| Citation: |

Xiang Zhang, Chunlai Huang, Lei Wang, Min Zhou. Collaborative R&D between multicrystalline silicon ingots and battery efficiency improvement—effect of shadow area in multicrystalline silicon ingots on cell efficiency[J]. Journal of Semiconductors, 2018, 39(8): 083004. doi: 10.1088/1674-4926/39/8/083004

****

X Zhang, C L Huang, L Wang, M Zhou, Collaborative R&D between multicrystalline silicon ingots and battery efficiency improvement—effect of shadow area in multicrystalline silicon ingots on cell efficiency[J]. J. Semicond., 2018, 39(8): 083004. doi: 10.1088/1674-4926/39/8/083004.

|

Collaborative R&D between multicrystalline silicon ingots and battery efficiency improvement—effect of shadow area in multicrystalline silicon ingots on cell efficiency

DOI: 10.1088/1674-4926/39/8/083004

More Information

-

Abstract

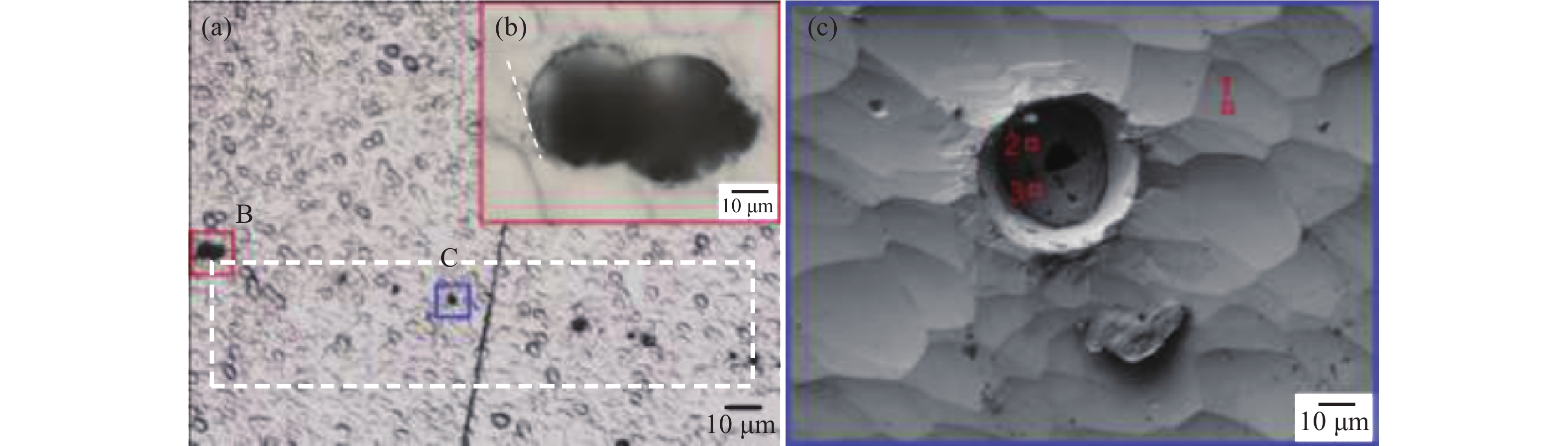

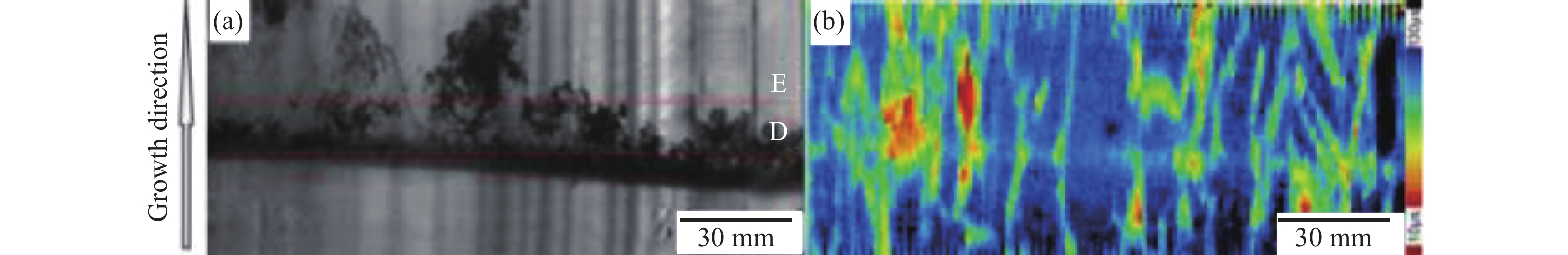

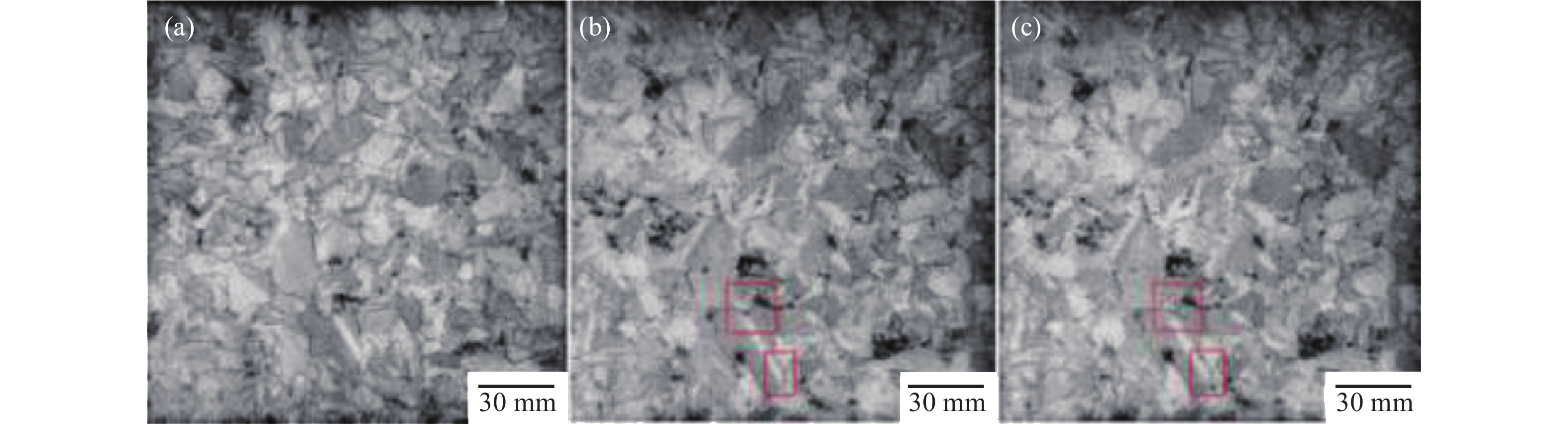

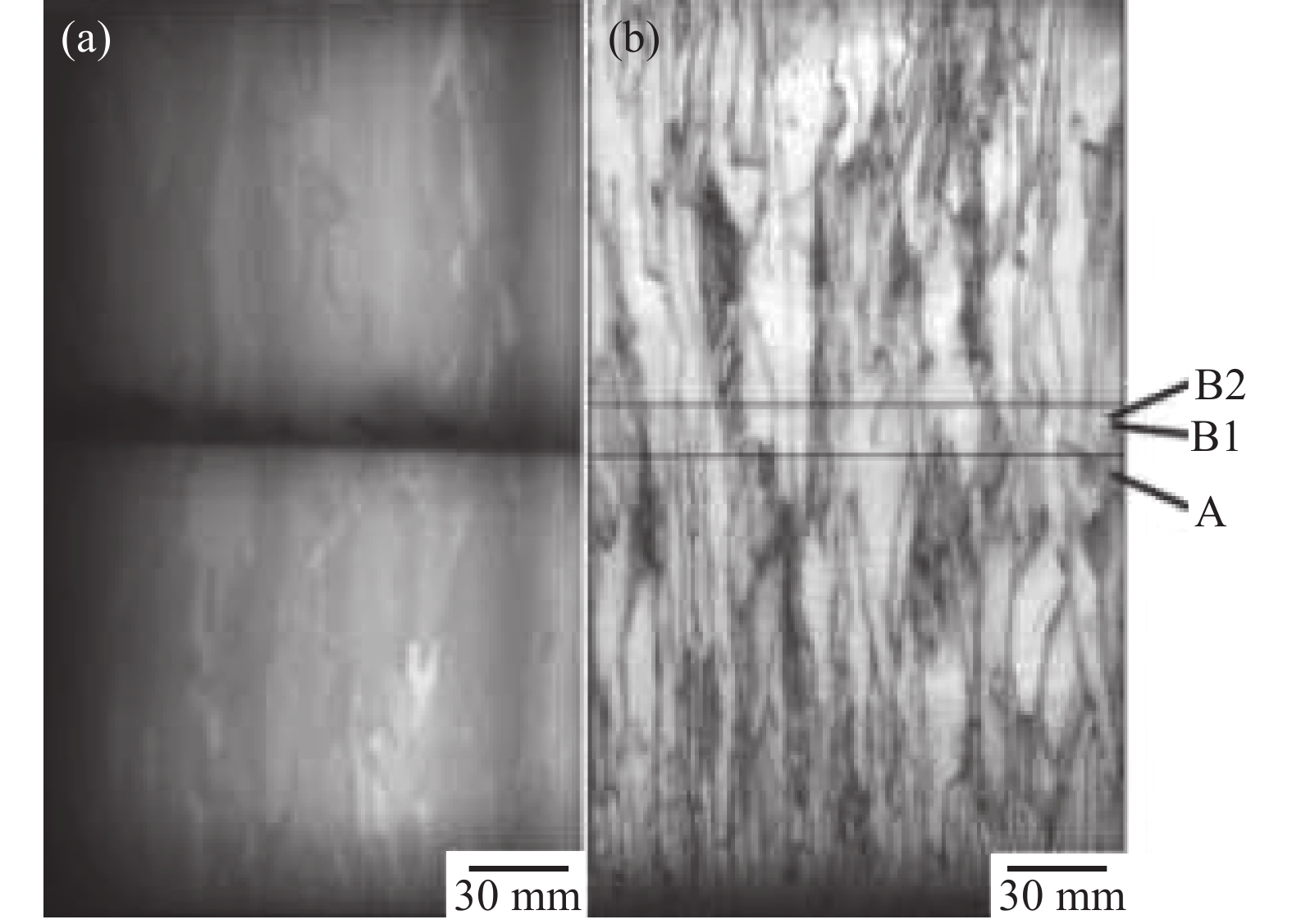

We characterized strip-like shadows in cast multicrystalline silicon (mc-Si) ingots. Blocks and wafers were analyzed using scanning infrared microscopy, photoluminescence spectroscopy, laser scanning confocal microscopy, field-emission scanning electron microscopy, X-ray energy-dispersive spectrometry, and microwave photoconductivity decay technique. The effect on solar cell performance is discussed. The results show that the non-microcrystalline shadow region in Si ingots consists of precipitates of Fe, O, and C. The size of these Fe–O–C precipitates found at the shadow region is ~25 μm. Fe–O–C impurities can slightly reduce the minority carrier lifetime of the wafers while severely decrease in shunt resistance, leading to the increase in reverse current of the solar cells and degradation in cell efficiency. -

References

[1] Zhu D, Ming L, Huang M, et al. Seed-assisted growth of high-quality multi-crystalline silicon in directional solidification. J Cryst Growth, 2014, 386: 52 doi: 10.1016/j.jcrysgro.2013.09.051[2] Zhang H, You D, Huang C, et al. Growth of multicrystalline silicon ingot with both enhanced quality and yield through quartz seeded method. J Cryst Growth, 2016, 435: L91 doi: 10.1016/j.jcrysgro.2015.11.020[3] Yuan S, Hu D, Yu X, et al. Multicrystalline silicon crystal assisted by silicon flakes as seeds. Sol Energy Mater Sol Cells, 2018, 174: 202 doi: 10.1016/j.solmat.2017.09.004[4] Huang C, Zhang H, Yuan S, et al. Multicrystalline silicon assisted by polycrystalline silicon slabs as seeds. Sol Energy Mater Sol Cells, 2018, 179: 312 doi: 10.1016/j.solmat.2017.12.026[5] Xu J, Wang Y, Yang D, et al. Influence of nickel precipitation on the formation of denuded zone in Czochralski silicon. J Alloys Compd, 2010, 502(2): 351 doi: 10.1016/j.jallcom.2010.04.164[6] Li X Q, Yang D R, Yu X G, et al. Precipitation and gettering behaviors of copper in multicrystalline silicon used for solar cells. Trans Nonferrous Metals Soc Chin, 2011, 21(3): 691 doi: 10.1016/S1003-6326(11)60767-X[7] Murphy J D, McGuire R, Bothe K, et al. Minority carrier lifetime in silicon photovoltaics: The effect of oxygen precipitation. Sol Energy Mater Sol Cells, 2014, 120: 402 doi: 10.1016/j.solmat.2013.06.018[8] Gaspar G, Modanese C, Schøn H, et al. Influence of copper diffusion on lifetime degradation in n-type Czochralski silicon for solar cells. Energy Procedia, 2015, 77: 586 doi: 10.1016/j.egypro.2015.07.084[9] Jiang T, Yu X, Wang L, et al. On the low carrier lifetime edge zone in multicrystalline silicon ingots. J Appl Phys, 2014, 115(1): 012007 doi: 10.1063/1.4837998[10] Zeng Y, Yang D, Xi Z, et al. Iron precipitation in as-received Czochralski silicon during low temperature annealing. Mater Sci Semicond Process, 2009, 12(4): 185[11] Seifert W, Vyvenko O, Arguirov T, et al. Synchrotron-based investigation of iron precipitation in multicrystalline silicon. Superlattices Microstruct, 2009, 45(4): 168[12] Trushin M, Vyvenko O, Seifert W, et al. Iron–oxygen interaction in silicon: A combined XBIC/XRF-EBIC-DLTS study of precipitation and complex building. Physica B, 2009, 404(23): 4645[13] Haarahiltunen A, Savin H, Yli-Koski M, et al. As-grown iron precipitates and gettering in multicrystalline silicon. Mater Sci Eng B, 2009, 159: 248[14] Qian M, Cao P, Easton M, et al. An analytical model for constitutional supercooling-driven grain formation and grain size prediction. Acta Mater, 2010, 58(9): 3262 doi: 10.1016/j.actamat.2010.01.052[15] Kodera H. Constitutional supercooling during the crystal growth of germanium and silicon. Jpn J Appl Phys, 1963, 2(9): 527 doi: 10.1143/JJAP.2.527[16] Friedrich J, Stockmeier L, Müller G. Constitutional supercooling in Czochralski growth of heavily doped silicon crystals. Acta Phys Polon A, 2013, 124(2): 219 doi: 10.12693/APhysPolA.124.219[17] Glicksman M E. Principles of solidification. Springer, 2011[18] Tsoutsouva M, Oliveira V, Camel D, et al. Segregation, precipitation and dislocation generation between seeds in directionally solidified mono-like silicon for photovoltaic applications. J Cryst Growth, 2014, 401: 397 doi: 10.1016/j.jcrysgro.2013.12.022[19] Stoffers A, Cojocaru-Mirédin O, Seifert W, et al. Grain boundary segregation in multicrystalline silicon: correlative characterization by EBSD, EBIC, and atom probe tomography. Prog Photovolt: Res Appl, 2015, 23: 1742 doi: 10.1002/pip.2614[20] Breitenstein O, Bauer J, Bothe K, et al. Understanding junction breakdown in multicrystalline solar cells. J Appl Phys, 2011, 109(7): 071101 doi: 10.1063/1.3562200 -

Proportional views

DownLoad:

DownLoad: