| Citation: |

Tingting Han, Shaobo Dun, Yuanjie Lü, Guodong Gu, Xubo Song, Yuangang Wang, Peng Xu, Zhihong Feng. 70-nm-gated InAlN/GaN HEMTs grown on SiC substrate with fT/fmax > 160 GHz[J]. Journal of Semiconductors, 2016, 37(2): 024007. doi: 10.1088/1674-4926/37/2/024007

****

T T Han, S B Dun, Y Lü, G D Gu, X B Song, Y G Wang, P Xu, Z H Feng. 70-nm-gated InAlN/GaN HEMTs grown on SiC substrate with fT/fmax > 160 GHz[J]. J. Semicond., 2016, 37(2): 024007. doi: 10.1088/1674-4926/37/2/024007.

|

70-nm-gated InAlN/GaN HEMTs grown on SiC substrate with fT/fmax > 160 GHz

DOI: 10.1088/1674-4926/37/2/024007

More Information

-

Abstract

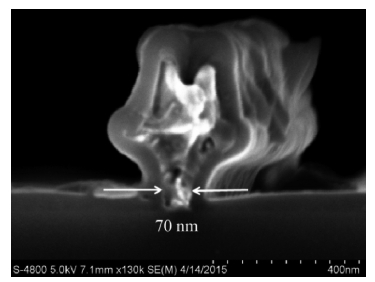

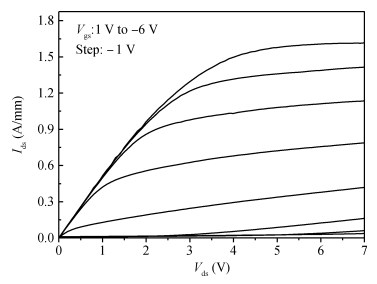

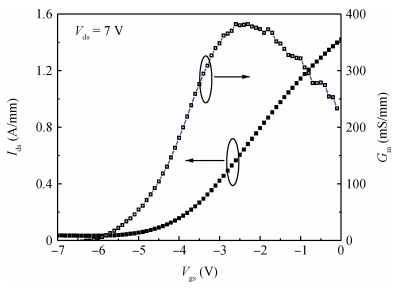

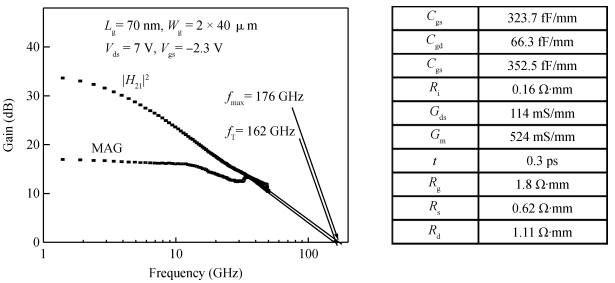

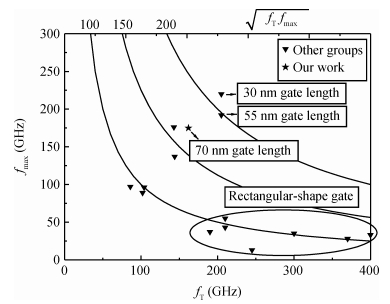

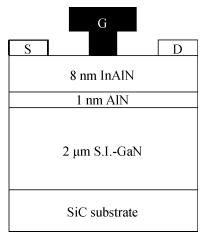

InAlN/GaN high-electron-mobility transistors (HEMTs) on SiC substrate were fabricated and characterized. Several techniques, consisting of high electron density, 70 nm T-shaped gate, low ohmic contacts and a short drain-source distance, are integrated to gain high device performance. The fabricated InAlN/GaN HEMTs exhibit a maximum drain saturation current density of 1.65 A/mm at Vgs = 1 V and a maximum peak transconductance of 382 mS/mm. In addition, a unity current gain cut-off frequency (fT) of 162 GHz and a maximum oscillation frequency (fmax) of 176 GHz are achieved on the devices with the 70 nm gate length. -

References

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] [21] [22] [23] [24] [25] [26] [27] [28] -

Proportional views

DownLoad:

DownLoad: