| Citation: |

Bo Duan, Jianwei Zhou, Yuling Liu, Chenwei Wang, Yufeng Zhang. Investigation on surface roughness in chemical mechanical polishing of TiO2 thin film[J]. Journal of Semiconductors, 2014, 35(6): 063003. doi: 10.1088/1674-4926/35/6/063003

****

B Duan, J W Zhou, Y L Liu, C W Wang, Y F Zhang. Investigation on surface roughness in chemical mechanical polishing of TiO2 thin film[J]. J. Semicond., 2014, 35(6): 063003. doi: 10.1088/1674-4926/35/6/063003.

|

Investigation on surface roughness in chemical mechanical polishing of TiO2 thin film

DOI: 10.1088/1674-4926/35/6/063003

More Information

-

Abstract

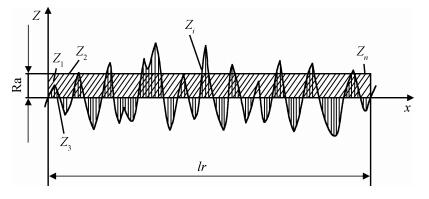

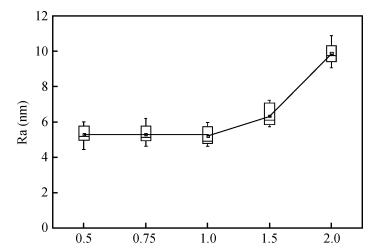

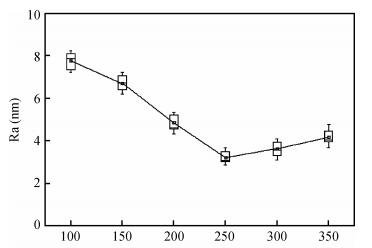

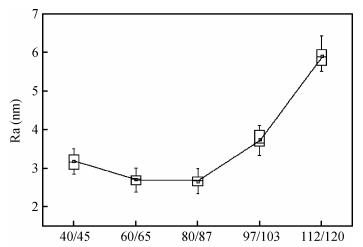

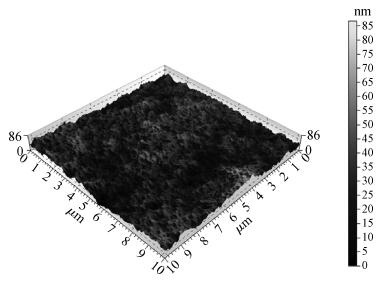

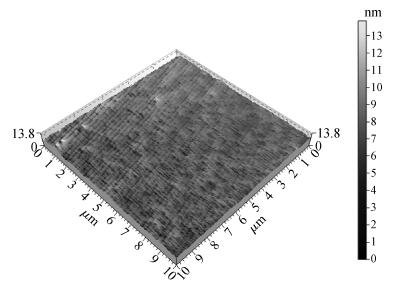

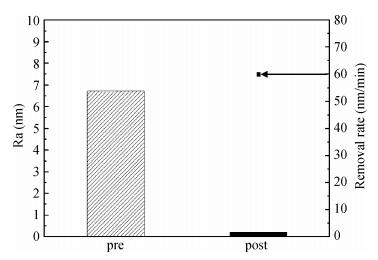

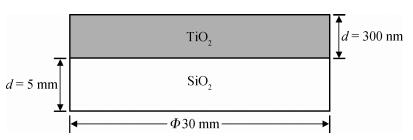

Surface roughness by peaks and depressions on the surface of titanium dioxide (TiO2) thin film, which was widely used for an antireflection coating of optical systems, caused the extinction coefficient increase and affected the properties of optical system. Chemical mechanical polishing (CMP) is a very important method for surface smoothing. In this polishing experiment, we used self-formulated weakly alkaline slurry. Other process parameters were working pressure, slurry flow rate, head speed, and platen speed. In order to get the best surface roughness (1.16 Å, the scanned area was 10×10 μm2) and a higher polishing rate (60.8 nm/min), the optimal parameters were:pressure, 1 psi; slurry flow rate, 250 mL/min; polishing head speed, 80 rpm; platen speed, 87 rpm.-

Keywords:

- TiO2 thin film,

- surface roughness,

- CMP,

- process parameters

-

References

[1] Callback K, Sikora M, Kapusta C, et al. X-ray absorption and emission spectroscopy of TiO2 thin films with modified anionic sublattice. Radiation Physics and Chemistry, 2013, 93:40 doi: 10.1016/j.radphyschem.2013.03.035[2] Gioti M, Logothetidis S, Charitidis C, et al. On the properties and functionality of ultra-thin diamond related protective coatings used in optical systems. Sensors and Actuators A:Physical, 2002, 99:35 doi: 10.1016/S0924-4247(01)00887-1[3] Pareek R, Joshi A S, Gupta P D, et al. Sol-gel based anti-reflection coatings on wedged laser rods using a spin coater. Opt Laser Technol, 2005, 37:369 doi: 10.1016/j.optlastec.2004.05.005[4] Szczyrbowski J, Bräuer G, Teschner G, et al. Large-scale antireflective coatings on glass produced by reactive magnetron sputtering. Surf Coatings Technol, 1998, 98:1460 doi: 10.1016/S0257-8972(97)00151-5[5] Wang Wuyu, Wang Xijing, Yang Taili. Review on optoelectronic properties and applications of TiO2 films. Chinese Journal of Rare Metals, 2008, 32(6):781[6] Li F, Ni X. Improving poly(3-hexylthiophene)-TiO2 heterojunction solar cells by connecting polypyrrole to the TiO2 nanorods. Solar Energy Materials and Solar Cells, 2013, 118:109 doi: 10.1016/j.solmat.2013.08.012[7] Pei Z J, Fisher G R, Bhagavat M, et al. A grinding-based manufacturing method for silicon wafer:an experimental investigation. International Journal of Machine Tools and Manufacture, 2005, 45(10):1140 doi: 10.1016/j.ijmachtools.2004.12.006[8] Zhou L, Hosseini B S, Tsuruga T, et al. Fabrication and evaluation for extremely thin Si wafer. International Journal of Abrasive Technology, 2007, 1(1):94 doi: 10.1504/IJAT.2007.013852[9] Yin Kangda, Wang Shengli, Liu Yuling, et al. Evaluation of planarization capability of copper slurry in the CMP process. Journal of Semiconductors, 2013, 34(3):036002 doi: 10.1088/1674-4926/34/3/036002[10] Wang Chenwei, Liu Yuling, Tian Jianyin, et al. Planarization properties of an alkaline slurry without an inhibitor on copper patterned wafer CMP. Journal of Semiconductors, 2012, 33(11):116001 doi: 10.1088/1674-4926/33/11/116001[11] Liu Yuling, Zhang Kailiang, Wang Fang, et al. Investigation on the final polishing slurry and technique of silicon substrate in ULSI. Microelectron Eng, 2003, 66:438 doi: 10.1016/S0167-9317(02)00908-5[12] Wang Chenwei, Liu Yuling, Tian Jianying, et al. A study on the comparison of CMP performance between a novel alkaline slurry and a commercial slurry for barrier removal. Microelectron Eng, 2012, 98:29 doi: 10.1016/j.mee.2012.05.028[13] Wei Wenhao, Liu Yuling, Wang Chenwei, et al. Study of a novel alkaline barrier slurry applied in copper chemical mechanical planarization. J Func Mater, 2012, 43(23):3333[14] Liu Yuling, Jia Yingqian. Used for large scale integrated circuit wiring multilayer tungsten plug in polishing slurry. China Patent, No. 200610013976. 8. 2006. 11. 08[15] Liu Yuling, Zhang Kailiang, Li Weiwei. Very large scale integrated circuit of multilayer copper wiring copper and tantalum in the CMP polishing slurry. China Patent, No. 2116761. 3. 2003. 03. 05 -

Proportional views

DownLoad:

DownLoad: