| Citation: |

Song Li, Chuanbin Zeng, Jiajun Luo, Zhengsheng Han. The abnormal electrostatic discharge of a no-connect metal cover in a ceramic packaging device[J]. Journal of Semiconductors, 2013, 34(8): 084007. doi: 10.1088/1674-4926/34/8/084007

****

S Li, C B Zeng, J J Luo, Z S Han. The abnormal electrostatic discharge of a no-connect metal cover in a ceramic packaging device[J]. J. Semicond., 2013, 34(8): 084007. doi: 10.1088/1674-4926/34/8/084007.

|

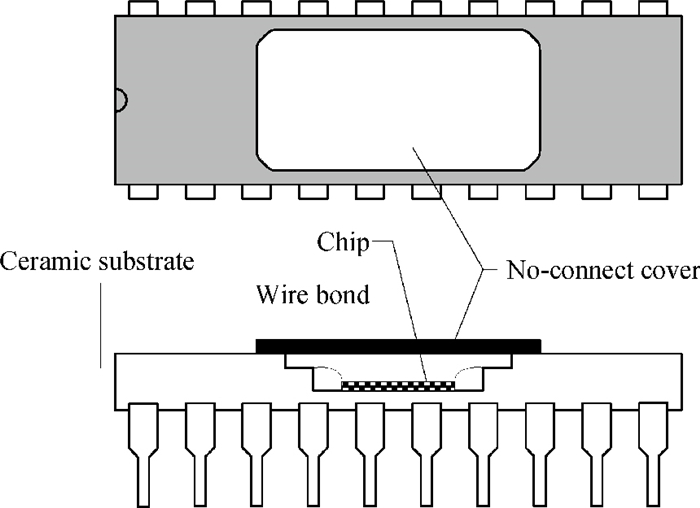

The abnormal electrostatic discharge of a no-connect metal cover in a ceramic packaging device

DOI: 10.1088/1674-4926/34/8/084007

More Information

-

Abstract

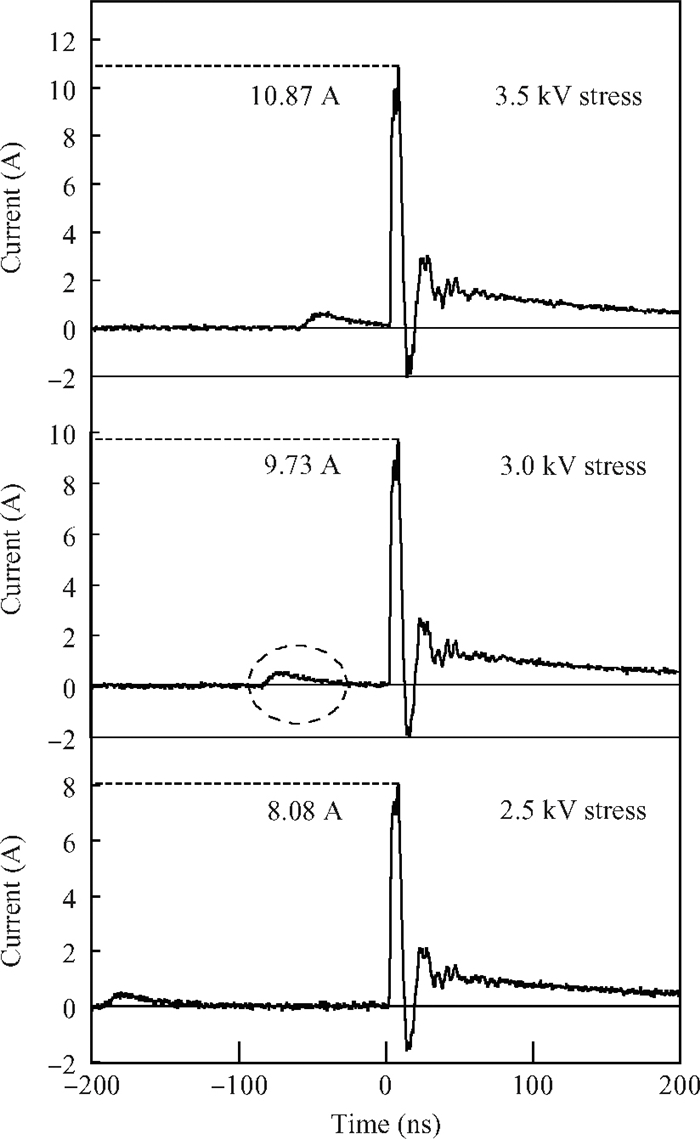

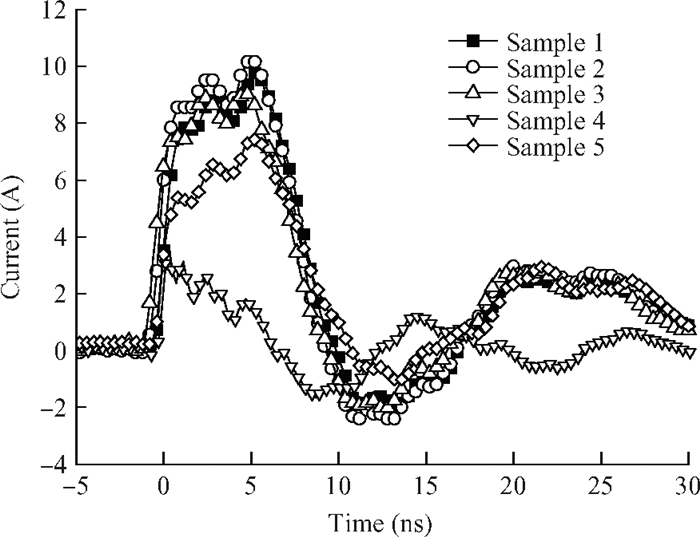

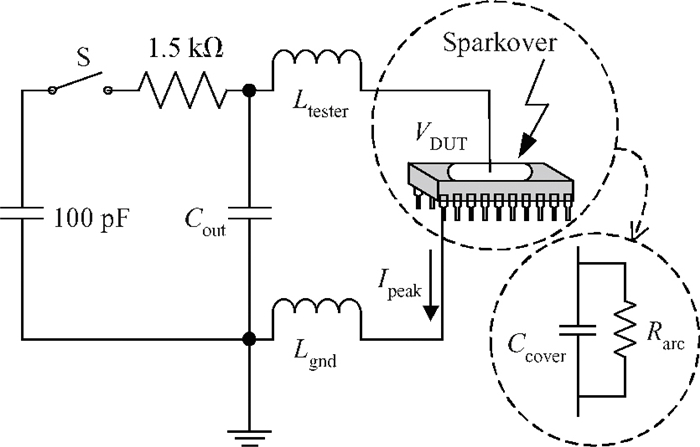

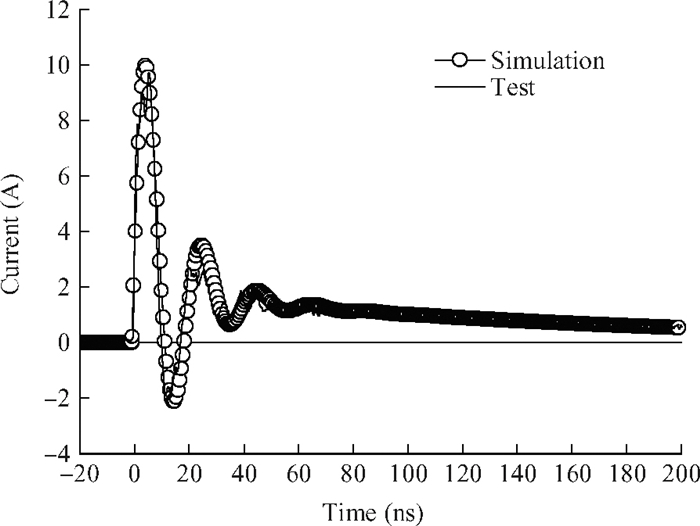

The human body model (HBM) stress of a no-connect metal cover is tested to obtain the characteristics of abnormal electrostatic discharge, including current waveforms and peak current under varied stress voltage and device failure voltage. A new discharge model called the "sparkover-induced model" is proposed based on the results. Then, failure mechanism analysis and model simulation are performed to prove that the transient peak current caused by a sparkover of low arc impedance will result in the devices' premature damage when the potential difference between the no-connect metal cover and the chip exceeds the threshold voltage of sparkover. -

References

[1] Fang R, Wang J, Huang L, et al. The development of electronic packaging. Science & Technology Association Forum, 2012, (2):84[2] Inspection criteria for microelectronic packages and covers. JEDEC Solid State Technology Association, May 2011[3] MIL-STD-883H. Departments and Agencies of the Department of Defense, February 2010[4] ESDA/JEDEC joint standard for electrostatic discharge sensitivity testing-human body model (HBM)-component level. ESD Association & JEDEC Solid State Technology Association, November 2011[5] Wen Y L, Ming D K. Abnormal ESD failure mechanism in high-pin-count BGA packaged ICs due to stressing nonconnected balls. IEEE Trans Device Mater Reliab, 2004, 4(1):24 doi: 10.1109/TDMR.2004.824362[6] Kunz H, Duvvury C, Brodsky J, et al. HBM stress of no-connect IC pins and subsequent arc-over events that lead to human-metal-discharge-like events into unstressed neighbor pins. Electrical Overstress/Electrostatic Discharge Symposium, 2006 https://www.infona.pl/resource/bwmeta1.element.ieee-art-000005256807[7] Kaschani K T, Schimon M, Hofmann M, et al. ESD damage due to HBM stressing of non-connected pins. Electrical Overstress/Electrostatic Discharge Symposium, 2006 http://ieeexplore.ieee.org/document/5256806/keywords[8] ESD association technical report for the protection of electrostatic discharge susceptible items-human metal model (HMM). Electrostatic Discharge Association, 2009[9] IEC 61000-4-2: electromagnetic compatibility(emc)-part 4-2: testing and measurement techniques-electrostatic discharge immunity test. IEC International Standard, 2008[10] Field-induced charged-device model test method for electrostatic-discharge-withstand thresholds of microelectronic components. JEDEC Solid State Technology Association, December 2009[11] ESD association standard for electrostatic discharge sensitivity testing-charged device model (CDM)-component level. Electrostatic Discharge Association, July 2009[12] Muhonen K, Peachey N, Testin A. Human metal model (HMM) testing, challenges to using ESD guns. Electrical Overstress/Electrostatic Discharge Symposium, 2009 https://www.infona.pl/resource/bwmeta1.element.ieee-art-000005340100[13] Karp J, Kireev V, Tsaggaris D, et al. Effect of flip-chip package parameters on CDM discharge. Electrical Overstress/Electrostatic Discharge Symposium, 2008 http://ieeexplore.ieee.org/document/4772108/authors -

Proportional views

DownLoad:

DownLoad: