| Citation: |

Licheng Jia, Rihui Xue, Fansheng Meng. Design and characterization of a multi-ring nested CMUT array for hydrophone[J]. Journal of Semiconductors, 2024, 45(11): 112301. doi: 10.1088/1674-4926/24060007

****

L C Jia, R H Xue, and F S Meng, Design and characterization of a multi-ring nested CMUT array for hydrophone[J]. J. Semicond., 2024, 45(11), 112301 doi: 10.1088/1674-4926/24060007

|

Design and characterization of a multi-ring nested CMUT array for hydrophone

DOI: 10.1088/1674-4926/24060007

More Information

-

Abstract

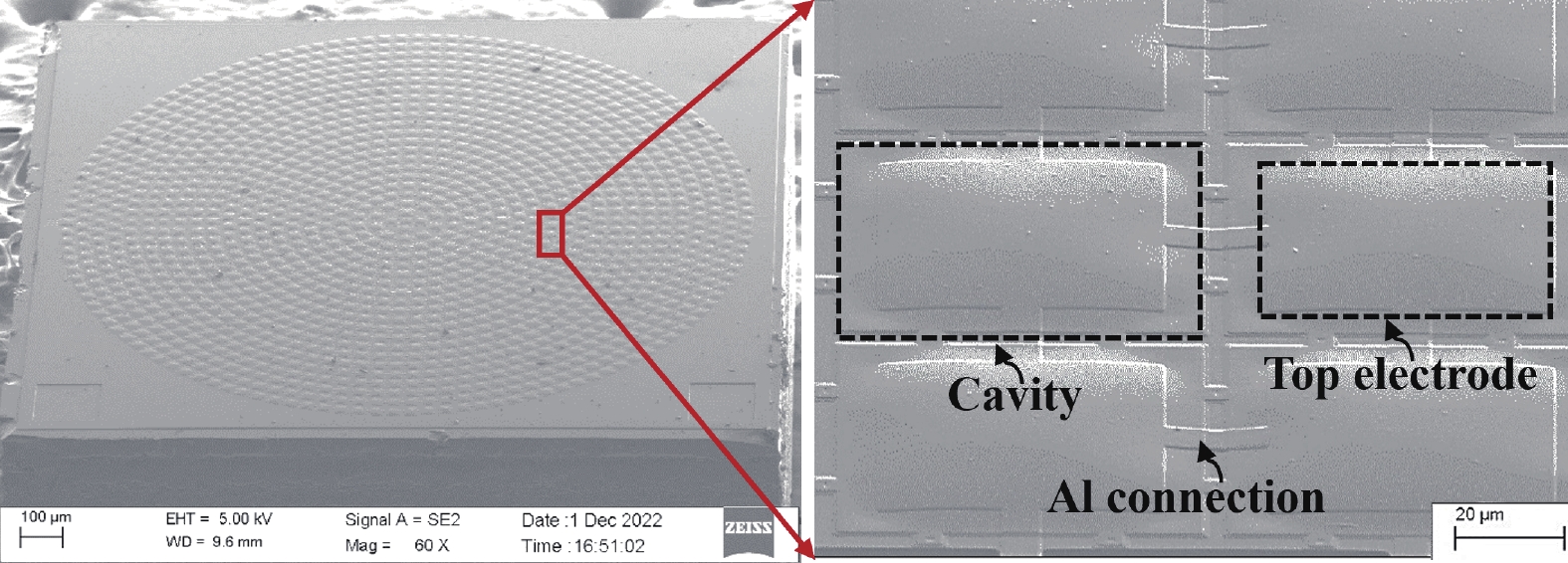

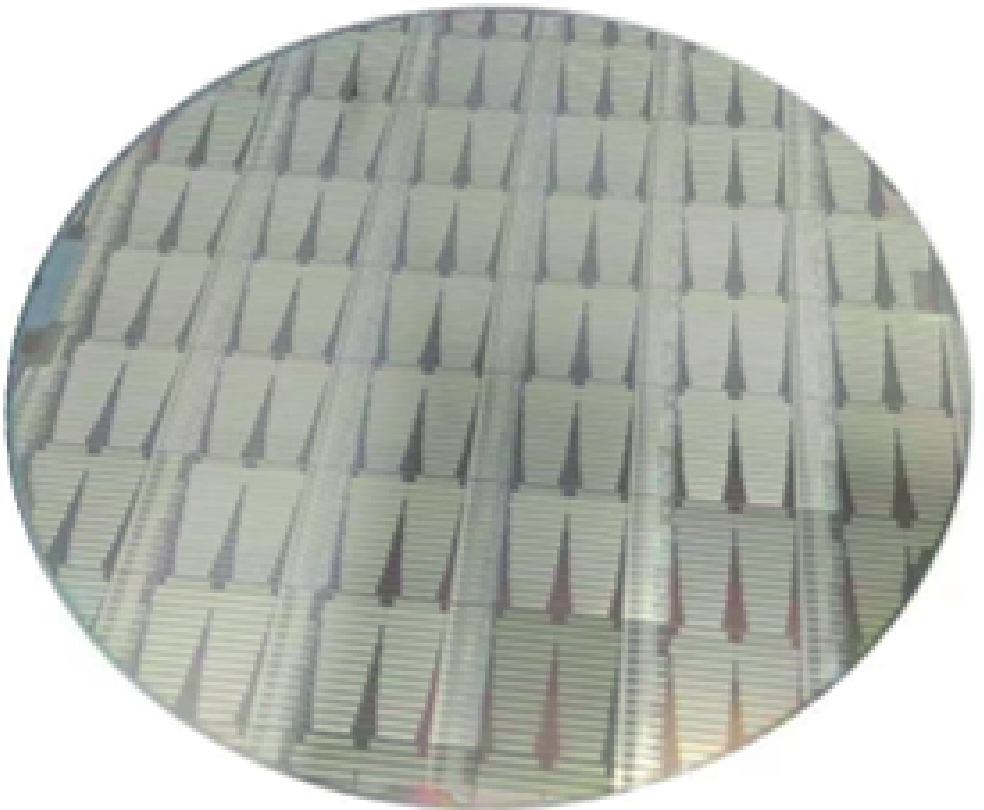

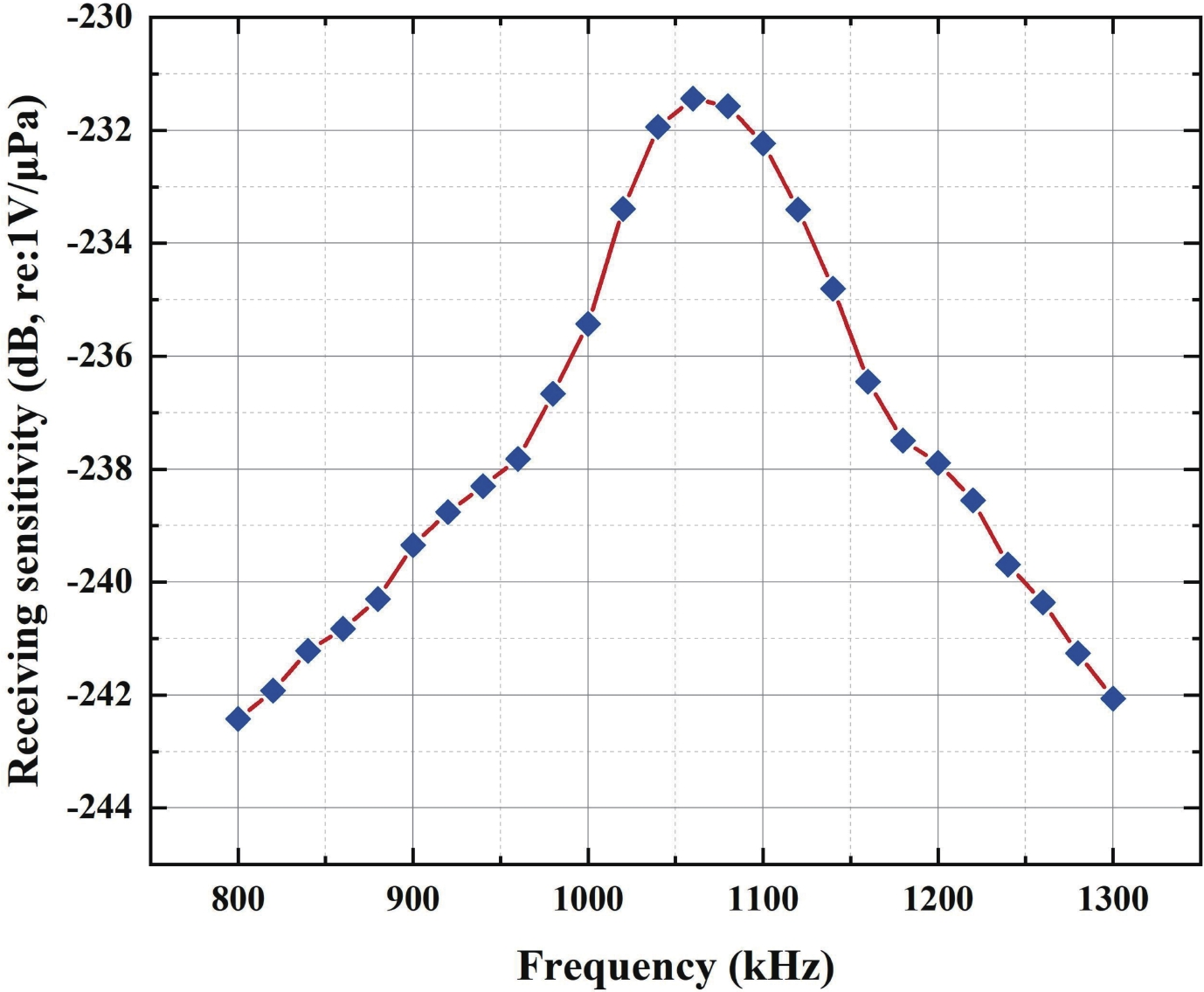

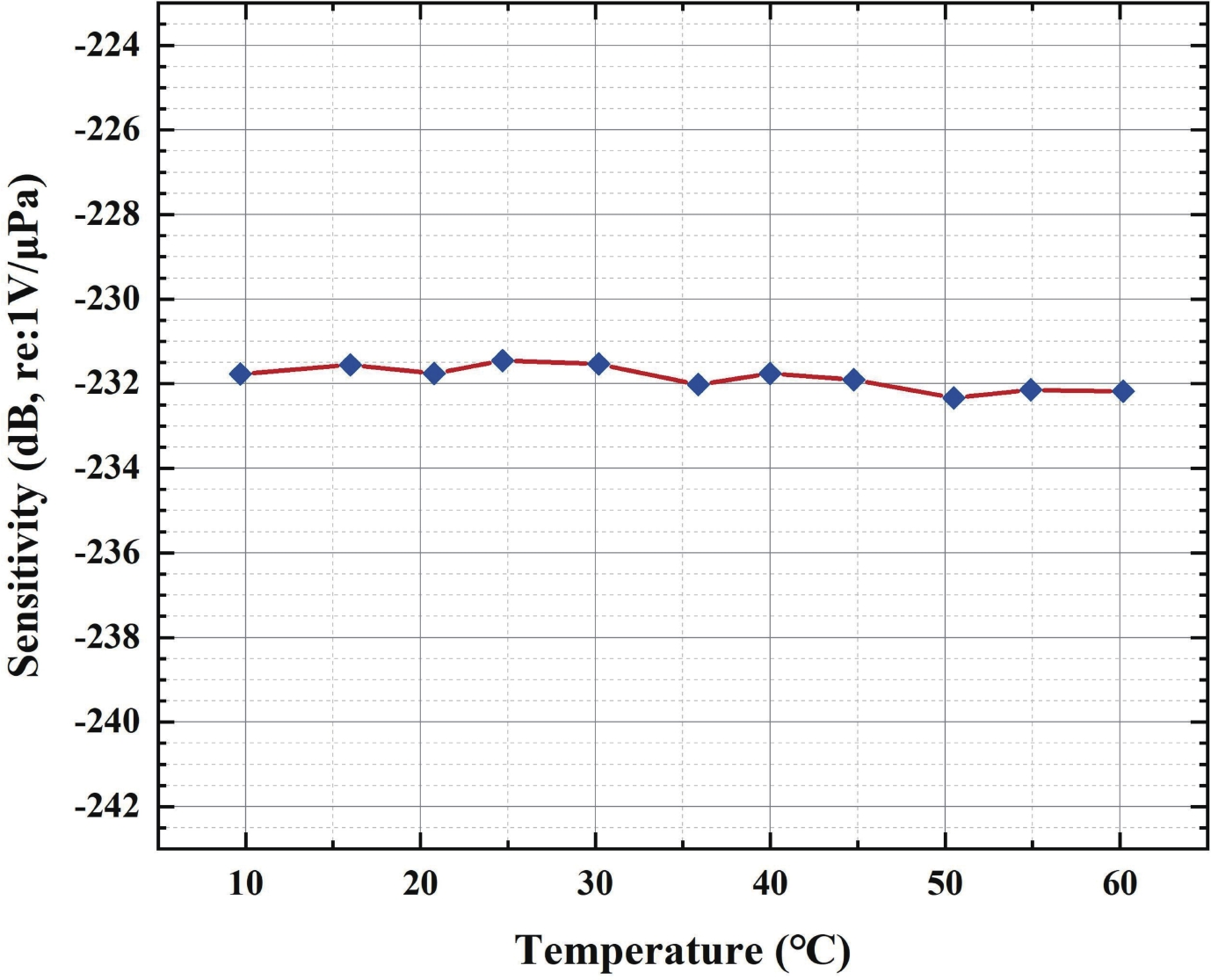

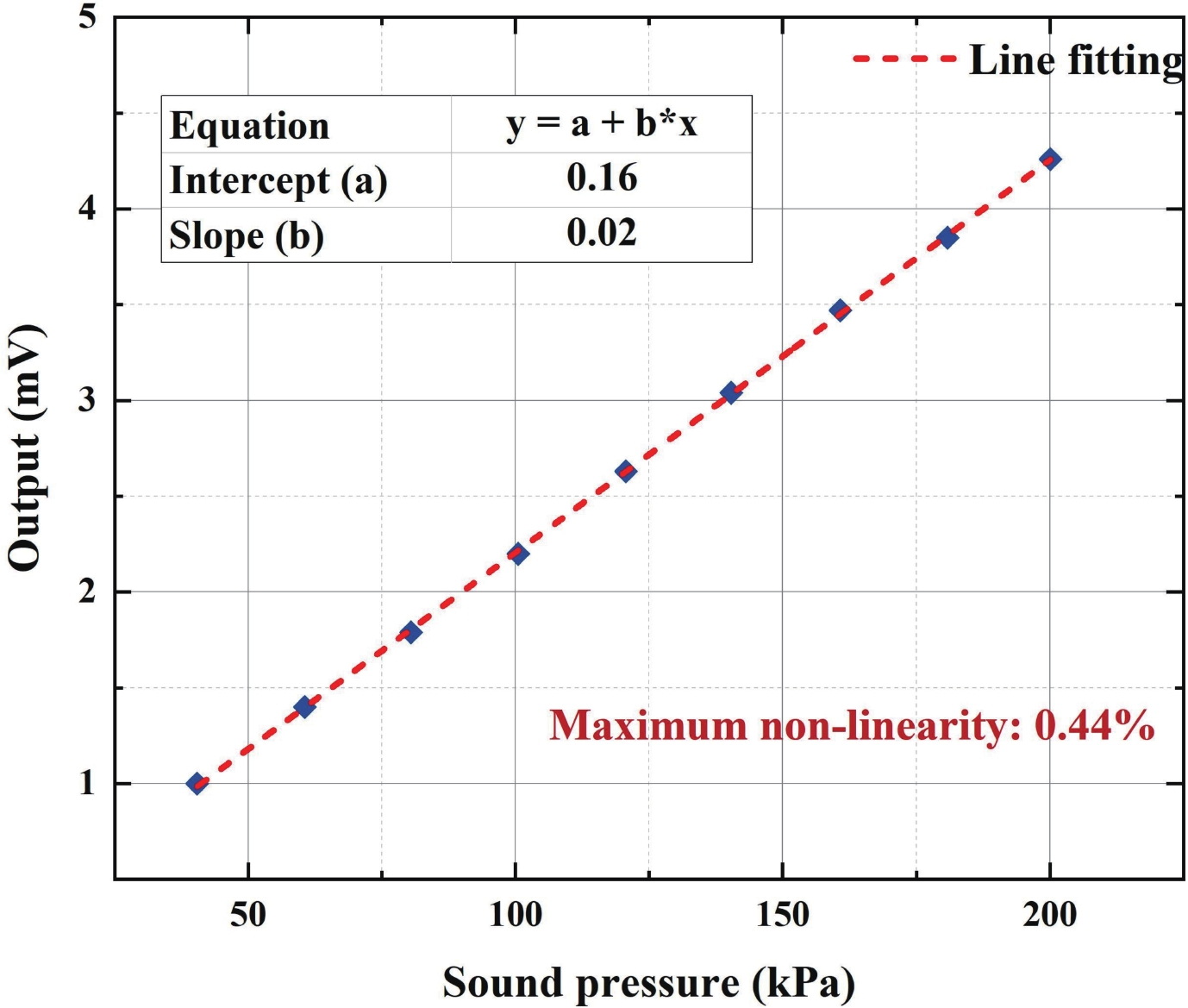

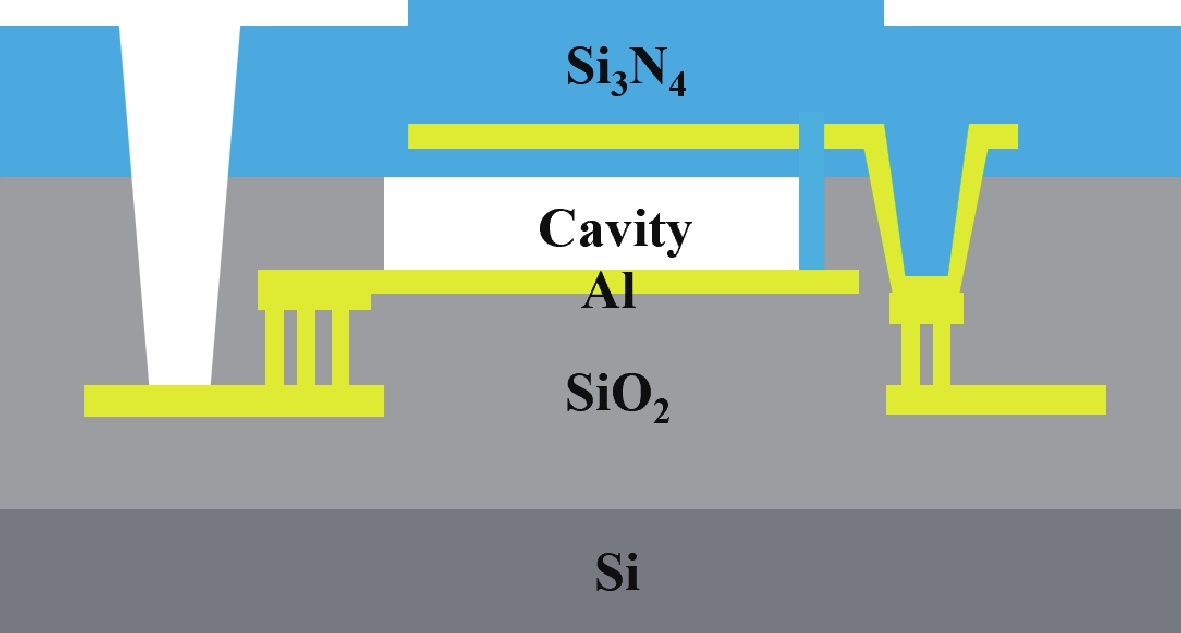

This paper presents the design, fabrication, packaging, and characterization of a high-performance CMUT array. The array, which features rectangular cells fabricated using a sacrificial release process, achieves a receiving sensitivity of −231.44 dB (re: 1 V/μPa) with a 40 dB gain. Notably, the CMUT array exhibits a minimal sensitivity variation of just 0.87 dB across a temperature range of 0 to 60 °C. Furthermore, the output voltage non-linearity at 1 kHz is approximately 0.44%. These test results demonstrate that the reception performance of the 67-element CMUT array is superior to that of commercial transducers. The high performance and compact design of this CMUT array underscore its significant commercial potential for hydrophone applications. -

References

[1] Jia L, He C, Xue C, et al. The device characteristics and fabrication method of 72-element CMUT array for long-range underwater imaging applications. Microsyst Technol, 2019, 25, 1195 doi: 10.1007/s00542-018-4062-4[2] Stojanovic M, and Preisig J. Underwater acoustic communication channels: Propagation models and statistical characterization. IEEE Commun Mag, 2009, 47, 84 doi: 10.1109/MCOM.2009.4752682[3] Herrera B, Pop F, Cassella C, et al. Miniaturized PMUT-based receiver for underwater acoustic networking. J Microelectromech S, 2020, 29, 832 doi: 10.1109/JMEMS.2020.3018070[4] Almeida R, Cruz N, and Matos A. Synchronized intelligent buoy network for underwater positioning. In Proceedings of the OMAE2010 29th International Conference on Ocean, 2010, 1 doi: 10.1109/OCEANS.2010.5663995[5] Francois D, Royer J, Perrot J. Long-term autonomous hydrophones for large-scale hydroacoustic monitoring of the oceans. In Proceedings of the 2012OCEANS, Yeosu, 2012, 1 doi: 10.1109/OCEANS-Yeosu.2012.6263519[6] Przybyla R, Flynn A, Jain V, et al. A micromechanical ultrasonic distance sensor with > 1 meter range. In Proceedings of the 16th International Conference on Solid-State Sensors, 2011, 2070 doi: 10.1109/TRANSDUCERS.2011.5969226[7] Benthowave Instrument Inc, Product Datasheet. [Online]. Available: https://www.benthowave.com/products/BII-7150Hydrophone.html[8] DolphinEar Hydrophones, Product Datasheet. [Online]. Available: http://www.dolphinear.com/de200.html[9] H2a Hydrophone User's Guide, Aquarian Audio, Anacortes, WA, USA[10] Brüel & Kjser. Hydrophones-Types 8103, 8104, 8105 and 8106. Sep, 2017[11] Liao W, Ren T, Yang Y, et al. Novel device design for an ultrasonic ranging system. Integr Ferroelectr, 2009, 105, 53 doi: 10.1080/10584580903039257[12] Jia L, Shi L, Liu C, et al. Design and characterization of an aluminum nitride-based MEMS hydrophone with biologically honeycomb architecture. IEEE T Electron Dev, 2021, 68, 4656 doi: 10.1109/TED.2021.3093020[13] Jia L, Shi L, Lu Z, et al. A high-performance 9.5% scandium-doped aluminum nitride piezoelectric MEMS hydrophone with honeycomb structure. IEEE Electr Device L, 2021, 42, 1845 doi: 10.1109/LED.2021.3120806[14] Yaralioglu G, Ergun A, Bayram B, et al. Calculation and measurement of electromechanical coupling coefficient of capacitive micromachined ultrasonic transducers. IEEE T Ultrason Ferr, 2003, 50, 449 doi: 10.1109/TUFFC.2003.1197968[15] Khuri-Yakub B, Oralkan Ö. Capacitive micromachined ultrasonic transducers for medical imaging and therapy. J Micromech Microeng, 2011, 21, 054004 doi: 10.1088/0960-1317/21/5/054004 -

Proportional views

Licheng Jia received the Ph.D. degree in microelectronics and solid-state electronics in Wuhan University, Wuhan, China, in 2022. Presently, he is a lecturer at State Key Laboratory of Dynamic Measurement Technology, North University of China, Taiyuan, China. His research work is focusing on microfabrication, underwater MEMS and Bio-MEMS applications.

Licheng Jia received the Ph.D. degree in microelectronics and solid-state electronics in Wuhan University, Wuhan, China, in 2022. Presently, he is a lecturer at State Key Laboratory of Dynamic Measurement Technology, North University of China, Taiyuan, China. His research work is focusing on microfabrication, underwater MEMS and Bio-MEMS applications.

DownLoad:

DownLoad: