| Citation: |

Suohui Ma, Shengli Wang, Yuling Liu, Chenwei Wang, Yan Yang. Alkaline barrier slurry applied in TSV chemical mechanical planarization[J]. Journal of Semiconductors, 2014, 35(2): 026002. doi: 10.1088/1674-4926/35/2/026002

****

S H Ma, S L Wang, Y L Liu, C W Wang, Y Yang. Alkaline barrier slurry applied in TSV chemical mechanical planarization[J]. J. Semicond., 2014, 35(2): 026002. doi: 10.1088/1674-4926/35/2/026002.

|

Alkaline barrier slurry applied in TSV chemical mechanical planarization

DOI: 10.1088/1674-4926/35/2/026002

More Information

-

Abstract

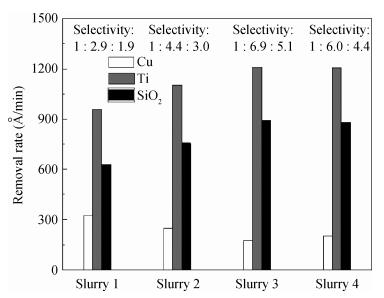

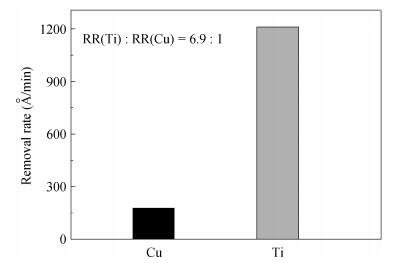

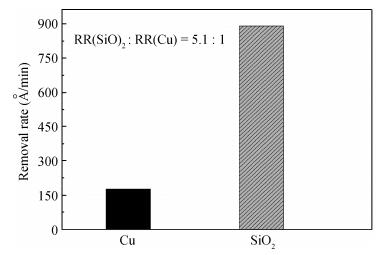

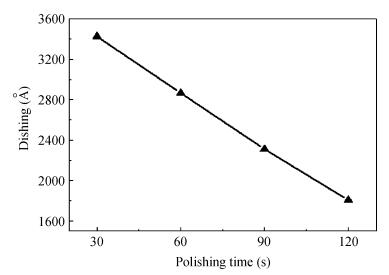

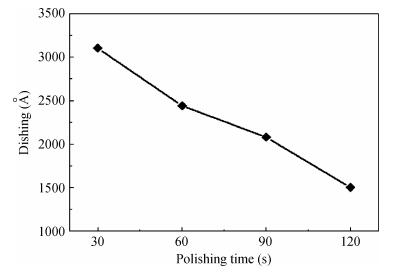

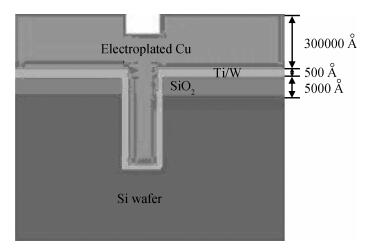

We have proposed a TSV (through-silicon-via) alkaline barrier slurry without any inhibitors for barrier CMP (chemical mechanical planarization) and investigated its CMP performance. The characteristics of removal rate and selectivity of Ti/SiO2/Cu were investigated under the same process conditions. The results obtained from 6.2 mm copper, titanium and silica show that copper has a low removal rate during barrier CMP by using this slurry, and Ti and SiO2 have high removal rate selectivity to Cu. Thus it may be helpful to modify the dishing. The TSV wafer results reveal that the alkaline barrier slurry has an obvious effect on surface topography correction, and can be applied in TSV barrier CMP.-

Keywords:

- TSV,

- alkaline barrier slurry,

- removal rate,

- selectivity,

- dishing

-

References

[1] Wu X D. Research status of through silicon via interconnection for 3D integration technology. Electron Packag, 2012, 12(9):1 http://en.cnki.com.cn/Article_en/CJFDTOTAL-DYFZ201209002.htm[2] Gao S, Kwong D L. 3D IC integration with TSV current progress and future outlook. Institute of Microelectronics, 2010, 9:1[3] Ramaswami S, Director S. Recent advances in TSV processing technology. Silicon Systems Group, 2010[4] Sun S M. The study on CMP slurry of titaium nitride barrier. Electronic Design Engineering, 2011, 19(16):190 http://en.cnki.com.cn/Article_en/CJFDTOTAL-GWDZ201116066.htm[5] Seo Y J, Lee W S. Effects of oxidant additives for exact selectivity control of W and Ti CMP process. Microelectron Eng, 2005, 77:132 doi: 10.1016/j.mee.2004.10.003[6] Chiu Y S, Wang Y L, Liu C P, et al. The application of electrochemical metrologies for investigating chemical mechanical polishing of Al with a Ti barrier layer. Mater Chem Phys, 2003, 82:444 doi: 10.1016/S0254-0584(03)00312-2[7] Tsai T C, Tsao W C, Lin W, et al. CMP process development for the via-middle 3D TSV applications at 28 nm. Microelectron Eng, 2012, 92:29 doi: 10.1016/j.mee.2011.03.004[8] Rhoades R L. CMP for TSV's. Presentation for AVS Joint Meeting, 2011[9] Hsu A. TSV CMP technology, market, & challenges. Anji Microelectronics Corp, 2012[10] Wang C W, Liu Y L, Tian J X, et al. A study on the comparison of CMP performance between a novel alkaline slurry and a commercial slurry for barrier removal. Microelectron Eng, 2012, 98:29 doi: 10.1016/j.mee.2012.05.028[11] Jacqueline J P, Alone E, Yalicheff C, et al. TaN/Ta belayed barrier characteristics and integration for 90 and 65 nm nodes. Microelectron Eng, 2005, 82(3/4):613 http://www.sciencedirect.com/science/article/pii/S016793170500403X[12] Zantye P B, Kumar A, Sikder A K. Chemical mechanical planarization for microelectronics applications. Mater Sci Eng, 2004, 45:89 doi: 10.1016/j.mser.2004.06.002[13] Chang S H. A dishing model for chemical mechanical polishing of metal interconnects structures. Microelectron Eng, 2005, 77(7):76[14] Wang C W, Liu Y L, Niu X H, et al. An advanced alkaline slurry for barrier chemical mechanical planarization on patterned wafers. Journal of Semiconductors, 2012, 33(4):046001 doi: 10.1088/1674-4926/33/4/046001 -

Proportional views

DownLoad:

DownLoad: