| Citation: |

Shihao Zhang, Hongyue Hao, Ye Zhang, Shuo Wang, Xiangyu Zhang, Ruoyu Xie, Lingze Yao, Faran Chang, Yifan Shan, Haofeng Liu, Guowei Wang, Donghai Wu, Dongwei Jiang, Yingqiang Xu, Zhichuan Niu, Wenjing Dong. Mid-wavelength infrared planar junction photodetector based on InAs/GaSb Type-Ⅱ superlattices[J]. Journal of Semiconductors, 2025, 46(11): 112404. doi: 10.1088/1674-4926/24120014

****

S H Zhang, H Y Hao, Y Zhang, S Wang, X Y Zhang, R Y Xie, L Z Yao, F R Chang, Y F shan, H F Liu, G W Wang, D H Wu, D W Jiang, Y Q Xu, Z C Niu, and W J Dong, Mid-wavelength infrared planar junction photodetector based on InAs/GaSb Type-Ⅱ superlattices[J]. J. Semicond., 2025, 46(11), 112404 doi: 10.1088/1674-4926/24120014

|

Mid-wavelength infrared planar junction photodetector based on InAs/GaSb Type-Ⅱ superlattices

DOI: 10.1088/1674-4926/24120014

CSTR: 32376.14.1674-4926.24120014

More Information-

Abstract

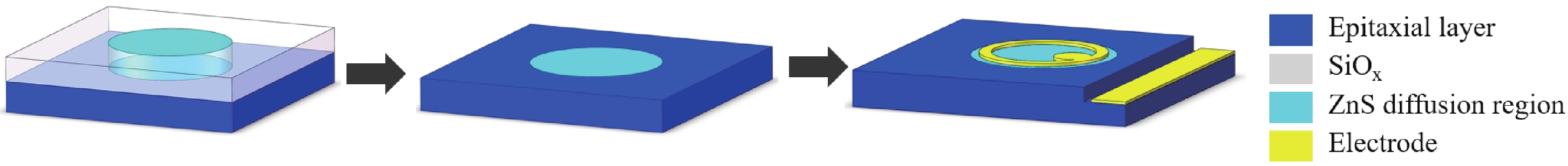

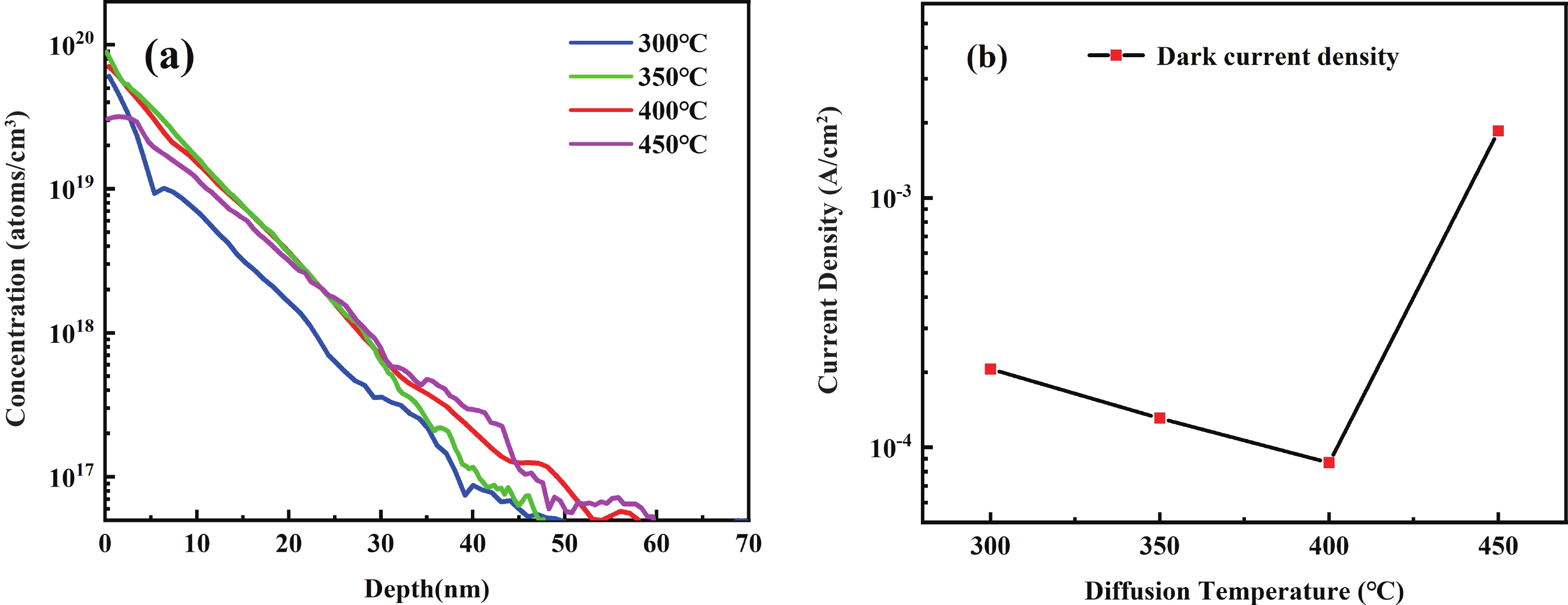

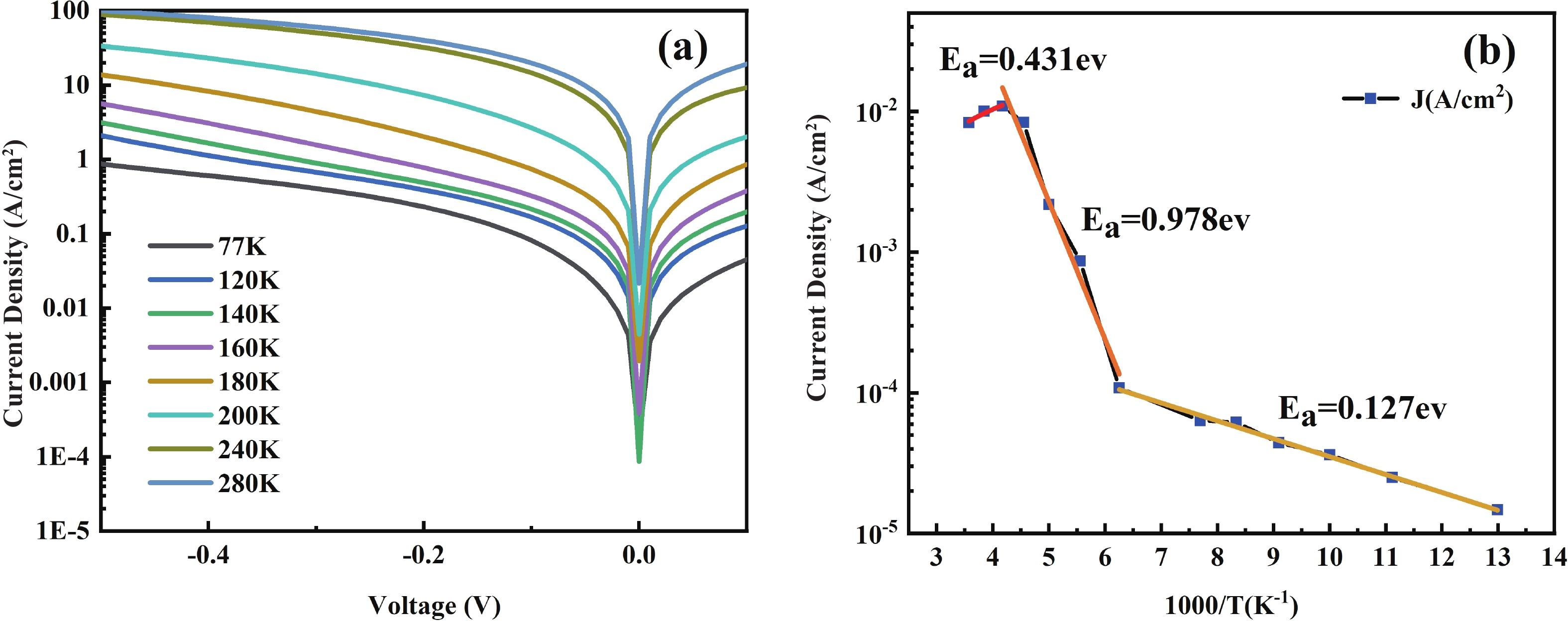

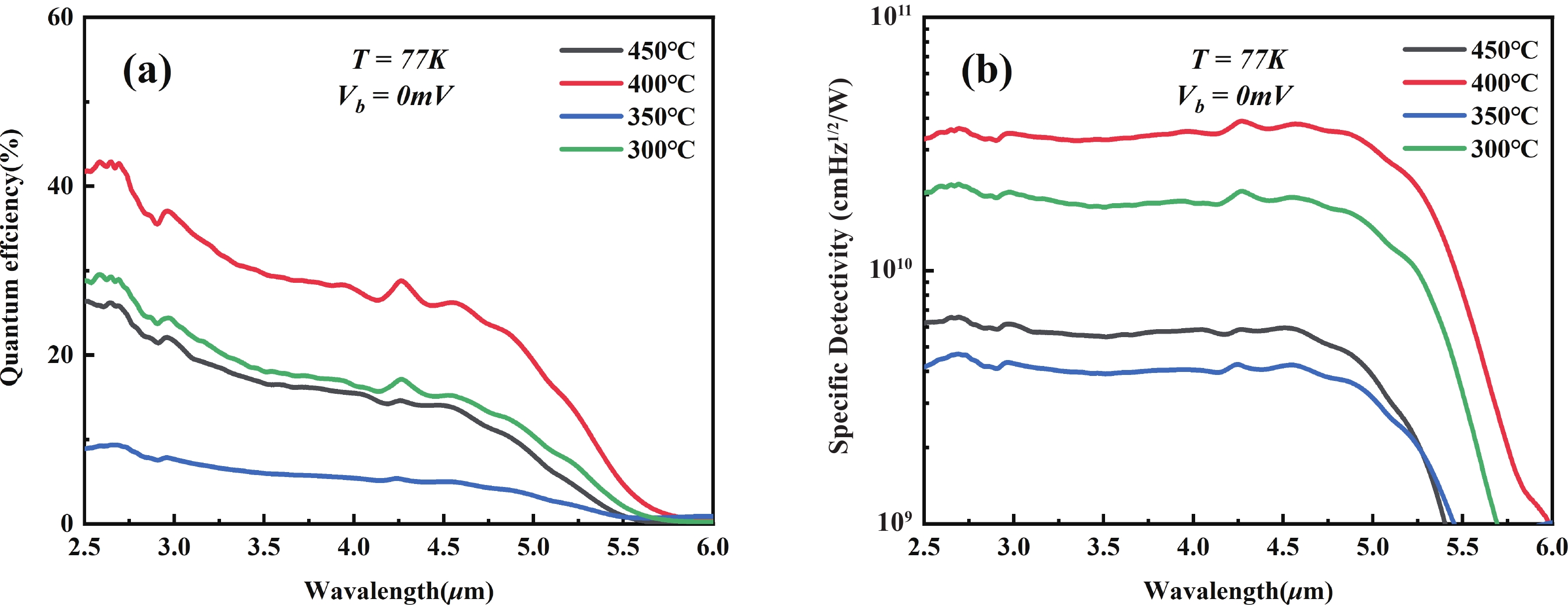

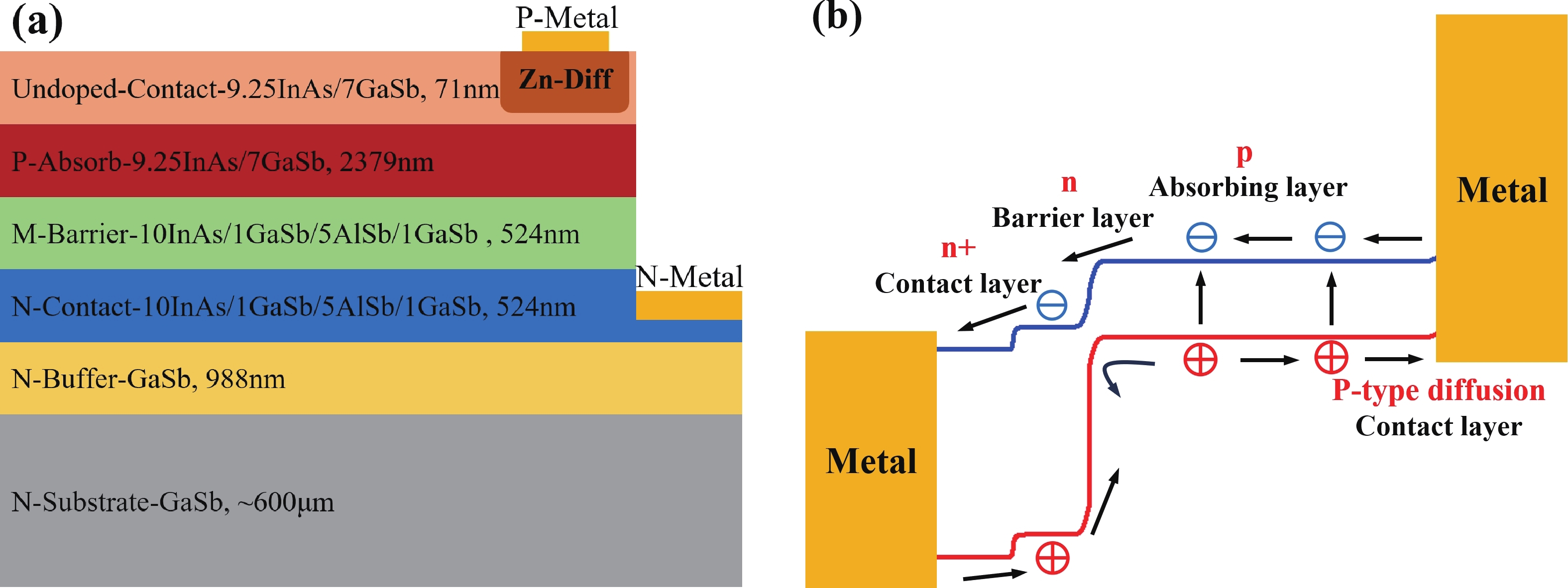

In this paper, a planar junction mid-wavelength infrared (MWIR) photodetector based on an InAs/GaSb type-Ⅱ superlattices (T2SLs) is reported. The Intrinsic-πMN superlattices was grown by the molecular beam epitaxy (MBE), followed with a ZnS layer grown by the chemical vapor deposition (CVD). The p-type contact layer was constructed by thermal diffusion in the undoped superlattices. The Zinc atom was successfully realised into the superlattice and a PπMN T2SL structure was constructed. Furthermore, the effects of different diffusion temperatures on the dark current performance of the devices were researched. The 50% cut-off wavelength of the photodetector is 5.26 μm at 77 K with 0 V bias. The minimum dark current density is 8.67 × 10−5 A/cm2 and the maximum quantum efficiency of 42.5%, and the maximum detectivity reaches 3.90 × 1010 cm·Hz1/2/W at 77 K. The 640 × 512 focal plane arrays (FPA) based on the planner junction were fabricated afterwards. The FPA achieves a noise equivalent temperature difference (NETD) of 539 mK. -

References

[1] Rogalski A. Progress in focal plane array technologies. Prog Quantum Electron, 2012, 36(2/3), 342 doi: 10.1016/j.pquantelec.2012.07.001[2] Dong C Y, An X, Wu Z C, et al. Multilayered PdTe2/thin Si heterostructures as self-powered flexible photodetectors with heart rate monitoring ability. J Semicond, 2023, 44(11), 112001 doi: 10.1088/1674-4926/44/11/112001[3] Rogalski A. HgCdTe infrared detector material: History, status and outlook. Rep Prog Phys, 2005, 68(10), 2267 doi: 10.1088/0034-4885/68/10/R01[4] Si J. Novel InSb-based infrared detector materials. Infrared and Laser engineering, 2022, 51(1), 20210811[5] Sai-Halasz G A, Tsu R, Esaki L. A new semiconductor superlattice. Appl Phys Lett, 1977, 30(12), 651 doi: 10.1063/1.89273[6] Smith D L, Mailhiot C. Proposal for strained type II superlattice infrared detectors. J Appl Phys, 1987, 62(6), 2545 doi: 10.1063/1.339468[7] Nguyen B M, Razeghi M, Nathan V, et al. Type-II M structure photodiodes: an alternative material design for mid-wave to long wavelength infrared regimes. Quantum Sensing and Nanophotonic Devices IV, 2007, 91(9), 091112 doi: 10.1117/12.7115888[8] Grein C H, Young P M, Flatté M E, et al. Long wavelength InAs/InGaSb infrared detectors: Optimization of carrier lifetimes. J Appl Phys, 1995, 78(12), 7143 doi: 10.1063/1.360422[9] Rogalski A. Material considerations for third generation infrared photon detectors. Infrared Phys Technol, 2007, 50(2/3), 240 doi: 10.1016/j.infrared.2006.10.015[10] Delaunay P Y, Hood A, Nguyen B M, et al. Passivation of type-II InAs∕GaSb double heterostructure. Appl Phys Lett, 2007, 91(9), 091112 doi: 10.1063/1.2776353[11] Zhang Z, Yates J T Jr. Band bending in semiconductors: Chemical and physical consequences at surfaces and interfaces. Chem Rev, 2012, 112(10), 5520 doi: 10.1021/cr3000626[12] Plis E A. InAs/GaSb type-II superlattice detectors. Adv Electron, 2014, 2014, 246769 doi: 10.1155/2014/246769[13] Marozas B T, Hughes W D, Du X, et al. Surface dark current mechanisms in III-V infrared photodetectors. Opt Mater Express, 2018, 8(6), 1419 doi: 10.1364/OME.8.001419[14] Salihoglu O, Muti A, Kutluer K, et al. Passivation of type II InAs/GaSb superlattice photodetectors with atomic layer deposited Al2O3. Infrared Technology and Applications XXXVIII. Baltimore, 2012, 83530Z doi: 10.1117/12.920406[15] Hou X Y, Wen L J, He F Y, et al. Embedded high-quality ternary GaAs1–xSbx quantum dots in GaAs nanowires by molecular-beam epitaxy. J Semicond, 2024, 45(8), 082101 doi: 10.1088/1674-4926/24030038[16] Kinch M A. The rationale for ultra-small pitch IR systems. Infrared Technology and Applications XL. Baltimore, 2014, 907032-1 doi: 10.1117/12.2051335[17] Cui Y Z, Hao H Y, Zhang S H, et al. High-performance GaSb planar PN junction detector. J Semicond, 2024, 45(9), 092403 doi: 10.1088/1674-4926/24040024[18] Musca C A, Antoszewski J, Dell J M, et al. Planar p-on-n HgCdTe heterojunction mid-wavelength infrared photodiodes formed using plasma-induced junction isolation. J Electron Mater, 2003, 32(7), 622 doi: 10.1007/s11664-003-0042-1[19] Iwamura Y, Watanabe N. InAs planar diode fabricated by Zn diffusion. Jpn J Appl Phys, 2000, 39(10R), 5740 doi: 10.1143/JJAP.39.5740[20] Pitts O J, Hisko M, Benyon W, et al. Optimization of MOCVD-diffused p-InP for planar avalanche photodiodes. J Cryst Growth, 2014, 393, 85 doi: 10.1016/j.jcrysgro.2013.09.053[21] Wang T T, Xiong M, Zhao Y C, et al. Planar mid-infrared InAsSb photodetector grown on GaAs substrates by MOCVD. Appl Phys Express, 2019, 12(12), 122009 doi: 10.7567/1882-0786/ab507c[22] Dehzangi A, Wu D H, McClintock R, et al. Demonstration of planar type-II superlattice-based photodetectors using silicon ion-implantation. Photonics, 2020, 7(3), 68 doi: 10.3390/photonics7030068[23] Wu D H, Dehzangi A, Li J K, et al. High performance Zn-diffused planar mid-wavelength infrared type-II InAs/InAs1−xSbx superlattice photodetector by MOCVD. Appl Phys Lett, 2020, 116(16), 161108 doi: 10.1063/5.0005326[24] Nguyen B M, Hoffman D, Delaunay P Y, et al. Dark current suppression in type II InAs/GaSb superlattice long wavelength infrared photodiodes with M-structure barrier. Appl Phys Lett, 2007, 91(16), 163511 doi: 10.1063/1.2800808[25] Simcock M N. Zinc diffusion in GaSb for thermophotovoltaic cell applications. Thermophotovoltaic Generation of Electricity: Sixth Conference on Thermophotovoltaic Generation of Electricity: TPV6, 2004, 303 doi: 10.1063/1.1841907[26] Hao H Y, Wang G W, Xiang W, et al. Fabrication of type-II InAs/GaSb superlattice long-wavelength infrared focal plane arrays. Infrared Phys Technol, 2015, 72, 276 doi: 10.1016/j.infrared.2015.07.025[27] Mao J X, Zhuang J S. Calculation of factor g in measurement of parameters of IRFPA detectors. Infrared, 2008, 048[28] Zhou X C, Li D S, Huang J L, et al. Mid-wavelength type II InAs/GaSb superlattice infrared focal plane arrays. Infrared Phys Technol, 2016, 78, 263 doi: 10.1016/j.infrared.2016.08.014[29] Rehm R, Walther M, Schmitz J, et al. InAs/GaSb superlattice focal plane arrays for high-resolution thermal imaging. Opto Electron Rev, 2006, 14(1), 19 doi: 10.2478/s11772-006-0003-3[30] Bogdanov S. Planar engineering for dark current suppression in type-II superlattice infrared photodiodes. Northwestern University, United States-Illinois, 2014, 172 -

Proportional views

Shihao Zhang received a bachelor’s degree from Jingchu University of Technology in 2021. He is currently pursuing a master’s degree with the Hubei University. His present research interests include infrared detector of antimonide.

Shihao Zhang received a bachelor’s degree from Jingchu University of Technology in 2021. He is currently pursuing a master’s degree with the Hubei University. His present research interests include infrared detector of antimonide. Hongyue Hao received her doctoral degree from the Institute of Semiconductors, Chinese Academy of Sciences in 2018. Following her PhD, she worked as a postdoctoral researcher in the Juelich Research Center in Germany. She is currently a Youth Researcher at the Institute of Semiconductors, Chinese Academy of Sciences. Her research focused on the Sb-based infrared detectors, especially including the broadband and multi-band detectors with meta-surface, low-cost, low noise and high sensitivity detectors.

Hongyue Hao received her doctoral degree from the Institute of Semiconductors, Chinese Academy of Sciences in 2018. Following her PhD, she worked as a postdoctoral researcher in the Juelich Research Center in Germany. She is currently a Youth Researcher at the Institute of Semiconductors, Chinese Academy of Sciences. Her research focused on the Sb-based infrared detectors, especially including the broadband and multi-band detectors with meta-surface, low-cost, low noise and high sensitivity detectors. Wenjing Dong received the Ph.D. degree in Microelectronics and Solid State Electronics from Shanghai Institute of Technical Physics, Chinese Academy of Sciences. She is currently an associate professor in Hubei University. She had been an visiting scholar in University of Maryland from 2019 to 2020. Her research interests include semiconductor materials and devices, solid state ionics and solid state electronics.

Wenjing Dong received the Ph.D. degree in Microelectronics and Solid State Electronics from Shanghai Institute of Technical Physics, Chinese Academy of Sciences. She is currently an associate professor in Hubei University. She had been an visiting scholar in University of Maryland from 2019 to 2020. Her research interests include semiconductor materials and devices, solid state ionics and solid state electronics.

DownLoad:

DownLoad: