| Citation: |

Tao Yin, Chong Zhang, Huanming Wu, Qisong Wu, Haigang Yang. A 97 dB dynamic range CSA-based readout circuit with analog temperature compensation for MEMS capacitive sensors[J]. Journal of Semiconductors, 2013, 34(11): 115005. doi: 10.1088/1674-4926/34/11/115005

****

T Yin, C Zhang, H M Wu, Q S Wu, H G Yang. A 97 dB dynamic range CSA-based readout circuit with analog temperature compensation for MEMS capacitive sensors[J]. J. Semicond., 2013, 34(11): 115005. doi: 10.1088/1674-4926/34/11/115005.

|

A 97 dB dynamic range CSA-based readout circuit with analog temperature compensation for MEMS capacitive sensors

DOI: 10.1088/1674-4926/34/11/115005

More Information

-

Abstract

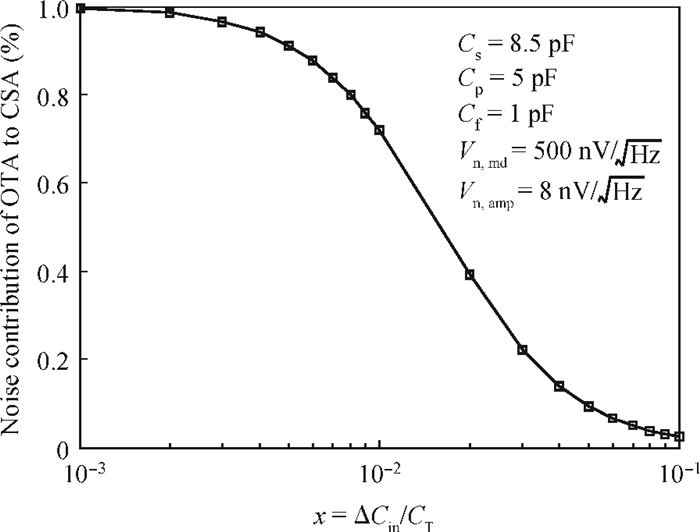

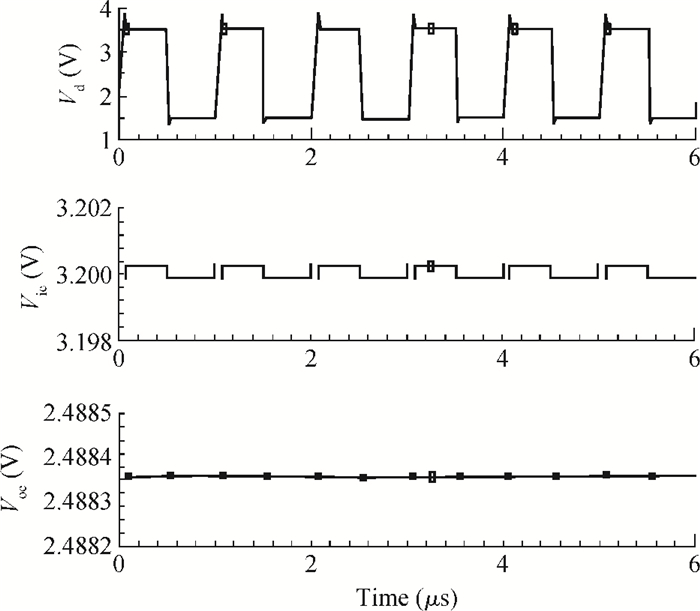

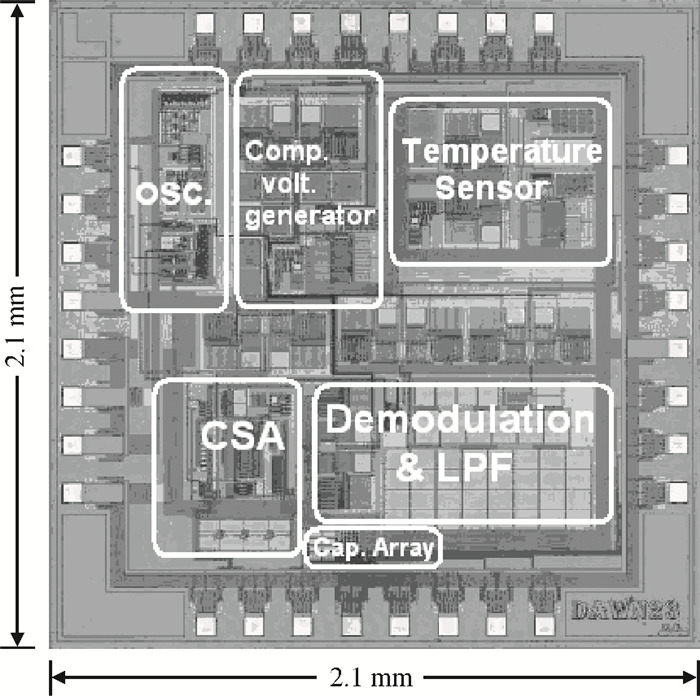

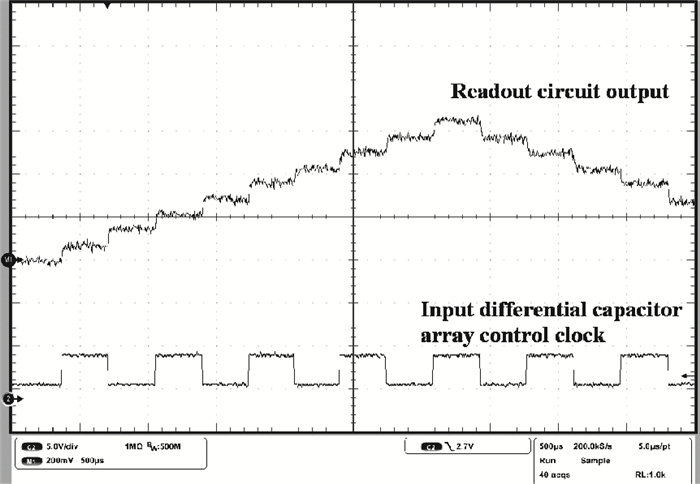

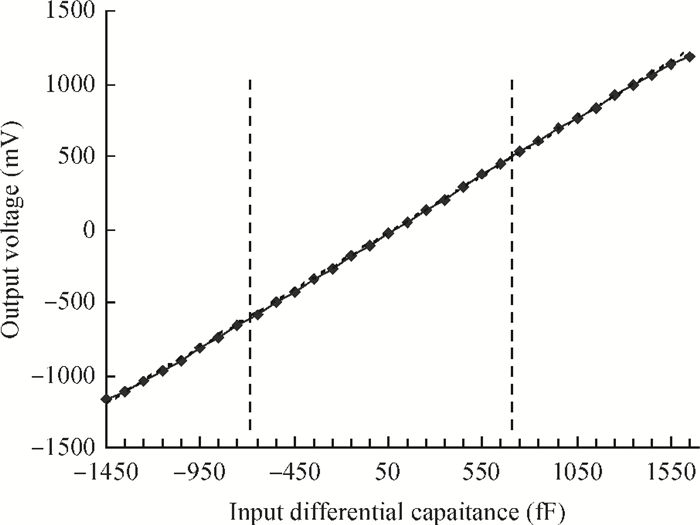

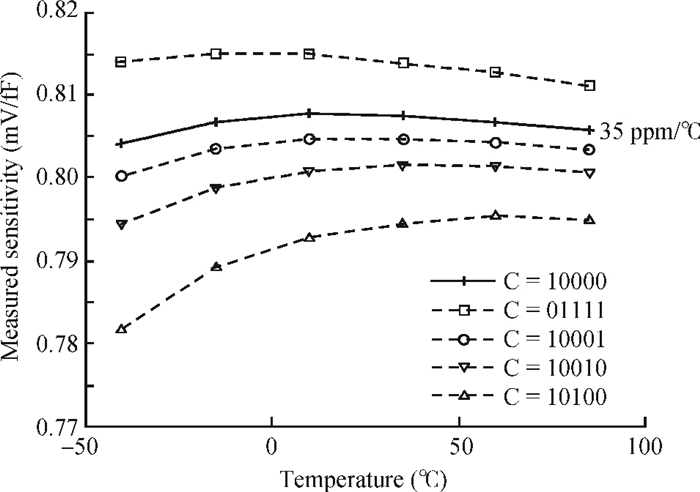

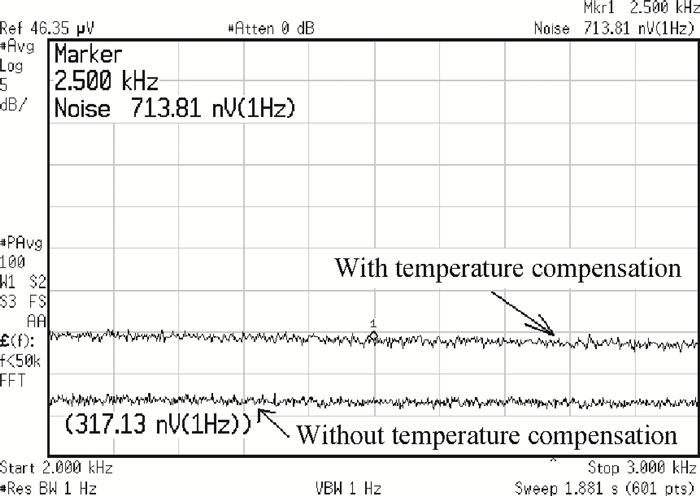

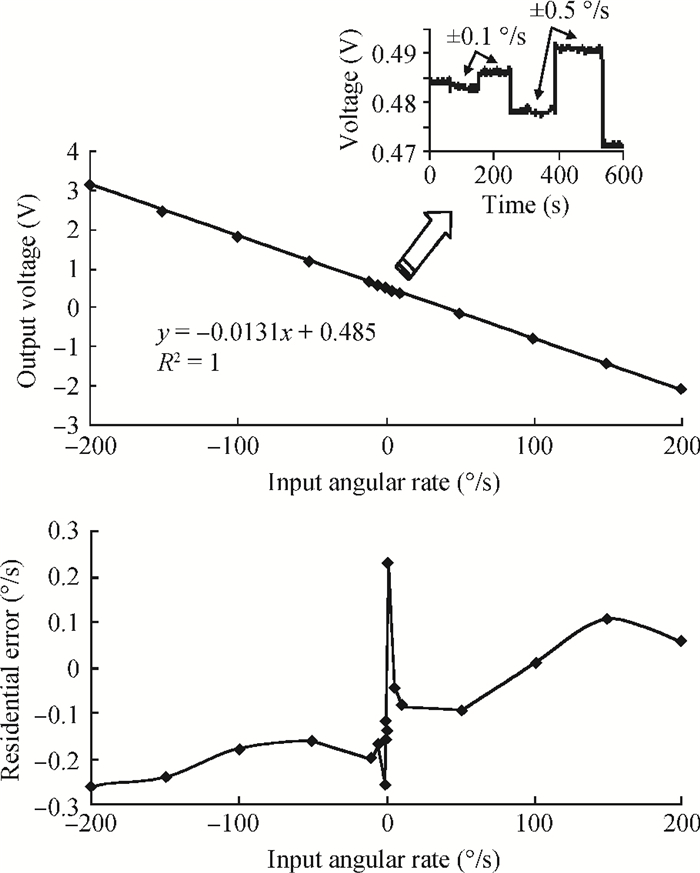

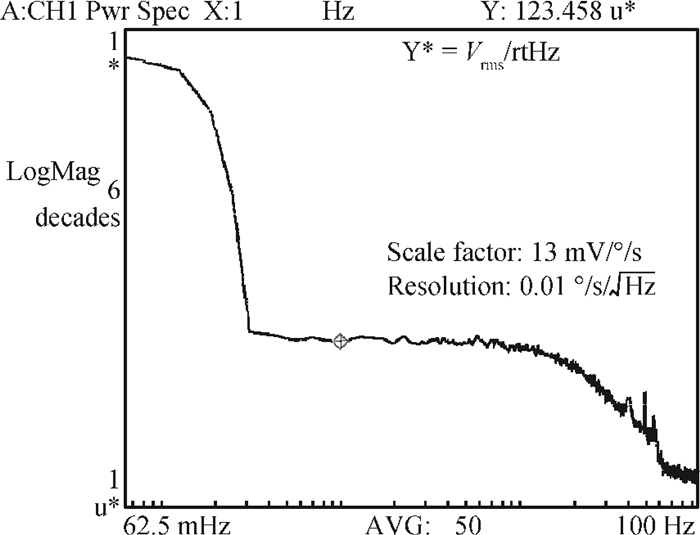

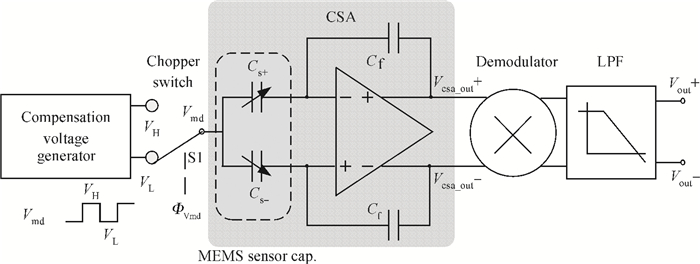

This paper presents a charge-sensitive-amplifier (CSA) based readout circuit for capacitive micro-electro-mechanical-system (MEMS) sensors. A continuous-time (CT) readout structure using the chopper technique is adopted to cancel the low frequency noise and improve the resolution of the readout circuits. An operational trans-conductance amplifier (OTA) structure with an auxiliary common-mode-feedback-OTA is proposed in the fully differential CSA to suppress the chopper modulation induced disturbance at the OTA input terminal. An analog temperature compensation method is proposed, which adjusts the chopper signal amplitude with temperature variation to compensate the temperature drift of the CSA readout sensitivity. The chip is designed and implemented in a 0.35 μm CMOS process and is 2.1×2.1 mm2 in area. The measurement shows that the readout circuit achieves 0.9 aF/$\sqrt {{\rm{Hz}}}$ capacitive resolution, 97 dB dynamic range in 100 Hz signal bandwidth, and 0.8 mV/fF sensitivity with a temperature drift of 35 ppm/℃ after optimized compensation. -

References

[1] Yazdi N, Kulah H, Najafi K. Precision readout circuits for capacitive micro accelerometers. Proc 3rd IEEE Sensors, Vienna, 2004, 1:28 http://ieeexplore.ieee.org/document/1426091/[2] Saukoski M, Aaltonen L, Salo T, et al. Fully integrated charge sensitive amplifier for readout of micromechanical capacitive sensors. IEEE International Symposium on Circuits and Systems (ISACS), Japan, 2005:5377 http://ieeexplore.ieee.org/document/1465851/[3] Boser B E. Capacitive interfaces for monolithic integrated sensors. RF Analog-to-Digital Converters, Sensor and Actuator Interfaces, Low-Noise Oscillators, PLLs and Synthesizers, Kluwer, 1997:220 doi: 10.1007%2F978-1-4757-2602-2_9[4] Geen J, Sherman S, Chang J, et al. Single chip surface micromachined integrated gyroscope with 50°/h Allan deviation. IEEE J Solid-State Circuits, 2002, 37(12):1860 doi: 10.1109/JSSC.2002.804345[5] Wu J, Fedder G K, Carley L R. A low-noise low-offset capacitive sensing amplifier for a 50μg/$\sqrt {{\rm{Hz}}}$ monolithic CMOS MEMS accelerometer. IEEE J Solid-State Circuits, 2004, 39(5):722 doi: 10.1109/JSSC.2004.826329[6] Rodjegard H, Loof A. A differential charge-transfer readout circuit for multiple output capacitive sensors. Sensors and Actuators, 2005, A119:309 http://cat.inist.fr/?aModele=afficheN&cpsidt=16709705[7] Ferguson M I, Keymeulen D, Peay C, et al. Effect of temperature on MEMS vibratory rate gyroscope. IEEE Aerospace Conference, 2005:1 https://www.infona.pl/resource/bwmeta1.element.ieee-art-000001559561[8] Xia D, Chen S, Wang S, et al. Microgyroscope temperature effects and compensation-control methods. Sensors, 2009, 9:8349 doi: 10.3390/s91008349[9] Melexis Inc. Application note, temperature compensation improvement of MLX90609. www. melexis. com[10] Trieu H K, Kordas N, Mokwa W. Fully CMOS compatible capacitive differential pressure sensors with on-chip programmabilities and temperature compensation. IEEE International Conference on Sensors, Orlando, USA, 2002:1451 http://ieeexplore.ieee.org/document/1037336/?reload=true&arnumber=1037336&contentType=Conference%20Publications[11] Enz C C, Temes G C. Circuit techniques for reducing the effects of op-amp imperfections:autozeroing, correlated double sampling, and chopper stabilization. Proc IEEE, 1996, 84:1584 doi: 10.1109/5.542410[12] Zhang Chong, Wu Qisong, Yin Tao, et al. Noise and mismatch optimization for capacitive MEMS readout. Journal of Semiconductors, 2009, 30(11):115003 doi: 10.1088/1674-4926/30/11/115003[13] Aragonés R, Oliver J, Ferrerl C. A 23 ppm/℃ readout circuitry improvement for capacitive sensor acquisition platforms. IEEE 5th International Conference on Sensing Technology, 2011:628[14] Dei M, Marchetti E, Bruschi P. A Micro power capacitive sensor readout channel based on the chopper modulation technique. IEEE Prime Conference, 2007:113[15] Zhu Z, Wei W, Liu L, et al. A high precision CMOS voltage reference without resistors. Journal of Circuits, Systems, and Computers, 2012, 21(3):1250019 doi: 10.1142/S0218126612500193[16] AD7745/AD7746, 24-bit capacitance-to-digital converter with temperature sensor. www. analog. com[17] Chen Y, Jiao J, Dong L, et al. Micromachined bar-structure gyroscope with high q-factors for both driving and sensing mode at atmospheric pressure. IEEE 2nd Conference on Sensors Proceedings, Toronto, Canada, Oct, 2003, 1:461[18] Ko H, Cho D D. Highly programmable temperature compensated readout circuit for capacitive microaccelerometer. Sensors and Actuators A, 2010, 158:72 doi: 10.1016/j.sna.2009.12.017 -

Proportional views

DownLoad:

DownLoad: