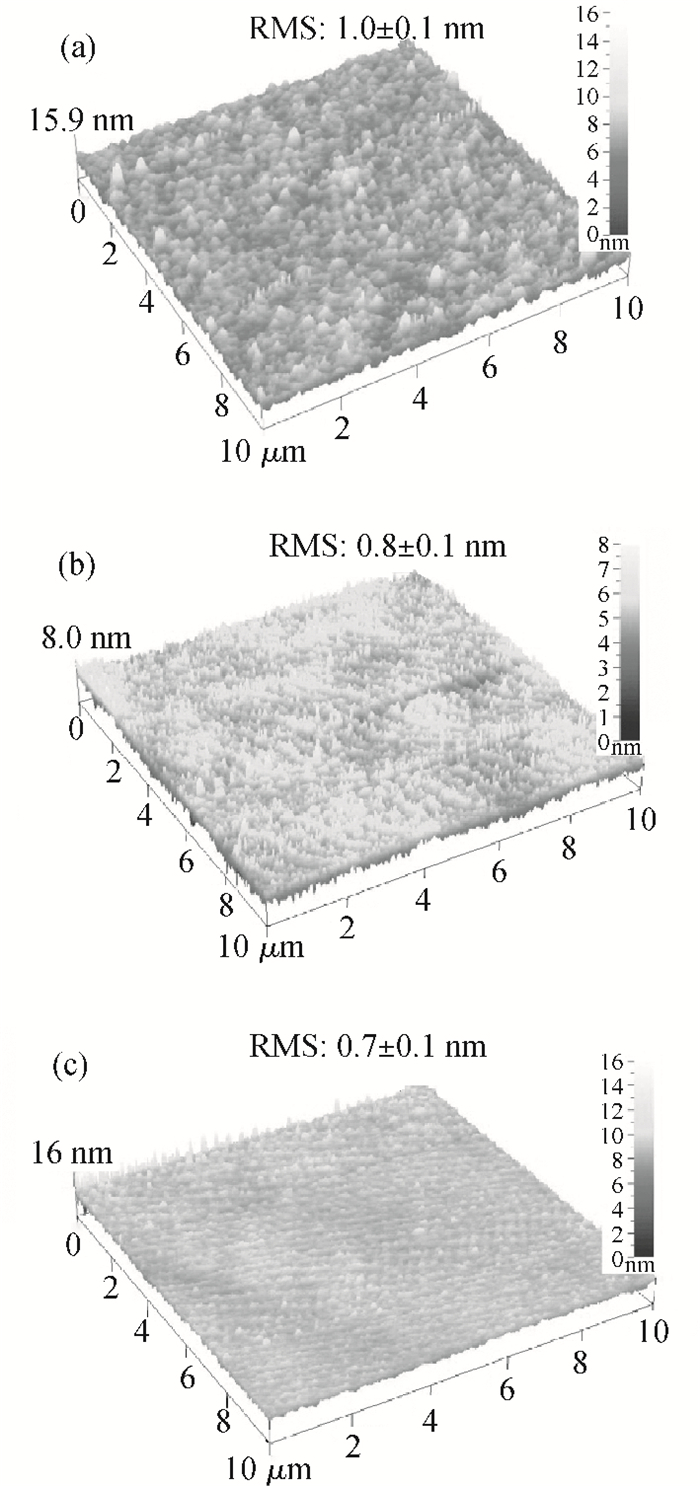

Chemical mechanical planarization (CMP) of amorphous Ge2Sb2Te5 (a-GST) is investigated using two typical soft pads (politex REG and AT) in acidic slurry. After CMP, it is found that the removal rate (RR) of a-GST increases with an increase of runs number for both pads. However, it achieves the higher RR and better surface quality of a-GST for an AT pad. The in-situ sheet resistance (Rs) measure shows the higher Rs of a-GST polishing can be gained after CMP using both pads and the high Rs is beneficial to lower the reset current for the PCM cells. In order to find the root cause of the different RR of a-GST polishing with different pads, the surface morphology and characteristics of both new and used pads are analyzed, it shows that the AT pad has smaller porosity size and more pore counts than that of the REG pad, and thus the AT pad can transport more fresh slurry to the reaction interface between the pad and a-GST, which results in the high RR of a-GST due to enhanced chemical reaction.-

Keywords:

- porosity,

- soft pad,

- chemical mechanical planarization,

- Ge2Sb2Te5

-

References

[1] Raoux S, Burr G W, Breitwisch M J, et al. Phase-change random access memory:a scalable technology. IBM J Res, 2008, 52:465 doi: 10.1147/rd.524.0465[2] Wu Z, Zhang G, Park Y, et al. Controlled recrystallization for low-current RESET programming characteristics of phase-change memory with Ge-doped SbTe. Appl Phys Lett, 2011, 99:143505 doi: 10.1063/1.3641470[3] Liu Q B, Song Z T, Zhang K L, et al. Damascene arrays of phase change memory fabricated with chemical mechanical polishing method. Chin Phys Lett, 2006, 23:2296 doi: 10.1088/0256-307X/23/8/091[4] McGrath J, Davis C. Polishing pad surface characterisation in chemical mechanical planarization. J Mater Process Technol, 2004, 153/154:666 http://cat.inist.fr/?aModele=afficheN&cpsidt=16317422[5] Stavreva Z, Zeidler D, Plotner M. Characteristics in chemical-mechanical polishing of copper:comparison of polishing pads. Appl Surf Sci, 1997, 108:39 doi: 10.1016/S0169-4332(96)00572-7[6] Zhong M, Song Z T, Liu B, et al. Oxidant addition effect on Ge2Sb2Te5 phase change film chemical mechanical polishing. J Electrochem Soc, 2008, 155:929 http://journals.cambridge.org/article_S0884291400030880[7] Cho J Y, Cui H, Park J H, et al. Role of hydrogen peroxide in alkaline slurry on the polishing rate of polycrystalline Ge2Sb2Te5 film in chemical mechanical polishing. Electrochem Solid-State Lett, 2010, 13:H155[8] Yan W X, Wang L Y, Zhang Z F, et al. Chemical mechanical polishing of Ge2Sb2Te5 Using abrasive-free solutions of iron trichloride. Chin Phys Lett, 2012, 29:038301 doi: 10.1088/0256-307X/29/3/038301[9] Penta N K, Matovu J B, Veera1 P R D, et al. Role of polycation adsorption in poly-Si, SiO2and Si3N4 removal during chemical mechanical polishing:Effect of polishing pad surface chemistry. Colloid Surf A-Physicochem Eng Asp, 2011, 388:21 doi: 10.1016/j.colsurfa.2011.07.039[10] Yoon S Y, Lee J H. A study on optimized conditioner for soft pad in Cu barrier removal. ECS Trans, 2011, 34:597 http://ecst.ecsdl.org/content/34/1/597[11] Wang L Y, Song Z T, Zhong M, et al. Mechanism of Ge2Sb2Te5 chemical mechanical polishing. Appl Surf Sci, 2012, 258:5185 doi: 10.1016/j.apsusc.2012.02.001[12] He A D, Wang L Y, Song Z T, et al. Amorphous Ge2Sb2Te5 chemical mechanical planarization using (NH4)2S2O8 or H2O2 as oxidizer in acidic slurry. ECS J Solid-State Sci Technol, 2012, 1:179 doi: 10.1149/2.014204jss[13] Hooper B J, Byrne G, Galligan S. Pad conditioning in chemical mechanical polishing. J Mater Process Technol, 2002, 123:107 doi: 10.1016/S0924-0136(01)01137-2[14] McGrath J, Davis C. Polishing pad surface characterization in chemical mechanical planarization. J Mater Process Technol, 2004, 153/154:666 https://escholarship.org/uc/item/326856vn[15] Bajaj R, Desai M, Jairath R, et al. Effect of polishing pad material properties on chemical mechanical polishing (CMP) processes. Mater Res Soc Symp Proc, 1994, 337:637 doi: 10.1557/PROC-337-637[16] Moon Y, Park I, Dornfeld D A. Investigation of the relationship between Preston's coefficient and friction coefficient in chemical mechanical polishing (CMP) of silicon. Proc Am Soc Precision Eng (ASPE), ASPE Spring Topical Conference on Silicon, Monterey, 1998, 4:78[17] Moon Y, Dornfield D A. Mechanical properties and relationship to process performance of the polishing pad in chemical mechanical polishing (CMP) of silicon. Proc Am Soc Precision Eng (ASPE), ASPE Spring Topical Conference on Silicon, Monterey, 1998, 4:83 -

Proportional views

DownLoad:

DownLoad: