| Citation: |

Qing Ke, Shaoyang Tan, Songtao Liu, Dan Lu, Ruikang Zhang, Wei Wang, Chen Ji. Fabrication and optimization of 1.55-μm InGaAsP/InP high-power semiconductor diode laser[J]. Journal of Semiconductors, 2015, 36(9): 094010. doi: 10.1088/1674-4926/36/9/094010

****

Q Ke, S Y Tan, S T Liu, D Lu, R K Zhang, W Wang, C Ji. Fabrication and optimization of 1.55-μm InGaAsP/InP high-power semiconductor diode laser[J]. J. Semicond., 2015, 36(9): 094010. doi: 10.1088/1674-4926/36/9/094010.

|

Fabrication and optimization of 1.55-μm InGaAsP/InP high-power semiconductor diode laser

DOI: 10.1088/1674-4926/36/9/094010

More Information

-

Abstract

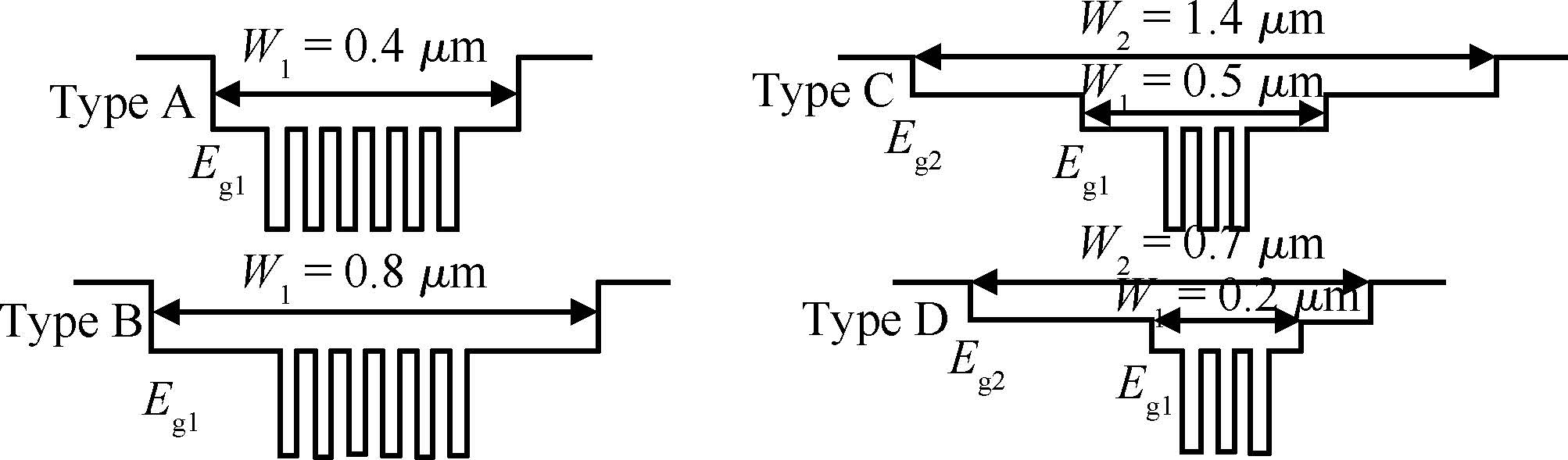

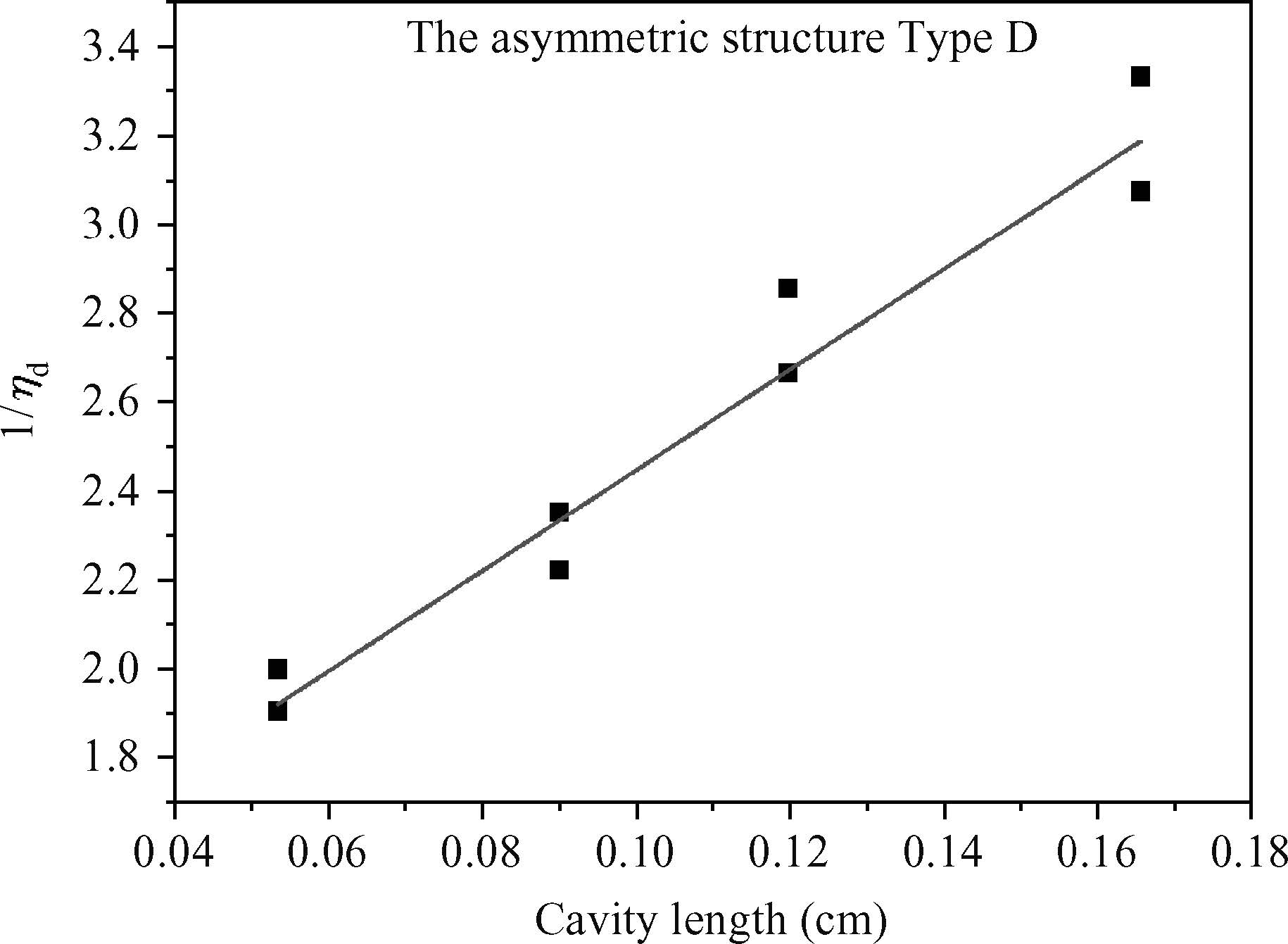

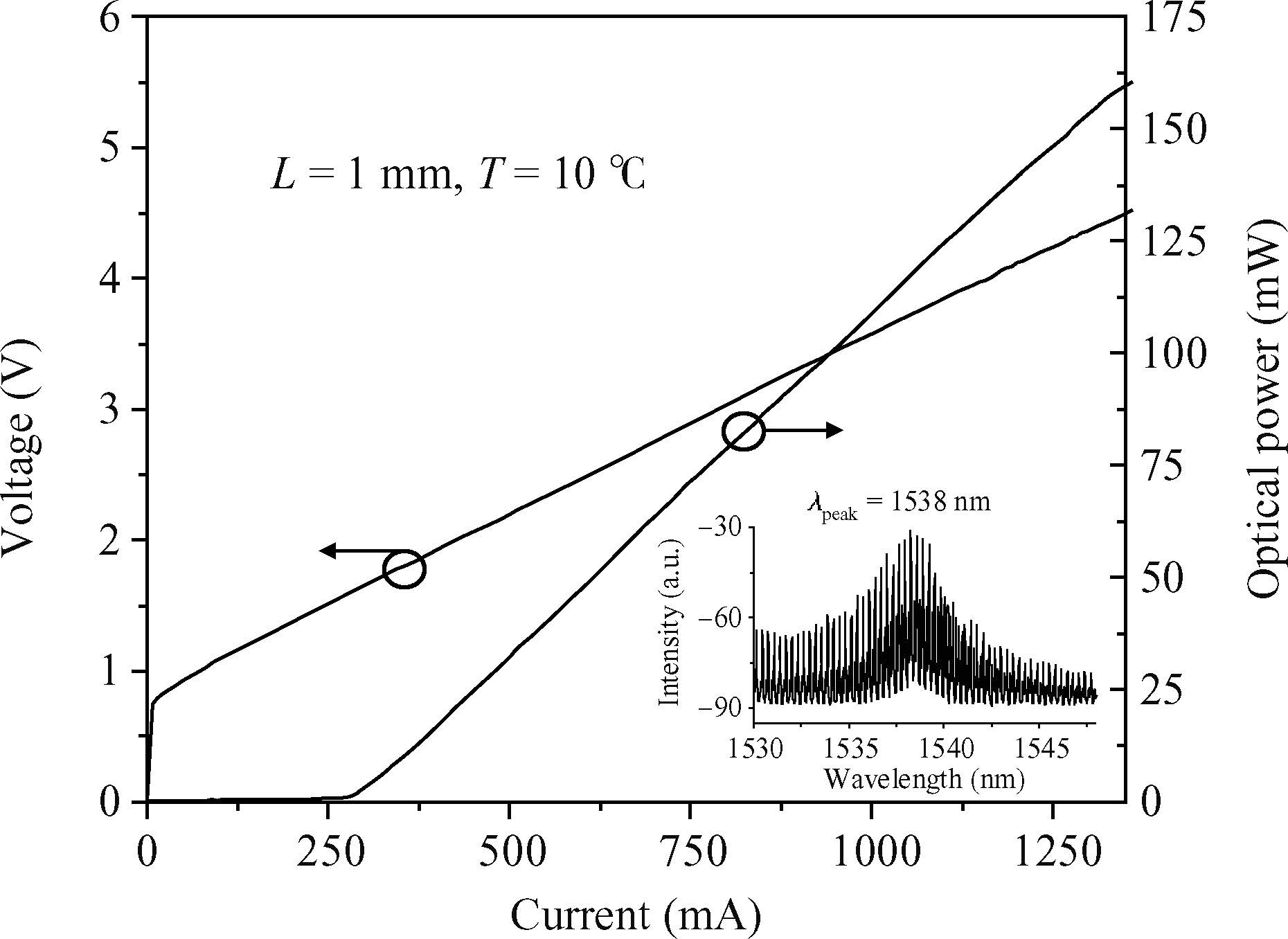

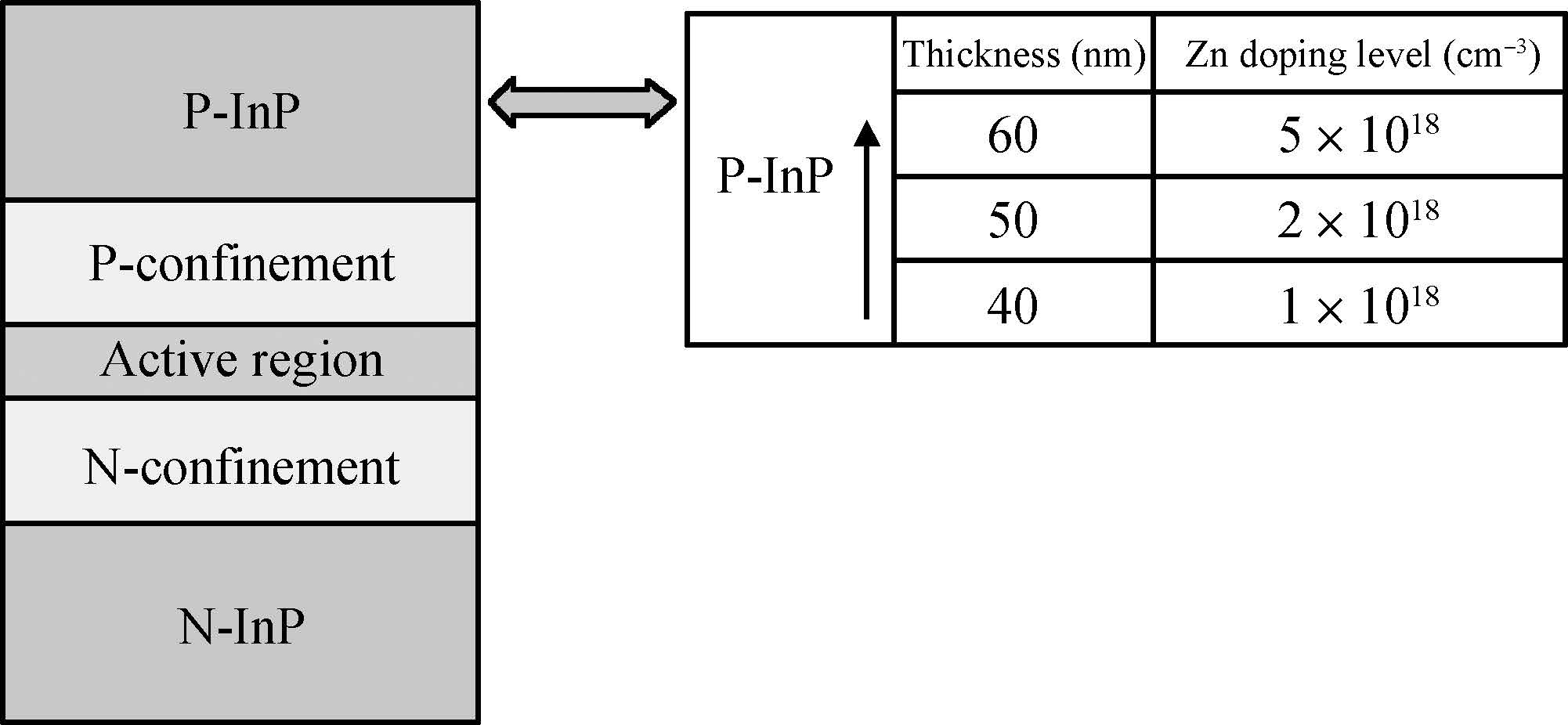

A comprehensive design optimization of 1.55-μm high power InGaAsP/InP board area lasers is performed aiming at increasing the internal quantum efficiency (ηi) while maintaining the low internal loss (αi) of the device, thereby achieving high power operation. Four different waveguide structures of broad area lasers were fabricated and characterized in depth. Through theoretical analysis and experiment verifications, we show that laser structures with stepped waveguide and thin upper separate confinement layer will result in high ηi and overall slope efficiency. A continuous wave (CW) single side output power of 160 mW was obtained for an uncoated laser with a 50-μm active area width and 1 mm cavity length.-

Keywords:

- high power,

- laser,

- InP,

- internal loss,

- internal quantum efficiency

-

References

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] -

Proportional views

DownLoad:

DownLoad: