| Citation: |

Longhua Cai, Lusheng Liang, Jifeng Wu, Bin Ding, Lili Gao, Bin Fan. Large area perovskite solar cell module[J]. Journal of Semiconductors, 2017, 38(1): 014006. doi: 10.1088/1674-4926/38/1/014006

****

L H Cai, L S Liang, J F Wu, B Ding, L L Gao, B Fan. Large area perovskite solar cell module[J]. J. Semicond., 2017, 38(1): 014006. doi: 10.1088/1674-4926/38/1/014006.

|

-

Abstract

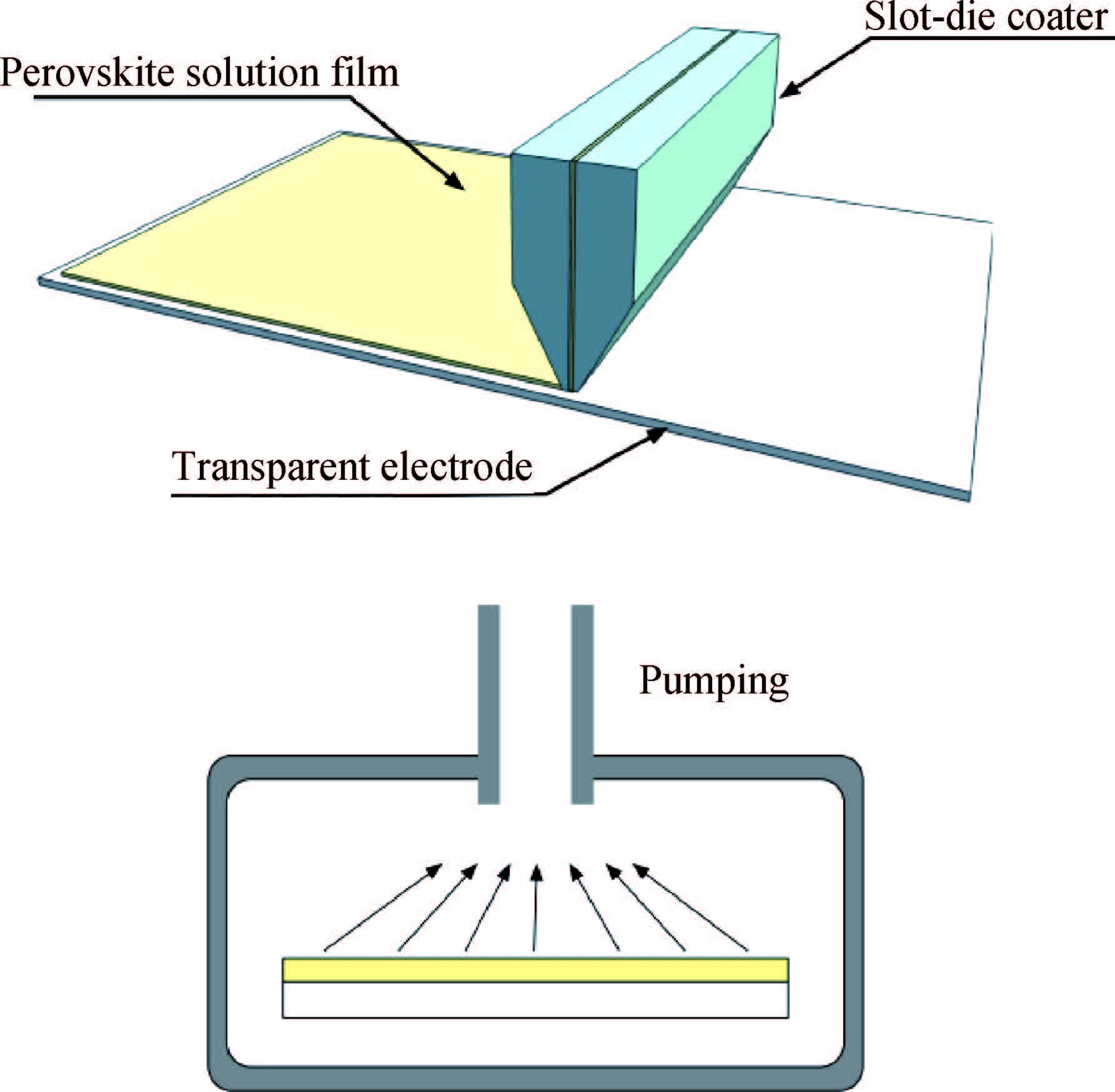

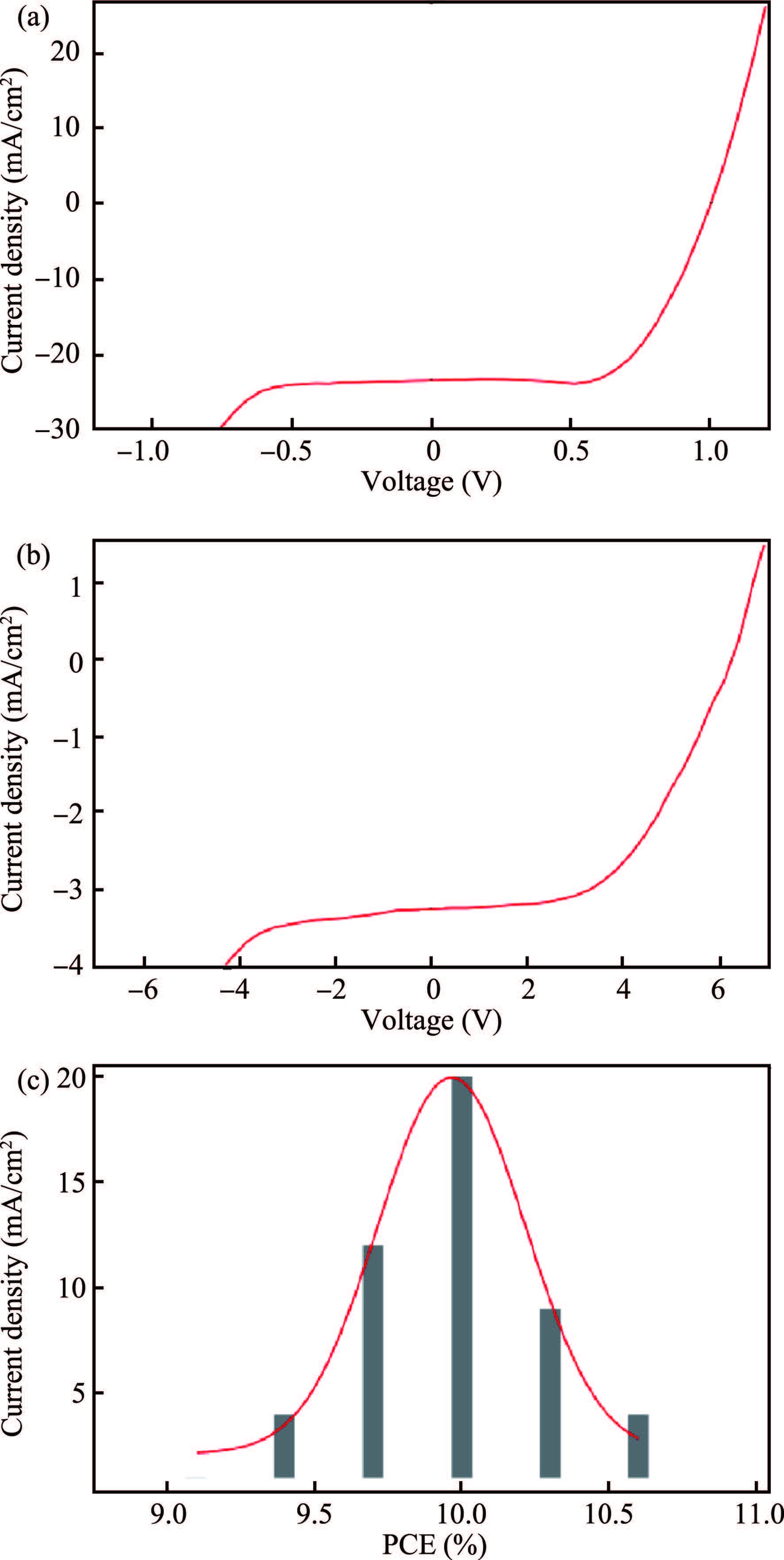

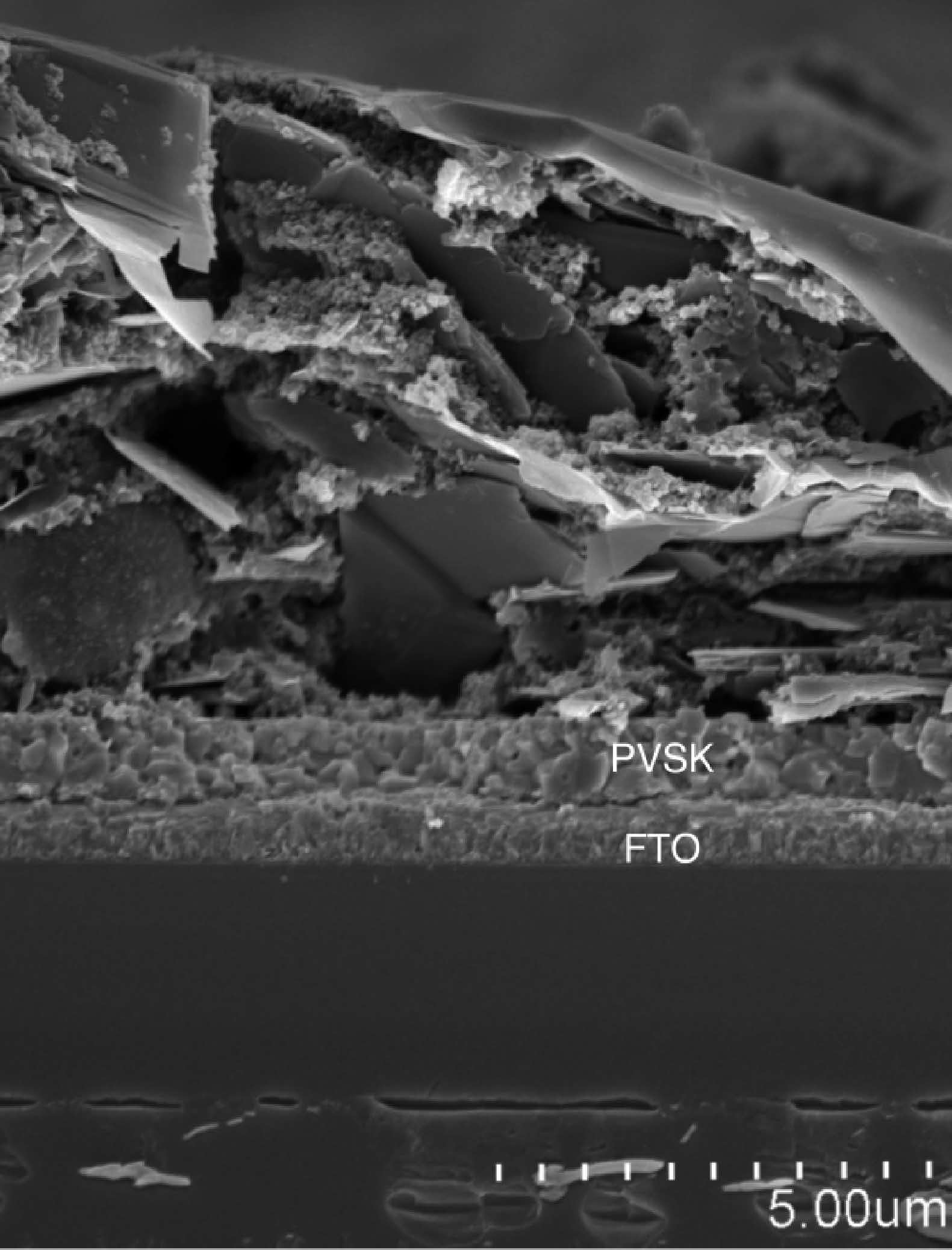

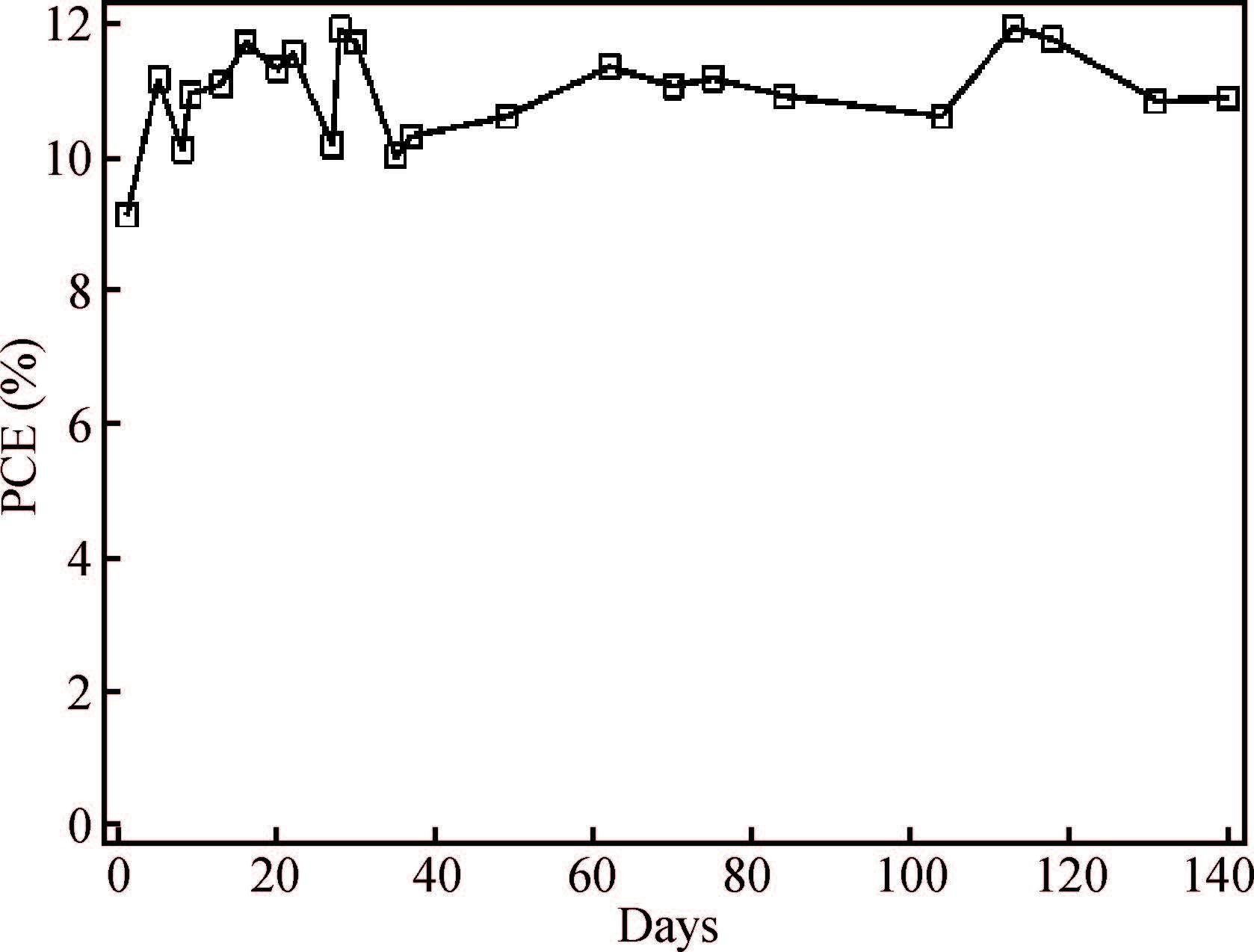

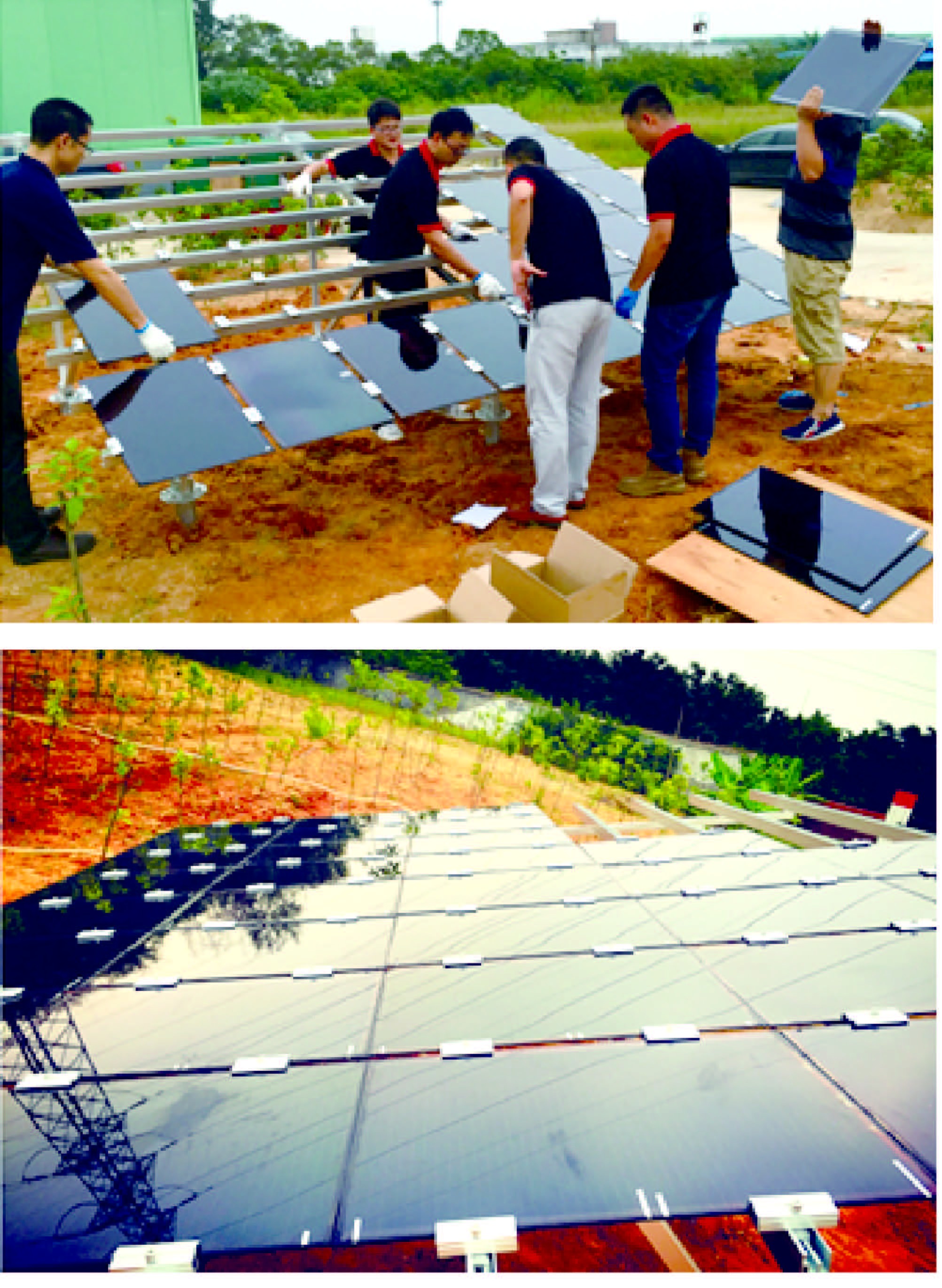

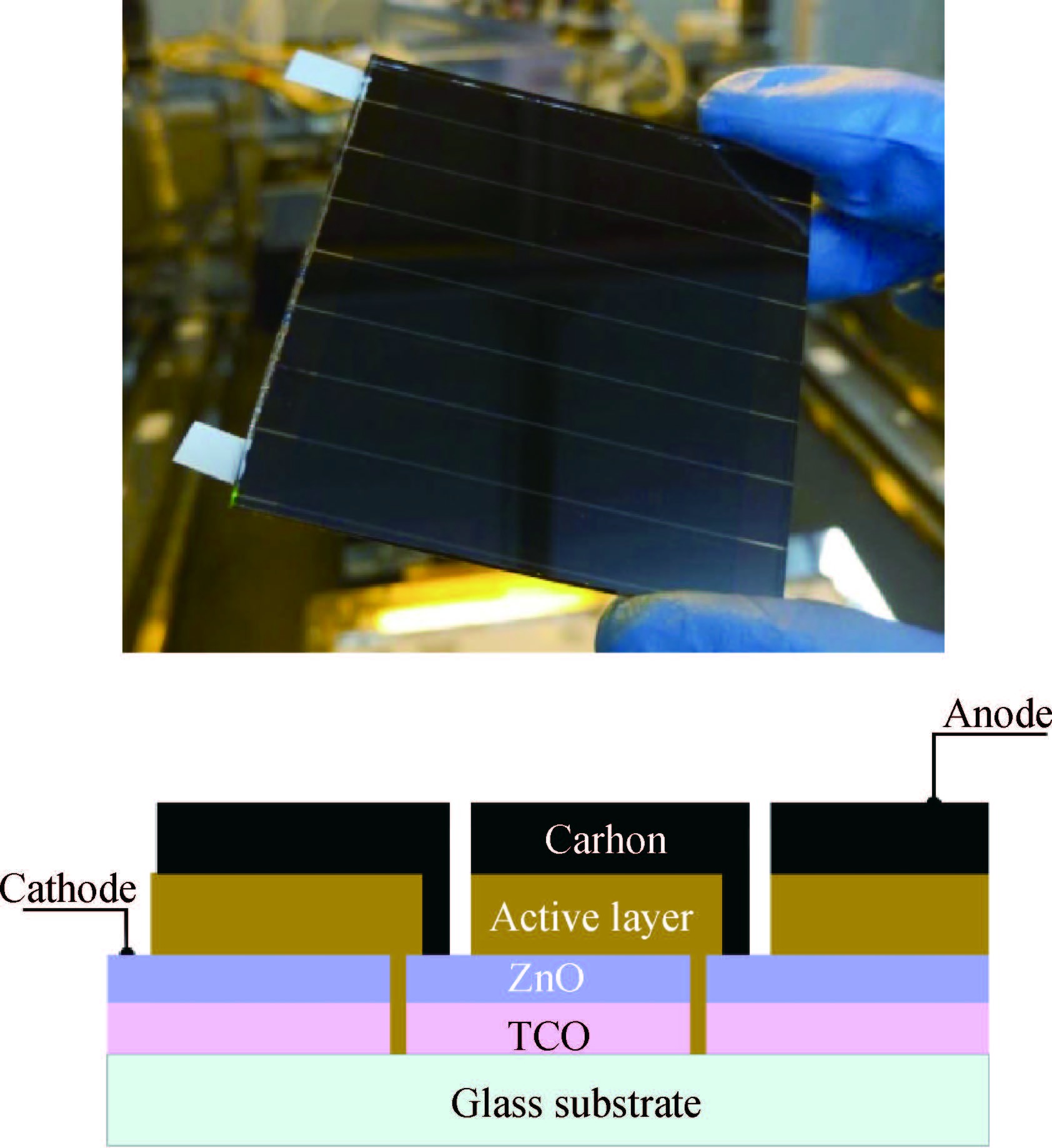

The recent dramatic rise in power conversion efficiencies (PCE) of perovskite solar cells has triggered intense research worldwide. However, their practical development is hampered by poor stability and low PCE values with large areas devices. Here, we developed a gas-pumping method to avoid pinholes and eliminate local structural defects over large areas of perovskite film, even for 5×5 cm2 modules, the PCE reached 10.6% and no significant degradation was found after 140 days of outdoor testing. Our approach enables the realization of high performance large-area PSCs for practical application.

-

References

[1] Kojima A, Teshima K, Shirai Y, et al. Organometal halide perovskites as visible-light sensitizers for photovoltaic cells. J Am Chem Soc, 2009, 131(17): 6050 doi: 10.1021/ja809598r[2] Best research-cell efficiencies NREL (2016). www.nrel.gov/ncpv/images/efficiency_chart.jpg[3] Lee M M, Teuscher J, Miyasaka T, et al. Efficient hybrid solar cells based on meso-superstructured organometal halide perovskites. Science, 2012, 338(6107): 643 doi: 10.1126/science.1228604[4] Burschka J, Pellet N, Moon S, et al. Sequential deposition as a route to high-performance perovskite-sensitized solar cells. Nature, 2013, 499(7458): 316 doi: 10.1038/nature12340[5] Mei A Y, Li X, Liu L F, et al. A hole-conductor-free, fully printable mesoscopic perovskite solar cell with high stability. Science, 2014, 345(6194): 295 doi: 10.1126/science.1254763[6] Yang W S, Noh J H, Jeon N J, et al. High-performance photovoltaic perovskite layers fabricated through intramolecular exchange. Science, 2015, 348(6240): 1234 doi: 10.1126/science.aaa9272[7] Ding B, Gao L L, Liang L S, et al. Facile and scalable fabrication of highly efficient lead iodide perovskite thin-film solar cells in air using gas pump method. ACS Appl Mater Interfaces, 2016, 8(31): 20067 doi: 10.1021/acsami.6b05862[8] Gao L L, Liang L S, Song X X, et al. Preparation of flexible perovskite solar cells by a gas pump drying method on a plastic substrate. J Mater Chem A, 2016, 4(10): 3704 doi: 10.1039/C6TA00230G -

Proportional views

DownLoad:

DownLoad: