1. Introduction

AlGaN/GaN-based high-electron mobility transistors (HEMTs) have remarkable potential and are very attractive for high-power, high-frequency devices[1-5]. This is attributed to the attractive physical features of group Ⅲ nitride semiconductors, such as a wide bandgap, large breakdown field, high thermal coefficient, and favorable two-dimensional electron gas formation at the AlGaN/GaN hetero interface together with a high electron saturation velocity. Along with the development of epitaxial material growth technology, GaN-based HEMTs are growing rapidly. Many experiments have been done to achieve further electrical improvement in these transistors with their robust material properties. Large ohmic contact resistance can lead to a serious deterioration of the peak current availability and reliability. Ohmic contact with low resistance is essential in realizing the full potential of AlGaN/GaN HEMTs. Due to the insulating characteristic of AlGaN, Ohmic contact formation for AlGaN/GaN HEMTs may rely on carrier tunneling across AlGaN.

To obtain a better ohmic contact by selective doping, ion implantation has been developed for the source/drain contacts of AlGaN/GaN HEMTs. The characteristics of ion implanted HEMTs were improved using the optimized annealing temperature of 1150 ℃[6]. As reported in Ref. [7], a method of ohmic area recess etching has been used for a direct contact to AlGaN/GaN heterostructures. It removes AlGaN/GaN epitaxial layers with SiCl4 reactive ion etching (RIE) and a direct sideways contact made by the electrode to the 2DEG around the edges of the active-layer mesas or pads. This is believed to be a more efficient carrier transport mechanism than tunneling through the AlGaN barrier. Recent experiments have shown that an in-situ Si3N4 passivation layer under the metal contact results in lower contact resistance than in the test cases where the passivation layer has been removed or is not deposited at all[8].

In general, multilayer metal structure is the most popular method to achieve a good ohmic contact. So far, it typically has a Ti/Al/blocking layer/Au multilayer scheme, such as Ti/Al/Ti/Au[9] and Ti/Al/Ni/Au. Ti, Ni, Mo, or Pt[10] is often used for the blocking layer, which acts as a barrier layer in the metallization scheme. In this paper, we present a detailed investigation of the effects of rapid thermal annealing on the enhancement of Ti/Al/Ti/Au ohmic performance on AlGaN/GaN epitaxial layers. The experiment is set as in Refs. [9, 11].

2. Experimental procedure

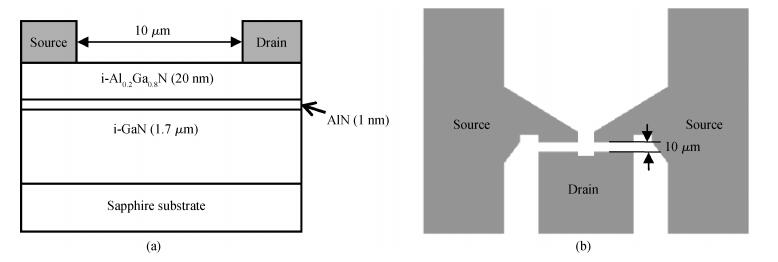

The AlGaN/GaN hetero-junction structure used in this paper is grown by metal-organic chemical vapor deposition (MOCVD) on 150

3. Results and discussion

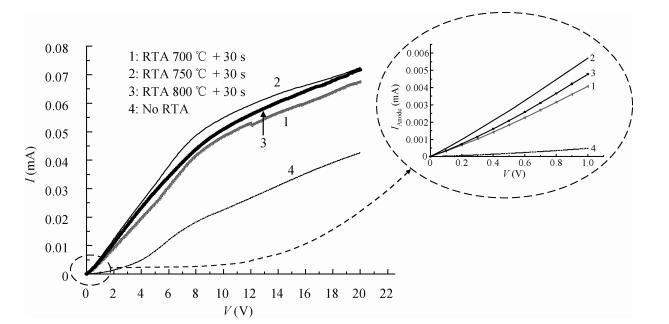

We measured the I-V curves between the source and drain electrodes. All specific contact resistances (

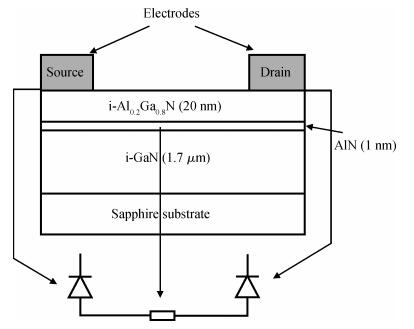

As is shown in Fig. 2, three annealed samples show an ohmic contact compared to the sample without annealing. Before annealing, the sample reveals special back-to-back Schottky diode (Fig. 3.) and shows rectifying properties. The I-V characteristic of the equivalent circuit has the same curve without annealing which is shown in Fig. 2. With annealing at 700 ℃, the contact resistance and series resistance have greatly improved. Therefore a higher temperature should be conducted to improve contact resistance. When the temperature gets to 750 ℃, the ohmic contact characteristics keep improving steadily. But when the temperature is raised to 800 ℃ the performance of the ohmic contact drops down compared to annealing at 750 ℃. When the samples were annealed at 750 ℃ for 30 s, a higher drain current is found compared to the ones without RTA. This indicates that an increased 2DEG concentration

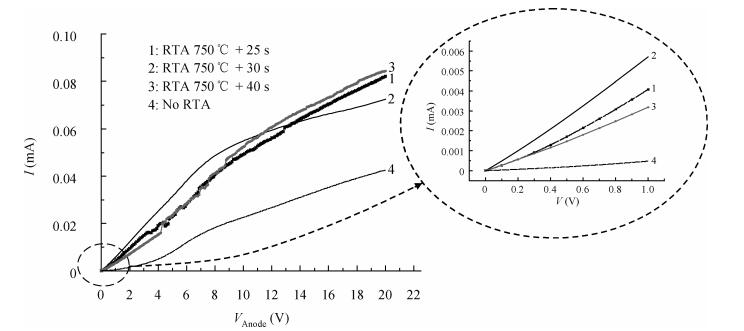

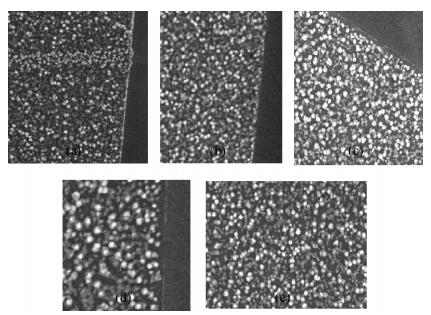

Figure 4 shows the I-V characteristics of annealing at 750 ℃ for 25 s, 30 s, and 40 s, respectively. The samples of annealing for 25 s and 40 s observed an inferior ohmic contact and have bad curves. The group of annealing for 30 s reveals a better performance than the group of annealing for 25 s. The reason is that shorter annealing time leads to the metallization electrodes not completely reacting with the AlGaN/GaN layer. Samples annealed for 40 s show the worst performance. It maybe results from the metal layer turning pelletized with a longer annealing time. Similarly, this can conclude that with the annealing time increasing the ohmic contact resistance become lower first, then get the lowest ohmic resistance, and finally become large again. Considering Figs. 2 and 4, samples annealed at 750 ℃ for 30 s have the best current saturation character compared with other groups.

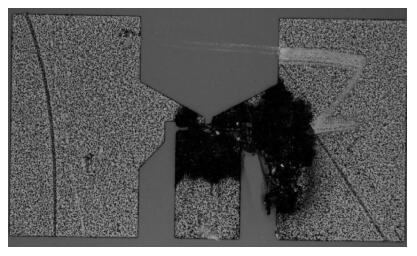

SEM is used to characterize the film smoothness and edge acuity. As shown in Fig. 5, the surface of electrodes gets quite rough and lots of spikes are produced on the surface after annealing at high temperature. According to Fig. 6, some electrodes of the device were burned out when we measured the I-V character at a large current. In conclusion, a rough surface of electrodes is bad for reliability and stability. The roughness is due to the Al existing in the ohmic contact scheme, which does not react completely and is subject to melting at these high annealing temperatures. Because Al plays an essential role in the ohmic contact scheme, another metal cannot be used instead of it or decrease its component. HEMT is usually used as a high-power device and its reliability and stability at large current is important, therefore improving its surface by annealing samples at an optimal condition is very important. Figure 5(a) shows the typical morphology of Ti/Al/Ti/Au electrode annealed at 750 ℃ for 30 s. It is found that a smooth surface and superior edge acuity were obtained in a large area in the sample. There is a continuous increase in metal roughness upon moving from annealing 700 ℃ to 800 ℃. It presents the same trend when the annealing time is increasing. The ohmic contact characteristic presents a similar trend when either annealing temperature or time is increasing. When we considered both of them, we chose the 750 ℃ and 30 s as the annealing condition. Besides, thickening the ohmic contact electrodes when the gate electrodes are fabricated is another way to improve reliability and stability of the device.

4. Conclusion

The contact scheme Ti/Al/Ti/Au is fabricated on AlGaN/GaN heterojunction, which is used for AlGaN/GaN HEMT ohmic contacts. To achieve a change from Schottky contact to ohmic contact, samples were annealed at different temperatures and times. The experiments indicate that, with annealing temperature or annealing time increasing, the performance of the ohmic contact is firstly increased and then decreased. A lower specific contact resistance of 7.41 × 10

DownLoad:

DownLoad:

DownLoad:

DownLoad: