| Citation: |

Yixuan Fan, Le Huang, Dechao Geng, Wenping Hu. Controlled growth of Mo2C pyramids on liquid Cu surface[J]. Journal of Semiconductors, 2020, 41(8): 082001. doi: 10.1088/1674-4926/41/8/082001

****

Y X Fan, L Huang, D C Geng, W P Hu, Controlled growth of Mo2C pyramids on liquid Cu surface[J]. J. Semicond., 2020, 41(8): 082001. doi: 10.1088/1674-4926/41/8/082001.

|

Controlled growth of Mo2C pyramids on liquid Cu surface

DOI: 10.1088/1674-4926/41/8/082001

More Information

-

Abstract

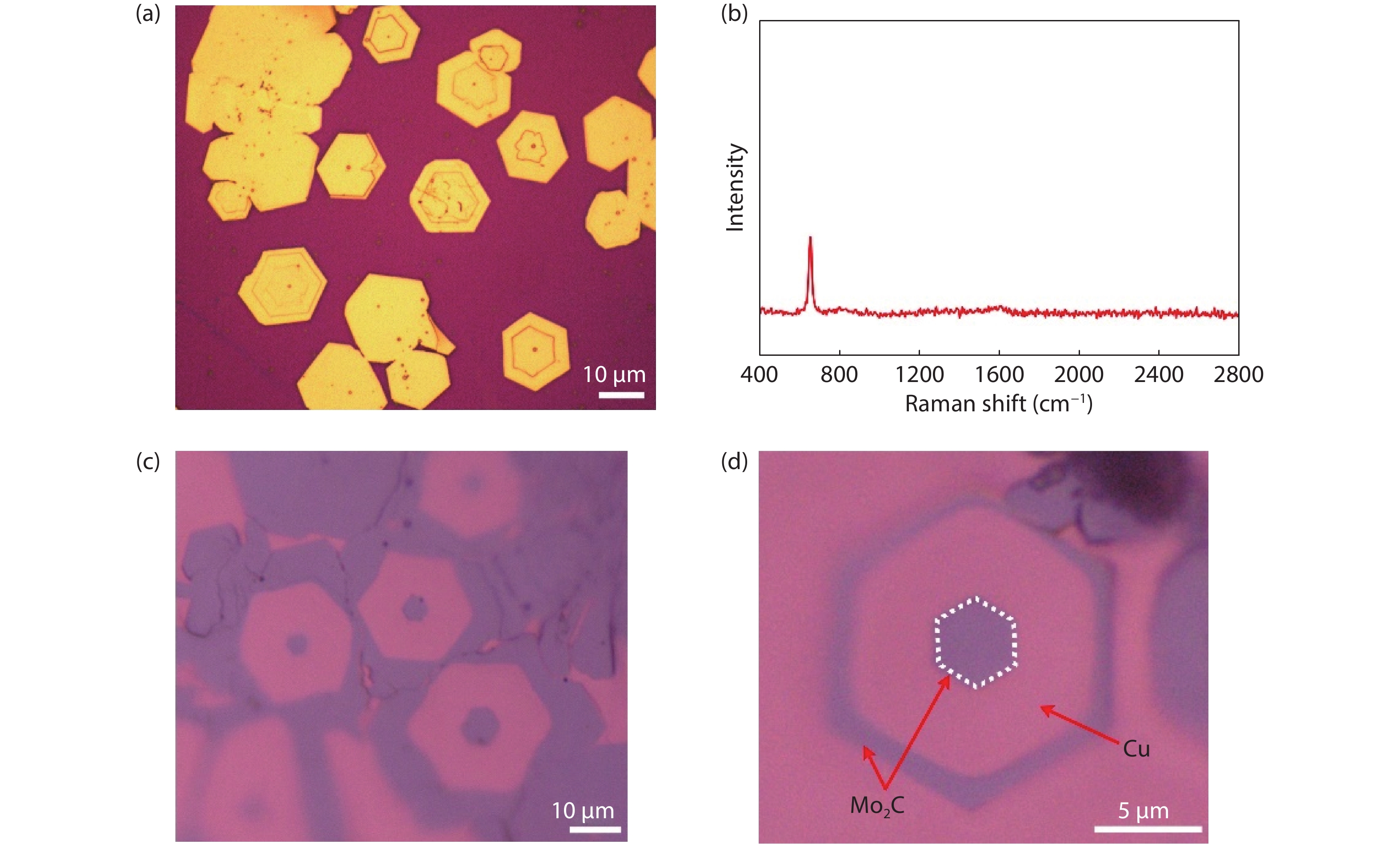

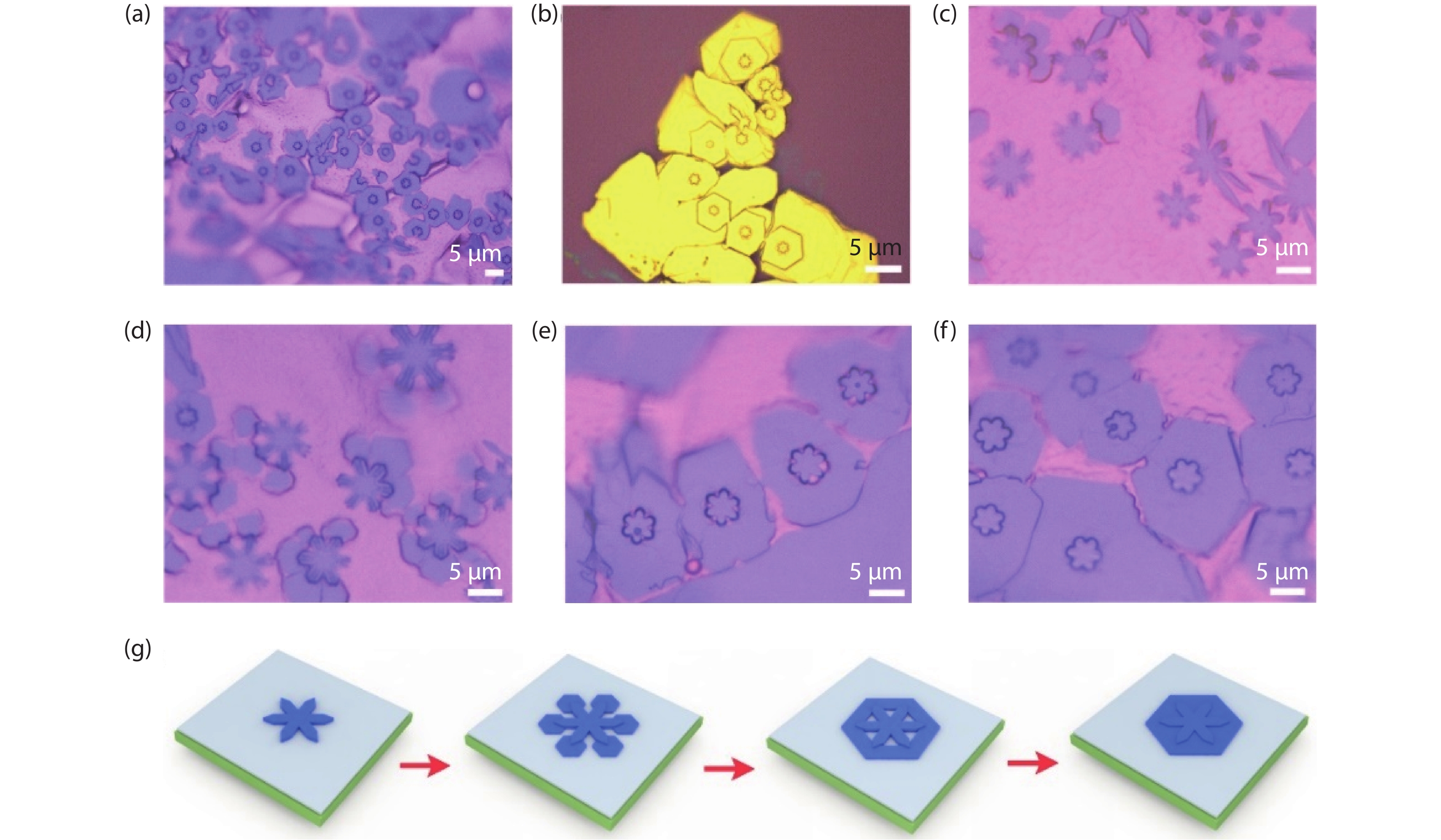

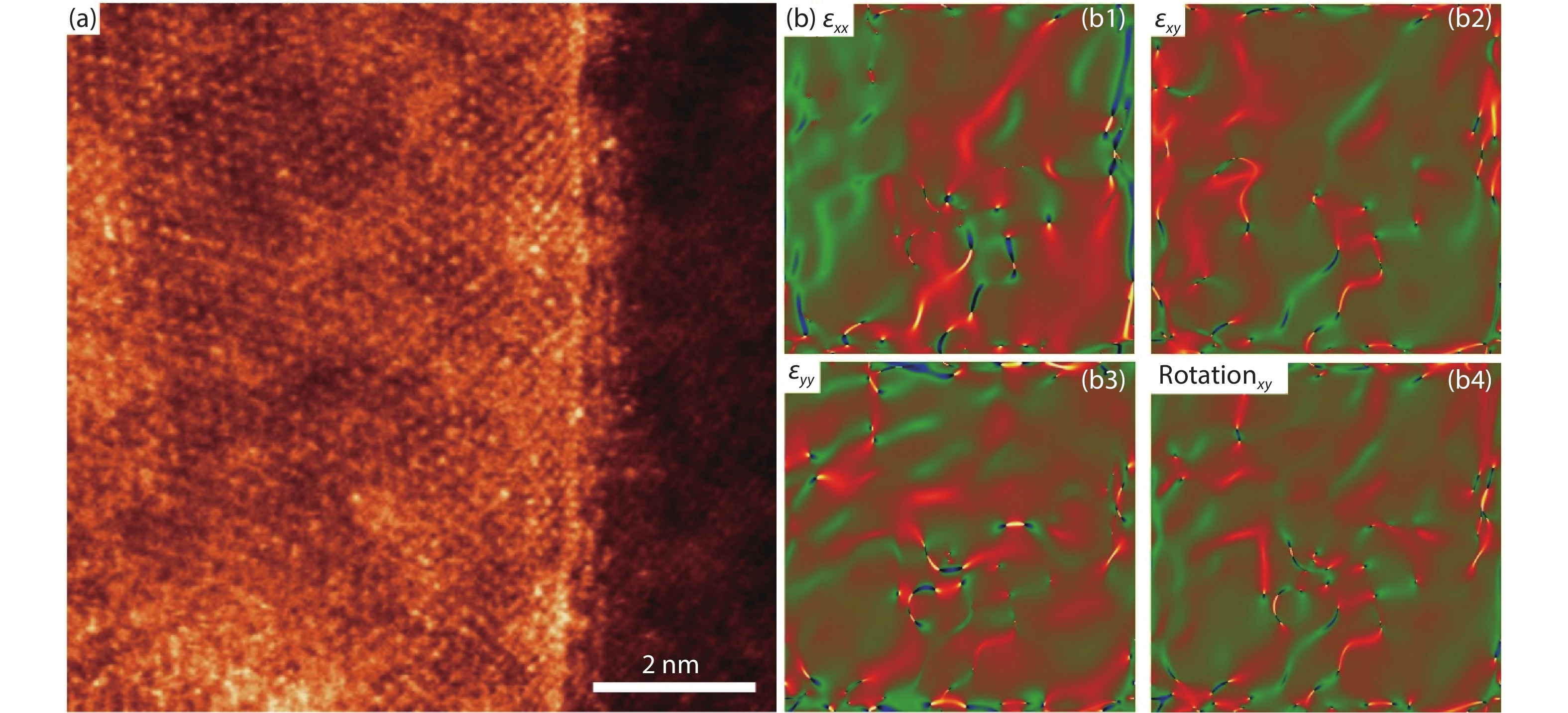

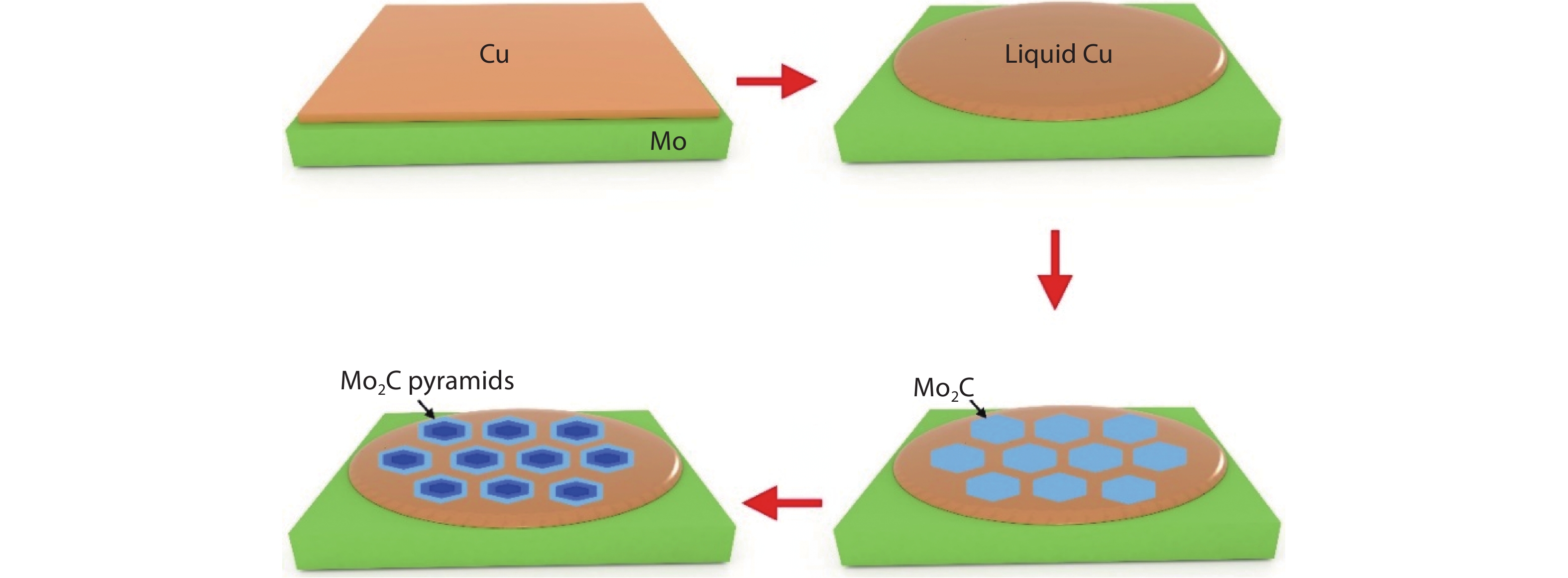

Precise spatial control of 2D materials is the key capability of engineering their optical, electronic, and mechanical properties. However, growth of novel 2D Mo2C on Cu surface by chemical vapor deposition method was revealed to be seed-induced 2D growth, limiting further synthesis of complex Mo2C spatial structures. In this research, we demonstrate the controlled growth of Mo2C pyramids with numerous morphologies, which are characterized with clear terraces within the structures. The whole evolution for Mo2C pyramids in the coursed of CVD process has been detected, posing significant potential in probing growth mechanism. The formation of the Mo2C pyramids arises from the supersaturation-induced nucleation and concentration-gradient driven diffused growth of a new Mo2C layer on the edged areas of intrinsic ones, as supported by STEM imaging. This work provides a novel Mo2C-based pyramid structure and further reveals a sliding growth mechanism, which could offer impetus for the design of new 3D spatial structures of Mo2C and other 2D materials.-

Keywords:

- Mo2C pyramids,

- liquid Cu,

- chemical vapor deposition

-

References

[1] Zhang J C, Lin L, Jia K C, et al. Controlled growth of single-crystal graphene films. Adv Mater, 2020, 32, 1903266 doi: 10.1002/adma.201903266[2] Liu C, Wang L, Qi J J, et al. Designed growth of large-size 2D single crystals. Adv Mater, 2020, 32, 2000046 doi: 10.1002/adma.202000046[3] Cui Y, Li B, Li J B, et al. Chemical vapor deposition growth of two-dimensional heterojunctions. Sci China Phys Mech Astron, 2018, 61, 016801 doi: 10.1007/s11433-017-9105-x[4] Kwak W J, Lau K C, Shin C D, et al. A Mo2C/carbon nanotube composite cathode for lithium-oxygen batteries with high energy efficiency and long cycle life. ACS Nano, 2015, 9, 4129 doi: 10.1021/acsnano.5b00267[5] Çakır D, Sevik C, Gülseren O, et al. Mo2C as a high capacity anode material: A first-principles study. J Mater Chem A, 2016, 4, 6029 doi: 10.1039/C6TA01918H[6] Liu Y P, Yu G T, Li G D, et al. Frontispiece: coupling Mo2C with nitrogen-rich nanocarbon leads to efficient hydrogen-evolution electrocatalytic sites. Angew Chem Int Ed, 2015, 54, 10752 doi: 10.1002/anie.201583761[7] Halim J, Kota S, Lukatskaya M R, et al. Synthesis and characterization of 2D molybdenum carbide (MXene). Adv Funct Mater, 2016, 26, 3118 doi: 10.1002/adfm.201505328[8] Anasori B, Lukatskaya M R, Gogotsi Y. 2D metal carbides and nitrides (MXenes) for energy storage. Nat Rev Mater, 2017, 2, 16098 doi: 10.1038/natrevmats.2016.98[9] Xu C, Wang L B, Liu Z B, et al. Large-area high-quality 2D ultrathin Mo2C superconducting crystals. Nat Mater, 2015, 14, 1135 doi: 10.1038/nmat4374[10] Wang L B, Xu C, Liu Z B, et al. Magnetotransport properties in high-quality ultrathin two-dimensional superconducting Mo2C crystals. ACS Nano, 2016, 10, 4504 doi: 10.1021/acsnano.6b00270[11] Geng D C, Zhao X X, Li L J, et al. Controlled growth of ultrathin Mo2C superconducting crystals on liquid Cu surface. 2D Mater, 2016, 4, 011012 doi: 10.1088/2053-1583/aa51b7[12] Geng D C, Zhao X X, Chen Z X, et al. Direct synthesis of large-area 2D Mo2C on in situ grown graphene. Adv Mater, 2017, 29, 1700072 doi: 10.1002/adma.201700072[13] Deng R X, Zhang H R, Zhang Y H, et al. Graphene/Mo2C heterostructure directly grown by chemical vapor deposition. Chin Phys B, 2017, 26, 067901 doi: 10.1088/1674-1056/26/6/067901[14] Qiao J B, Gong Y, Zuo W J, et al. One-step synthesis of van der Waals heterostructures of graphene and two-dimensional superconducting α-Mo2C. Phys Rev B, 2017, 95, 201403 doi: 10.1103/PhysRevB.95.201403[15] Geng D, Wu B, Guo Y, et al. Uniform hexagonal graphene flakes and films grown on liquid copper surface. PNAS, 2012, 109, 7992 doi: 10.1073/pnas.1200339109[16] Wu Y A, Fan Y, Speller S, et al. Large single crystals of graphene on melted copper using chemical vapor deposition. ACS Nano, 2012, 6, 5010 doi: 10.1021/nn3016629[17] Zeng M Q, Tan L F, Wang J, et al. Liquid metal: An innovative solution to uniform graphene films. Chem Mater, 2014, 26, 3637 doi: 10.1021/cm501571h[18] Wu B, Geng D C, Xu Z P, et al. Self-organized graphene crystal patterns. NPG Asia Mater, 2013, 5, e36 doi: 10.1038/am.2012.68[19] Wang Y, Zheng Y, Xu X F, et al. Electrochemical delamination of CVD-grown graphene film: Toward the recyclable use of copper catalyst. ACS Nano, 2011, 5, 9927 doi: 10.1021/nn203700w[20] Hÿtch M J, Snoeck E, Kilaas R. Quantitative measurement of displacement and strain fields from HREM micrographs. Ultramicroscopy, 1998, 74, 131 doi: 10.1016/S0304-3991(98)00035-7 -

Supplements

20050022suppl.pdf

20050022suppl.pdf

-

Proportional views

DownLoad:

DownLoad: