| Citation: |

Kunal B. Modi, Pooja Y. Raval, Dolly J. Parekh, Shrey K. Modi, Niketa P. Joshi, Akshay R. Makadiya, Nimish H. Vasoya, Utpal S. Joshi. Fe3+-substitution effect on the thermal variation of J–E characteristics and DC resistivity of quadruple perovskite CaCu3Ti4O12[J]. Journal of Semiconductors, 2022, 43(3): 032001. doi: 10.1088/1674-4926/43/3/032001

****

K B Modi, P Y Raval, D J Parekh, S K Modi, N P Joshi, A R Makadiya, N H Vasoya, U S Joshi, Fe3+-substitution effect on the thermal variation of J–E characteristics and DC resistivity of quadruple perovskite CaCu3Ti4O12[J]. J. Semicond., 2022, 43(3): 032001. doi: 10.1088/1674-4926/43/3/032001.

|

Fe3+-substitution effect on the thermal variation of J–E characteristics and DC resistivity of quadruple perovskite CaCu3Ti4O12

DOI: 10.1088/1674-4926/43/3/032001

More Information

-

Abstract

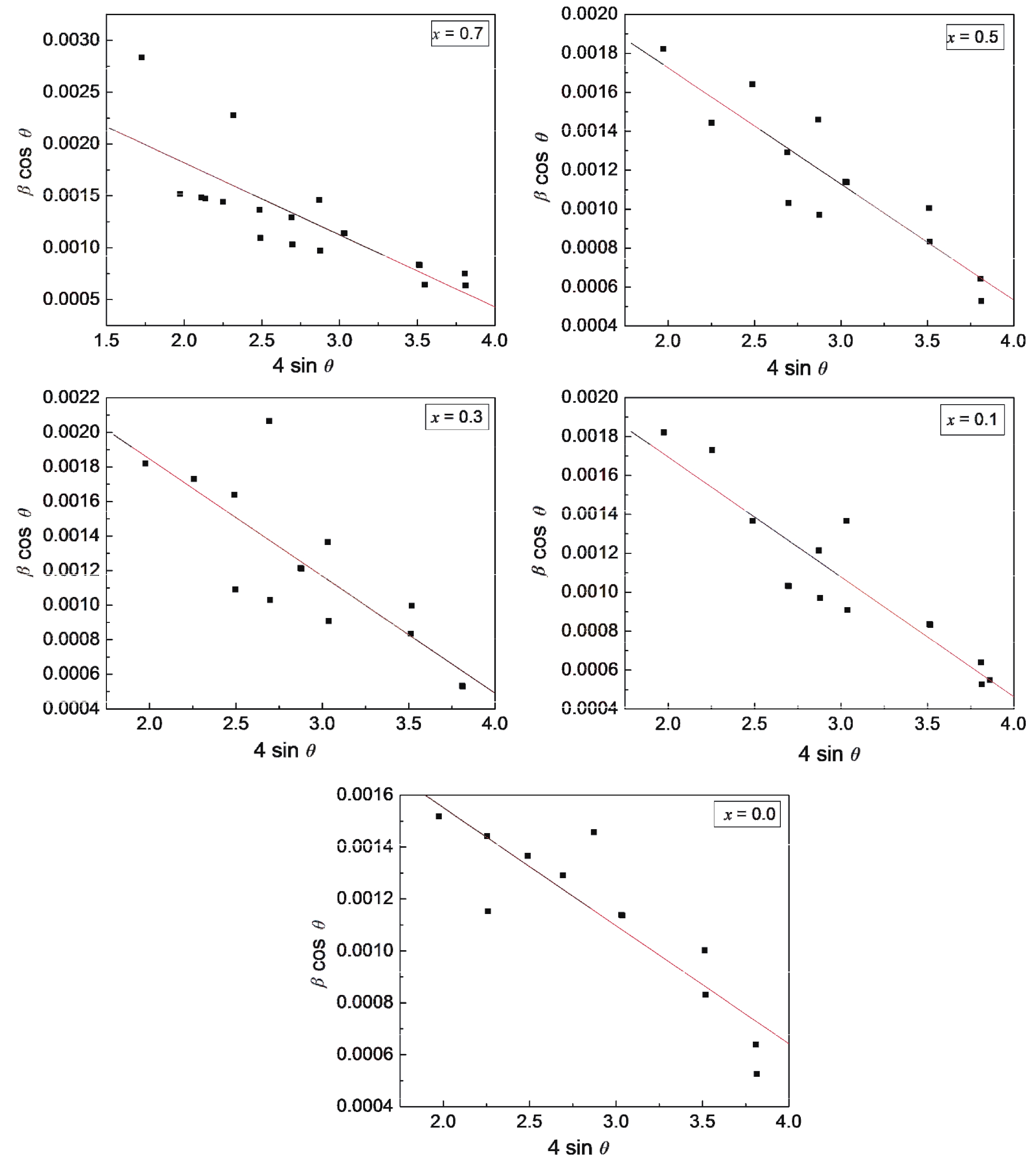

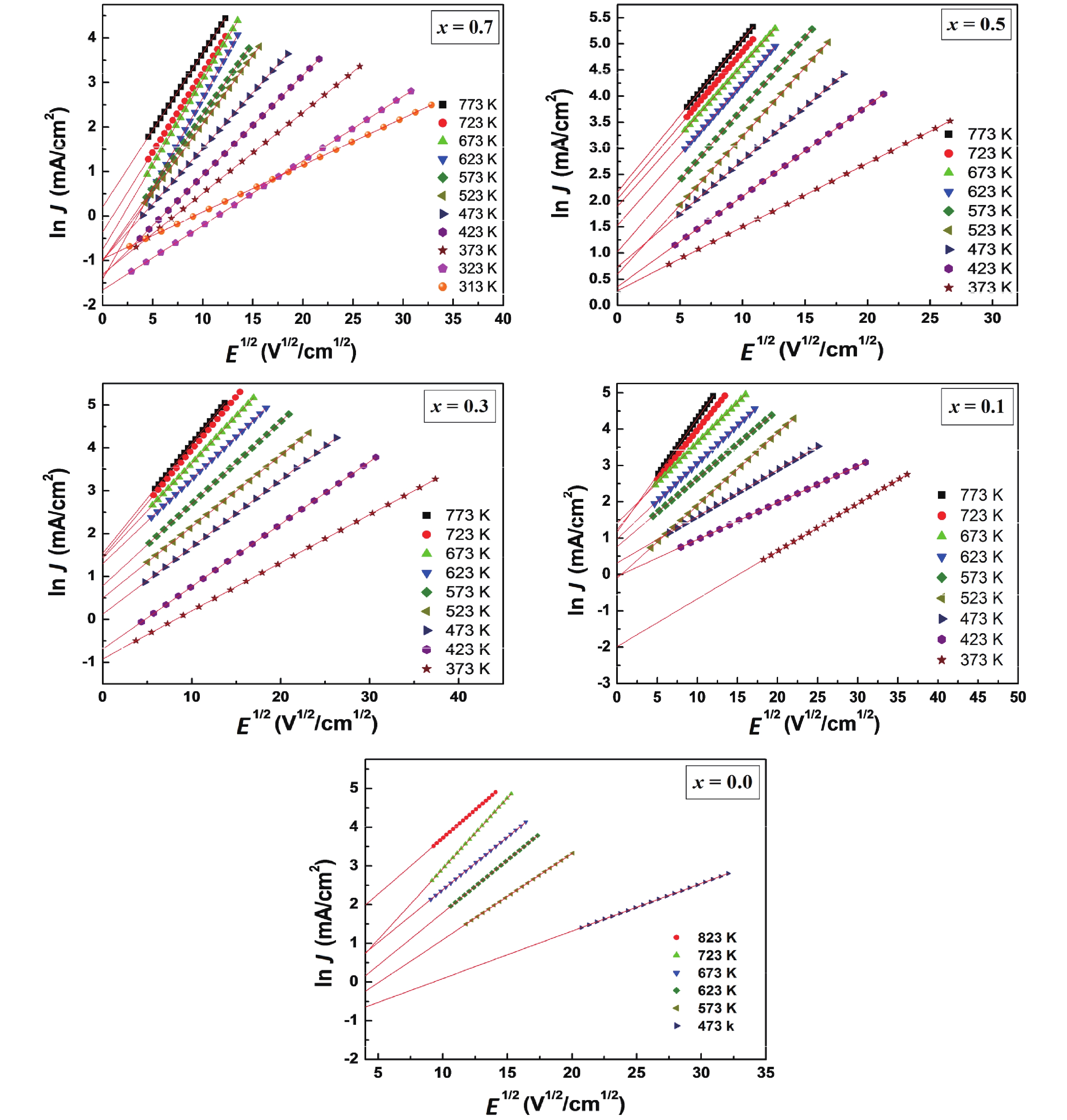

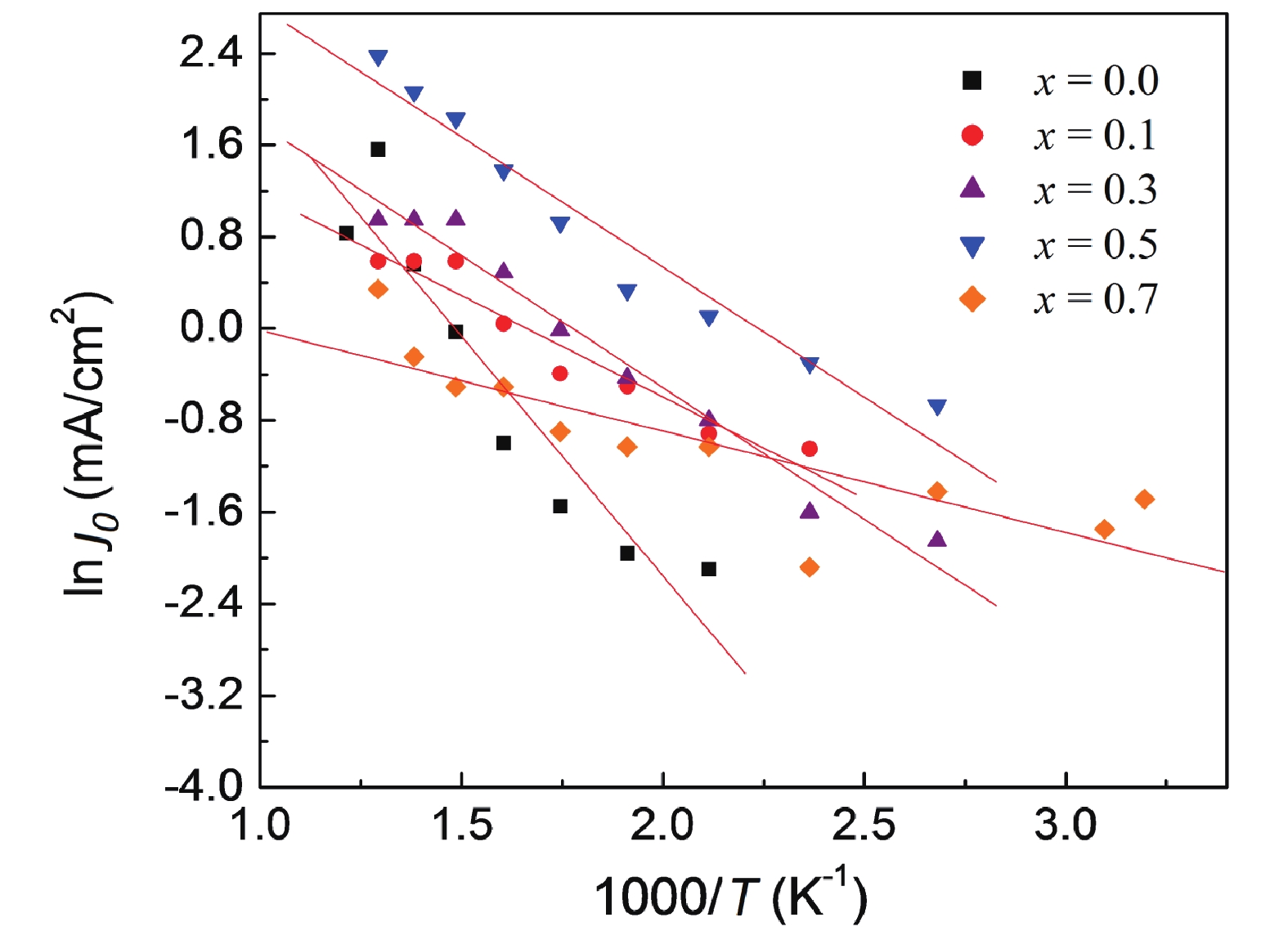

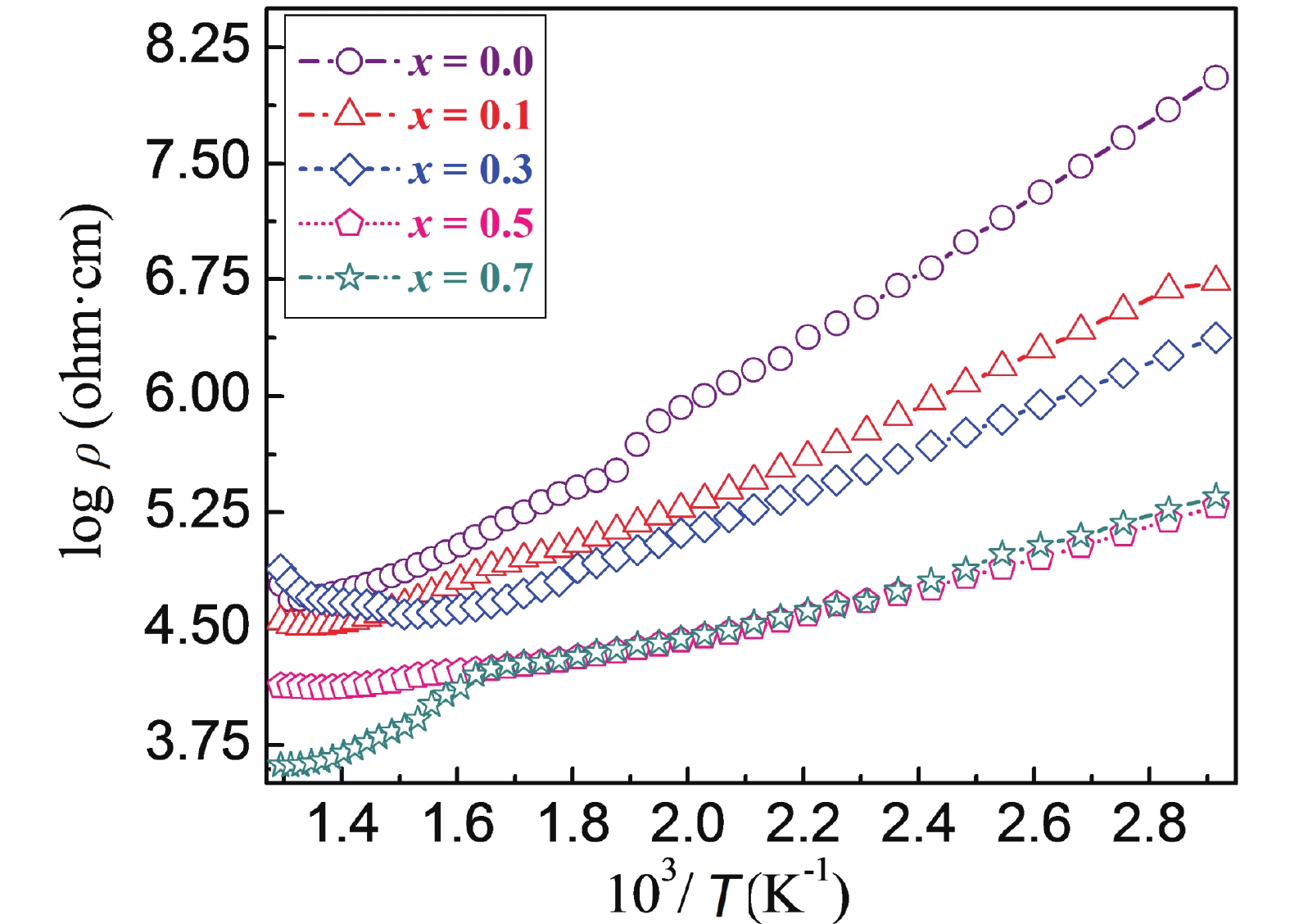

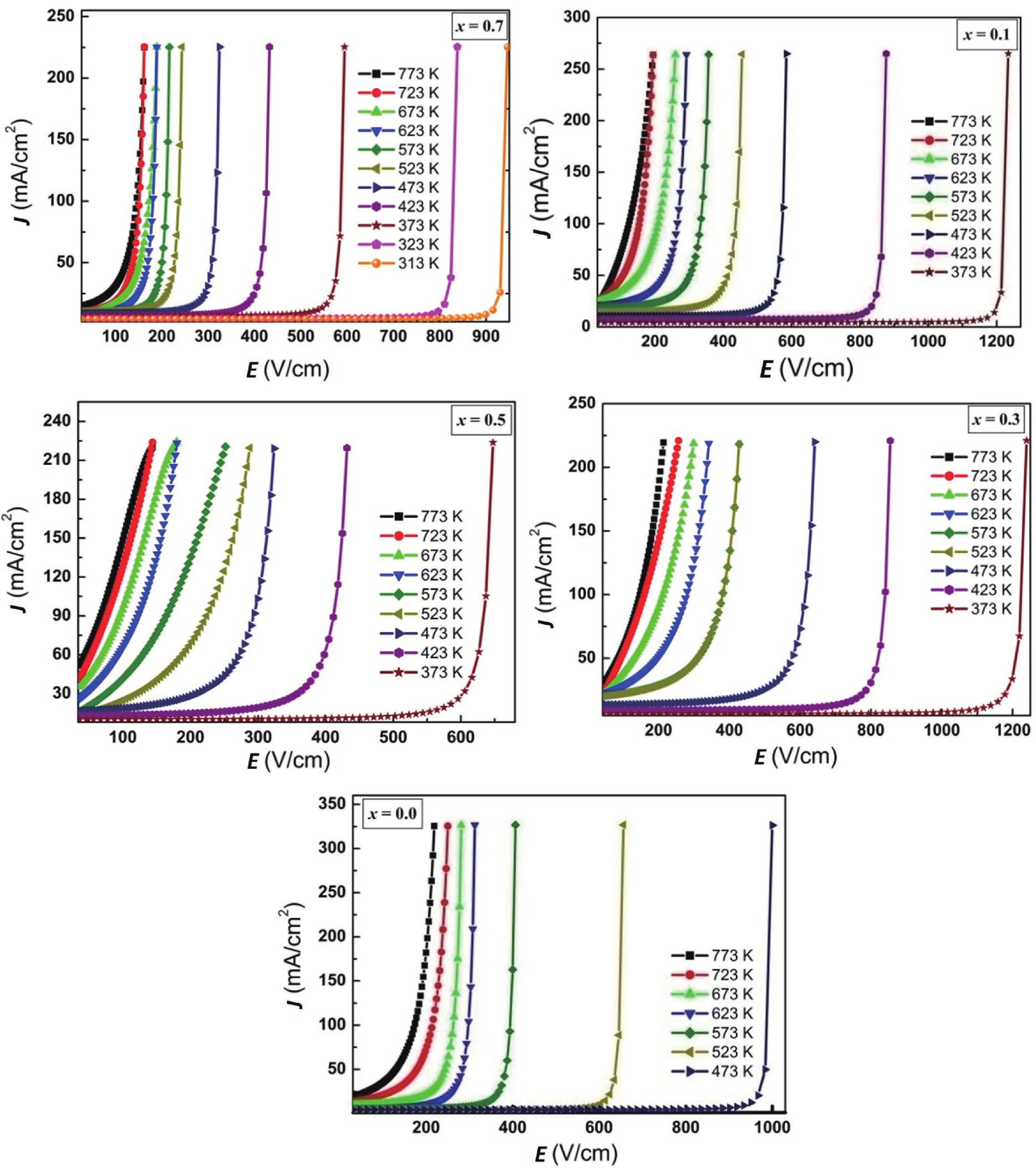

The electrical properties of cubic perovskite series, CaCu3–xTi4–xFe2xO12 with x = 0.0, 0.1, 0.3, 0.5, and 0.7, have been studied by employing current density as a function of electric field characteristics registered at different temperatures and thermal variations of direct current electrical resistivity measurements. All of the compositions exhibit strong non-ohmic behavior. The concentration dependence of breakdown field, the temperature at which switching action takes place, and maximum value of current density (Jmax) has been explained on account of structural, microstructural, and positron lifetime parameters. The highest ever reported value of Jmax = 327 mA/cm2 has been observed for pristine composition. The values of the nonlinear coefficient advise the suitability of ceramics for low-voltage varistor applications. The Arrhenius plots show typical semiconducting nature. The activation energy values indicate that electric conduction proceeds through electrons with deformation in the system.-

Keywords:

- perovskites,

- magnetic materials,

- J–E characteristics,

- capacitor

-

References

[1] Subramanian M A, Li D, Duan N, et al. High dielectric constant in ACu3Ti4O12 and ACu3Ti3FeO12 phases. J Solid State Chem, 2000, 151, 323 doi: 10.1006/jssc.2000.8703[2] Ramirez A P, Subramanian M A, Gardel M, et al. Giant dielectric constant response in a copper-titanate. Solid State Commun, 2000, 115, 217 doi: 10.1016/S0038-1098(00)00182-4[3] Prompa K, Swatsitang E, Saiyasombat C, et al. Very high performance dielectric and non-Ohmics properties of CaCu3Ti4.2O12 ceramics for X8R capacitors. Ceram Int, 2018, 44, 13267 doi: 10.1016/j.ceramint.2018.04.156[4] Kretly L C, Almeida A F L, de Oliveira R S, et al. Electrical and optical properties of CaCu3Ti4O12 (CCTO) substrates for microwave devices and antennas. Microw Opt Technol Lett, 2003, 39, 145 doi: 10.1002/mop.11152[5] Chung S Y, Kim I D, Kang S J L. Strong nonlinear current-voltage behaviour in perovskite-derivative calcium copper titanate. Nat Mater, 2004, 3, 774 doi: 10.1038/nmat1238[6] Felix A A, Rupp J L M, Varela J A, et al. Multi-functional properties of CaCu3Ti4O12 thin films. J Appl Phys, 2012, 112, 054512 doi: 10.1063/1.4751344[7] Kushwaha H S, Madhar N A, Ilahi B, et al. Efficient solar energy conversion using CaCu3Ti4O12 photoanode for photocatalysis and photoelectrocatalysis. Sci Rep, 2016, 6, 1 doi: 10.1038/s41598-016-0001-8[8] Chhetry A, Sharma S, Yoon H, et al. Enhanced sensitivity of capacitive pressure and strain sensor based on CaCu3Ti4O12 wrapped hybrid sponge for wearable applications. Adv Funct Mater, 2020, 30, 1910020 doi: 10.1002/adfm.201910020[9] Chattopadhyay A, Nayak J. Synthesis of CCTO powder for application in humidity sensor. AIP Conference Proceedings, 2020, 040020[10] Prompa K, Swatsitang E, Putjuso T. Enhancement of nonlinear electrical properties with high performance dielectric properties of CaCu2.95Cr0.05Ti4.1O12 ceramics. Ceram Int, 2018, 44, S72 doi: 10.1016/j.ceramint.2018.08.237[11] Ren L L, Yang L J, Xu C, et al. Improvement of breakdown field and dielectric properties of CaCu3Ti4O12 ceramics by Bi and Al co-doping. J Alloys Compd, 2018, 768, 652 doi: 10.1016/j.jallcom.2018.07.293[12] Boonlakhorn J, Thongbai P. Dielectric properties, nonlinear electrical response and microstructural evolution of CaCu3Ti4– xSn xO12 ceramics prepared by a double ball-milling process. Ceram Int, 2020, 46, 4952 doi: 10.1016/j.ceramint.2019.10.233[13] Cortés J A, Cotrim G, Orrego S, et al. Dielectric and non-ohmic properties of Ca2Cu2Ti4– xSn xO12 (0.0 ≤ x ≤ 4.0) multiphasic ceramic composites. J Alloys Compd, 2018, 735, 140 doi: 10.1016/j.jallcom.2017.11.089[14] Rhouma S, Saîd S, Autret C, et al. Comparative studies of pure, Sr-doped, Ni-doped and co-doped CaCu3Ti4O12 ceramics: Enhancement of dielectric properties. J Alloys Compd, 2017, 717, 121 doi: 10.1016/j.jallcom.2017.05.053[15] Wu S, Liu P, Lai Y M, et al. Effect of Ba2+ doping on microstructure and electric properties of calcium copper titanate (CaCu3Ti4O12) ceramics. J Mater Sci: Mater Electron, 2016, 27, 10336 doi: 10.1007/s10854-016-5118-9[16] Barman N, Varma K B R. Enhanced non-linear current-voltage response of Te-doped calcium copper titanate ceramics. Ceram Int, 2017, 43, 6363 doi: 10.1016/j.ceramint.2017.02.045[17] Grzebielucka E C, Leandro Monteiro J F H, de Souza E C F, et al. Improvement in varistor properties of CaCu3Ti4O12 ceramics by chromium addition. J Mater Sci Technol, 2020, 41, 12 doi: 10.1016/j.jmst.2019.08.055[18] Sun J J, Xu C, Zhao X T, et al. Improved dielectric properties of indium and tantalum co-doped CaCu3Ti4O12 ceramic prepared by spark plasma sintering. IEEE Trans Dielectr Electr Insul, 2020, 27, 1400 doi: 10.1109/TDEI.2020.008451[19] Sripakdee C, Prompa K, Swatsitang E, et al. Very high-performance dielectric and non-ohmic properties of novel X8R type Ca1–1.5 xHo xCu3Ti4O12/TiO2 ceramics. J Alloys Compd, 2019, 779, 521 doi: 10.1016/j.jallcom.2018.11.298[20] Boonlakhorn J, Chanlek N, Manyam J, et al. Enhanced giant dielectric properties and improved nonlinear electrical response in acceptor-donor (Al3+, Ta5+)-substituted CaCu3Ti4O12 ceramics. J Adv Ceram, 2021, 10, 1243 doi: 10.1007/s40145-021-0499-5[21] Löhnert R, Bartsch H, Schmidt R, et al. Microstructure and electric properties of CaCu3Ti4O12 multilayer capacitors. J Am Ceram Soc, 2015, 98, 141 doi: 10.1111/jace.13260[22] Zheng Q, Fan H Q, Long C B. Microstructures and electrical responses of pure and chromium-doped CaCu3Ti4O12 ceramics. J Alloys Compd, 2012, 511, 90 doi: 10.1016/j.jallcom.2011.09.002[23] Amhil S, Choukri E, Ben Moumen S, et al. Evidence of large hopping polaron conduction process in strontium doped calcium copper titanate ceramics. Phys B, 2019, 556, 36 doi: 10.1016/j.physb.2018.12.032[24] Fan H Q, Zheng Q, Peng B L. Microstructure, dielectric and pyroelectric properties of CaCu3Ti4O12 ceramics fabricated by tape-casting method. Mater Res Bull, 2013, 48, 3278 doi: 10.1016/j.materresbull.2013.05.026[25] Chen L, Chen C L, Lin Y, et al. High temperature electrical properties of highly epitaxial CaCu3Ti4O12 thin films on (001) LaAlO3. Appl Phys Lett, 2003, 82, 2317 doi: 10.1063/1.1565702[26] Raval P Y, Makadiya A R, Pansara P R, et al. Effect of thermal history on structural, microstructural properties and J– E characteristics of CaCu3Ti4O12 polycrystalline ceramic. Mater Chem Phys, 2018, 212, 343 doi: 10.1016/j.matchemphys.2018.03.041[27] Pansara P R, Raval P Y, Vasoya N H, et al. Intriguing structural and magnetic properties correlation study on Fe3+-substituted calcium-copper-titanate. Phys Chem Chem Phys, 2018, 20, 1914 doi: 10.1039/C7CP06681C[28] Raval P Y, Pansara P R, Vasoya N H, et al. Positron annihilation spectroscopic investigation of high energy ball - milling engendered defects in CaCu3Ti4O12. Ceram Int, 2018, 44, 15887 doi: 10.1016/j.ceramint.2018.06.004[29] Pansara P R, Meshiya U M, Makadiya A R, et al. Defect structure transformation during substitution in quadruple perovskite CaCu3– xTi4– xFe2 xO12 studied by positron annihilation spectroscopy. Ceram Int, 2019, 45, 18599 doi: 10.1016/j.ceramint.2019.06.083[30] Raval P Y, Pansara P R, Makadiya A R, et al. Investigation on external stimuli engendered magnetic ordering in polycrystalline CaCu3Ti4O12 quadruple perovskite. Ceram Int, 2018, 44, 17667 doi: 10.1016/j.ceramint.2018.06.230[31] Meshiya U M, Raval P Y, Pansara P R, et al. Electronic structure, orbital symmetry transformation, charge transfer, and valence state studies on Fe3+-substituted CaCu3Ti4O12 quadruple perovskites using X-ray photoelectron spectroscopy. Ceram Int, 2020, 46, 2147 doi: 10.1016/j.ceramint.2019.09.198[32] Raval P Y, Pansara P R, Vasoya N H, et al. First observation of reversible mechanochromism and chromaticity study on calcium-copper-titanate. J Am Ceram Soc, 2019, 102, 6872 doi: 10.1111/jace.16609[33] Raval P Y, Joshi N P, Pansara P R, et al. A Ti L3, 2- and K- edge XANES and EXAFS study on Fe3+-substituted CaCu3Ti4O12. Ceram Int, 2018, 44, 20716 doi: 10.1016/j.ceramint.2018.08.066[34] Meshiya U M, Jani K K, Mange P L, et al. Defect characterization of slow-cooled and quenched samples of calcium-copper-titanate through positron annihilation spectroscopy. Spectrosc Lett, 2019, 52, 633 doi: 10.1080/00387010.2019.1681462[35] Pansara P R, Raval P Y, Pandit R, et al. First experimental evidence of non-collinear spin structure in CaCu2.3Ti3.3Fe1.4O12. Ceram Int, 2020, 46, 10016 doi: 10.1016/j.ceramint.2019.12.268[36] Meshiya U M, Raval P Y, Joshi N P, et al. Probing Fano resonance, relaxor ferroelectricity, light scattering by orbital exchange-bond, orbitons by Raman spectroscopy, and their correlation with dielectric properties of pure and Fe3+ - substituted calcium-copper-titanate. Vib Spectrosc, 2021, 112, 103201 doi: 10.1016/j.vibspec.2020.103201[37] Raval P Y, Pansara P R, Chen C L, et al. Probing reversal of orbital symmetry in CaCu3– xTi4– xFe2 xO12 (x = 0.0–0.7) by X-ray absorption spectroscopy. J Mater Sci: Mater Electron, 2021, 32, 13630 doi: 10.1007/s10854-021-05941-3[38] Modi K B, Vasoya N H, Pathak T K, et al. Observation of CCNR-type electrical switching in Zn0.3Mn0.7+ xSi xFe2−2 xO4 spinel ferrite series. SN Appl Sci, 2020, 2, 1840 doi: 10.1007/s42452-020-03658-2[39] Hu W, Qin N, Wu G H, et al. Opportunity of spinel ferrite materials in nonvolatile memory device applications based on their resistive switching performances. J Am Chem Soc, 2012, 134, 14658 doi: 10.1021/ja305681n[40] Zheng P, Zhang R Z, Chen H Y, et al. Thermoelectric properties and conduction mechanism of CaCu3Ti4O12 ceramics at high temperatures. J Electron Mater, 2014, 43, 1645 doi: 10.1007/s11664-013-2821-7[41] Chung S Y, Choi J H, Choi J K. Tunable current-voltage characteristics in polycrystalline calcium copper titanate. Appl Phys Lett, 2007, 91, 091912 doi: 10.1063/1.2777184[42] Mao P, Wang J P, Liu S J, et al. Grain size effect on the dielectric and non-ohmic properties of CaCu3Ti4O12 ceramics prepared by the Sol-gel process. J Alloys Compd, 2019, 778, 625 doi: 10.1016/j.jallcom.2018.11.200[43] Zhao X T, Ren L L, Yang L J, et al. Structure and dielectric relaxations of CaCu3Ti4O12 ceramics by heat treatments in different atmospheres. IEEE Trans Dielectr Electr Insul, 2017, 24, 764 doi: 10.1109/TDEI.2017.006278[44] Li T, He H F, Zhang T, et al. Effect of synthesizing temperatures on the microstructure and electrical property of CaCu3Ti4O12 ceramics prepared by sol-gel process. J Alloys Compd, 2016, 684, 315 doi: 10.1016/j.jallcom.2016.05.177[45] Putjuso S, Nunglek S, Putjuso T. Nonlinear current-voltage and dielectric properties of CaCu3Ti4O12 ceramics prepared by an aloe vera solution method. RMUTSB Acad J, 2016, 4, 172[46] Kaur S, Kumar A, Sharma A L, et al. Dielectric and energy storage behavior of CaCu3Ti4O12 nanoparticles for capacitor application. Ceram Int, 2019, 45, 7743 doi: 10.1016/j.ceramint.2019.01.077[47] Tang Z, Wu K N, Huang Y W, et al. High breakdown field CaCu3Ti4O12 ceramics: Roles of the secondary phase and of Sr doping. Energies, 2017, 10, 1031 doi: 10.3390/en10071031[48] Lin H, He X, Gong Y Y, et al. Tuning the nonlinear current-voltage behavior of CaCu3Ti4O12 ceramics by spark plasma sintering. Ceram Int, 2018, 44, 8650 doi: 10.1016/j.ceramint.2018.02.089[49] Boonlakhorn J, Putasaeng B, Kidkhunthod P, et al. Improved dielectric properties of (Y + Mg) co-doped CaCu3Ti4O12 ceramics by controlling geometric and intrinsic properties of grain boundaries. Mater Des, 2016, 92, 494 doi: 10.1016/j.matdes.2015.12.042[50] Swatsitang E, Putjuso T. Very low loss tangent, high dielectric and non-ohmic properties of Ca1−1.5 xPr xCu3Ti4O12 ceramics prepared by the sol-gel process. J Mater Sci: Mater Electron, 2017, 28, 18966 doi: 10.1007/s10854-017-7850-1[51] Xu D, Yue X N, Song J, et al. Improved dielectric and non-ohmic properties of (Zn + Zr) codoped CaCu3Ti4O12 thin films. Ceram Int, 2019, 45, 11421 doi: 10.1016/j.ceramint.2019.03.008[52] Mao P, Wang J P, Zhang L X, et al. Significantly enhanced breakdown field with high grain boundary resistance and dielectric response in 0.1Na0.5Bi0.5TiO3-0.9BaTiO3 doped CaCu3Ti4O12 ceramics. J Eur Ceram Soc, 2020, 40, 3011 doi: 10.1016/j.jeurceramsoc.2020.03.032[53] Zang G Z, Zhang J L, Zheng P, et al. Grain boundary effect on the dielectric properties of CaCu3Ti4O12 ceramics. J Phys D, 2005, 38, 1824 doi: 10.1088/0022-3727/38/11/022[54] Huang Y M, Shi D P, Li Y H, et al. Effect of holding time on the dielectric properties and non-ohmic behavior of CaCu3Ti4O12 capacitor-varistors. J Mater Sci: Mater Electron, 2013, 24, 1994 doi: 10.1007/s10854-012-1047-4[55] Xiao M, Wang K Y, Chenyang X Q, et al. Nonlinear current-voltage behavior of CaCu3Ti4O12 thin films derived from Sol-gel method. J Mater Sci: Mater Electron, 2014, 25, 2710 doi: 10.1007/s10854-014-1933-z[56] Felix A A, Orlandi M O, Varela J A. Schottky-type grain boundaries in CCTO ceramics. Solid State Commun, 2011, 151, 1377 doi: 10.1016/j.ssc.2011.06.012[57] [58] Abdullah K A L, Termanini M D, Omar F A. Effect of impurities and temperature on electrical properties of ZnO-based varistors. Energy Procedia, 2012, 18, 867 doi: 10.1016/j.egypro.2012.05.101[59] Russell H W. Principles of heat flow in porous insulators. J Am Ceram Soc, 1935, 18, 1 doi: 10.1111/j.1151-2916.1935.tb19340.x[60] Onodera A, Takesada M, Kawatani K, et al. Dielectric properties and phase transition in CaCu3Ti4O12 at high temperatures. Jpn J Appl Phys, 2008, 47, 7753 doi: 10.1143/JJAP.47.7753[61] Gorev M V, Flerov I N, Kartashev A V, et al. Investigation of the thermal expansion and heat capacity of the CaCu3Ti4O12 ceramics. Phys Solid State, 2012, 54, 1785 doi: 10.1134/S1063783412090120[62] Lakhani V K, Modi K B. Effect of Al3+ substitution on the transport properties of copper ferrite. J Phys D, 2011, 44, 245403 doi: 10.1088/0022-3727/44/24/245403 -

Proportional views

DownLoad:

DownLoad: