| Citation: |

Vaia Adamaki, A. Sergejevs, C. Clarke, F. Clemens, F. Marken, C. R. Bowen. Sub-stoichiometric functionally graded titania fibres for water-splitting applications[J]. Journal of Semiconductors, 2015, 36(6): 063001. doi: 10.1088/1674-4926/36/6/063001

****

V Adamaki, A. Sergejevs, C. Clarke, F. Clemens, F. Marken, C. R. Bowen. Sub-stoichiometric functionally graded titania fibres for water-splitting applications[J]. J. Semicond., 2015, 36(6): 063001. doi: 10.1088/1674-4926/36/6/063001.

|

Sub-stoichiometric functionally graded titania fibres for water-splitting applications

DOI: 10.1088/1674-4926/36/6/063001

More Information

-

Abstract

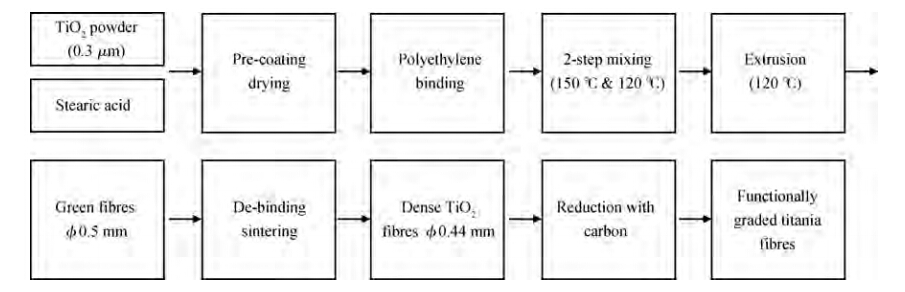

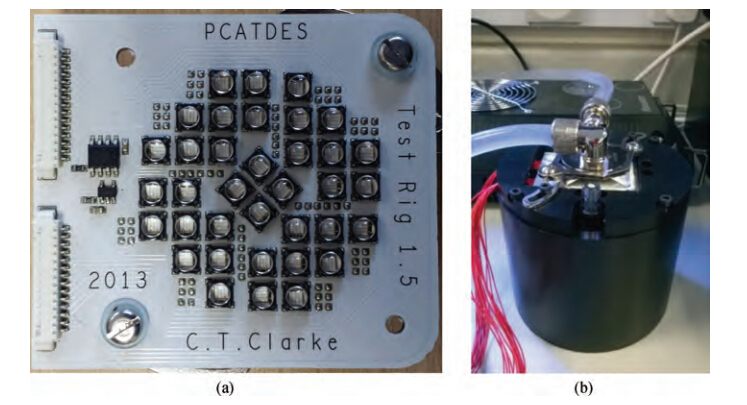

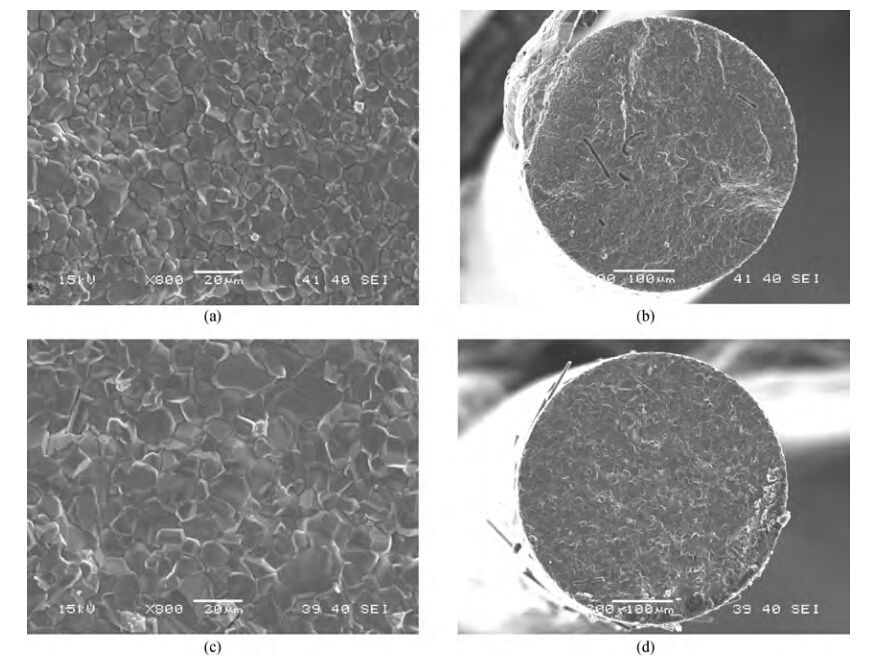

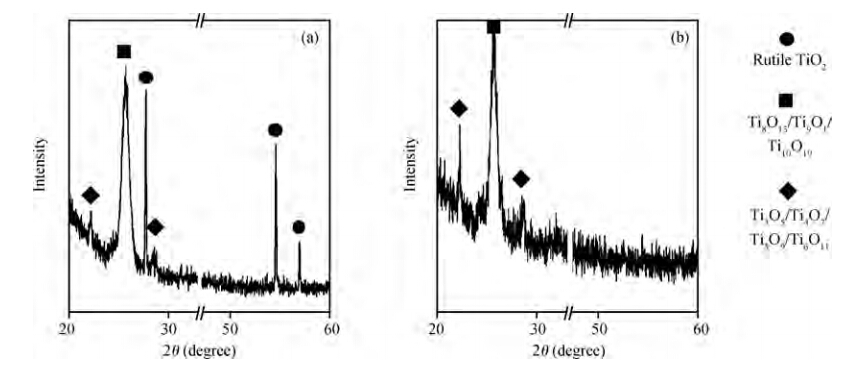

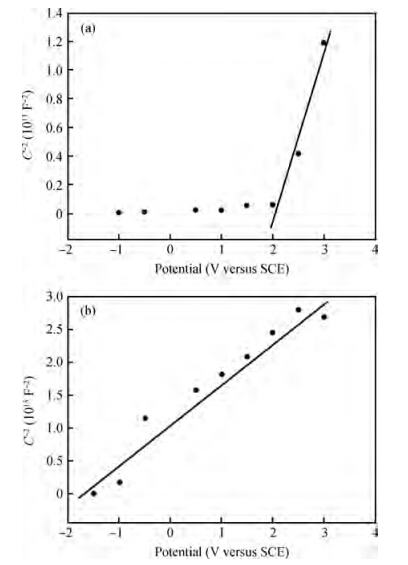

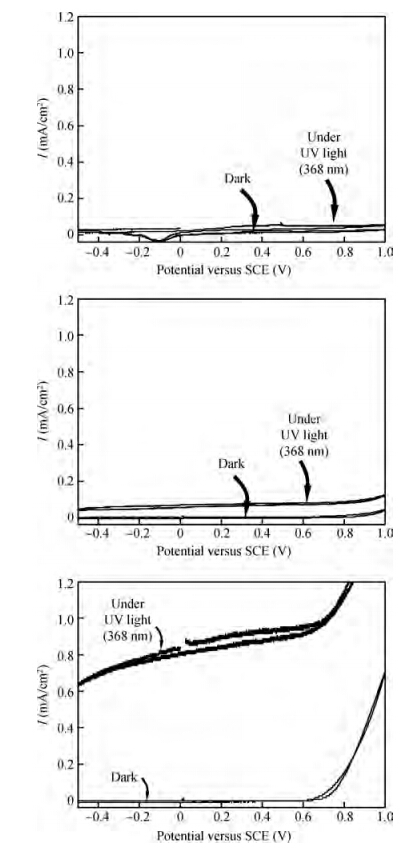

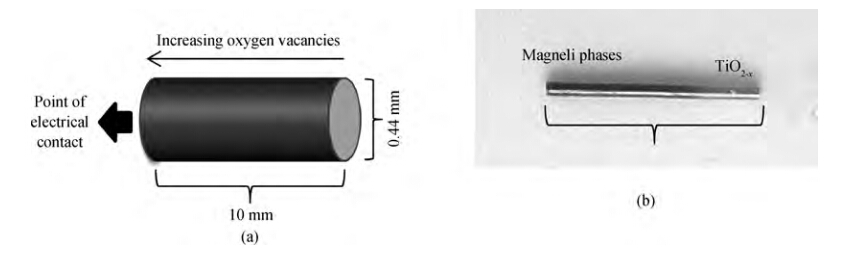

The photo-electro-chemical (PEC) splitting of water requires semiconductor materials with a minimum energy gap of 1.23 eV along with conduction and valence bands overlapping the oxidation of H2O and reduction of H+ respectively. The aim of this work is to overcome the limitations of stoichiometric titania by manufacturing fine scale fibres that exhibit a compositional gradient of oxygen vacancies across the fibre length. In such a fibre configuration the fibre end that is chemically reduced to a relatively small extent performs as the photoanode and the oxygen vacancies enhance the absorption of light. The fibre end that is reduced the most consists of Magnéli phases and exhibits metallic electrical conductivity that enhances the electron-hole separation. The structure and composition of the functionally graded fibres, which were manufactured through extrusion, pressureless sintering and carbo-thermal reduction, are studied using XRD and electron microscopy. Electrochemical impedance spectroscopy measurements were performed in a three-electrode electrochemical system and showed that the oxygen vacancies in the functionally graded fibres affect the flat band potential and have increased carrier density. The efficiency of the system was evaluated with PEC measurements that shows higher efficiency for the functionally graded fibres compared to homogeneous TiO2 or Magnéli phase fibres. The functionally graded and fine scale fibres have the potential to be used as an array of active fibres for water splitting applications.-

Keywords:

- titaniasuboxides,

- water splitting,

- photocurrent

-

References

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] -

Proportional views

DownLoad:

DownLoad: