| Citation: |

Xuliang Zhou, Jiaoqing Pan, Renrong Liang, Jing Wang, Wei Wang. Epitaxy of GaAs thin film with low defect density and smooth surface on Si substrate[J]. Journal of Semiconductors, 2014, 35(7): 073002. doi: 10.1088/1674-4926/35/7/073002

****

X L Zhou, J Q Pan, R R Liang, J Wang, W Wang. Epitaxy of GaAs thin film with low defect density and smooth surface on Si substrate[J]. J. Semicond., 2014, 35(7): 073002. doi: 10.1088/1674-4926/35/7/073002.

|

Epitaxy of GaAs thin film with low defect density and smooth surface on Si substrate

DOI: 10.1088/1674-4926/35/7/073002

More Information

-

Abstract

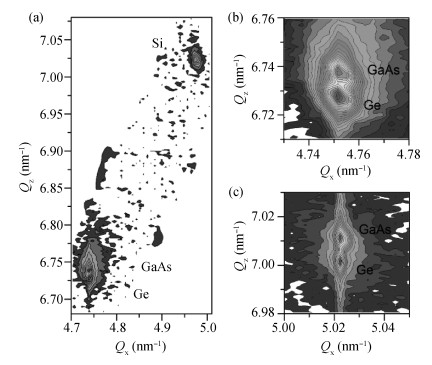

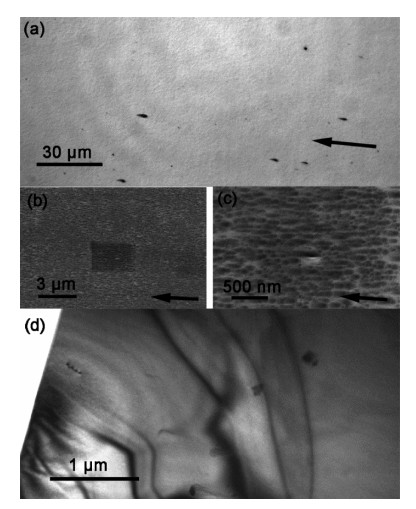

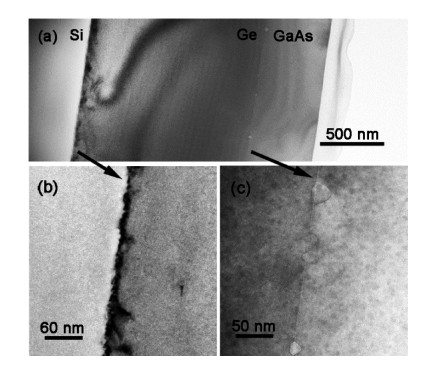

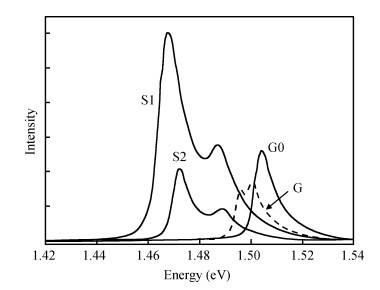

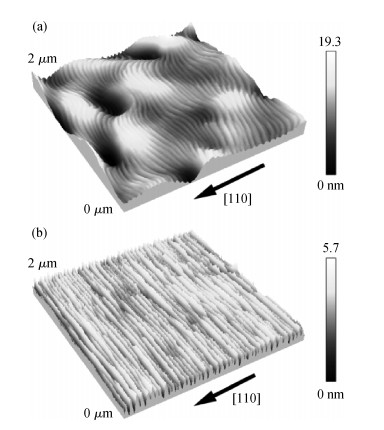

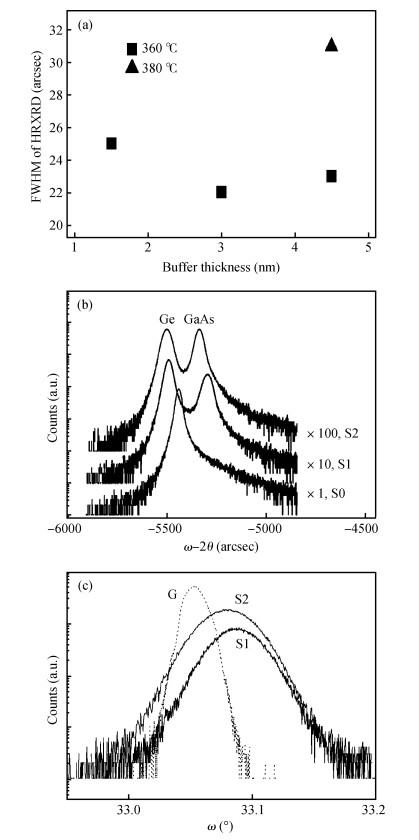

Device-quality GaAs thin films have been grown on miscut Ge-on-Si substrates by metal-organic chemical vapor deposition. A method of two-step epitaxy of GaAs is performed to achieve a high-quality top-layer. The initial thin buffer layer at 360℃ is critical for the suppression of anti-phase boundaries and threading dislocations. The etch pit density of GaAs epilayers by KOH etching could reach 2.25×105 cm-2 and high-quality GaAs top epilayers are observed by transmission electron microscopy. The band-to-band photoluminescence property of GaAs epilayers on different substrates is also investigated and negative band shifts of several to tens of meVs are found because of tensile strains in the GaAs epilayers. To achieve a smooth surface, a polishing process is performed, followed by a second epitaxy of GaAs. The root-mean-square roughness of the GaAs surface could be less than 1 nm, which is comparable with that of homo-epitaxial GaAs. These low-defect and smooth GaAs epilayers on Si are desirable for GaAs-based devices on silicon substrates. -

References

[1] Guter W, Schoöe J, Philipps S P, et al. Current-matched triple-junction solar cell reaching 41.1% conversion efficiency under concentrated sunlight. Appl Phys Lett, 2009, 94(22): 223504 doi: 10.1063/1.3148341[2] Cui Min, Chen Nuofu, Yang Xiaoli, et al. Fabrication and temperature dependence of a GaInP/GaAs/Ge tandem solar cell. Journal of Semiconductors, 2012, 33(2): 024006 doi: 10.1088/1674-4926/33/2/024006[3] Sandall I, Ng J S, David J P R, et al. 1300 nm wavelength InAs quantum dot photodetector grown on silicon. Opt Express, 2012, 20(10): 10446 doi: 10.1364/OE.20.010446[4] Liu H, Wang T, Hogg Q, et al. Long-wavelength InAs-GaAs quantum-dot laser diode monolithically grown on Ge substrate. Nat Photonics, 2011, 5(7): 416 doi: 10.1038/nphoton.2011.120[5] Lee A, Jiang Q, Tang M, et al. Continuous-wave InAs/GaAs quantum-dot laser diodes monolithically grown on Si substrate with low threshold current densities. Opt Express, 2012, 20(20): 22181 doi: 10.1364/OE.20.022181[6] Jalali B, Fathpour S. Silicon photonics. J Lightwave Technol, 2006, 24(12): 4600 doi: 10.1109/JLT.2006.885782[7] Liang D, Bowers J E. Recent progress in lasers on silicon. Nat Photonics, 2010, 4(8): 511 doi: 10.1038/nphoton.2010.167[8] Brammertz G, Caymax M, Meuris M, et al. GaAs on Ge for CMOS. Thin Solid Films, 2008, 517(1): 148 doi: 10.1016/j.tsf.2008.08.049[9] Yokoyama M, Kim S, Zhang R, et al. Ⅲ-Ⅴ/Ge high mobility channel integration of InGaAs n-channel and Ge p-channel metal-oxide-semiconductor field-effect transistors with self-aligned Ni-based metal source/drain using direct wafer bonding. Appl Phys Express, 2012, 5(7): 076501 doi: 10.1143/APEX.5.076501[10] Choi D, Harris J S, Kim E, et al. High-quality Ⅲ-Ⅴ semiconductor MBE growth on Ge/Si virtual substrates for metal-oxide-semiconductor device fabrication. J Cryst Growth, 2009, 311(7): 1962 doi: 10.1016/j.jcrysgro.2008.09.138[11] Fukuda Y, Kadota T, Ohmachi Y. Growth and characterization of GaAs layers grown on Ge/Si substrates by metaloganic chemical vaper deposition. Jpn J Appl Phys, 1988, 27(4): 485 http://ci.nii.ac.jp/naid/110003908072/en[12] Li Y, Giling L J. A closer study on the self-annihilation of antiphase boundaries in GaAs epilayers. J Cryst Growth, 1996, 163(3): 203 doi: 10.1016/0022-0248(95)00975-2[13] Hudait M K, Krupanidhi S B. Self-annihilation of antiphase boundaries in GaAs epilayers on Ge substrates grown by metal-organic vapor-phase epitaxy. J Appl Phys, 2001, 89(11): 5972 doi: 10.1063/1.1368870[14] Ting S M, Fitzgrald E A. Metal-organic chemical vapor deposition of single domain GaAs on Ge/GexSi1-x/Si and Ge substrates. J Appl Phys, 2000, 87(5): 2618 doi: 10.1063/1.372227[15] Knuuttila L, Lankinen A, Likonen J, et al. Low temperature growth GaAs on Ge. Jpn J Appl Phys, 2005, 44: 7777 doi: 10.1143/JJAP.44.7777[16] Li Y, Lazzarini L, Giling L J, et al. On the sublattice location of GaAs grown on Ge. J Appl Phys, 1994, 76(10): 5748 doi: 10.1063/1.358412[17] Bordel D, Guimard D, Rajesh M, et al. Growth of InAs/GaAs quantum dots on germanium-on-insulator-on-silicon (GeOI) substrate with high optical quality at room temperature in the 1.3μm band. Appl Phys Lett, 2010, 96(4): 043101 doi: 10.1063/1.3292591[18] Rajesh M, Bordel D, Kawaguchi K, et al. Growth of InAs/GaAs quantum dots on Si, Ge/Si and germanium-on-insulator-on-silicon (GeOI) substrates emitting in the 1.3μm band for silicon photonics. J Cryst Growth, 2011, 315(1): 114 doi: 10.1016/j.jcrysgro.2010.09.019[19] Brammertz G, Mols Y, Degroote S, et al. Low-temperature photoluminescence study of thin epitaxial GaAs films on Ge substrates. J Appl Phys, 2006, 99(9): 093514 doi: 10.1063/1.2194111[20] Stolz W, Guimaraes F E G, Ploog K. Optical and structural properties of GaAs grown on (100) Si by molecular-beam epitaxy. J Appl Phys, 1988, 63(2): 492 doi: 10.1063/1.340269[21] Yu H W, Chang E Y, Yamamoto Y, et al. Effect of graded-temperature arsenic prelayer on quality of GaAs on Ge/Si substrates by metalorganic vapor phase epitaxy. Appl Phys Lett, 2011, 99(17): 171908 doi: 10.1063/1.3656737[22] Yu G, Soga T, Watanabe J, et al. Effect of NaOCl-polishing on metal organic chemical vapor deposition grown GaAs surface on Si substrate by spectroscopic ellipsometry and atomic force microscopy. Jpn J Appl Phys, 1997, 36(5A): 2829 http://ci.nii.ac.jp/naid/110003905885 -

Proportional views

DownLoad:

DownLoad: